Pneumatic damping high-capacity pay-off technology for flat wire

A pneumatic damping and large-capacity technology, applied to electrical components, circuits, conductor/cable insulation, etc., can solve the problems of low production efficiency and troublesome operation of the wire-releasing device, and achieve high production efficiency, low labor intensity, and release smooth line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

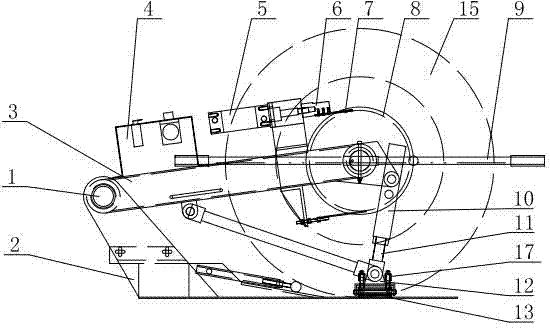

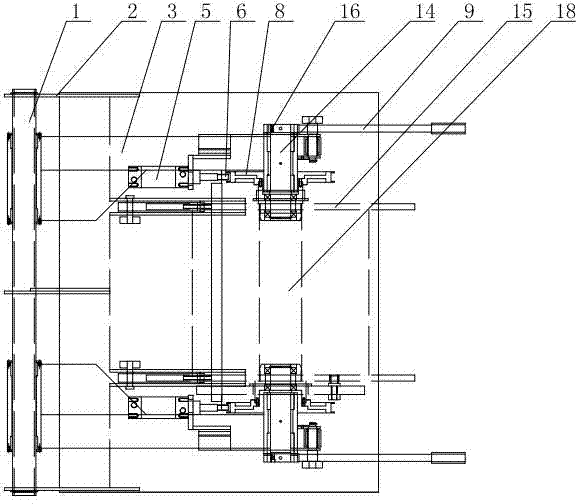

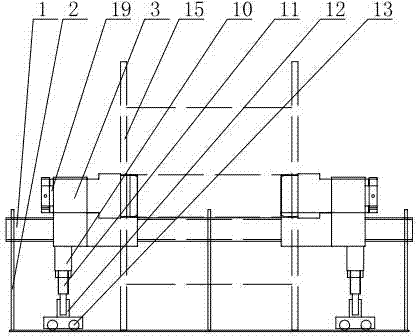

[0018] Such as figure 1 , figure 2 and image 3 As shown, the flat wire pneumatic damping large-capacity pay-off device of the present embodiment includes a frame 2 on which a sliding shaft 1 is installed, and supporting devices are arranged at intervals on the ground on one side of the displacement frame 2; Arm 3, one end of the rotating arm 3 is sleeved on the slide shaft 1, and the other end is connected with the support device. The structure of the support device is: a support seat 12 is installed, a roller 13 is installed on the bottom of the support seat 12, and a compression spring 17 is installed on the roller 13. The support base 12 is connected with the screw rod 11, the screw rod 11 is covered with a support rod 10, and the support rod 10 has a plurality of holes connected with one end of the rotating arm 3; the rotating arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com