OPGW fiber stainless steel welded tube production line

A stainless steel and production line technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of large jumping amount of the pay-off shaft, unstable fiber pay-out, low concentric precision of the pay-off shaft and the motor shaft, etc., and achieve stable pay-off , Simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

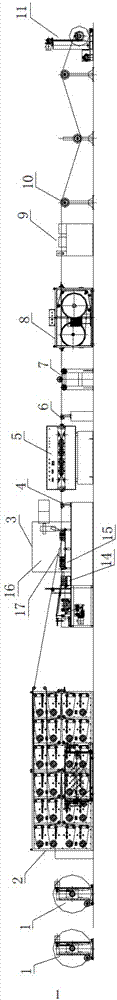

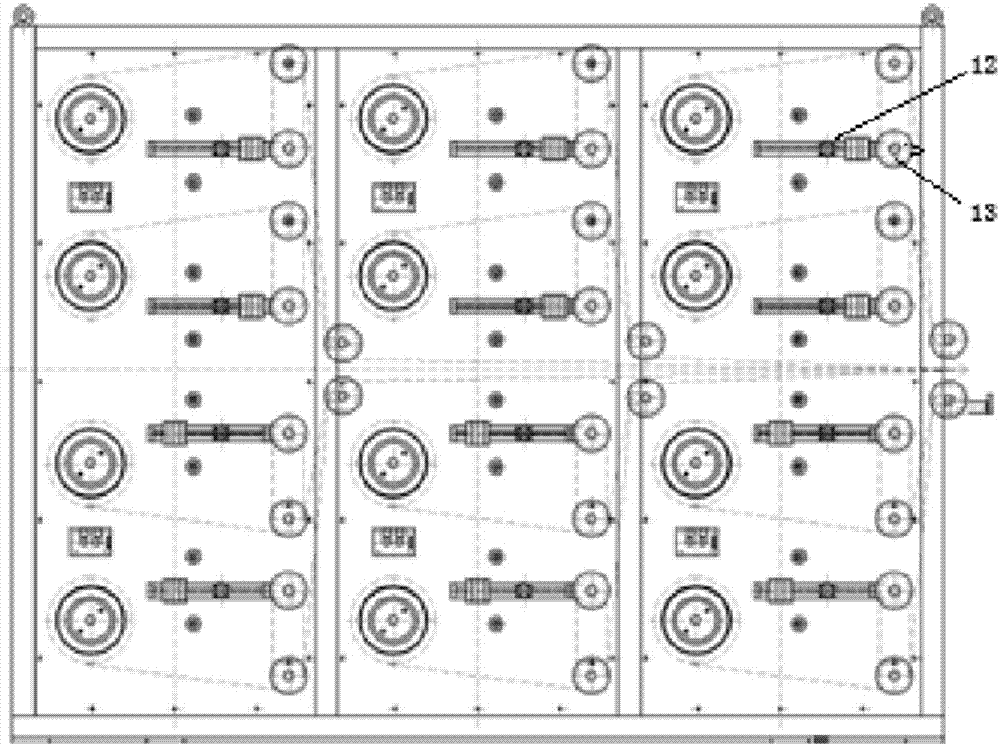

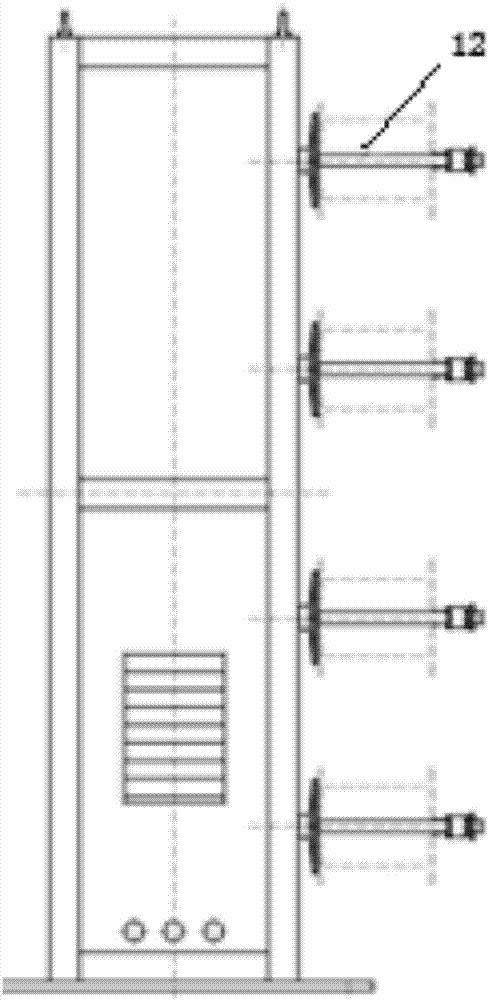

[0018] Such as Figure 1 to Figure 3 As shown, an OPGW optical fiber stainless steel welded pipe production line includes a tape unwinding device 1, an optical fiber pay-off cabinet 2, a molding device 3, a primary drawing die 4, a 1200kg crawler tractor 5, a secondary drawing die 6, and a Length control device 7, main traction equipment 8, flaw detection equipment 9, tension control device 10 and winding machine 11, a pay-off motor is arranged in the optical fiber pay-off cabinet 2, and an optical fiber is set on the output shaft 12 of the pay-off motor. The pay-off reel 13, the forming equipment 3 are equipped with a steel strip edge trimming mechanism 14, a stainless steel forming device 15, a longitudinal laser welding device 16 and an ointment argon gas mixing filling head 17, and the excess length control device 7 is provided with a tension c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com