Setting out device for textile equipment with good damping effect

A technology of textile equipment and pay-off device, which is applied in the field of pay-off device, which can solve the problems of high impact force of winding shaft and breaking of textile thread, etc., and achieve the effect of enhancing anti-collision ability, enhancing shock absorption effect and good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

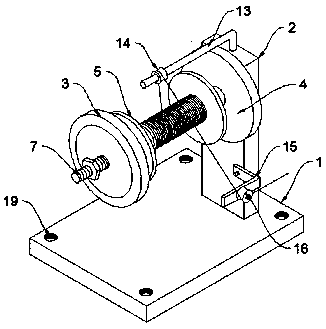

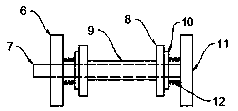

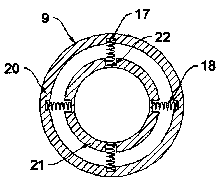

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention has a textile equipment pay-off device with good shock absorption effect, including a base 1 and a substrate 2 fixedly arranged on one side of the top of the base 1, and a pay-off mechanism 3 is fixedly arranged on the top of the base 2 side, and the pay-off The mechanism 3 is composed of a shock absorbing structure 4 and a winding structure 5. The winding structure 5 is located inside the shock absorbing structure 4 and is movably connected with the shock absorbing structure 4. The shock absorbing structure 4 is composed of two shock absorbing components 6 and a rotating shaft 7 One end of the rotating shaft 7 is located in the middle of the end face of one of the shock absorbing assemblies 6 and is fixedly connected to it, the other end of the rotating shaft 7 passes through the middle of the end face of the other shock absorbing assembly 6 and is screwed to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com