A cable rack

A pay-off rack and cable technology, used in cable laying equipment, conveying filamentous materials, thin material handling, etc., can solve the problems of easy deformation, high risk, and easy extension of support rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

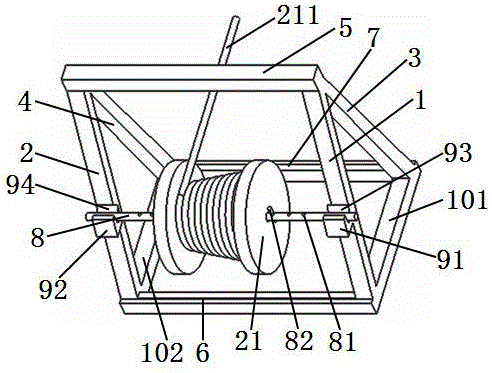

[0025] please see figure 1; A cable pay-off rack, which includes a first support rod 1, a second support rod 2, a third support rod 3, a fourth support rod 4, a push rod 5, a first fixed rod 6, a second fixed rod 7 , shaft-shaped body 8, the top of the first support bar, the third support bar and the top of the second support bar, the fourth support bar are connected by a push rod between the intersection, it is characterized in that: the first The bottom of the support rod and the second support rod is connected by the first fixed rod, the bottom of the third support rod and the fourth support rod is connected by the second fixed rod, the first support rod is parallel to the second support rod, and the third support rod The rod and the fourth support rod are also parallel, the first support rod and the third support rod are stretched apart, the second support rod and the fourth support rod are stretched apart, and the first support rod is fixed with the first support rod. A ...

Embodiment 2

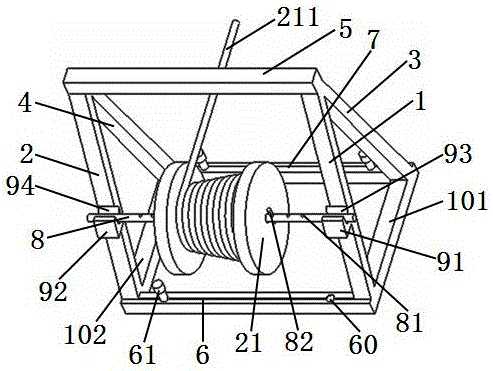

[0027] please see figure 2 , and refer to figure 1 , a cable pay-off frame, basically the same as the implementation example 1, the difference is: the positioning mechanism of the pay-off frame is a first connecting rod 101 connecting the first support rod and the third support rod, connecting the second support rod and the third support rod The second connecting rod 102 of the fourth support rod, the connecting rod positioning hole 60 on the first fixing rod and / or the second fixing rod, and the first fixing rod and / or the second fixing rod are fixed through the connecting rod positioning hole The connecting rod positioning pin 61.

Embodiment 3

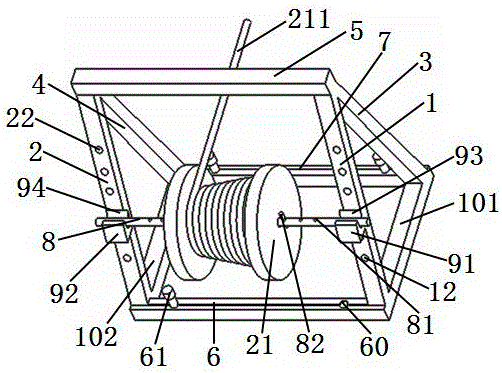

[0029] please see image 3 , and refer to figure 2 , a cable pay-off frame, basically the same as the implementation example 2, the difference is that there are a plurality of first bearing frame positioning parts 12 on the first support rod, and a plurality of second bearing frame positioning parts 12 on the second support rod. Part 22; the first bearing frame positioning part is a concave hole, and the second bearing frame positioning part is a concave hole; the first bearing frame is fixed on the first support rod through the concave hole, and the second bearing The axle frame is fixed on the second support rod through the concave hole; the concave hole is a cylindrical hole, of course, it can also be a hole of other shapes, and the concave hole runs through the first support rod and the second support rod.

[0030] Of course, when the first bearing frame positioning part is a concave hole, there should be at least one; when the second bearing frame positioning part is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com