Novel cable pay-off rack

A pay-off frame and cable technology, which is applied to cable laying equipment, conveying filamentous materials, thin material processing, etc., can solve the problems of high risk, laborious cable reel placed on the top, easy extension of support rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

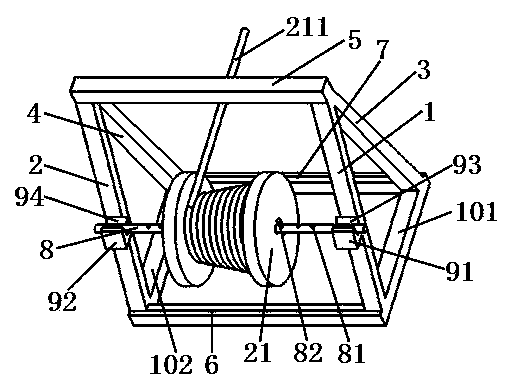

[0026] see figure 1 ; A new type of cable pay-off rack, it includes the first support rod 1, the second support rod 2, the third support rod 3, the fourth support rod 4, the top rod 5, the first fixed rod 6, the second fixed rod The rods 7 and the shaft-shaped bodies 8, the tops of the first support rod and the third support rod are connected to each other and the tops of the second support rod and the fourth support rod are connected by a top rod, characterized in that: The bottom of the first support rod and the second support rod are connected by a first fixing rod, the bottom of the third support rod and the fourth support rod are connected by a second fixing rod, the first support rod and the second support rod are parallel, and the third support rod and the bottom of the fourth support rod are connected by a second fixed rod. The third support rod and the fourth support rod are also parallel, the first support rod and the third support rod are spread apart, the second su...

Embodiment 2

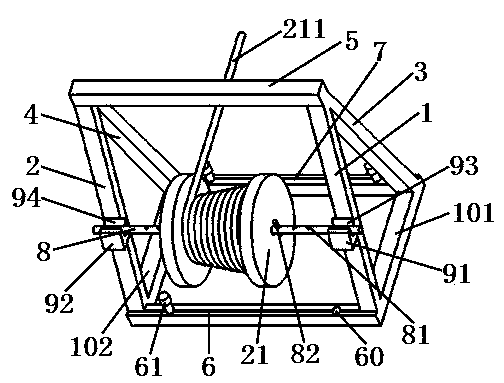

[0028] see figure 2 , and refer to figure 1, a new type of cable pay-off rack, basically the same as the implementation example 1, the difference is: the positioning mechanism of the pay-off rack is the first connecting rod 101 connecting the first supporting rod and the third supporting rod, connecting the second supporting rod The second connecting rod 102 of the rod and the fourth supporting rod, the connecting rod positioning hole 60 located on the first fixing rod and / or the second fixing rod, and the first fixing rod and / or the second fixing rod being fixed through the connecting rod positioning hole The rod is fixed to the connecting rod positioning pin 61.

Embodiment 3

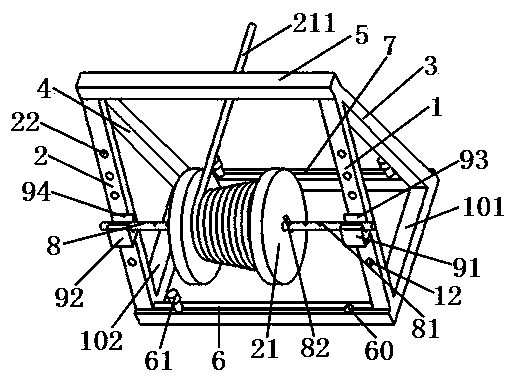

[0030] see image 3 , and refer to figure 2 , a new type of cable pay-off frame, which is basically the same as the implementation example 2, the difference is: the first support rod has a plurality of first bearing frame positioning parts 12, and the second support rod has a plurality of second bearing shafts Frame positioning member 22; the first bearing frame positioning member is a concave hole, and the second bearing frame positioning member is a concave hole; the first bearing frame is fixed on the first support rod through the concave hole, and the second bearing frame positioning member is a concave hole; The two bearing brackets are fixed on the second support rod through a concave hole; the concave hole is a cylindrical hole, of course, it can also be a hole of other shapes, and the concave hole penetrates the first support rod and the second support rod of.

[0031] Of course, when the first bearing frame positioning part is a concave hole, there should be at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com