Pay-off device of tubular strander

A pay-off device and tube stranding machine technology, which is applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of broken wires, poor production efficiency of tube stranding machines, and a large number of man-hours, so as to reduce broken wires, Comprehensive man-hour consumption reduction, the effect of smooth outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

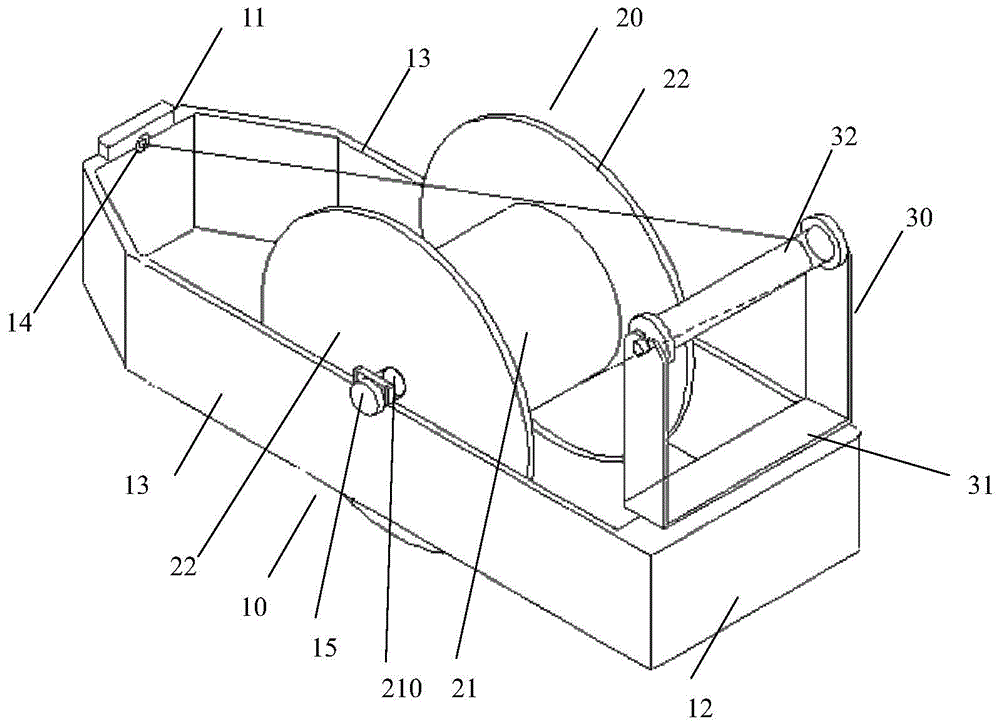

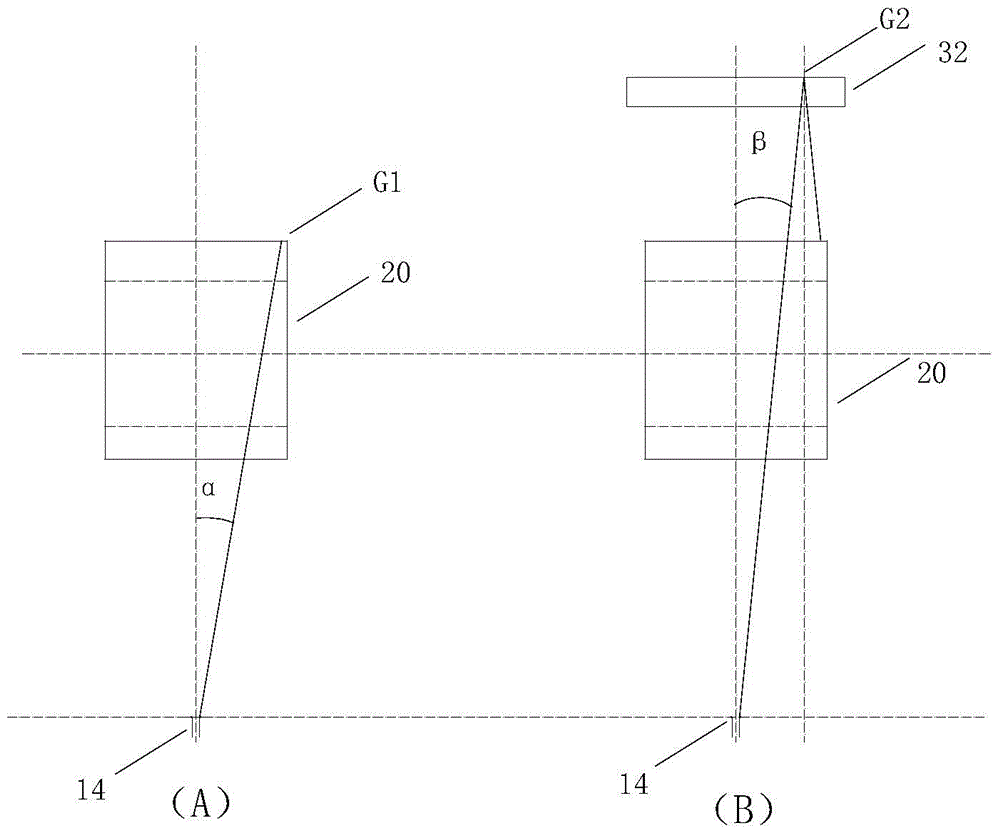

[0017] Next, a pay-off device for a tubular strander as an example of the present invention will be described based on the drawings.

[0018] figure 1 It is a schematic perspective view showing the pay-off device of the pipe stranding machine of the present invention. figure 2 It is a schematic diagram showing the principle of the pay-off device of the pipe strander of the present invention.

[0019] Such as figure 1 As shown, the pay-off device of the pipe strander of the present invention has a pay-off cradle support 10 , a pay-off reel 20 and an auxiliary guiding device 30 .

[0020] The wire-paying cradle support 10 is formed into a frame shape, has a front wall 11, a rear wall 12 and two side walls 13 that are positioned at both sides of the front wall 11 and the rear wall 12 to connect the front wall 11 and the rear wall 12 together. A threading hole 14 is formed on the wall 11 .

[0021] The payout reel 20 has a winding shaft 21 wound with wires and baffles 22 loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com