Winding displacement device for enameled wire production line

A wire arranging device and enameled wire technology are applied in conductor/cable supply devices, conductor/cable insulation, electrical components, etc., which can solve the problems of waste of bare wires, winding and knotting of bare wires, and poor quality of enameled wires. The effect of preventing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

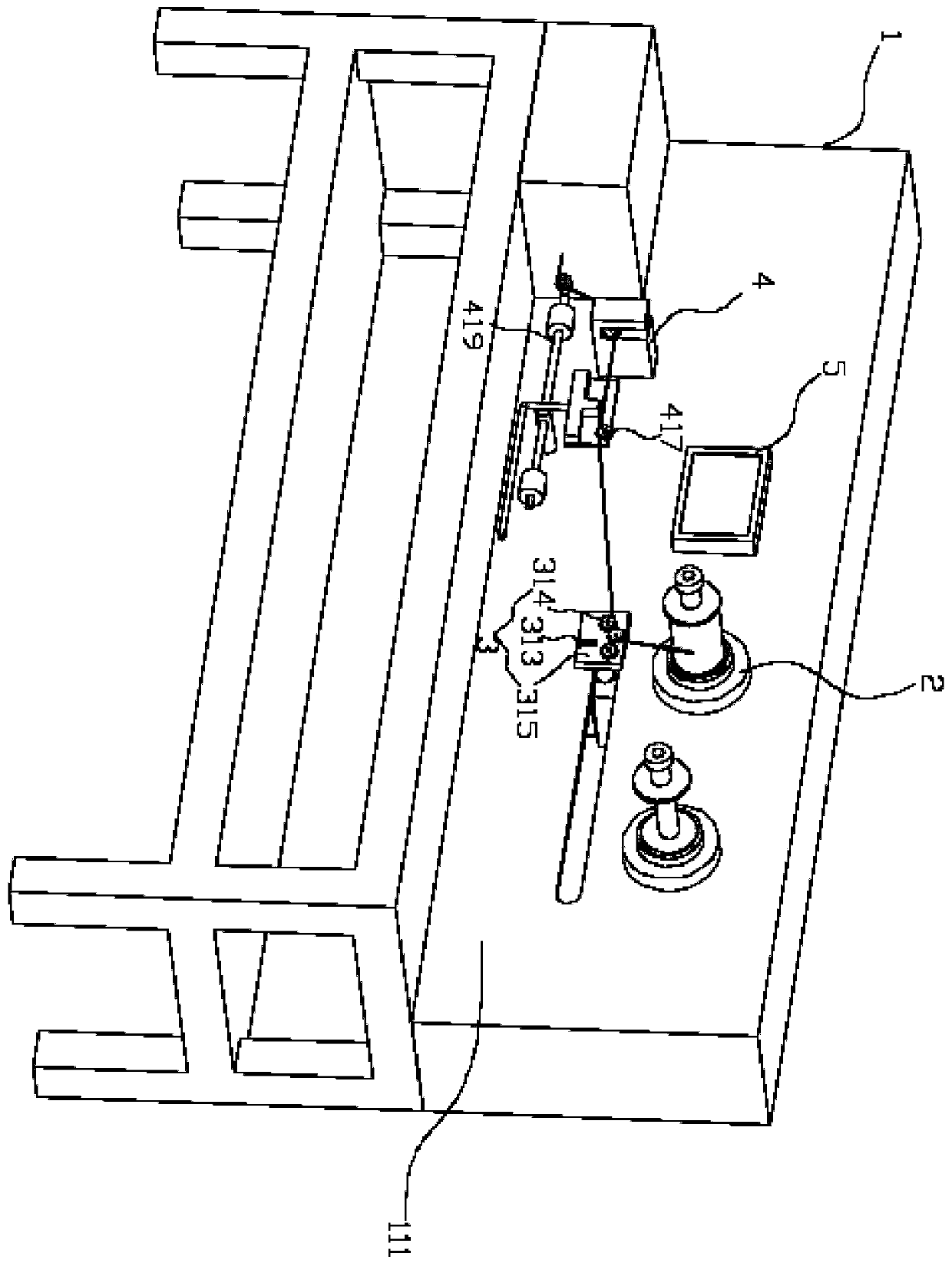

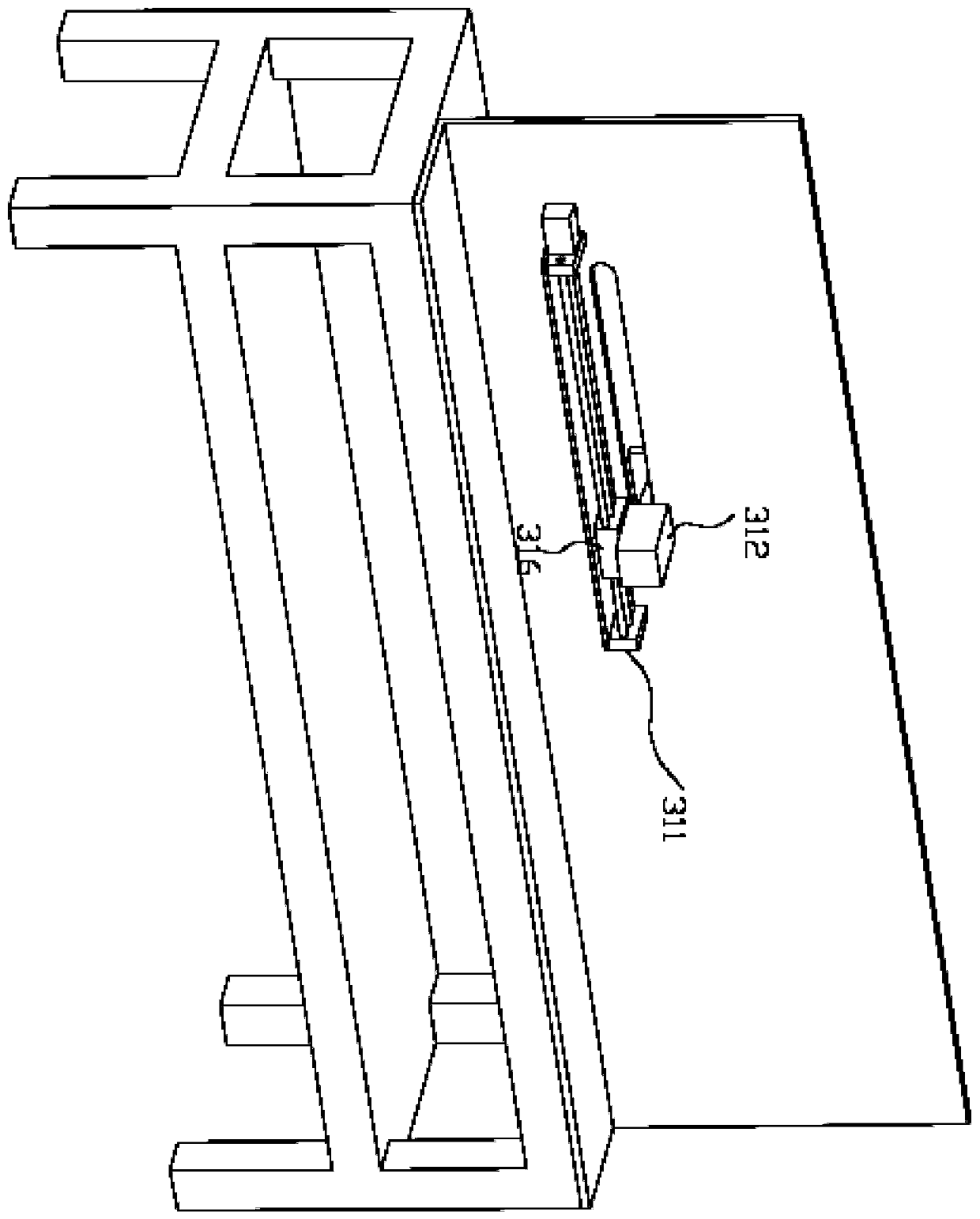

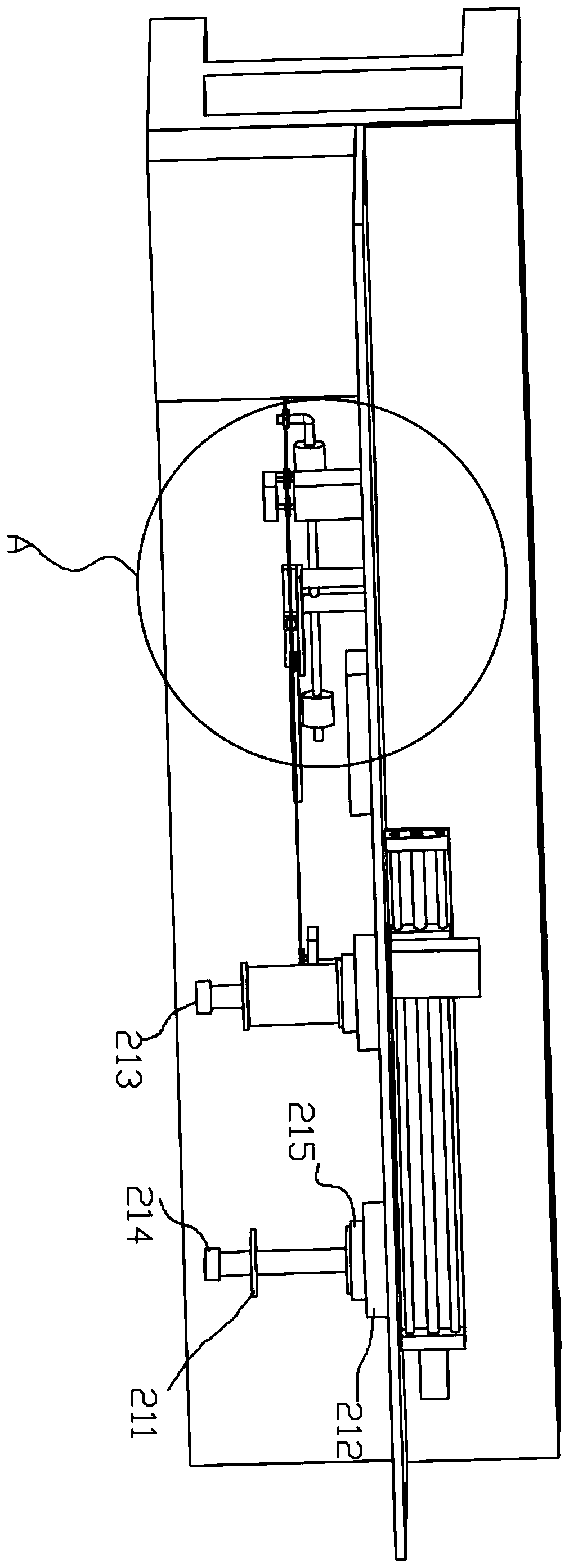

[0028] according to figure 1 -4, a wire arrangement device for an enameled wire production line, located at the front side of the console 111 of the enameled wire production equipment 1, including two pay-off reels 2, a positioning device 3, a detection device 4 and a control device 5;

[0029] The two pay-off reels 2 are located on the same horizontal straight line, and are used to place the pay-off reel 211 wrapped with bare wires. Each pay-off reel 211 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com