Multi-strand special conductor twisting and back-twisting cage wire stranding machine

A cage-type stranding machine and conductor technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve problems that cannot meet high-efficiency production, and achieve a large selection range, consistency assurance, and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

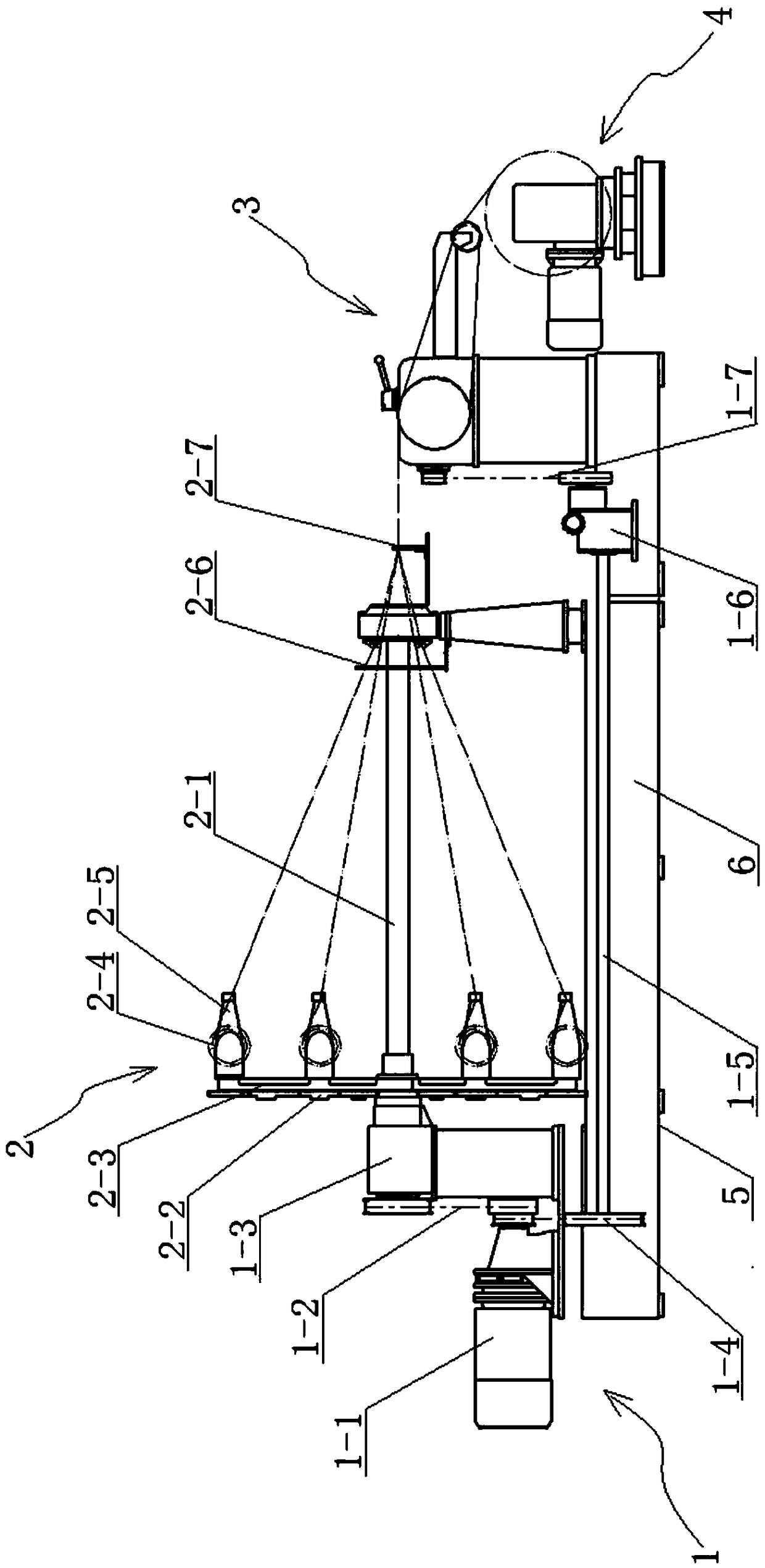

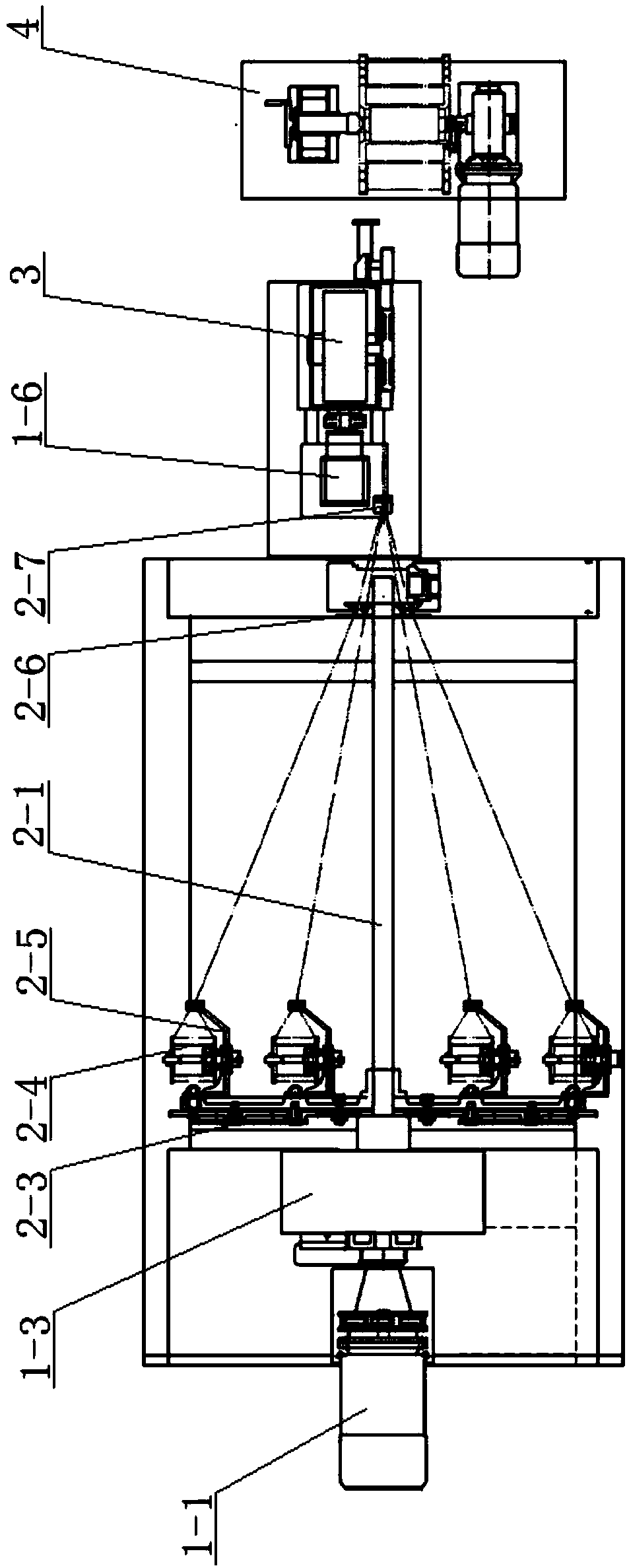

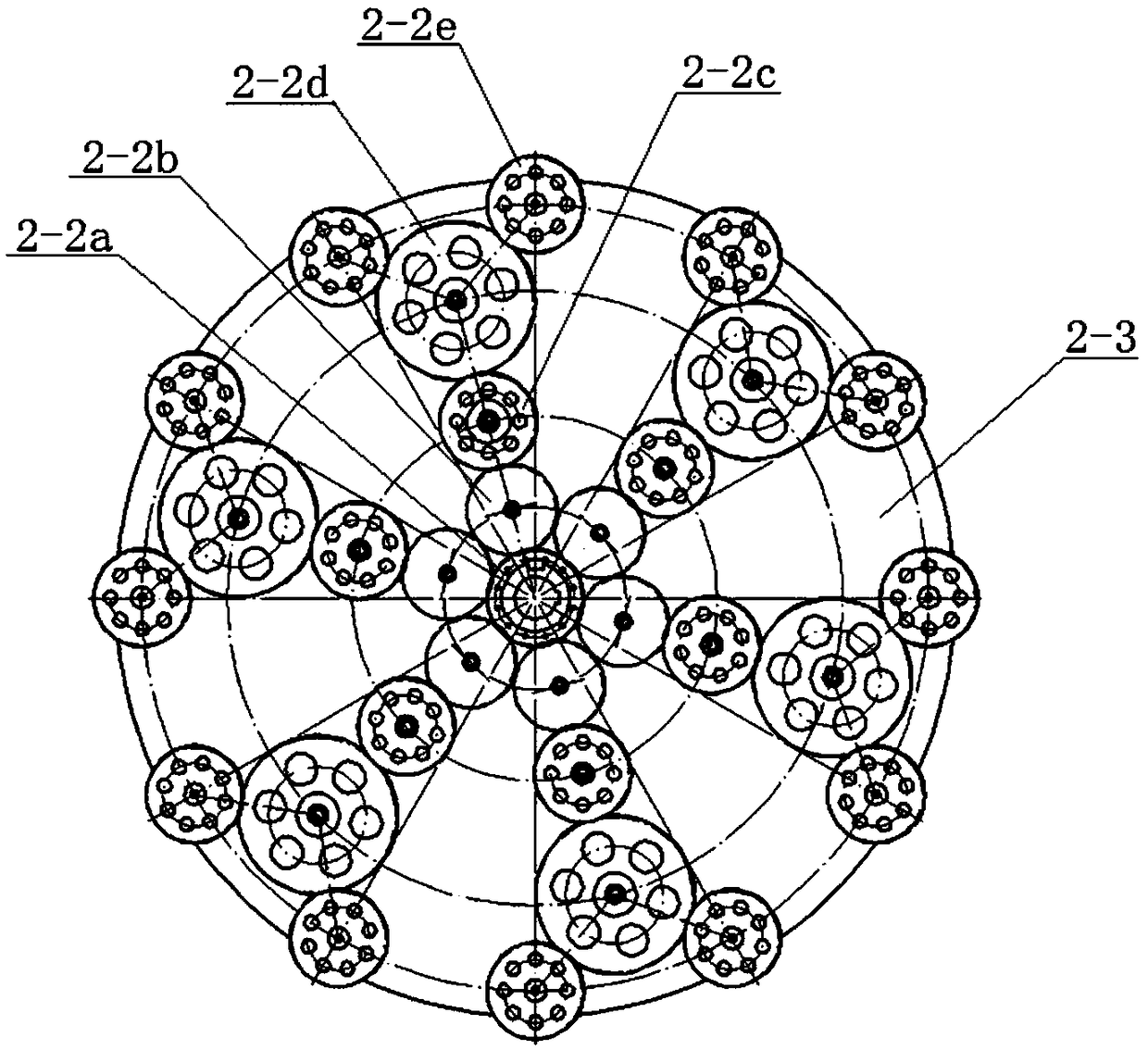

[0039] combine figure 1 and figure 2 As shown, a multi-strand special conductor twisting and untwisting cage type stranding machine in this embodiment includes a power transmission mechanism 1, a conductor twisting mechanism 2, a conductor winding mechanism 3 and a conductor take-up mechanism 4, and the power transmission mechanism 1 and the conductor twisting mechanism 2 are installed on the chassis 5, the power transmission mechanism 1 is connected to the conductor twisting mechanism 2, and is used to drive the conductor twisting mechanism 2 to rotate, the conductor twisting mechanism 2, and the conductor winding mechanism 3 It is arranged in sequence with the conductor take-up mechanism 4, and the stranded conductor formed by the conductor stranding mechanism 2 is unwound and twisted, and after being shaped by the conductor take-up mechanism 3, it is coiled and wound in the conductor take-up mechanism 4. In this embodiment, the power transmission mechanism 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com