Method and device for fabricating self-rotating diamond wire saw

A production method and self-rotation technology, applied in the direction of electrolytic coating, coating, cells, etc., can solve the problems of distribution uniformity and density affecting cutting ability, surface quality, diamond wire production cost, etc., to reduce the probability of wire breakage , diameter fluctuation is well controlled, and the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

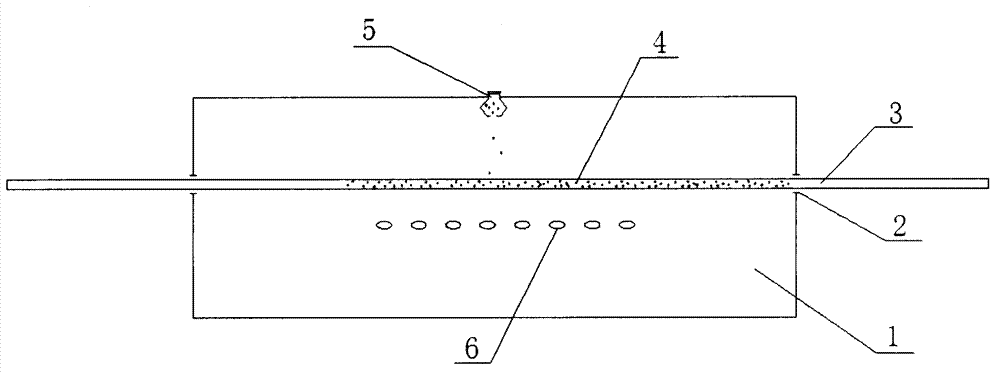

[0015] A production equipment for self-rotating electroplating diamond wire saw, including electroplating tank 1, wire inlet hole 2, metal wire 3, diamond particles 4, sand inlet 5 and air outlet 6.

[0016] The pretreated diamond particles 4 are flowed into the electroplating tank 1 through the sand inlet 5, and the gas flow size and the gas flow direction of the gas flow port 6 are adjusted, so that the diamond particles 4 can be evenly rotated in the plating solution of the electroplating tank 1; The current density of the plating solution in the tank 1 reaches the target value, and when the temperature of the plating solution reaches the set value, the movement control device of the metal wire 3 is opened; the metal wire 3 is pulled into the electroplating tank 1 at a constant speed through the wire inlet hole 2, and the metal wire 3 is traveling, through a series of reactions, the diamond particles 4 will be electroplated and solidified on the surface of the wire 3 continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com