Computer embroider machine needle bar cam mechanism with balancing device

A technology of cam mechanism and balance device, which is applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc. It can solve the problems that affect the service life of embroidery machine heads, the service life of bearings, hinder production efficiency, and cannot increase the speed of rotation, etc., and achieve improvement. Effects of working environment, reducing embroidery thread breakage rate, and eliminating vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

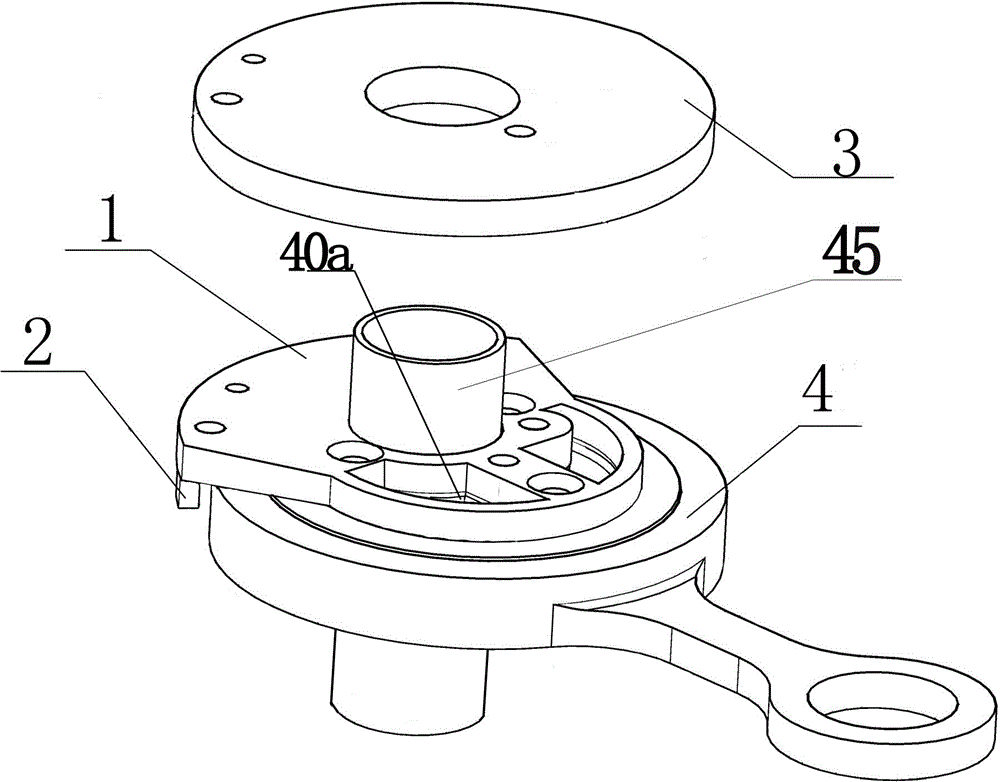

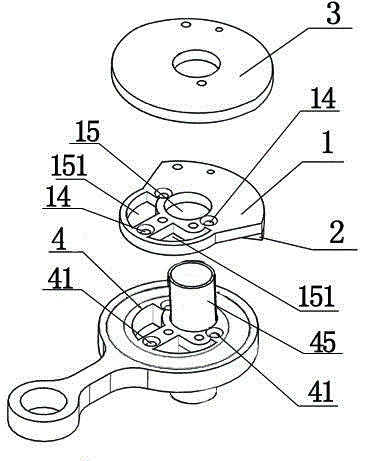

[0027] like Figure 1 to Figure 2 Shown: a computerized embroidery machine needle bar cam mechanism with a balance device, including an eccentric link bearing 4 and a thread take-up nylon cam 3, the eccentric link bearing 4 is the needle bar drive link and needle bar drive cam in the prior art And the bearing between the needle bar driving connecting rod and the needle bar driving cam is an integrally designed and manufactured connecting rod cam integrated bearing. The cam cover 1 is installed on the eccentric connecting rod bearing 4, and the thread take-up is installed on the cam cover 1. Nylon cam3.

[0028] in:

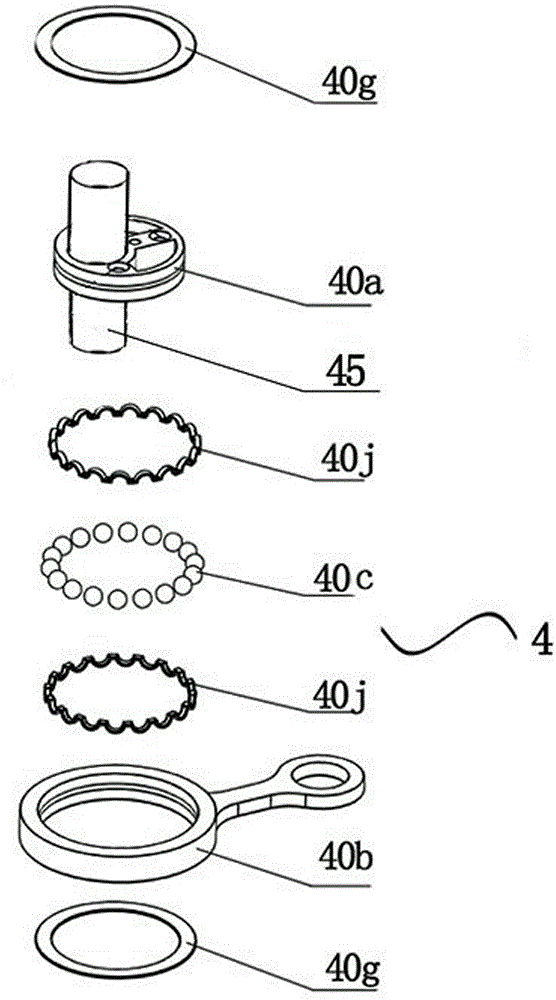

[0029] Eccentric connecting rod bearing 4: such as Figure 1 to Figure 4 As shown, the eccentric connecting rod bearing 4 includes an eccentric bearing inner ring 40a and a connecting rod outer ring 40b; wherein a rotating shaft 45 is arranged on the eccentric bearing inner ring 40a, and several connecting rod outer rings 40b and eccentric bearing inner ring 40a...

Embodiment 2

[0035] In this embodiment, only the cross-sectional shape of the counterweight block 12 in the cam cover plate 1 and the size of the counterweight block 2 are different, and the others are the same as the first embodiment.

[0036] like Figure 6 As shown, in the second embodiment, the cross section of the counterweight block 12 is a sector 17, and the sector 17 includes an inner arc ad171 and an outer arc bc172, wherein the inner arc ad171 is an arc on the circle 18, and the inner arc ad171 is The corresponding central angle is equal to or equal to 90 degrees; the radius of the circle 18 is equal to 22; the center of the outer arc bc172 is the second center 150, the diameter of the outer arc bc172 is 36 mm, and the corresponding central angle of the outer arc bc172 is 180 degrees .

[0037] Counterweight 2: such as figure 1 , figure 2 , image 3 As shown, the corresponding counterweight 2 is arranged on the arc outer edge of the counterweight block 12; the counterweight...

Embodiment 3

[0039] In this embodiment, only the cross-sectional shape of the counterweight block 12 in the cam cover plate 1 and the size of the counterweight block 2 are different, and the others are the same as the first embodiment.

[0040] like Figure 7 As shown, in the third embodiment, the cross section of the counterweight block 12 is a sector 17, and the sector 17 includes an inner arc ad171 and an outer arc bc172, wherein the inner arc ad171 is an arc on the circle 18, and the inner arc ad171 is formed by The corresponding central angle is equal to 133 degrees; the radius of the circle 18 is equal to 23; the center of the outer arc bc172 is the second center 150, the diameter of the outer arc bc172 is 42 mm, and the corresponding central angle of the outer arc bc172 is 180 degrees .

[0041] Counterweight 2: such as figure 1 , figure 2 , image 3 As shown, the counterweight 2 is located on the outer edge of the arc of the counterweight block 12; the counterweight 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com