Warp let-off device of double rib warp loom

A double-needle-bed warp knitting machine and double-needle-bed technology are applied in warp knitting, knitting, textiles and papermaking, and can solve problems such as downtime, difficulties, and reduced production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

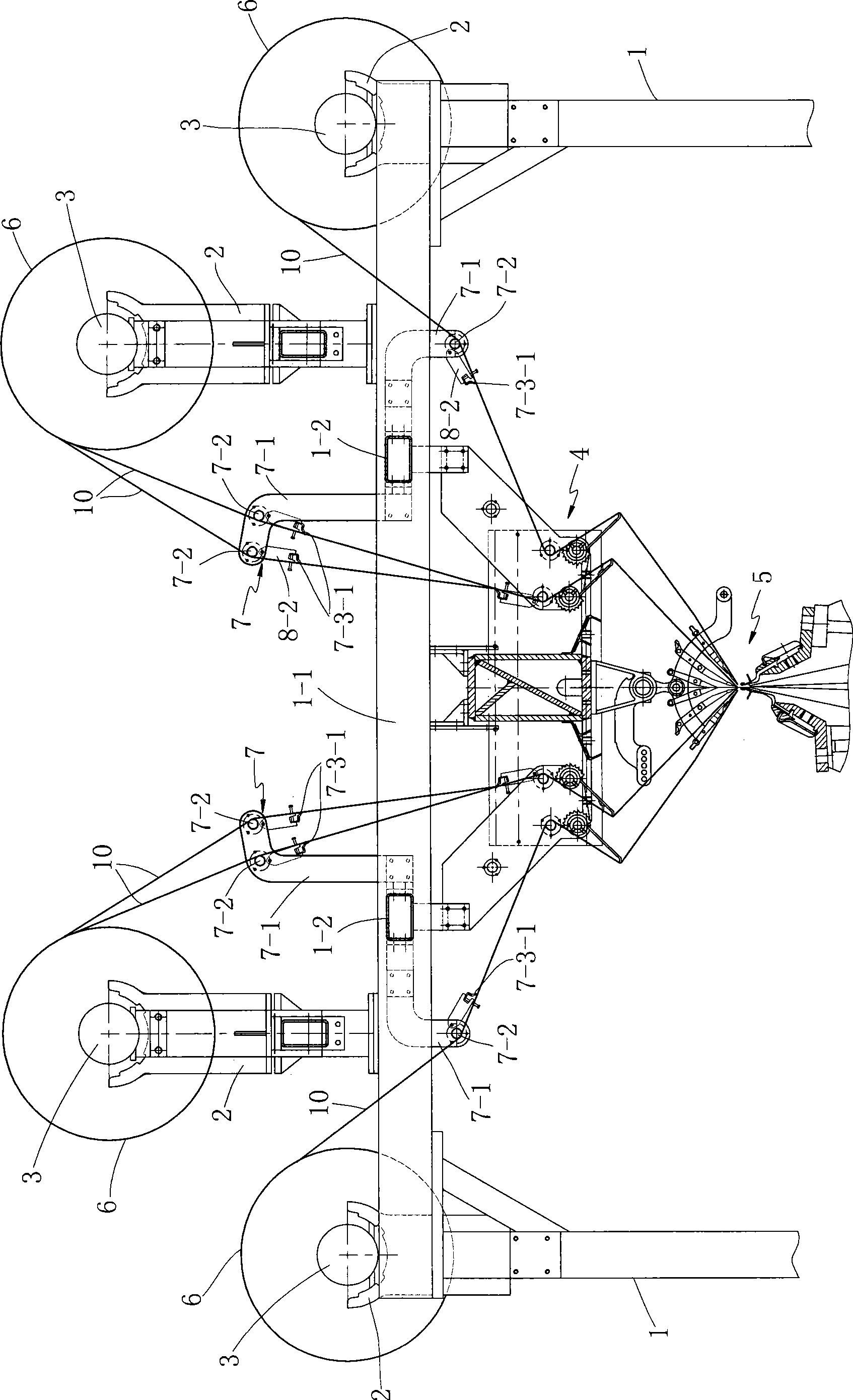

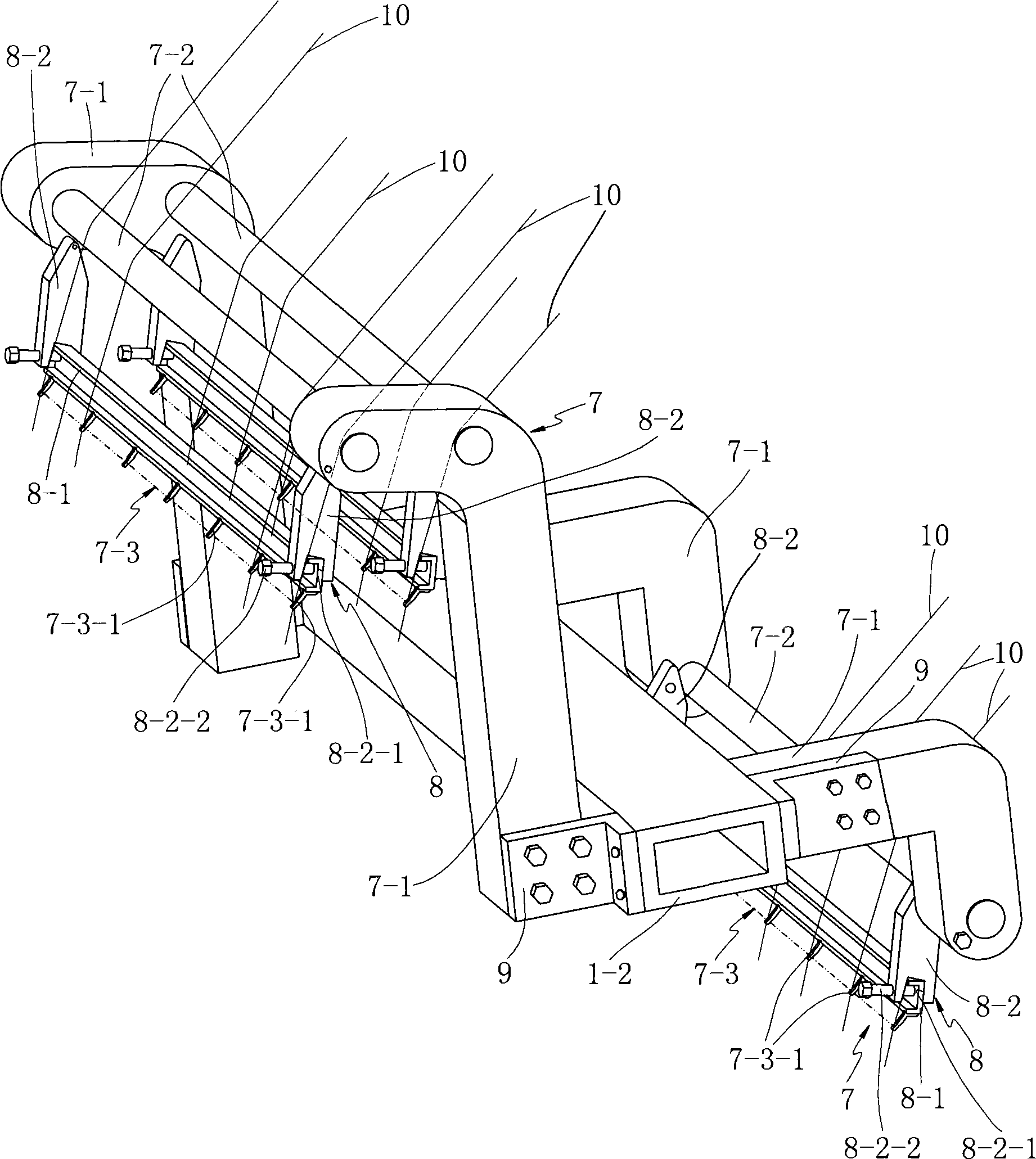

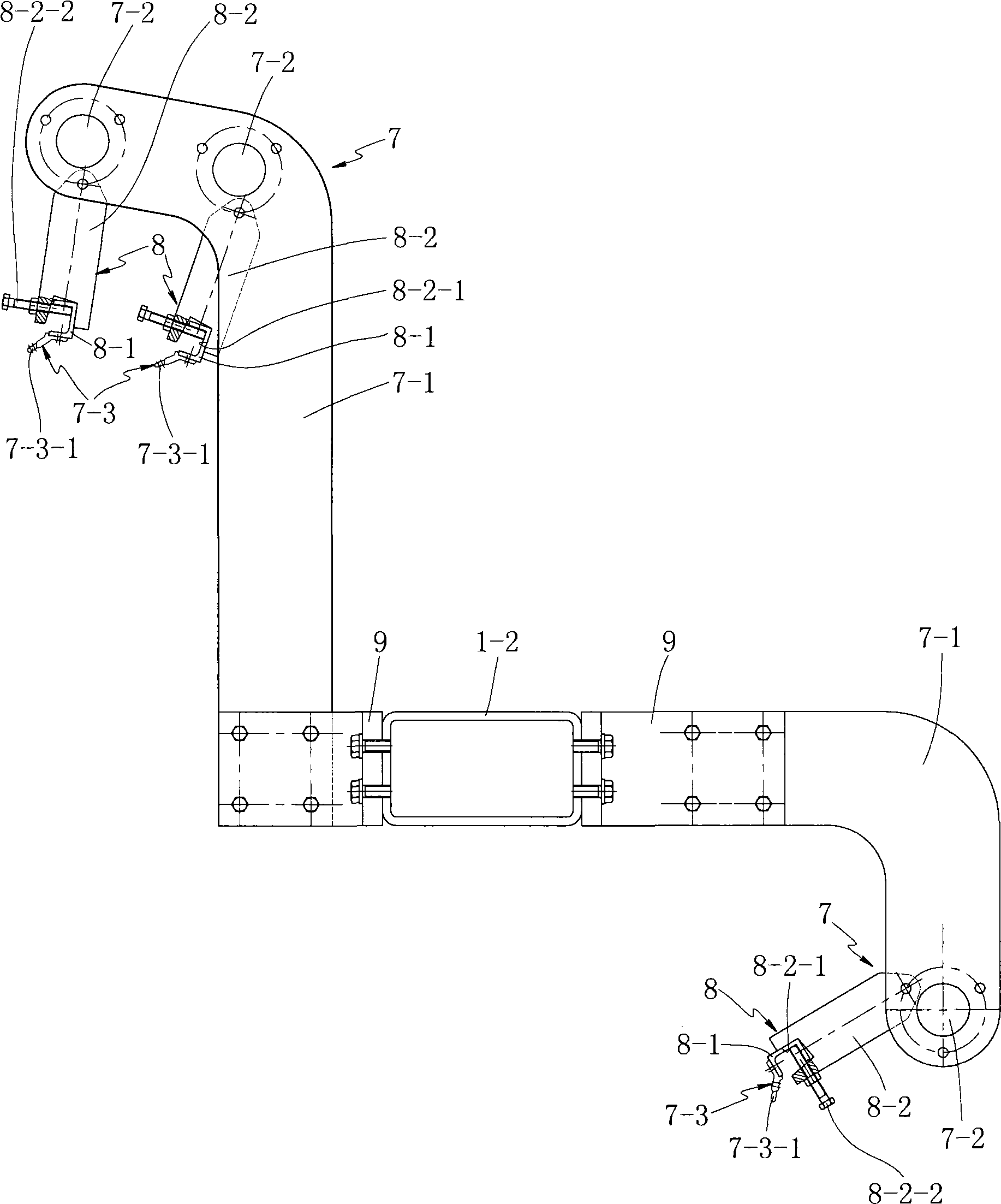

[0014] see Figure 1 to Figure 3 The let-off device of a double-needle-bed warp knitting machine shown includes a plurality of pan head support seats 2 fixedly connected to the double-needle-bed warp-knitting machine body 1 in the lateral direction, The pan head supporting base 2 is rotatably connected to a plurality of warp beams 3 arranged parallel to each other, a yarn tension adjustment mechanism 4 and a yarn knitting mechanism 5 fixedly connected to the bed 1, and a plurality of pan heads 6 are set on the On the warp beam 3, the bed 1 is a frame structure mainly composed of a beam 1-1 and a beam 1-2, the beam 1-1 is arranged longitudinally along the bed 1, and the beam 1 1-2 are arranged in the transverse direction; corresponding to each pan head 6, a yarn dividing and guiding mechanism 7 is respectively arranged, and the yarn dividing and guiding mechanism 7 is fixedly connected with the bed 1, and is respectively arranged on the bed 1 The yarn guide roller base 7-1 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com