Upcast method for producing high-purity bright copper rod

A bright copper, high-purity technology, applied in the direction of improving process efficiency, can solve the problems of unattainable oxygen content, extremely high taste of electrolytic copper, and many safety hazards, avoiding the secondary oxygen absorption process and improving the workshop. The working environment, the effect of the deoxidization process thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

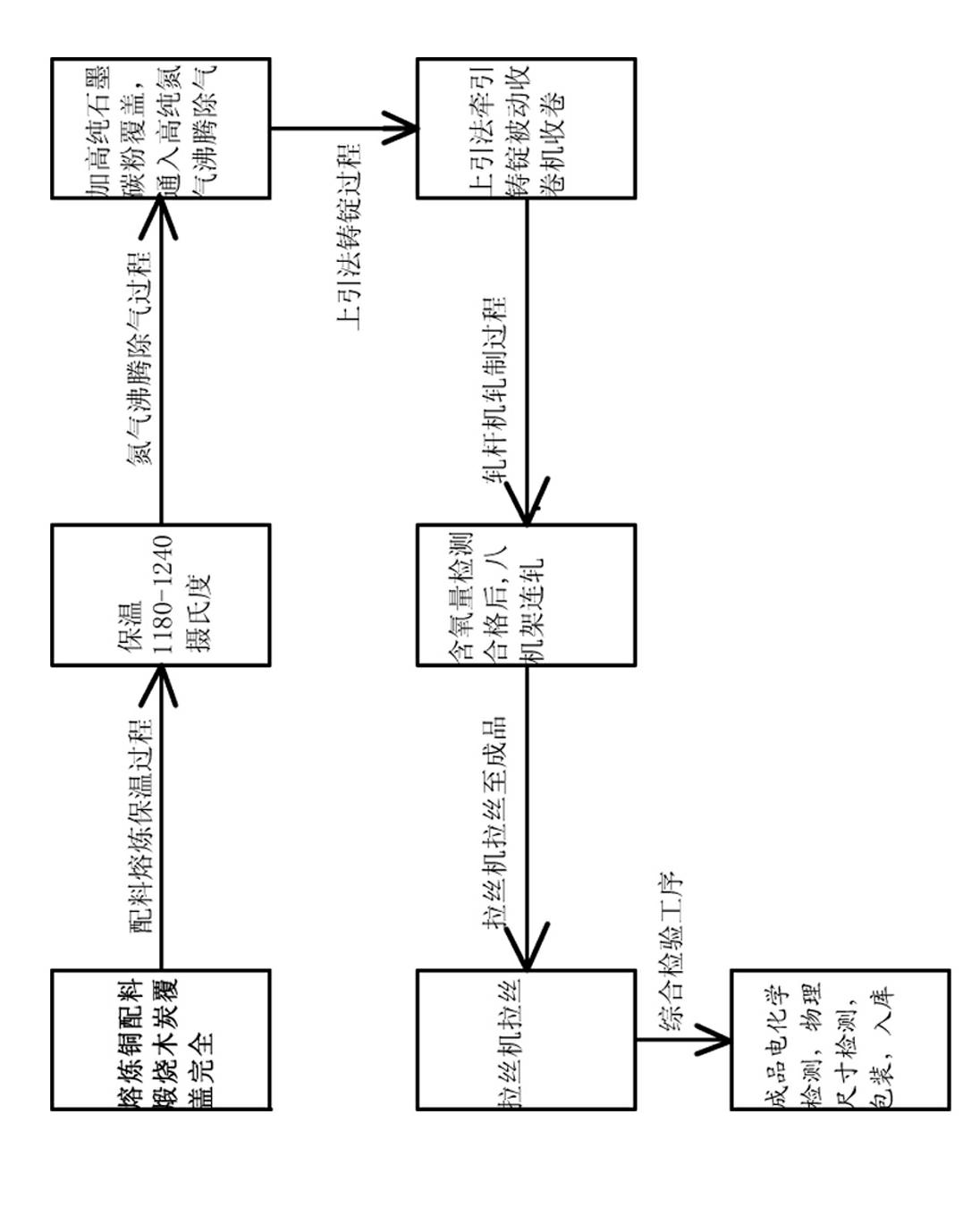

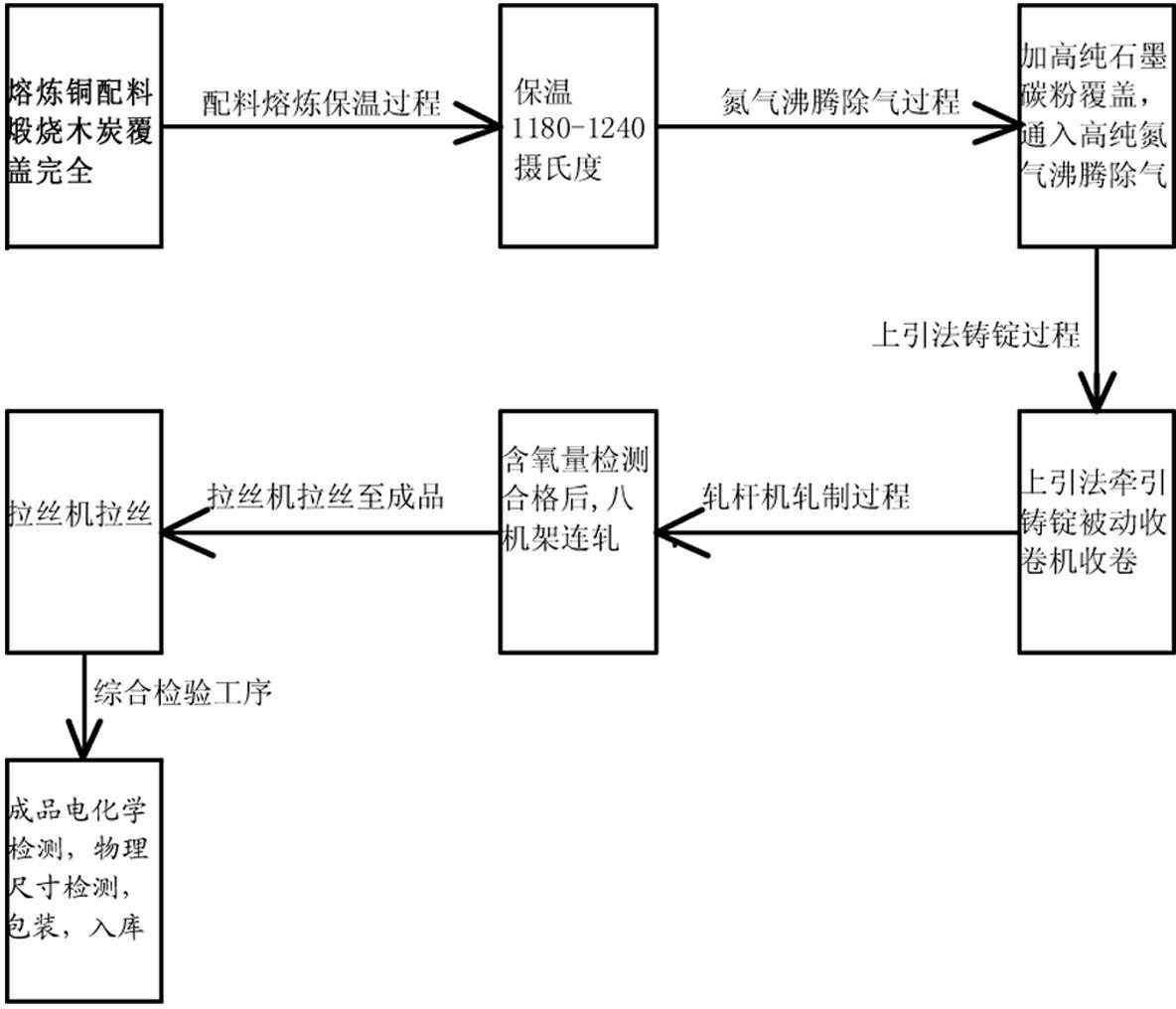

[0037] Refer to attached figure 1 , the method of producing high-purity bright copper rods by the upward quotation method is as follows:

[0038] After drying the smelting copper raw materials required for smelting, prepare the materials, add them to the smelting furnace, cover the upper part of the melting copper liquid with 100-150 mm thick calcined charcoal, close the furnace cover, and continue to smelt with high-voltage gear, AC voltage Control at 380-400V until the copper is completely melted. The melting temperature of the melting furnace is 1180-1250°C. When there is enough liquid level, the copper liquid will continuously flow to the holding furnace under the action of fluid force;

[0039] In the past, when the temperature-measuring thermocouple reached 1180-1250 degrees Celsius in the old process, the billet was drawn directly. Because of the coverage of calcined charcoal, the oxygen in the air was isolated from direct contact with the high-temperature copper liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com