Paper sticking device of battery machine and battery machine adopting paper sticking device

A technology of stickers and batteries, which is applied in the directions of transportation and packaging, sending objects, thin material handling, etc., can solve the problems of rising production costs, high defective products, scratched aluminum foil, etc., to reduce production costs, reduce defective products, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

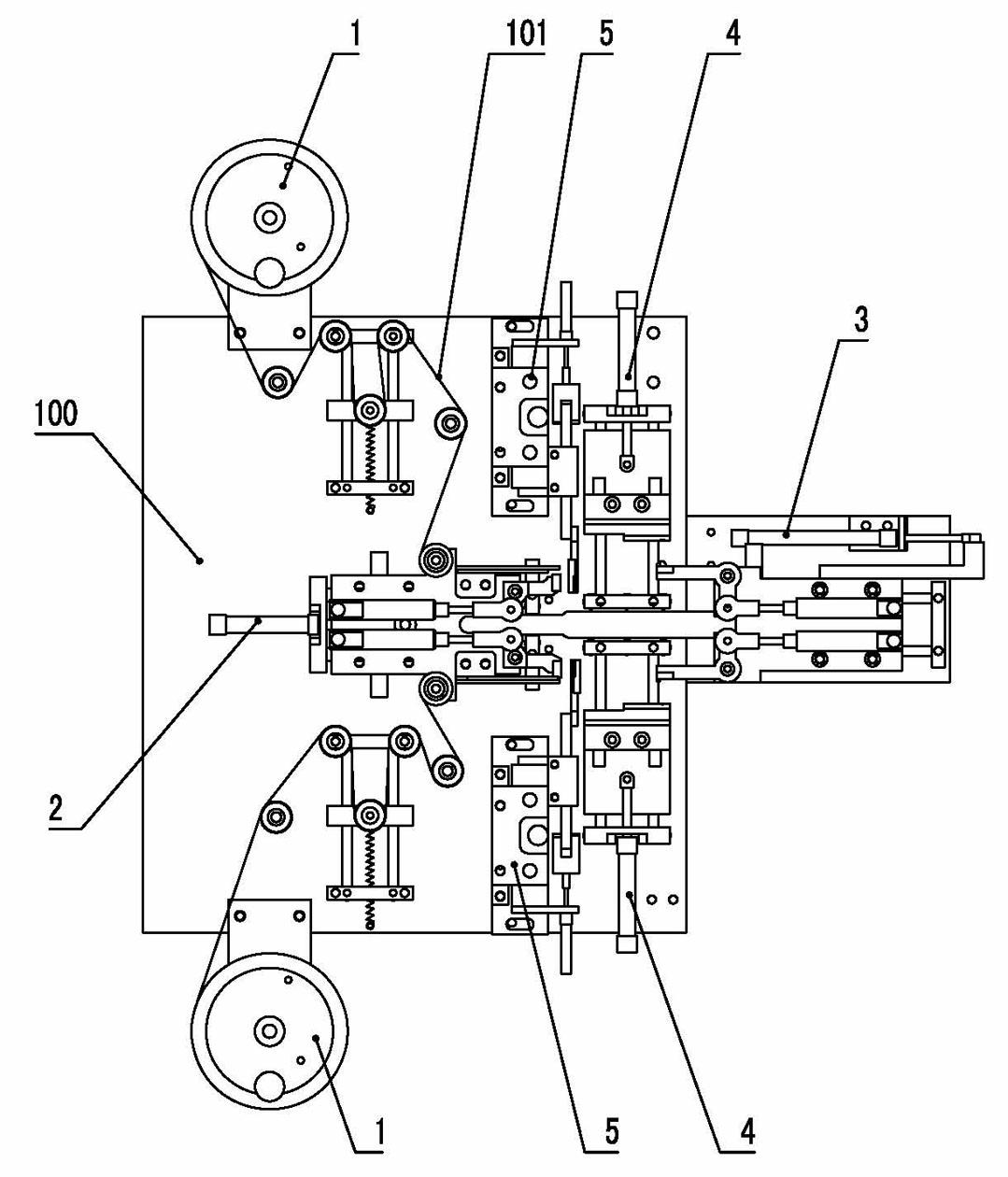

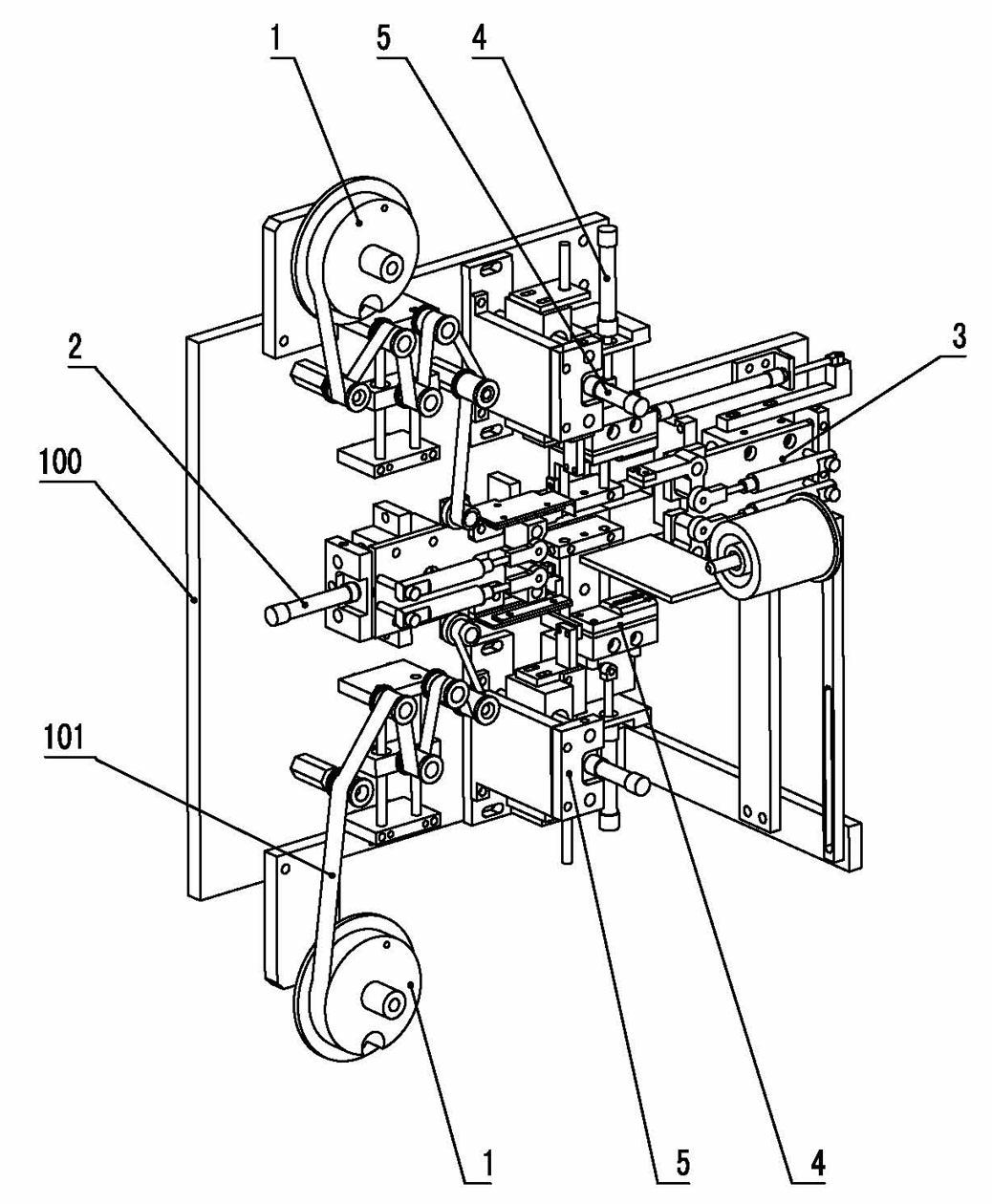

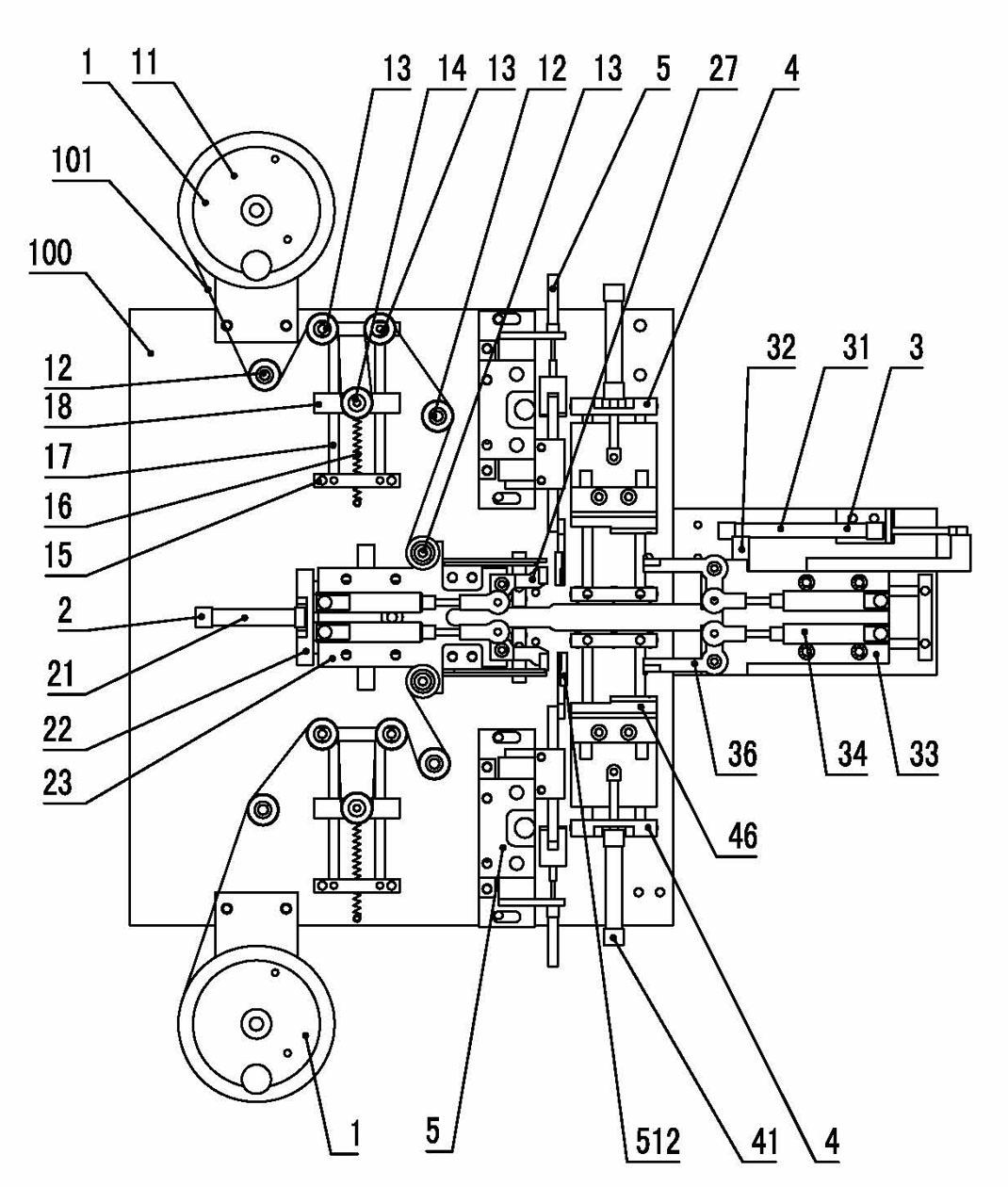

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] Figure 1 to Figure 12 The reference numbers in the figure are: machine base 100; adhesive paper tape 101; sticker transmission mechanism 1; paper tray 11; paper transfer wheel 12; fixed tension wheel 13; movable tension wheel 14; second fixed seat 15; Guide column 17; Tension adjustment slider 18; First fixed seat 19; First paper platen mechanism 2; First driving part 21; Cylinder fixing seat 22; 25; first swing arm 26; pressing block 27; paper feeding guide rail 28; second paper pressing mechanism 3; third driving part 31; cylinder fixing seat 32; Rod 35; second swing arm 36; paper pressing raised part 361; guide post 37; adsorption mechanism 4; fifth driving part 41; cylinder fixing seat 42; guide post 43; third slider 44; Sticker adsorption seat 46; pressure paper groove 461; step part 462; adsorption cavity 463; through hole 464; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com