Full-automatic nailing machine

A stitching machine, a fully automatic technology, applied in the field of automatic stitching machines, can solve the problems of difficult management, low carton forming rate, large labor, etc., to reduce maintenance workload, realize production automation, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

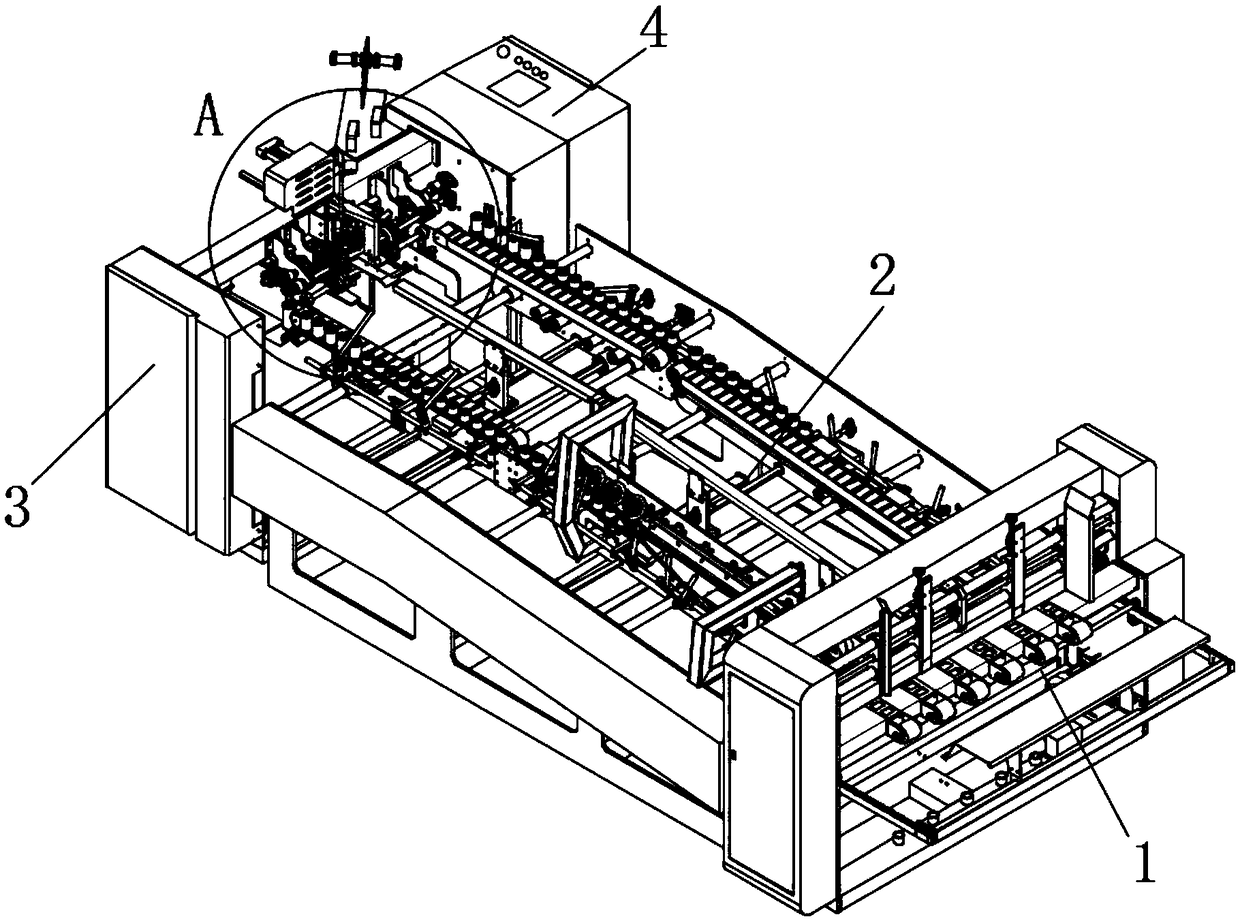

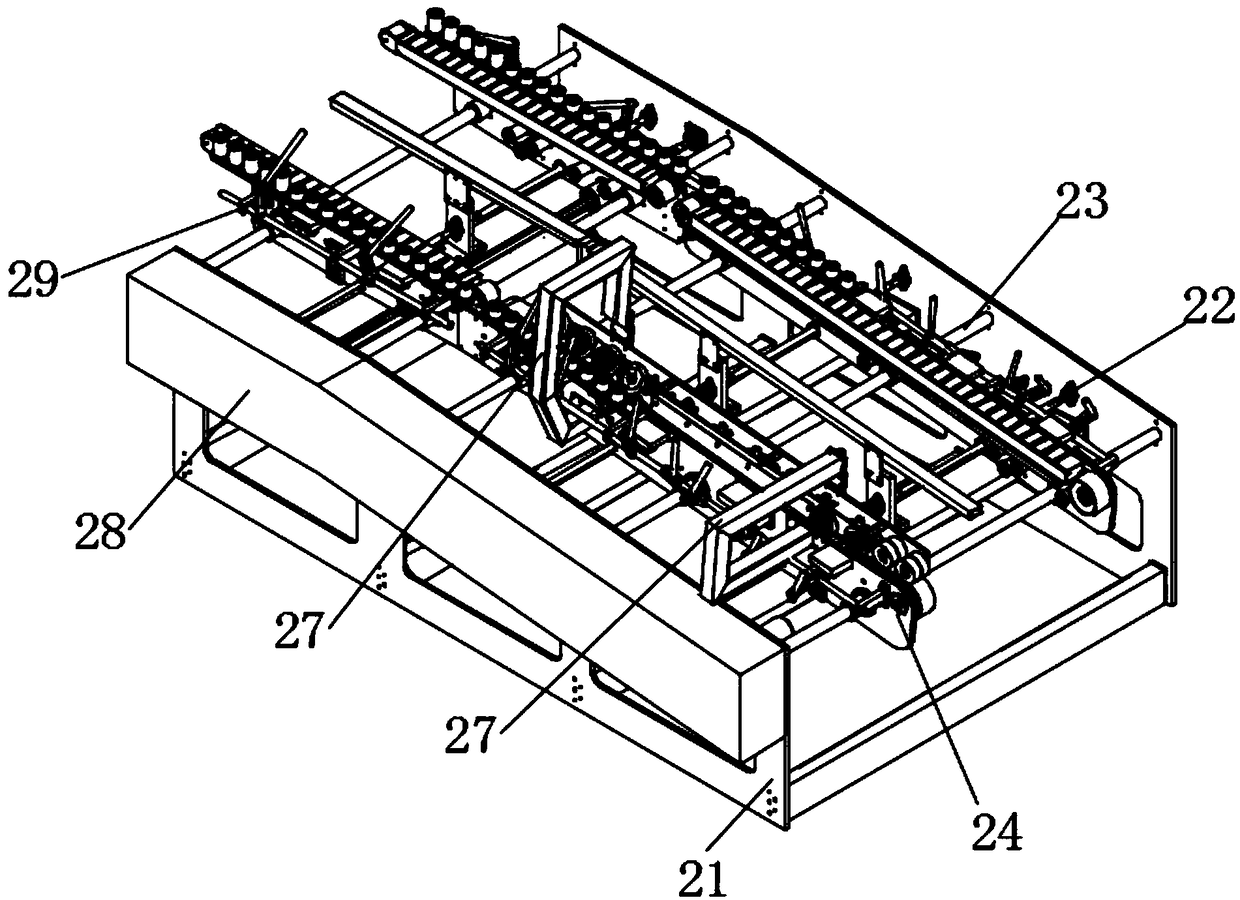

[0019] attached Figure 1-5 It is a full-automatic nail box machine according to the present invention, comprising a control box 4 and a paper feeding device 1, a box folding device 2 and a nail box device 3 arranged in sequence according to the work flow;

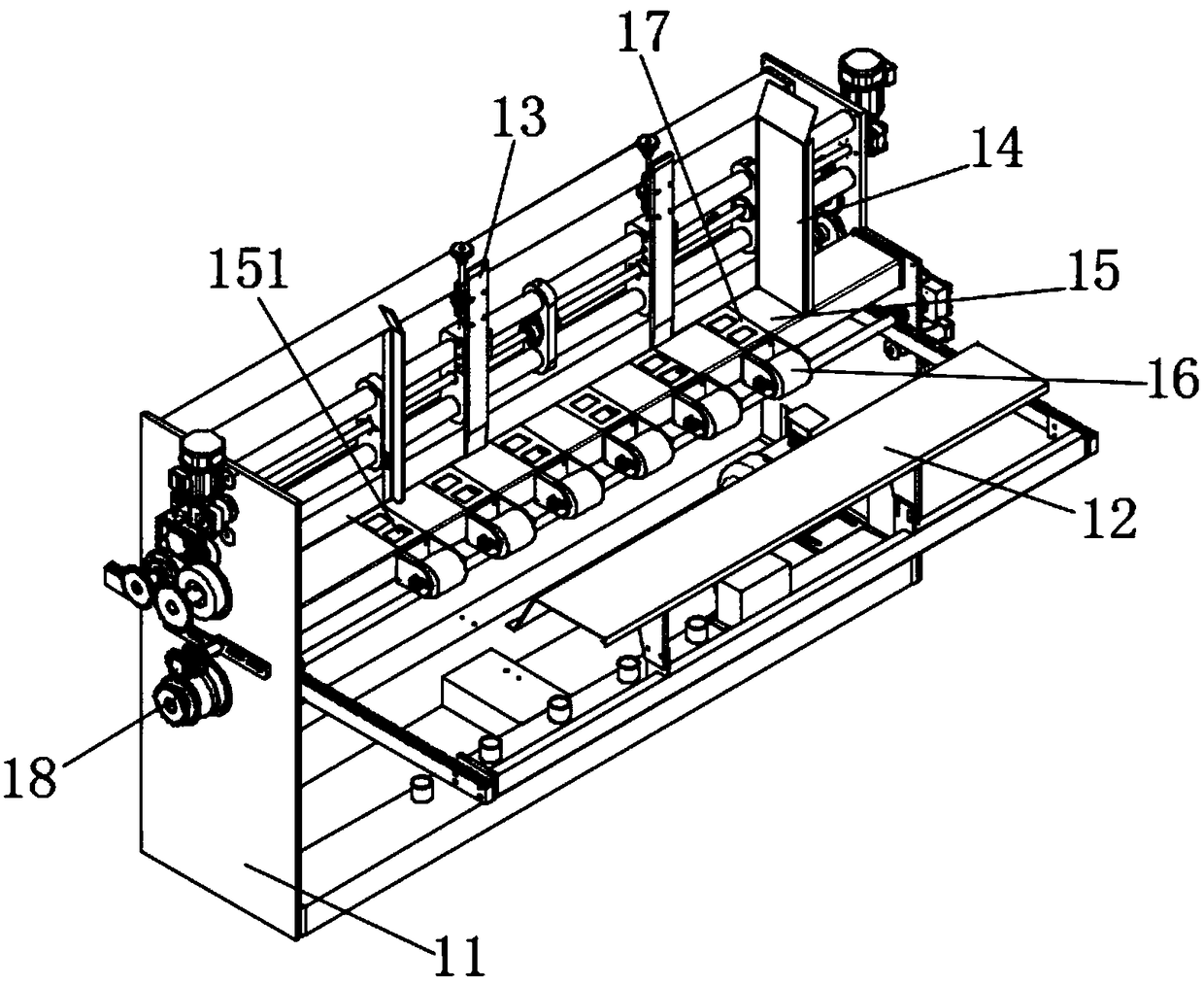

[0020] The paper feeding device 1 includes a paper feeding support 11, a paper lifting board 12 driven by a motor to move back and forth, and a front paper blocking board 13 that can move laterally and can be adjusted up and down; A suction beam 15 connected to the air pump is horizontally provided between the front cardboard 13, and a side cardboard 14 that can be adjusted and moved laterally is provided on one side of the suction beam 15; The suction holes 151 of the suction beam 15 are respectively provided with paper feeding wheels 16 corresponding to each row of suction hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com