Automobile filter casing automatic production line

An automatic production line and filter technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of low production efficiency, unstable precision, etc., and achieve the improvement of production efficiency, wide application range and reduction of defective products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

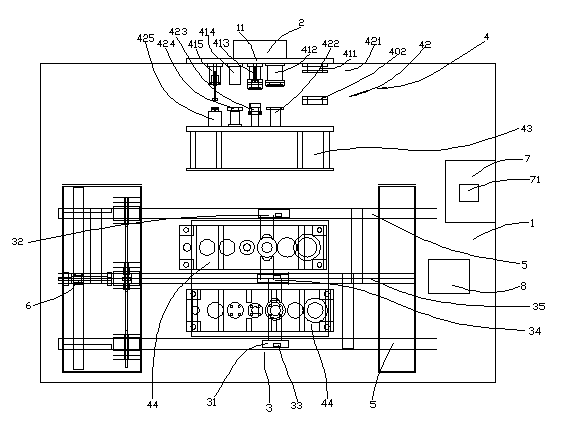

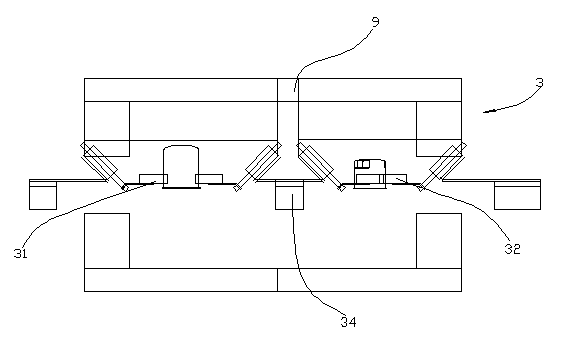

[0022] see figure 1 , figure 1 The shown automatic production line of an automobile filter housing includes a bed 1, a hydraulic press 2, a manipulator 3, and a mold set 4. The hydraulic press 2 is fixed above the bed 1 through an upper plate 11, and the hydraulic press 2 drives The mold group 4 acts to provide power for the mold action, and the size of the hydraulic press 2 is selected in combination with the actual product. For example, we have successfully debugged and produced two products at the same time and chose the 250-ton hydraulic press 2. For more than three products, hydraulic press 2 with a larger tonnage is needed to meet the actual production needs. This machine has two sets of mold sets, one product has five processes to complete, and two products have ten processes. Ten processes are concentrated on one machine, and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com