Dyeing and finishing process of viscose woven fabric

A technology for rayon machine and fabric, applied in the field of dyeing and finishing process of rayon woven fabric, can solve the problems of unsatisfactory market response, fuzzy and rough printing effect, poor three-dimensional feeling, etc., and achieves good hand feeling, good dyeing effect, and reduced The effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

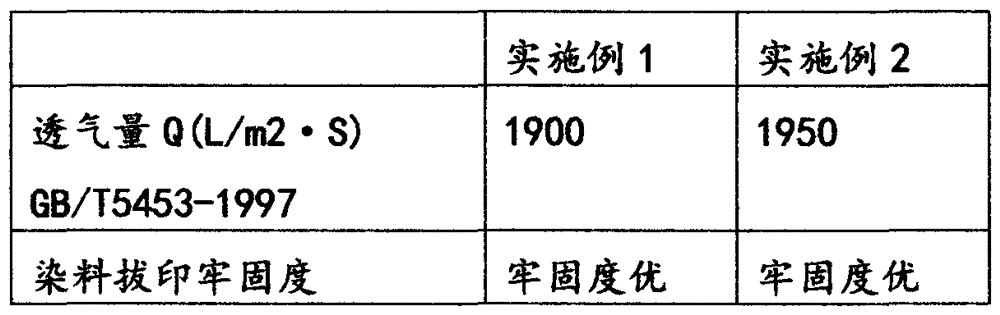

Embodiment 1

[0017] A dyeing and finishing process of rayon woven fabrics, comprising the following steps: 1) stacking and airflow treatment of semi-finished rayon woven fabrics; 2): dyeing pretreatment of rayon woven semi-finished products: washing rayon woven fabrics The semi-finished product is placed in the dyeing pretreatment solution for cooking. The temperature of the dyeing pretreatment is 50 ° C. The solution includes 0.15 g / L of defoamer, 4 g / L of dispersant, 4 g / L of penetrant, and 0.10 g / L of sulfuric acid. L, bleaching powder 0.10g / L, sodium carbonate 1g / L, hydrogen peroxide 3g / L, glacial acetic acid 0.20g / L, sodium phosphate 0.15g / L, Swire oil 0.15g / L, the time of described dyeing pretreatment is 10 -50min; Import the semi-finished rayon woven fabric after cooking into the overflow machine, cold wash and export it, and enter it into the rope washing machine for soaping; 3): The finalization of the semi-finished rayon woven fabric: the semi-finished rayon woven fabric after soa...

Embodiment 2

[0019] A dyeing and finishing process of rayon woven fabrics, comprising the following steps: 1): stacking and airflow treatment of rayon woven semi-finished products; 2): dyeing pretreatment of rayon woven semi-finished products: washing rayon woven fabrics The semi-finished product is placed in the dyeing pretreatment solution for cooking. The temperature of the dyeing pretreatment is 60 ° C. The solution includes 0.20 g / L of defoamer, 5 g / L of dispersant, 6 g / L of penetrant, and 0.20 g / L of sulfuric acid. L, bleaching powder 0.20g / L, sodium carbonate 3g / L, hydrogen peroxide 10g / L, glacial acetic acid 0.40g / L, sodium phosphate 0.25g / L, Swire oil 0.25g / L, the time of described dyeing pretreatment is 50min ; Import the semi-finished rayon woven fabric after cooking into the overflow machine and export it by cold washing, and then enter the rope washing machine for soaping; 3): The finalization of the semi-finished rayon woven fabric: the semi-finished rayon woven fabric tide cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com