Mold table driving device with air bag

A driving device and air bag technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of easy slippage of rubber friction wheels, low manufacturing cost, and uneven delivery of mold tables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

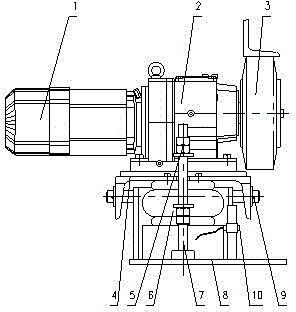

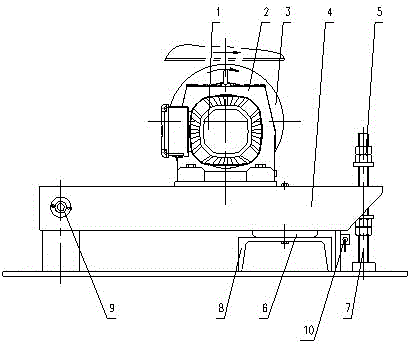

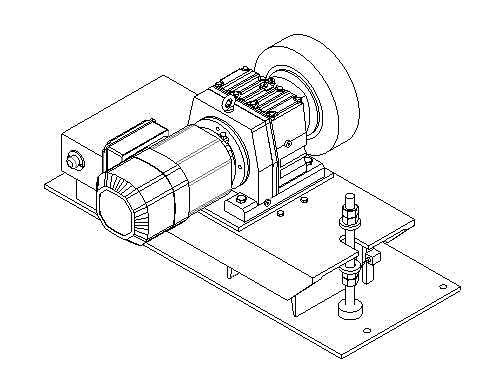

[0011] Referring to the accompanying drawings, a mold table driving device with an airbag includes a motor 1, a reducer 2, a rubber wheel 3, a reducer bottom plate 4, a washer nut 5, an airbag 6, a stud 7, a support 8, a pin 9, The sensor 10, the motor 1 and the reducer 2 are direct-coupled, the rubber wheel 3 is assembled on the output shaft of the reducer 2, the bottom plate 4 of the reducer is connected with the support 8 with a pin shaft 9, and the space between the bottom plate 4 of the reducer and the support 8 Install the airbag 6, the airbag 6 is respectively connected with the bottom plate 4 of the reducer and the support 8, the stud 7 is welded on the support 8, the stud 7 is equipped with a washer nut 5, and there are two sets of washer nuts 5, which are respectively installed on the reducer The sensor 10 is installed on the support 8 at appropriate positions above and below the bottom plate 4 . The working principle and method of operation of the device is that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com