Pavement compacting vehicle

A technology of compaction device and wheel, applied in the field of road machinery, can solve the problems of slow speed, small working surface, increase the cost of road construction, etc., and achieve the effect of simple use and high compaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

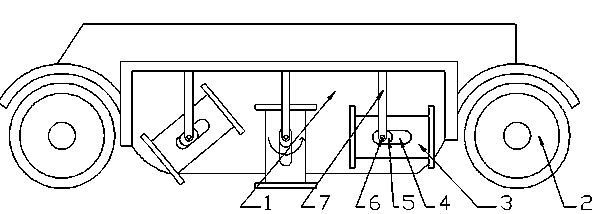

[0016] Do further description below in conjunction with accompanying drawing:

[0017] Such as figure 1 As shown, the present invention is a road compacting vehicle, the effective structure of the road compacting vehicle is a compacting device arranged in the middle of the wheel 2 of the vehicle, the compacting device is fixed on the chassis 1, and the compacting device is composed of several symmetrically distributed The vehicle chassis 1 is composed of cylindrical counterweights 3 on both sides. The tamping device also includes a number of rotating shafts 6. Two sliders 5 are fixedly connected to the rotating shafts 6. Two sliding blocks 5 are fixedly connected to the center of the counterweight 3. A groove 4 with the same width as the slider 5, the axis of the groove 4 is parallel to the central axis of the counterweight body 3, the length of the groove 4 is three times the length of the slider 5, and the slider 5 is connected to the slider 5. The groove 4 is slidingly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com