Road surface tramper

A technology of road pavement and tamping device, which is applied in the fields of soil protection, construction, infrastructure engineering, etc. It can solve the problems of affecting the service life of the machine, wasting manpower, and poor effect, so as to improve tamping efficiency, reduce operation steps, and improve The effect of automatic control rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

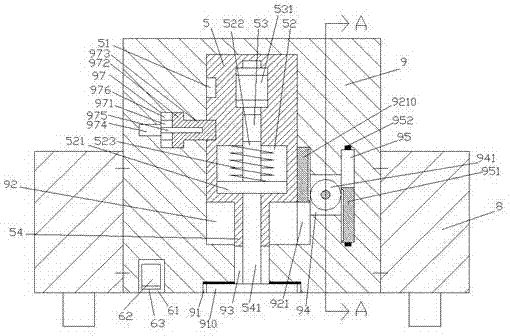

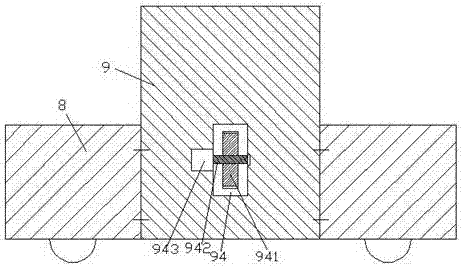

[0018] Such as Figure 1-Figure 4 As shown, a road surface tamper of the present invention includes a device body 8 and a tamping body 9 fixedly installed in the device body 8, and a first sliding cavity 92 is provided in the tamping body 9, A groove 91 is provided in the bottom end surface of the tamping body 9 directly below the first sliding chamber 92, and a sliding hole 93 is formed between the top of the groove 91 and the bottom of the first sliding chamber 92. A tamping block mechanism 5 is slidably connected to the first sliding cavity 92, and a firm locking mechanism 97 is provided on the left inner wall of the first sliding cavity 92 for locking and fitting connection with the tamping block mechanism 5. The stable locking mechanism 97 includes a locking sliding chamber 971 and a locking sliding block 973 that is slidingly fitted and connected in the locking sliding chamber 971. The inner walls of the upper and lower sides of the left section of the locking sliding ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com