Double-ramming-head small-sized compacting machine

A technology for compactors and rams, which is applied in the field of small compactors with double rams, and can solve the problems of not being able to cope well with compaction operations in changing road conditions, the machine body is not compact, and the transfer operation is inconvenient, etc. , to achieve the effect of simple structure, stable mechanism and large reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

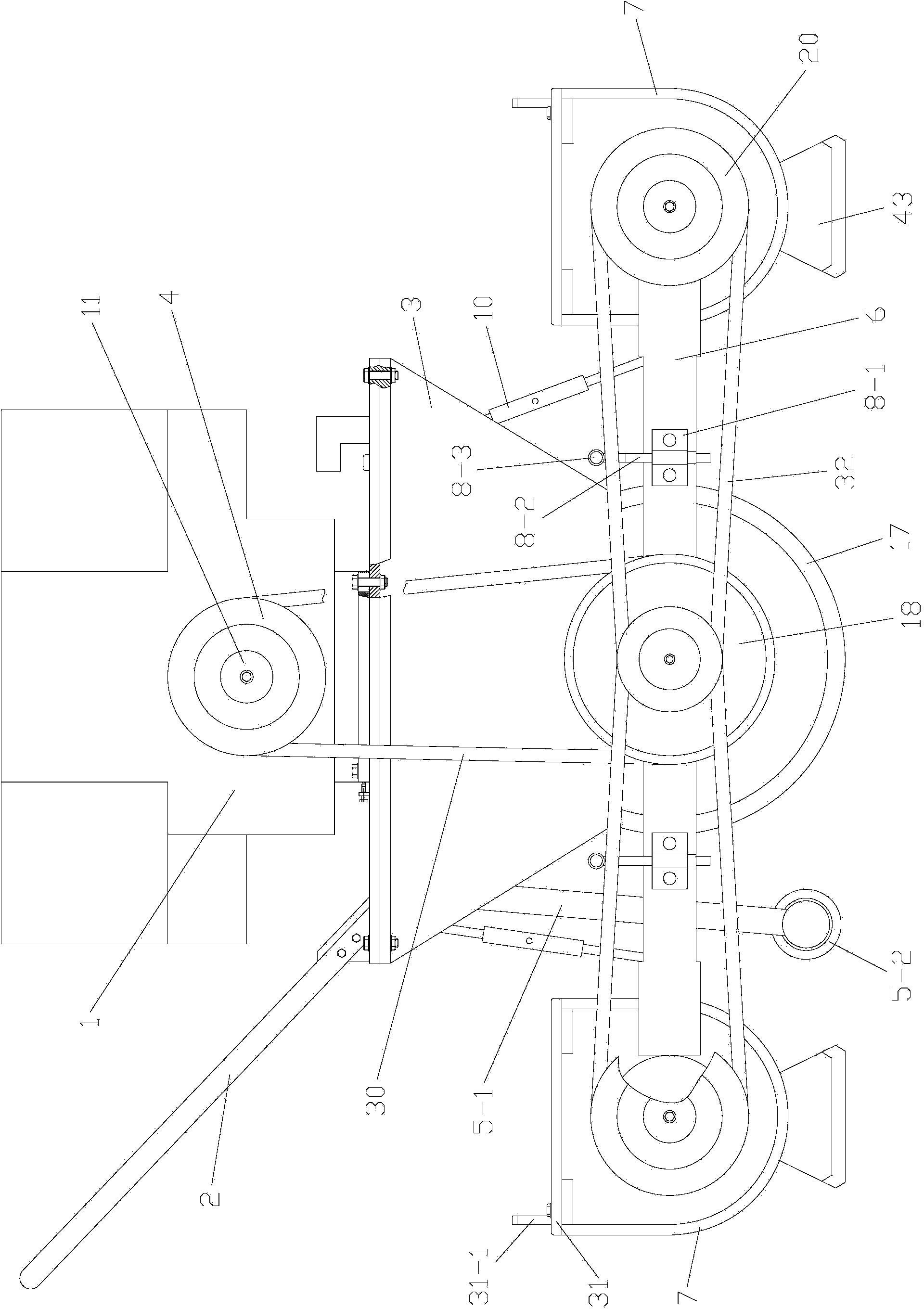

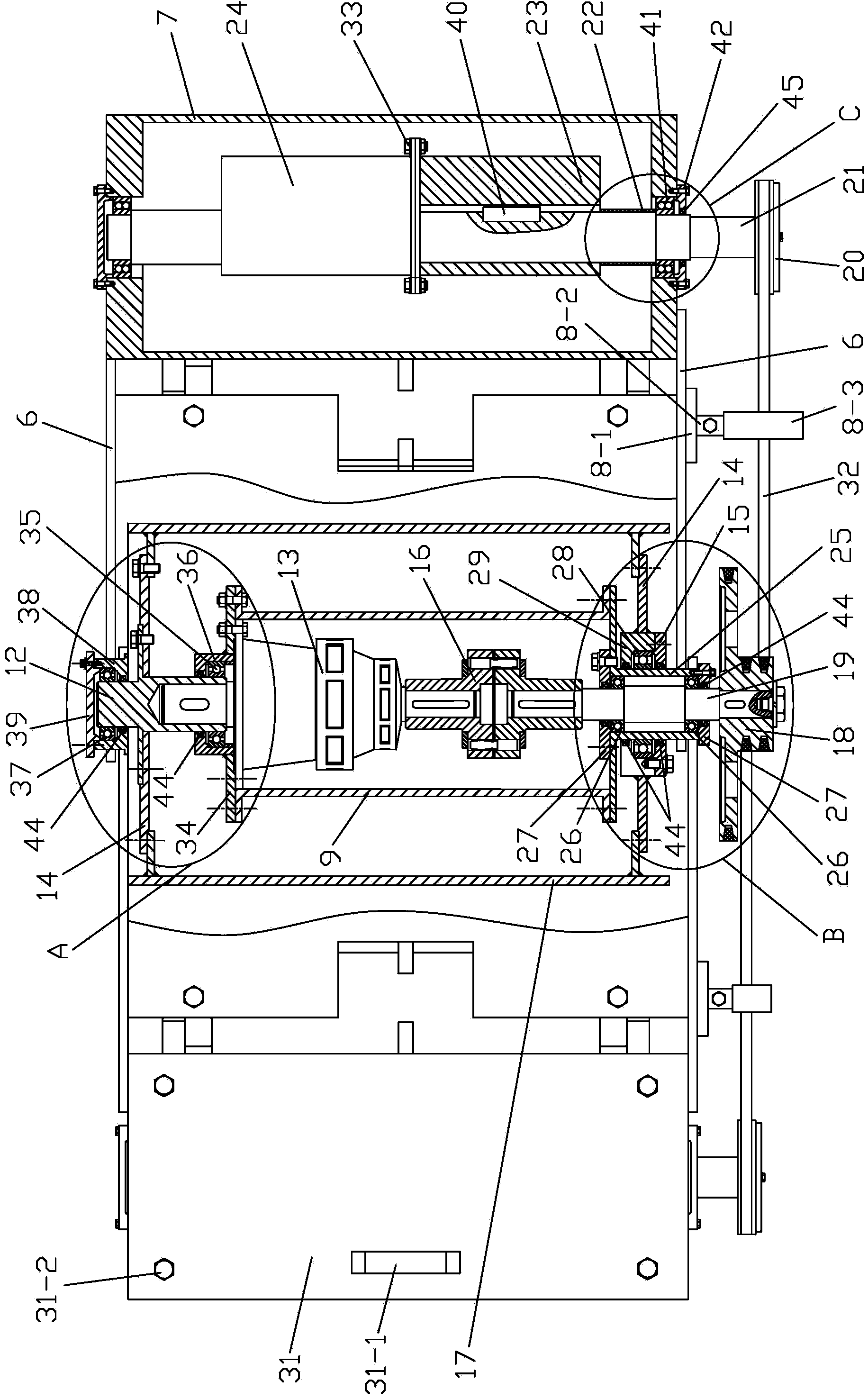

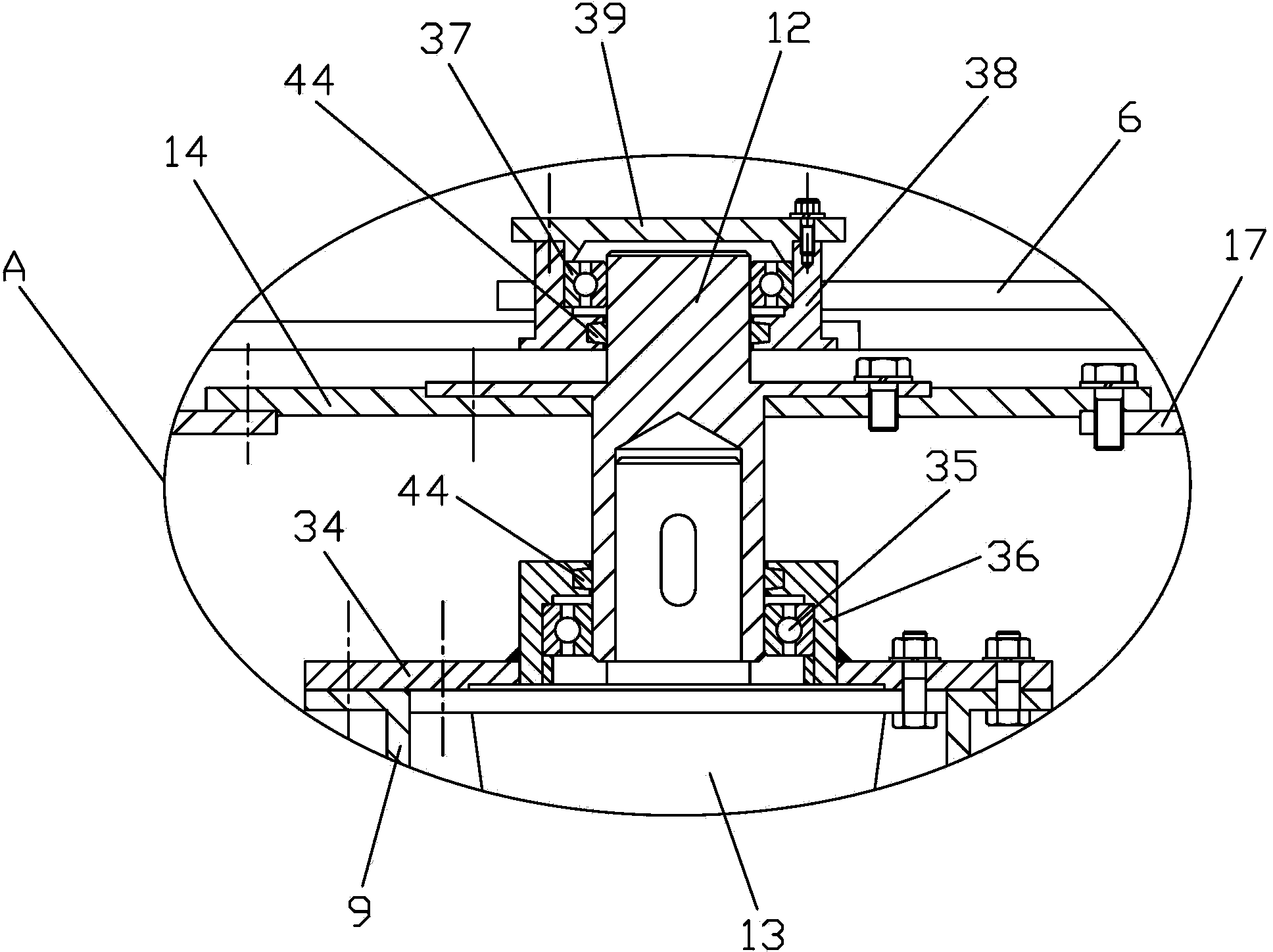

[0054] Such as Figure 1 to Figure 9 As shown, the present invention includes a frame 3, a power unit, a walking mechanism and a tamping device, the rear portion of the frame 3 is equipped with a handrail 2, the power unit includes a gasoline engine 1 and a centrifugal clutch 11, and the gasoline engine 1 is installed On the top of the frame 3, the output shaft of the gasoline engine 1 is connected to the driving part of the centrifugal clutch 11, and a pulley 4 is installed on the driven part of the centrifugal clutch 11; The road wheel 17 at the bottom and the high-speed shaft 19 axially arranged on the right part of the road wheel 17, the right end of the high-speed shaft 19 passes through the road wheel 17 and the end is equipped with a large pulley 18, and the large pulley 18 passes through The first belt 30 is connected with the pulley 4 to form the first belt transmission; the quantity of the tamping device is two and the two tamping devices are respectively arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com