Real-time asphalt road compactness monitoring method

A real-time monitoring technology for asphalt pavements, applied in roads, roads, road repairs, etc., can solve problems such as difficulty in ensuring construction quality requirements, imperfect compaction monitoring methods, etc., achieve high promotion and application value, shorten detection costs, and realize low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

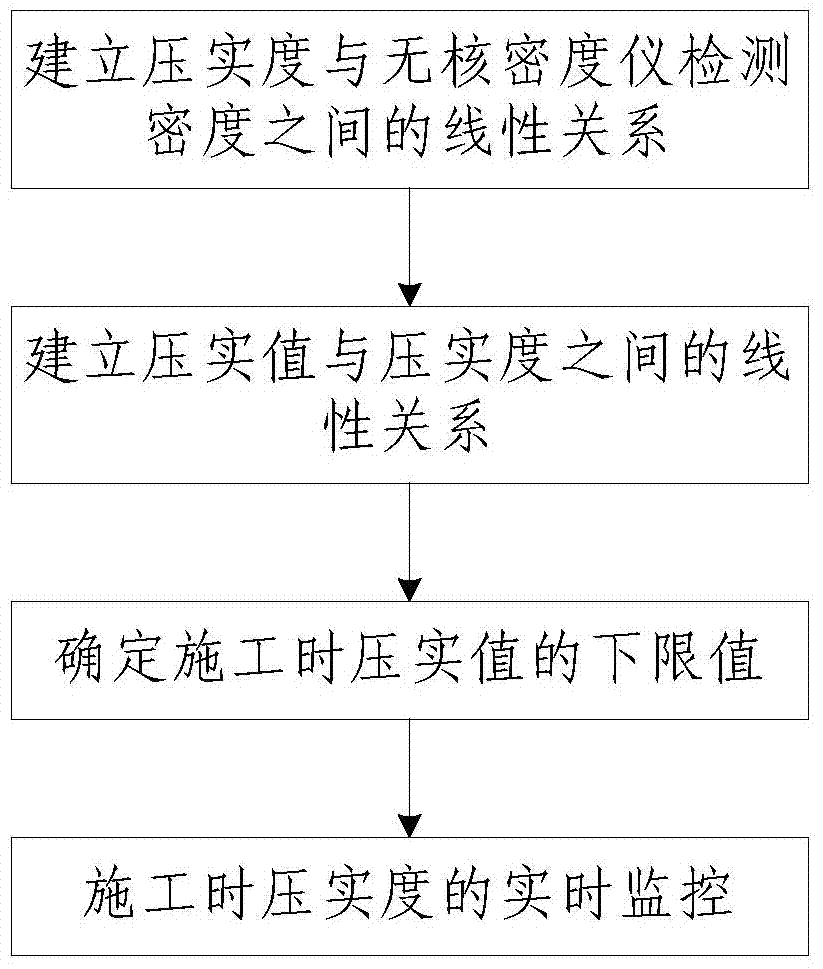

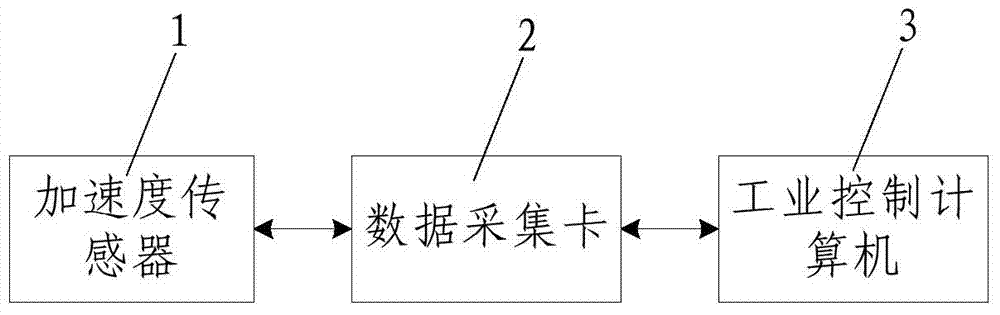

[0034] Such as figure 1 and figure 2 Shown, the asphalt pavement compactness real-time monitoring method of the present invention comprises the following steps:

[0035] Step 1. Establish a linear relationship between the degree of compaction and the detection density of the non-nuclear density meter. The specific process is:

[0036] Step 101. First, prepare a plurality of rutting slabs with different compaction degrees in the laboratory using the pavement material of asphalt pavement, and then detect the density of each rutting slab with a non-nuclear density meter;

[0037] In this embodiment, the number of rutting plates in step 101 is 3-5.

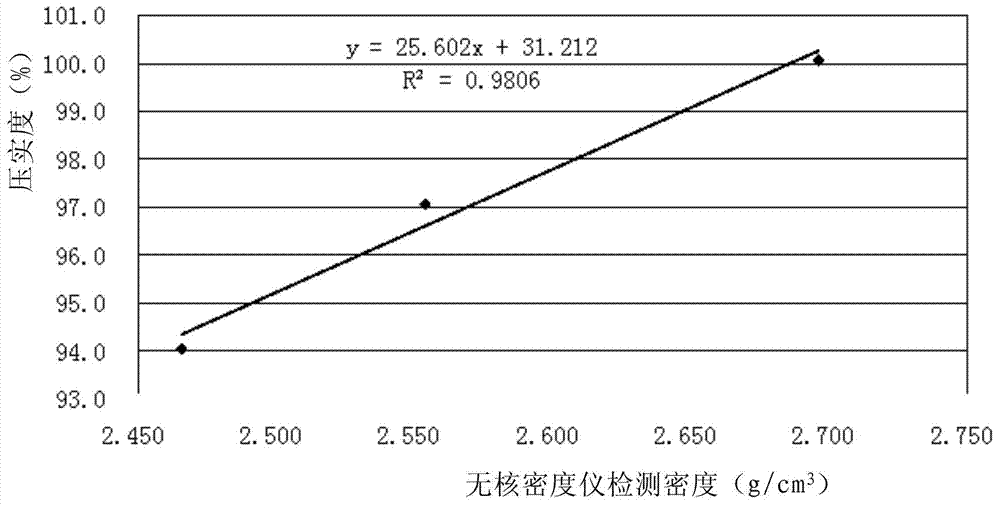

[0038] Step 102, take the density detected by the non-nuclear density meter as the abscissa, and the degree of compaction of the rutting plate as the ordinate, draw a relationship curve between the density detected by the non-nuclear density meter and the degree of compaction, and perform a calculation on the drawn relationship cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com