Patents

Literature

93results about How to "Improve compaction quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

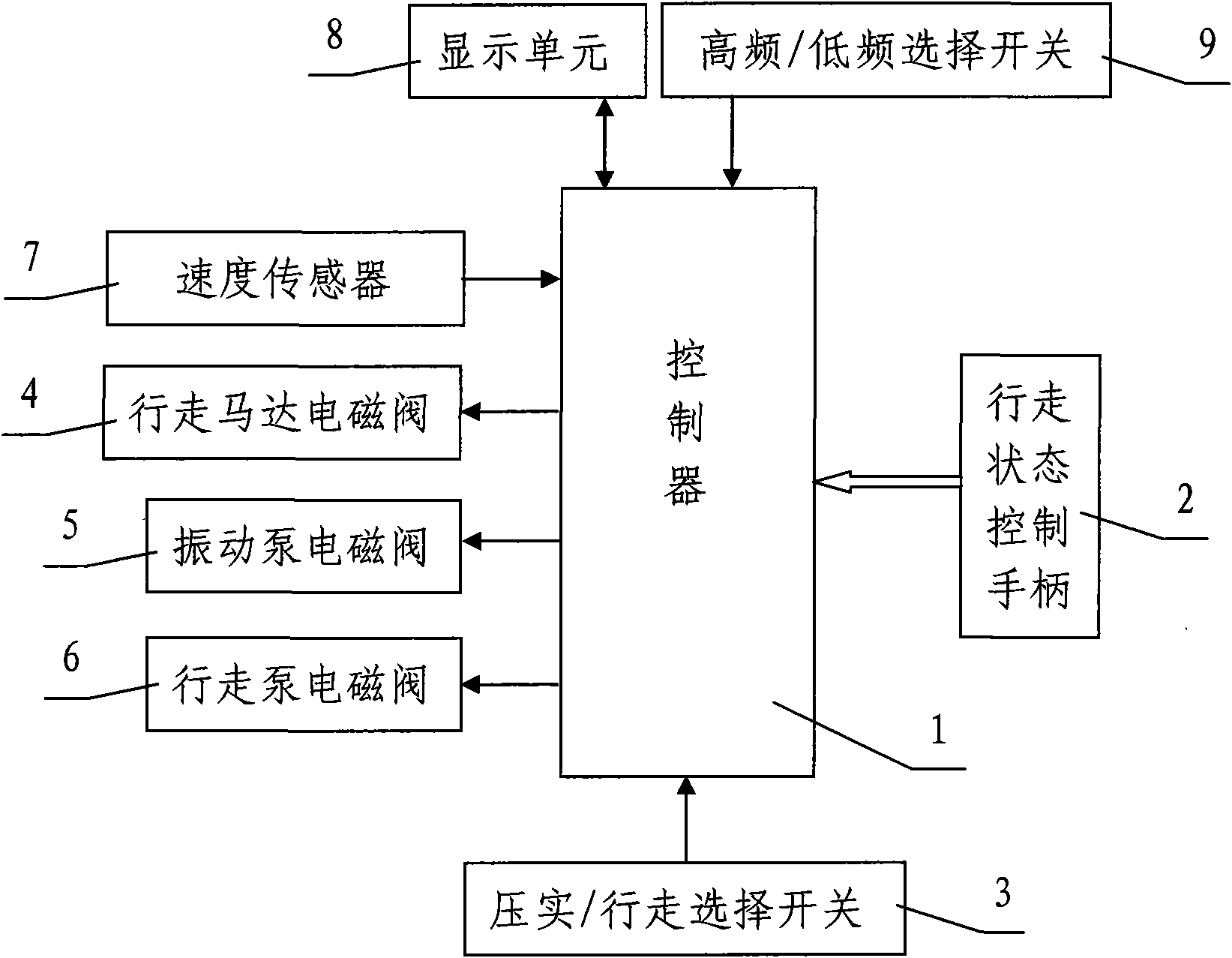

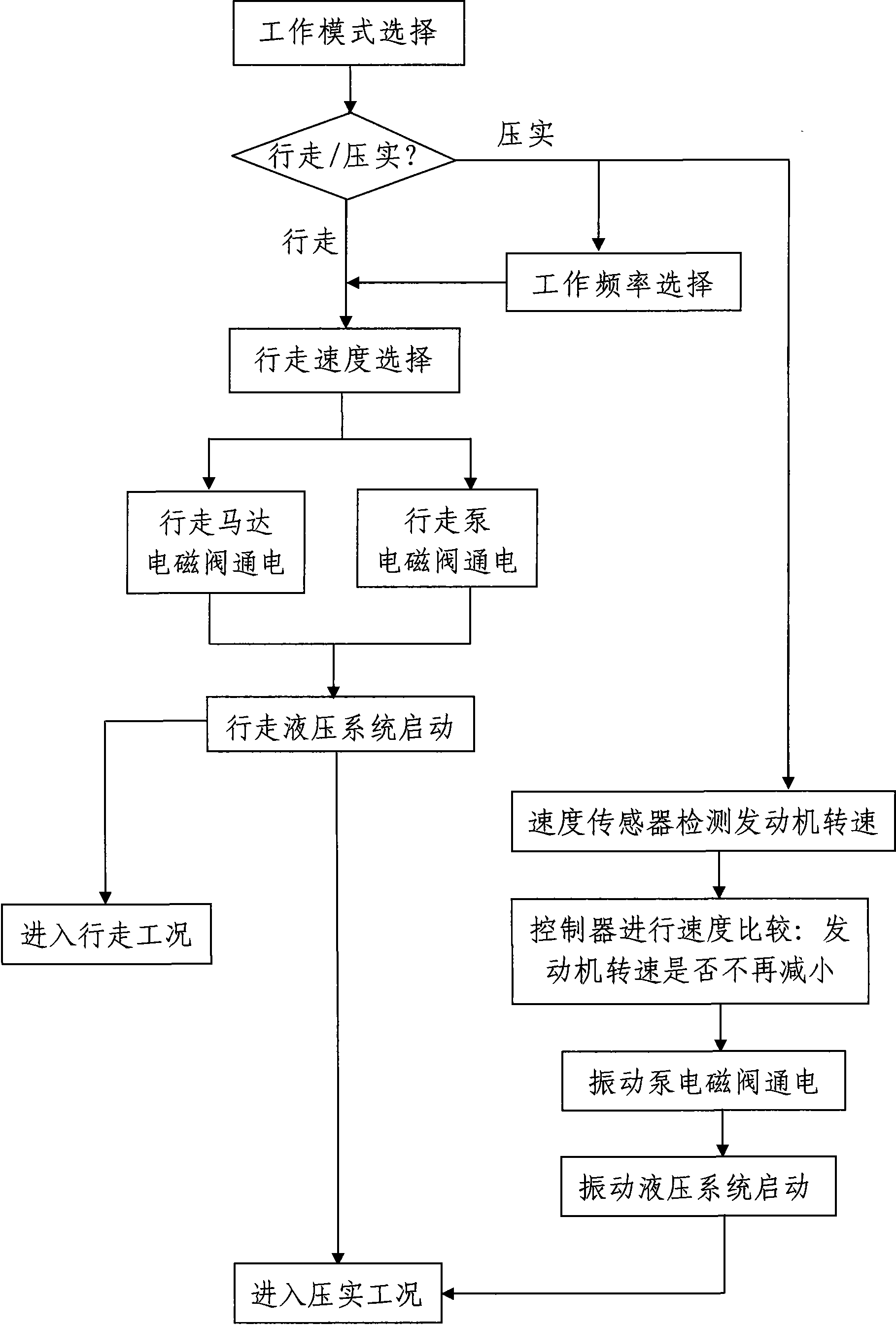

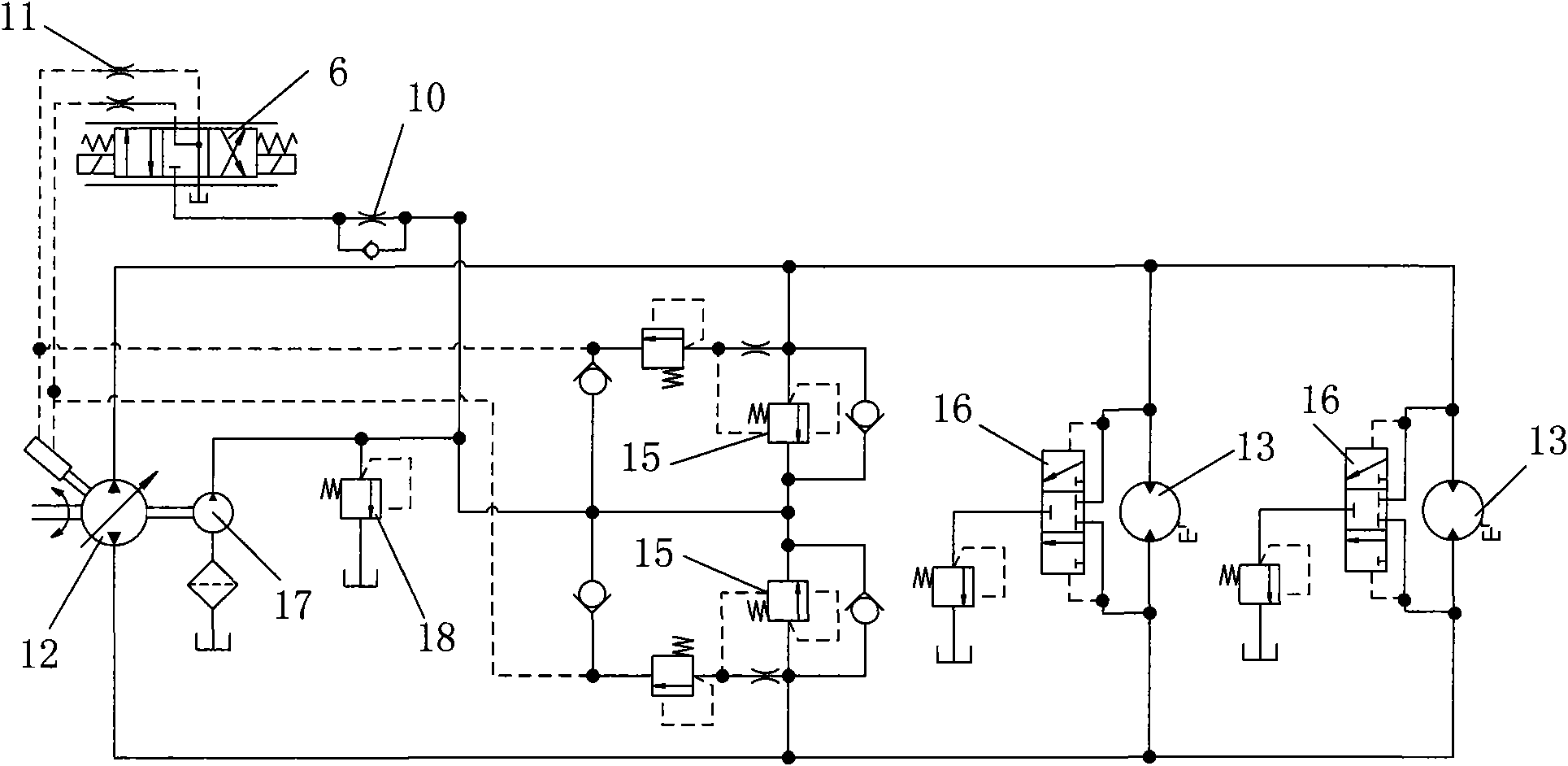

Power matching control system for novel energy-saving double-drum vibratory roller

InactiveCN101576738AInnovative designReasonable designRoads maintainenceProgramme control in sequence/logic controllersStart timeControl system

The invention discloses a power matching control system for a novel energy-saving double-drum vibratory roller. The power matching control system comprises a controller, a travel state control device, a frequency adjusting switch, a compaction / travel selection switch of the travel state and the compaction state of a roller and a speed sensor for detecting the rotate speed of an engine of the roller in real time, wherein a travel pump electromagnetic valve and a travel motor electromagnetic valve are controlled by the controller; a vibratory pump electromagnetic valve is connected with the controller which staggers the power peak values of a travel mechanism hydraulic drive system and a vibratory compaction hydraulic drive system by controlling the starting time of the vibratory pump electromagnetic valve; moreover, when the roller is in compaction work mode, the vibratory pump electromagnetic valve is correspondingly controlled and started by the controller according to a signal detected by the speed sensor. The power matching control system has reasonable design, simple use and operation, reliable performance and good use effect; moreover, the control system can effectively reduce the installed power of the vibratory roller, reduce power consumption and save use cost while reliably restraining the momentary power of the travel system and the vibratory system of the roller.

Owner:CHANGAN UNIV

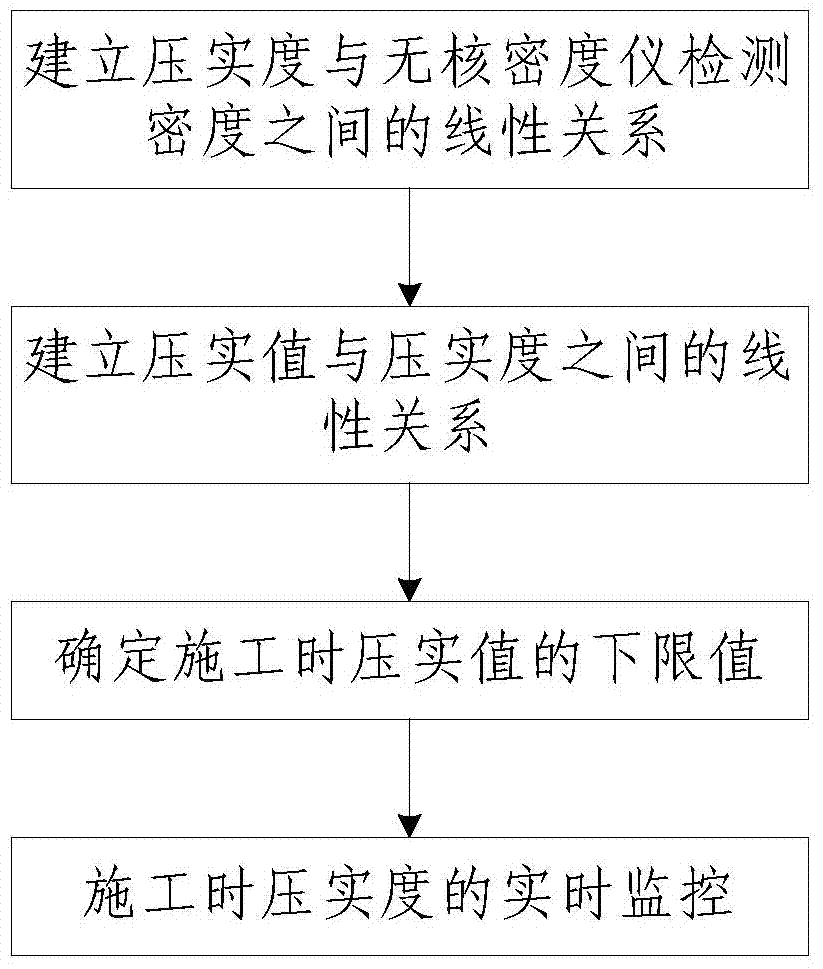

Real-time asphalt road compactness monitoring method

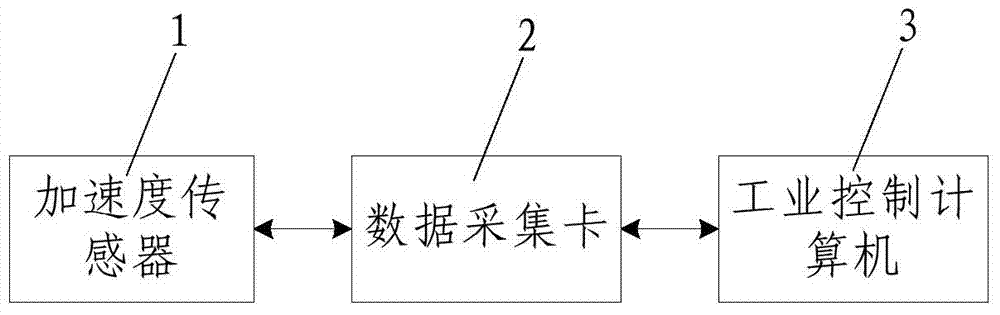

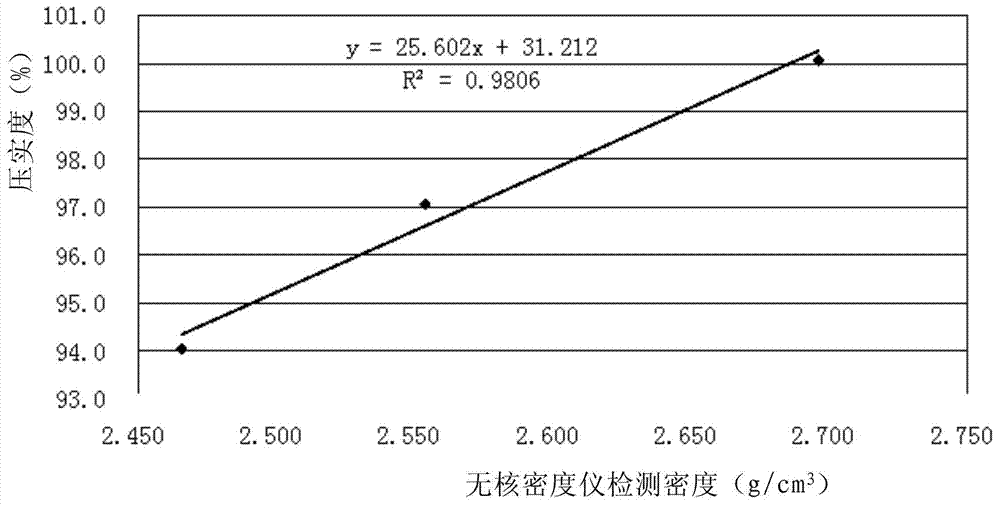

InactiveCN103487351ASimple monitoring methodNovel and reasonable designRoads maintainenceProgramme control in sequence/logic controllersLower limitEngineering

The invention discloses a real-time asphalt road compactness monitoring method which comprises the steps of (1) establishing a linear relation between compactness and detection density of a non-nuclear density gauge; (2) establishing a linear relation between a compaction value and the compactness; (3) according to the lower compactness limit requirement of a construction site and according to the linear relation between the compaction value and the compactness, established in the step (2), determining the lower limit of the compaction value; (4) monitoring the compactness in construction in real time, enabling an vibratory roller operator to control a vibratory roller through observing the compacted or uncompacted information displayed on an industrial control computer, continuously rolling when in uncompaction, and stopping rolling when in compaction. The real-time asphalt road compactness monitoring method is novel and reasonable in design, convenient to realize, capable of improving the compaction quality and efficiency of an asphalt road and avoiding damage to the road, relatively high in compactness detection accuracy, low in realization cost, strong in practicability, and high in popularization and application values.

Owner:CHANGAN UNIV +1

Low-energy-consumption asphalt concrete pavement hot in-place recycling method

ActiveCN106192700AReduce fuel consumptionGuarantee the construction qualityRoads maintainencePavement maintenanceRoad surface

The invention provides a low-energy-consumption asphalt concrete pavement hot in-place recycling method to solve the problems existing in the pavement heating process of three heating machines in an existing hot in-place recycling technology, and belongs to the technical field of asphalt concrete pavement maintenance. The method includes the steps of pavement sweeping, guide line drawing, pavement heating, pavement milling and planing, regenerant and new asphalt adding, recycled mixture re-stirring and paving, pavement compaction, high-permeability asphalt spraying to seal a recycled pavement and the like. Two heating machines are adopted for heating the pavement in a gradient heating manner, and the phenomenon that the pavement is heated to be too hot under the condition that the temperature of the pavement is high in summer or in South China is avoided; and for a road section aging seriously, after hot recycling construction is finished, the service life of the pavement is prolonged in a high-permeability asphalt spraying manner.

Owner:河北森远路桥工程有限公司

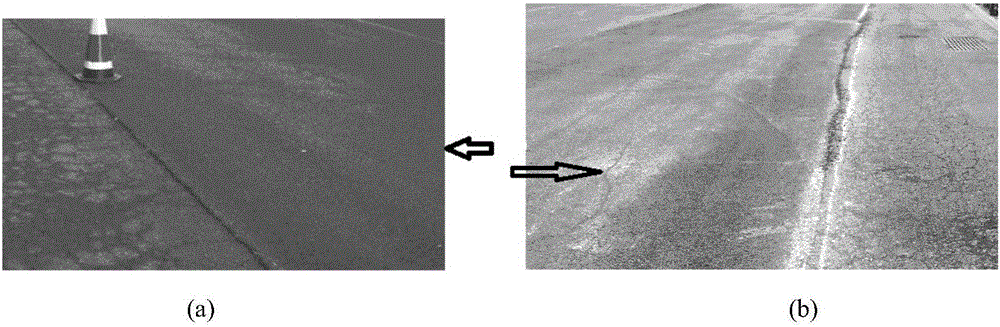

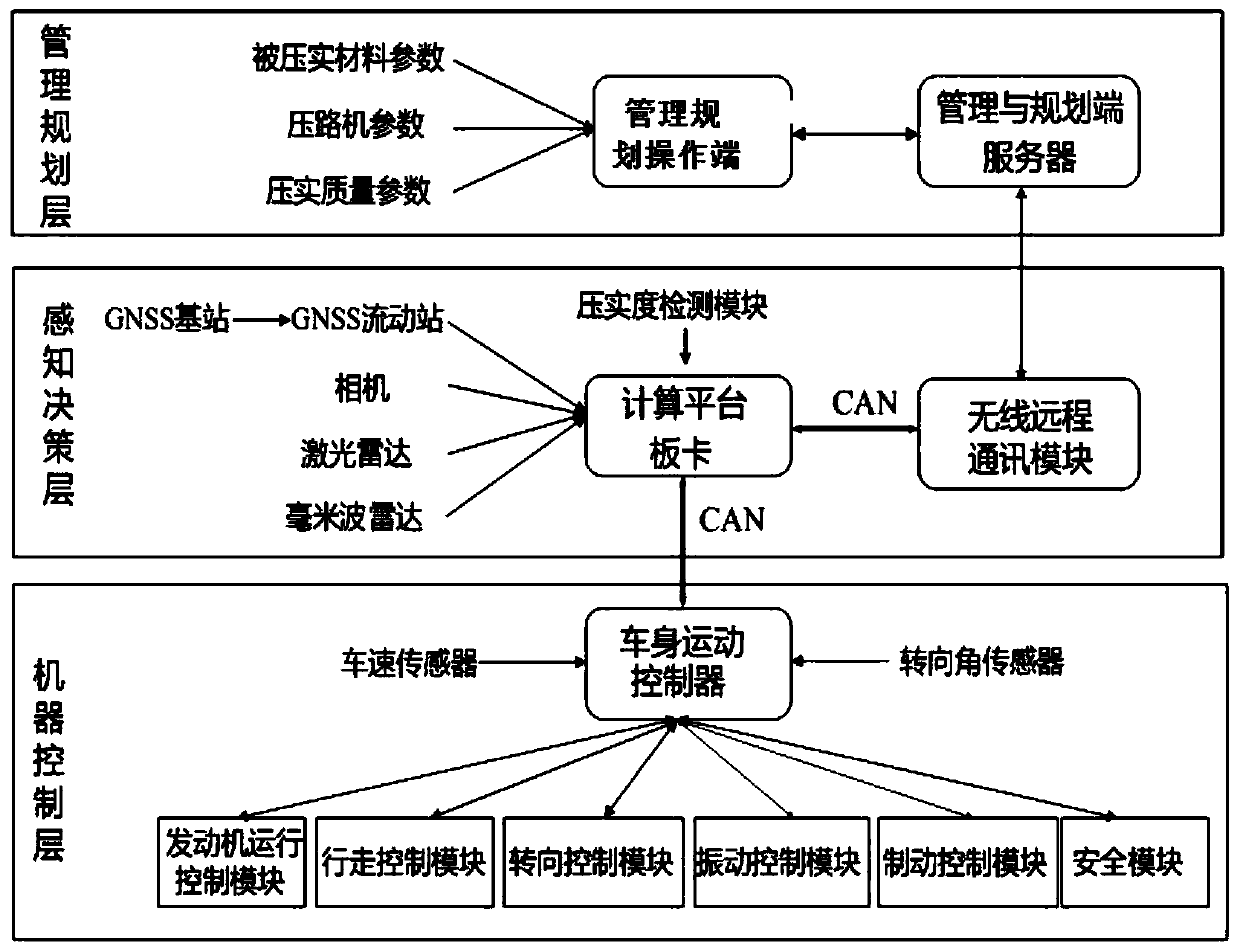

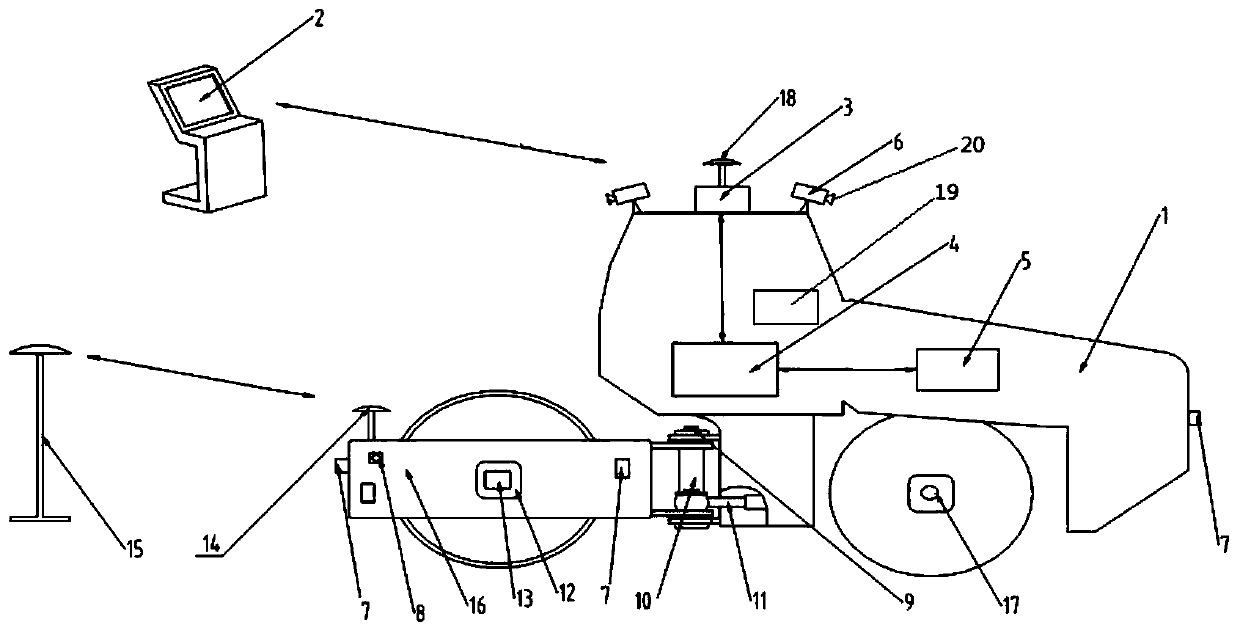

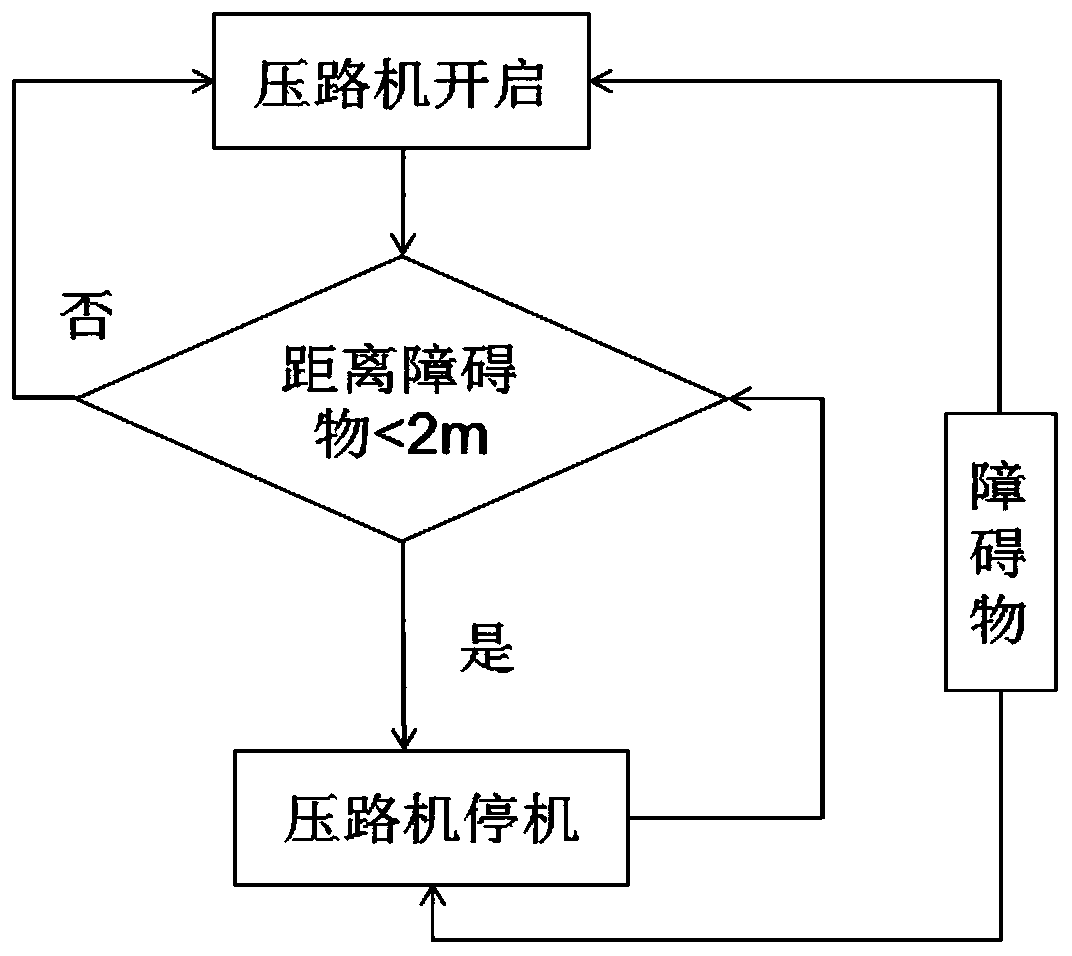

Autonomous operation intelligent road roller system

ActiveCN110331639AReduce harmReduce or get rid of dependenceSatellite radio beaconingMaterial testing goodsManagement planningEngineering

The invention discloses an autonomous operation intelligent road roller system comprising a road roller body, a machine control layer for controlling the motion of the road roller body, a perceive decision layer and a management planning layer; a carrier phase differential technology GNSS is adopted to realize high-precision positioning and course measurement; the vehicle body is provided with a millimeter wave radar for detecting obstacles in the periphery of the vehicle body; the vehicle body is provided with a laser radar and a camera used for high-precision map construction and side slopedetection of a rolling area, so that a management planning end can carry out rolling operation planning; an onboard compaction degree online detection technology is adopted to realize full-coverage online detection of the compaction degree, and a basis is provided for frequency modulation amplitude modulation; an expert system and a big data system are internally arranged in the management planning end, rolling planning can be autonomously performed according to the characteristics of the construction site compacted material, the parameters of the road roller, the compaction degree informationand the high-precision map, and cluster compaction data sharing and collaborative operation is realized; the vibration energy output can be adjusted in real time by the road roller according to the compaction progress, and the compaction quality and efficiency are effectively improved.

Owner:CHANGAN UNIV

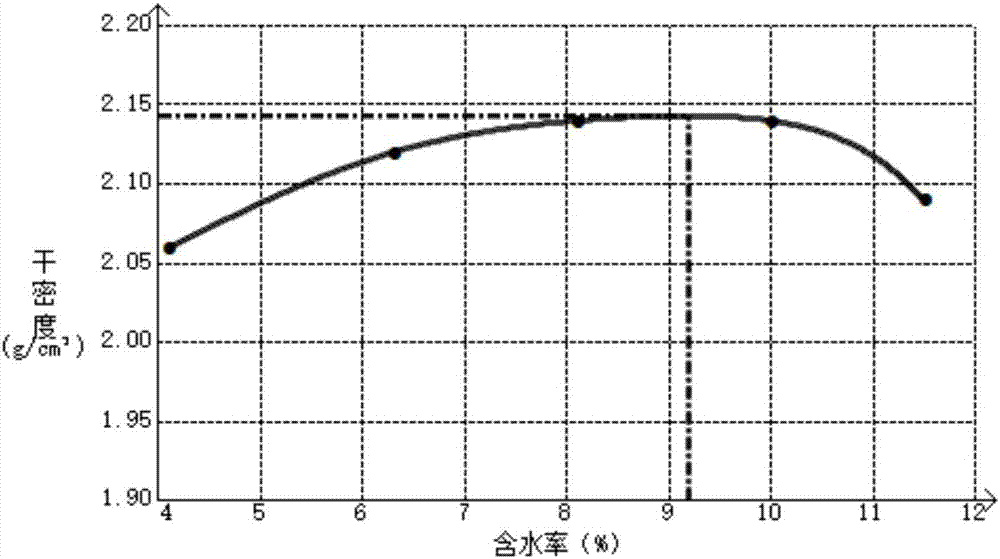

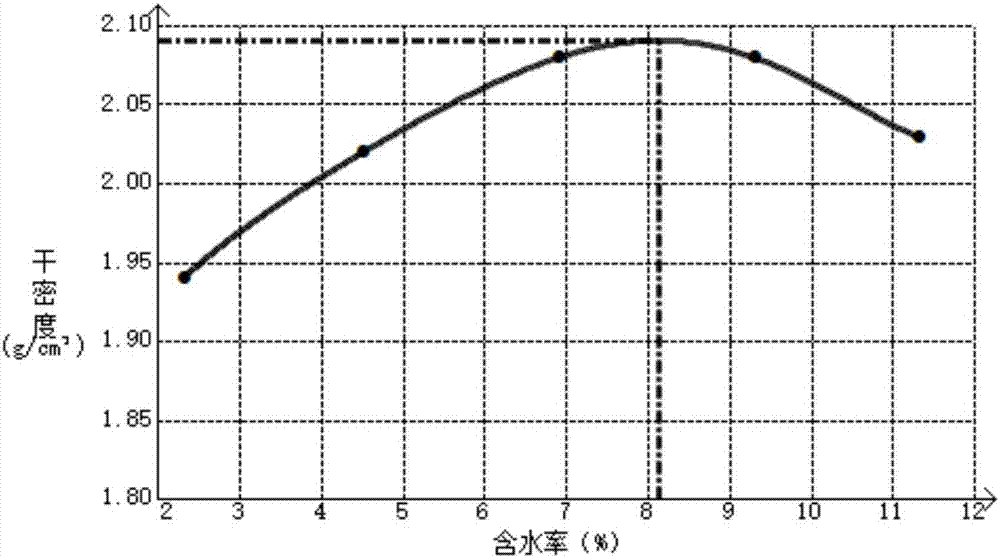

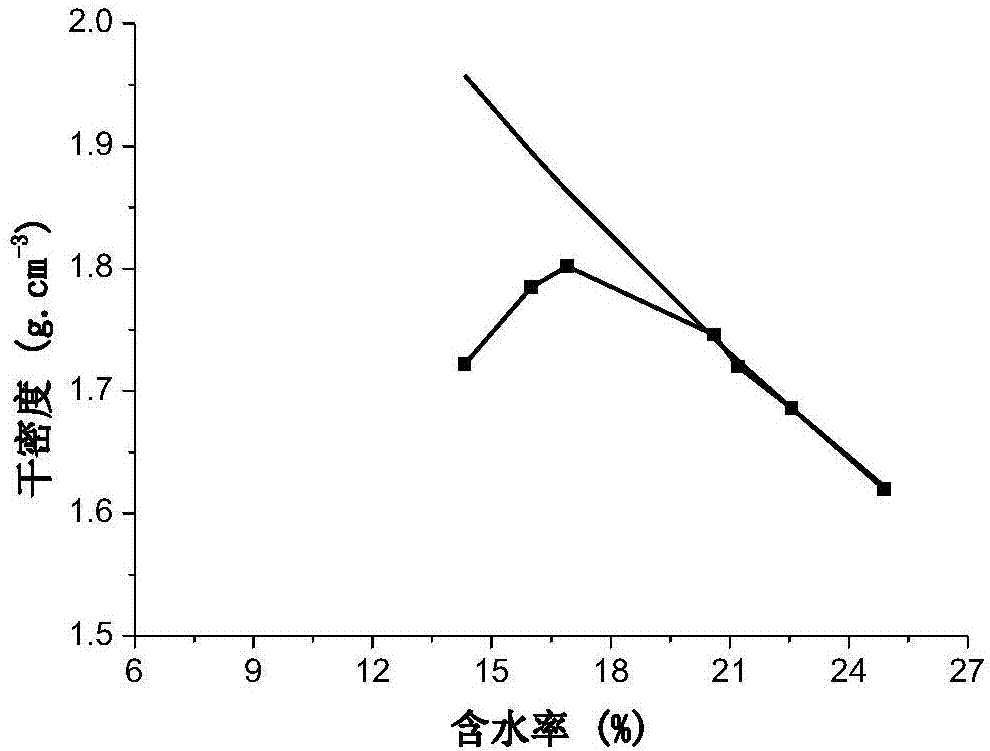

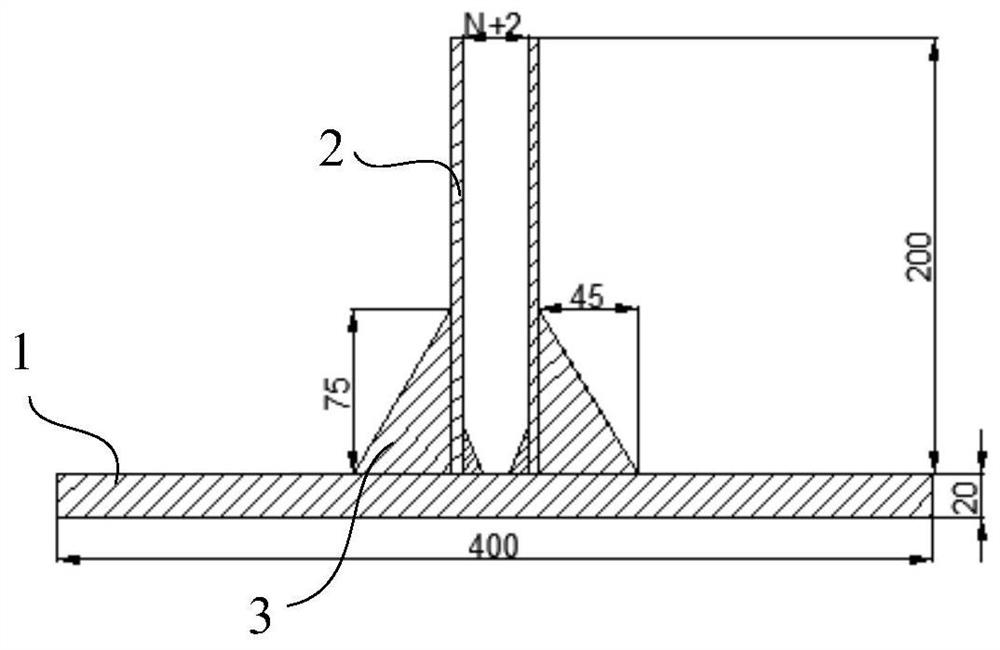

Test method for measuring maximum dry density of soil and stone mixture of road subgrade

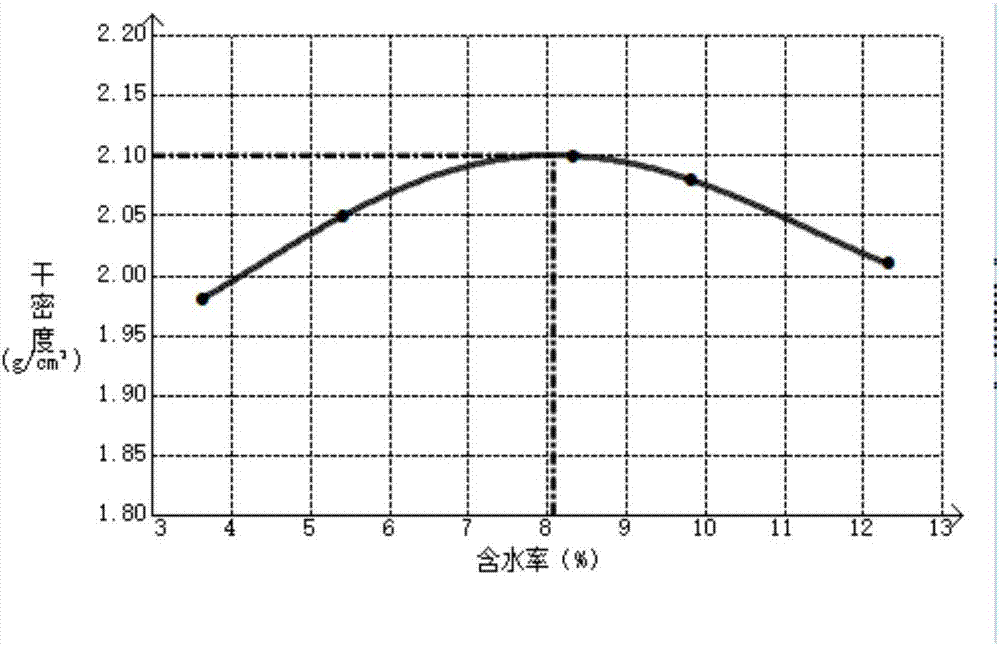

InactiveCN107219151ASmall difference in compactionEnsure complete removalPreparing sample for investigationSpecific gravity measurementVibration amplitudePeak value

The invention discloses a test method for measuring maximum dry density of soil and stone mixture of a road subgrade. The test method comprises the following steps of loading samples into a test die by two times, fixing onto a vibration compaction test instrument, and performing vibration compaction for two times, wherein the vibration compaction time is 50s each time, the parameter setting of the compaction test instrument is as follows: the vibration frequency is 25Hz, the excitation vibration force is 5.5kN, the nominal vibration amplitude is 1.4mm, the loading mass is 110+ / -2kg, the unloading mass is 170+ / -2kg, the eccentric block included angle is 0 degree, and the pressure of the static surface is 109kPa; testing the water content of each sample, and calculating the dry density of each sample; repeating the compaction test for five times, and drawing the dry density-water content relationship curve, wherein the transverse coordinate is the water content, and the longitudinal coordinate is the dry density; the dry density corresponding to the curve peak is the maximum dry density roudmax, and the corresponding water content is optimum water content omega0. The test method has the advantages that the operation is simple and convenient, the results are reliable, the variance is small, and the destroy to the raw materials is small.

Owner:CHANGAN UNIV +1

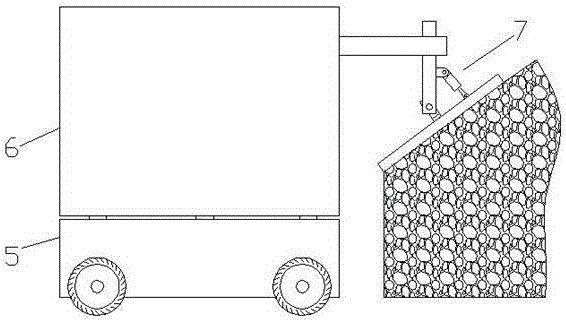

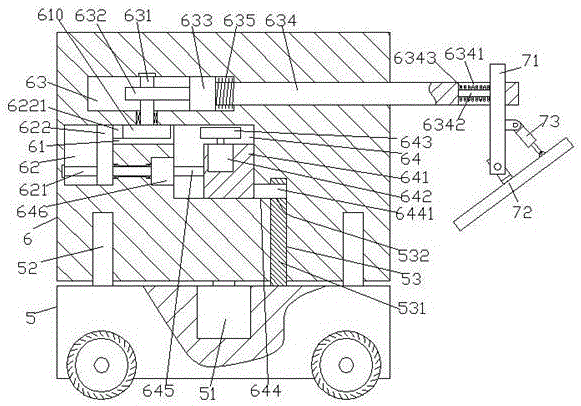

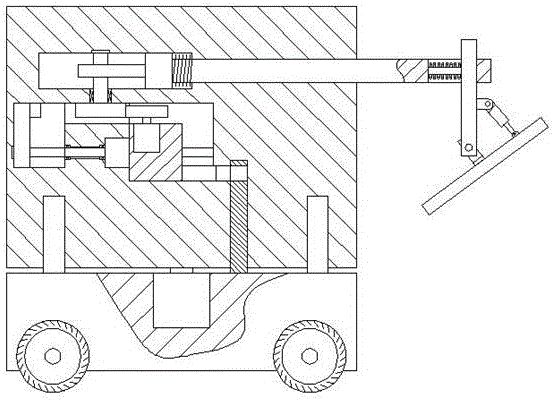

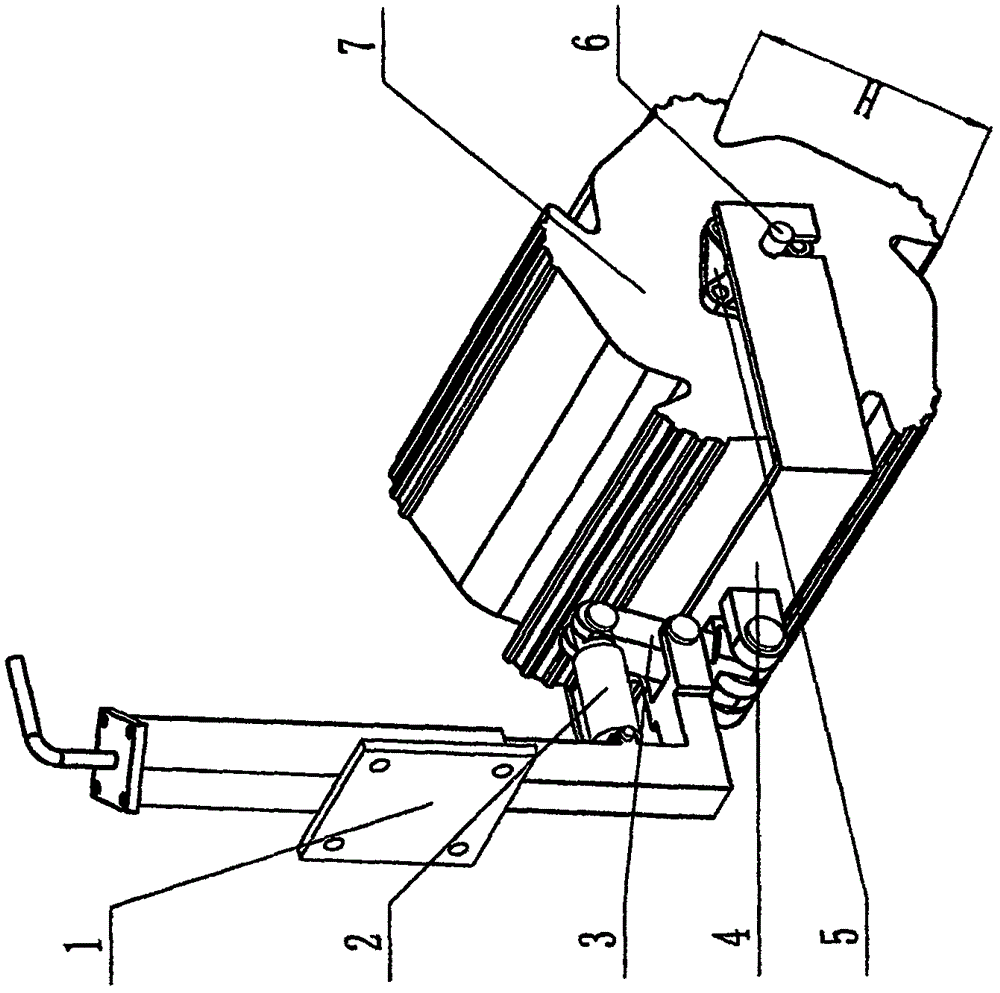

Roadbed slope compaction device

ActiveCN107524135ARealize automatic controlImprove work efficiencySoil preservationMechanical engineeringSubgrade

The invention discloses a roadbed slope compaction device. The roadbed slope compaction device comprises a mobile car body, and a compaction machine body arranged at the top of the mobile car body; a hydraulic lifting mechanism fixedly connected with the bottom end surface of the compaction machine body by the top is arranged in the top end surface of the mobile car body; first guide rods slidingly matched and connected with the compaction machine body are symmetrically arranged on the top end surface of the mobile car body on the left and right sides of the hydraulic lifting mechanism; a pushing slide cavity is formed in the compaction machine body; a first cavity is formed in the inner wall of the compaction machine body below the pushing slide cavity; the left and right sides of the first cavity respectively communicate with a second cavity and a third cavity downwards extending; a first rotating shaft extending up and down is arranged in the pushing slide cavity; the extension tail end of the top of the first rotating shaft is rotationally matched and connected with the inner top wall of the pushing slide cavity; and the bottom extension section of the first rotating shaft penetrates through the inner wall of the compaction machine body between the pushing slide cavity and the first cavity for rotary matching and connection. The roadbed slope compaction device is simple in structure and convenient to operate, reduces manual operations, and improves the compaction working efficiency.

Owner:山东鲁中公路建设有限公司

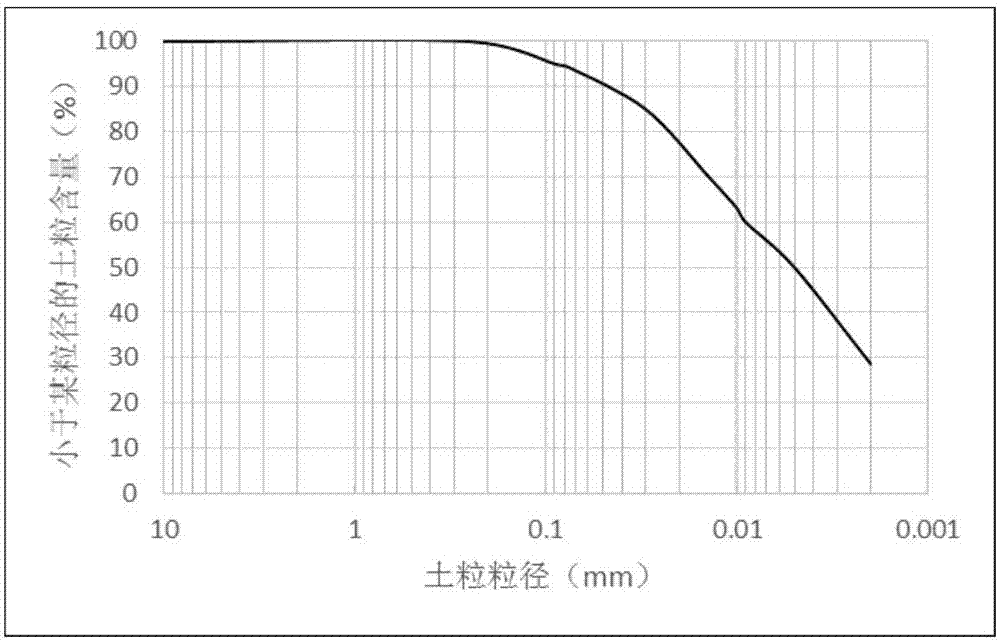

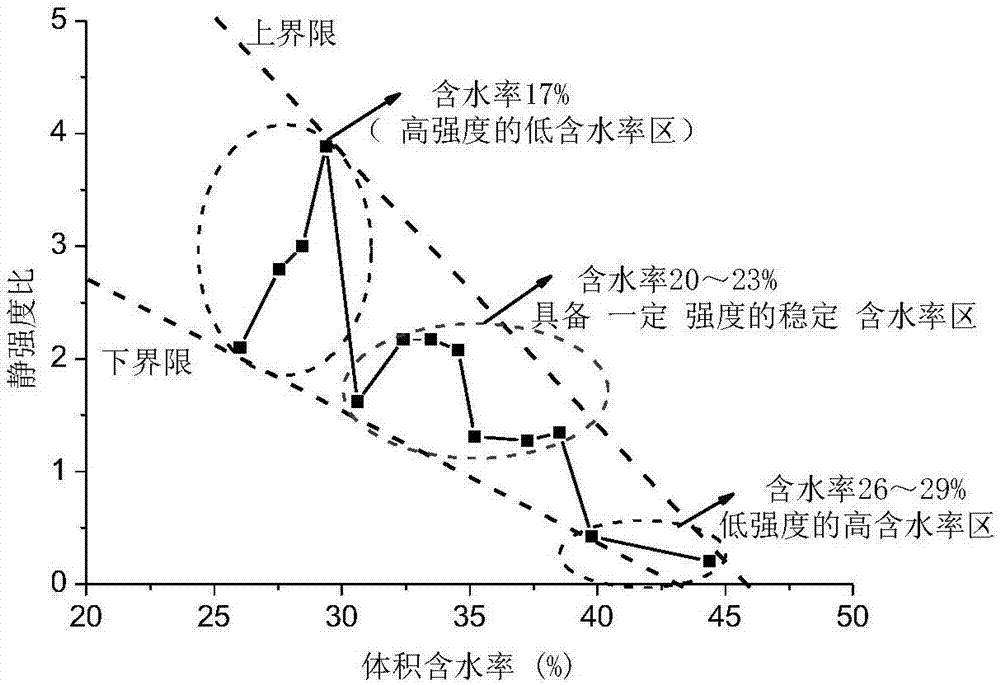

Guidepost determination method and rolling and compacting technology for rolling of high liquid limit clay road embankment in yellow river flood area

ActiveCN107476158AImprove compaction qualityImprove compact strengthRoadwaysSurface finishUltimate tensile strength

The invention discloses a guidepost determination method and a rolling and compacting technology for rolling of a high liquid limit clay road embankment in the yellow river flood area. Economical and efficient soil moisture content and compacting degree guideposts are proposed based on the physical mechanical properties of the high liquid limit clay in the yellow river flood area: the target moisture content range in the filling road embankment area is from the optimum moisture content W<opt>-2% to W<opt>+6%, and the compacting degree is not lower than 88%; in order to reach the guidepost, soil sampling and sun-curing of road embankment filling are organized reasonably and orderly, the compacting technology that a smooth-wheel roller suitable for a clay road embankment conducts static compacting for one time, a cam roller conducts strong vibration for four times and a rubber-tyred roller conducts surface finishing for one time is adopted, the compacting quality of the road embankment is improved obviously, the compacting strength of the road embankment is improved, and the problems that construction of the high liquid limit clay road embankment is difficult in rolling and compacting and the filling guidepost is not clear are solved. The filling guidepost determination method is economical, rapid and obvious in compacting effect, and has wide application prospects on filling of the high liquid limit clay road embankment.

Owner:SHANDONG UNIV

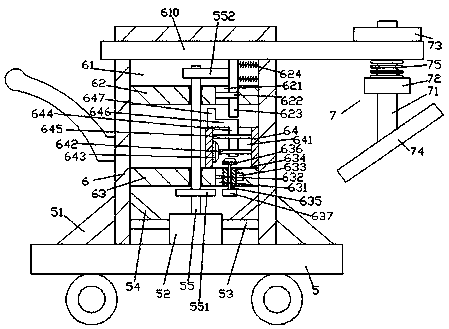

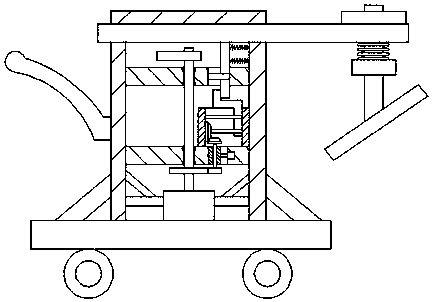

Miniature road tamping device

ActiveCN107700317ASimple structureEasy to operateRoads maintainenceMechanical engineeringBuilding construction

The invention discloses a miniature road tamping device. The miniature road tamping device comprises a load vehicle body and a tamping machine body which is fixedly mounted in the load vehicle body, wherein a first sliding slot which extends downwards and penetrates through the bottom end surface of the tamping machine body is formed in the tamping machine body; a transmission slot is formed in the inner wall of the left side of the first sliding slot in a communicating manner; a slide guiding slot is formed in the top wall in the transmission slot in the communicating manner; a transmission chamber which extends leftwards is formed in the wall body in the tamping machine body, on the upper side of the slide guiding slot; an adjustment driving chamber is formed in the wall body in the tamping machine body, on the left side of the transmission slot; the tail end of the top of the adjustment driving chamber is located right below the left extending segment of the transmission slot; a first siding rod which is rectangular and extends downwards is in sliding fit connection to the first sliding slot; the extending tail end at the bottom of the first sliding rod extends out of the bottomend surface of the tamping machine body; and a tamping head is fixedly arranged at the tail end. The miniature road tamping device disclosed by the invention is simple in structure and convenient tooperate, different tamping work demands can be met, and the tamping quality is improved; and besides, the construction efficiency is greatly improved, and the construction cost is reduced.

Owner:徐州山美环保科技发展有限公司

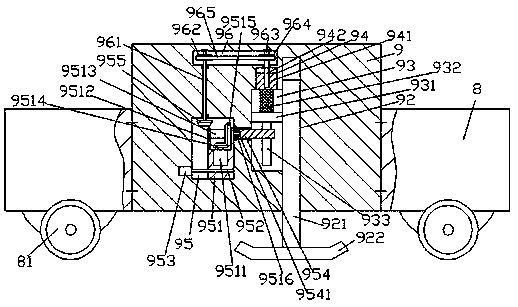

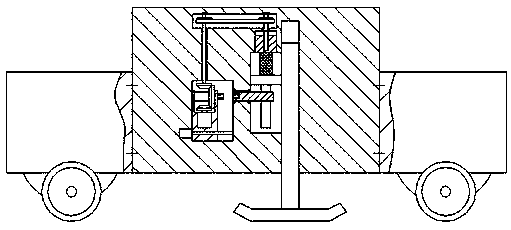

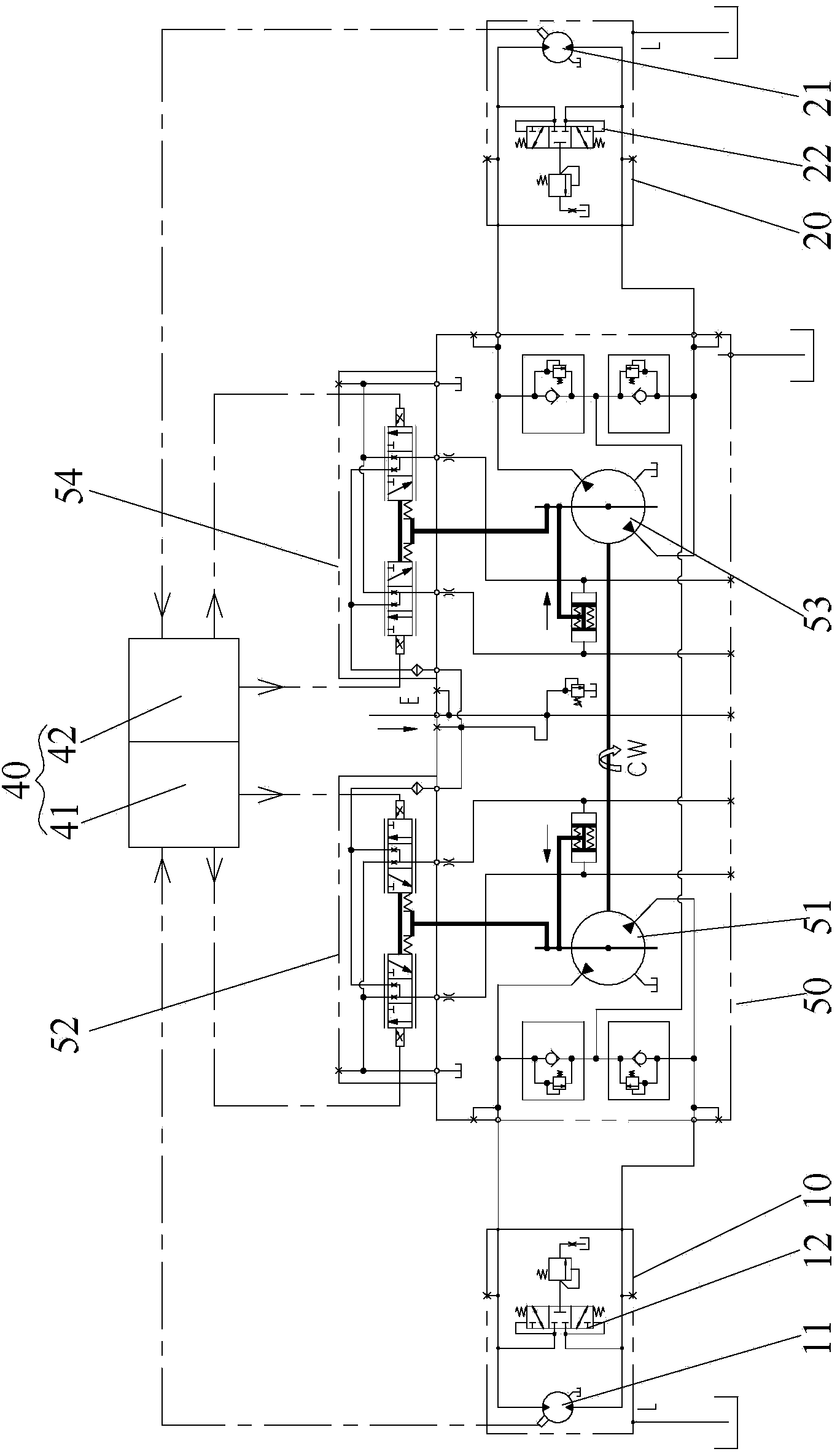

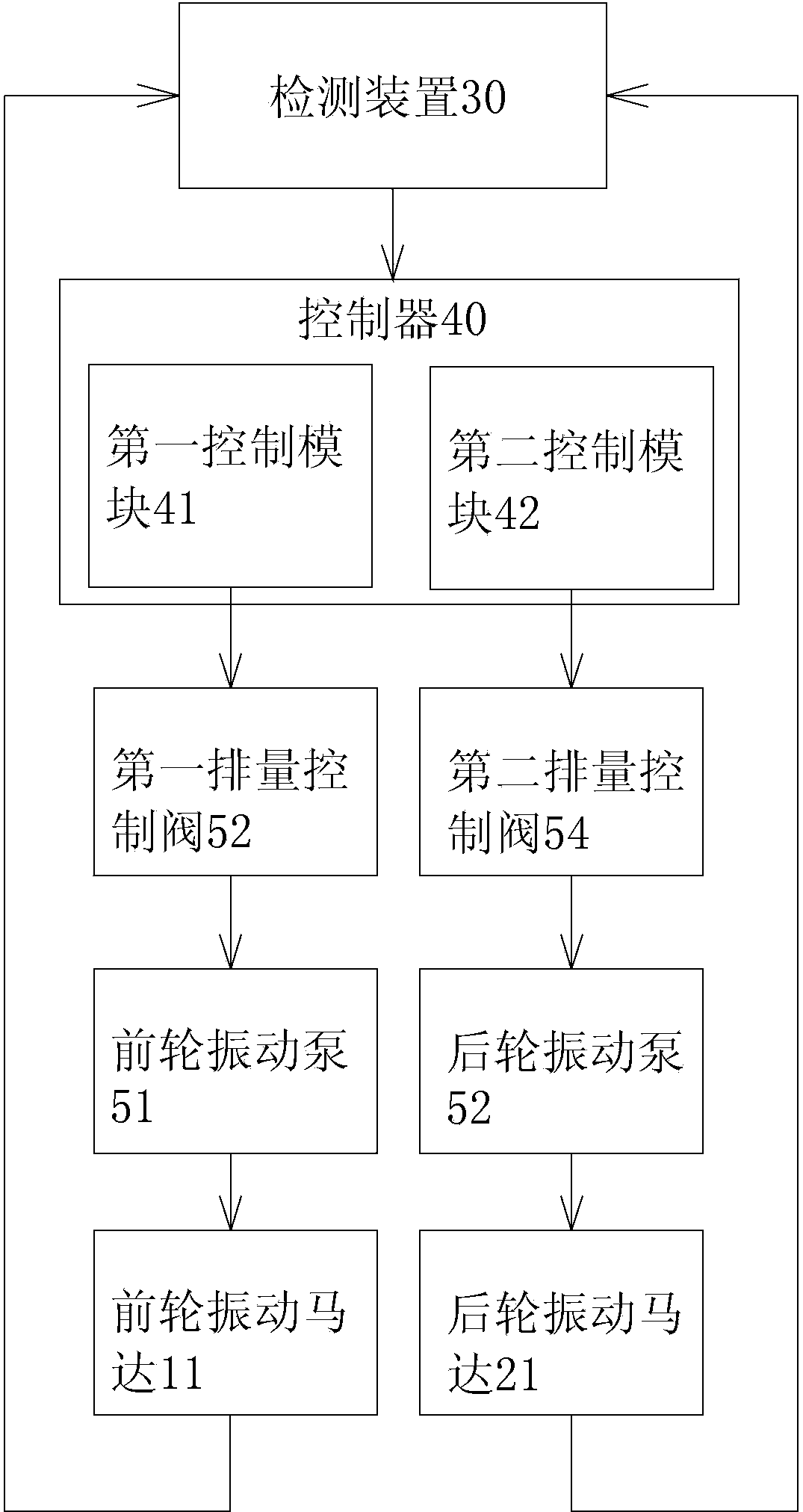

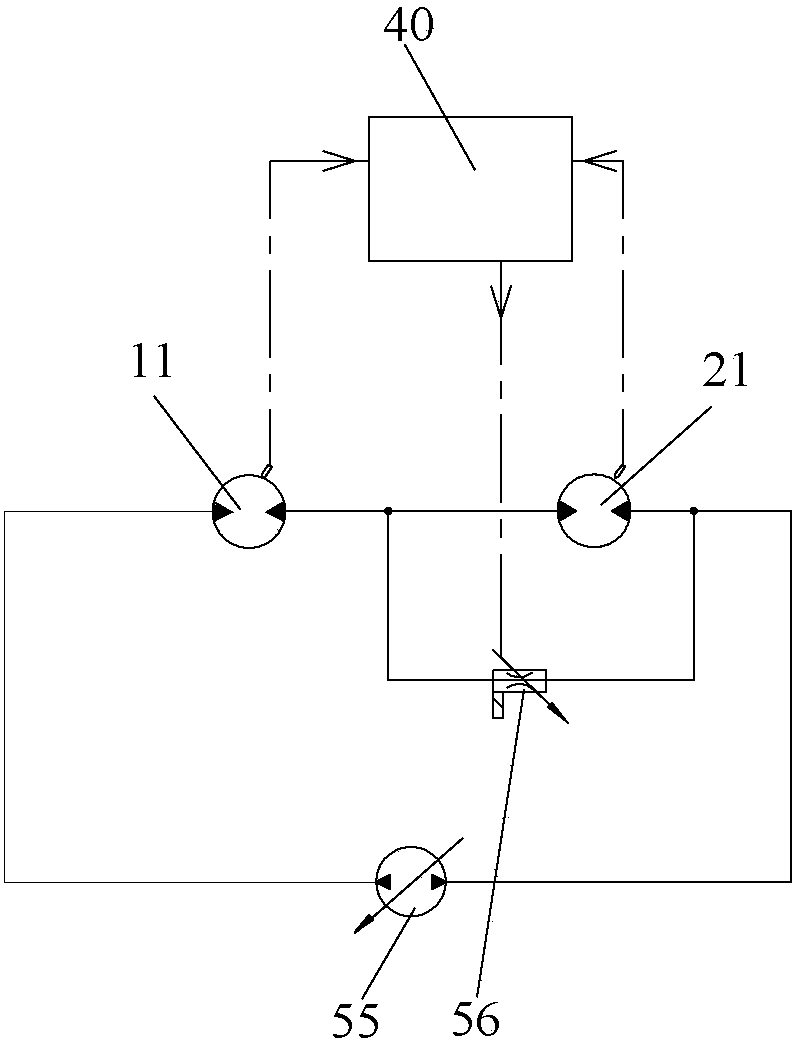

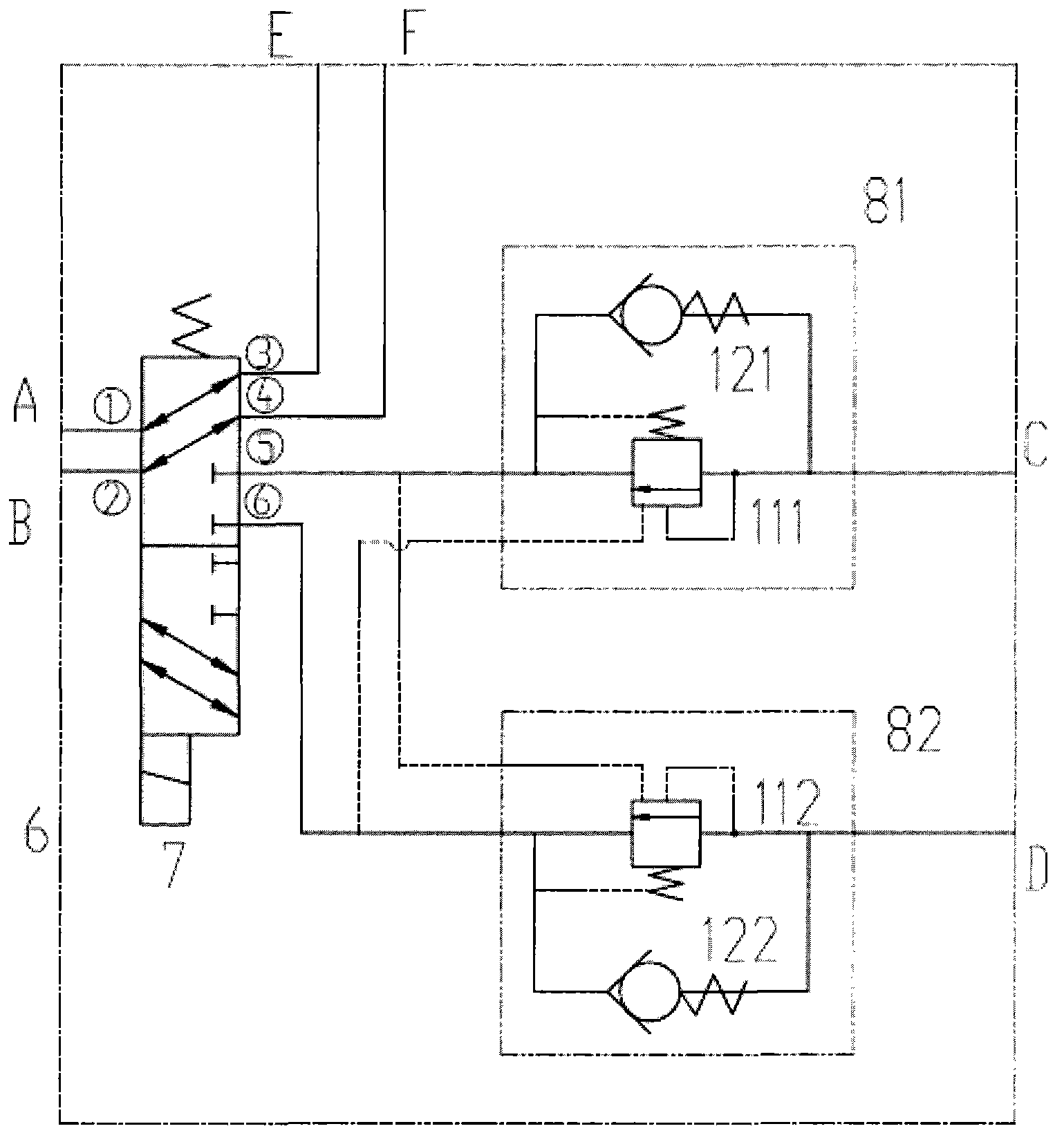

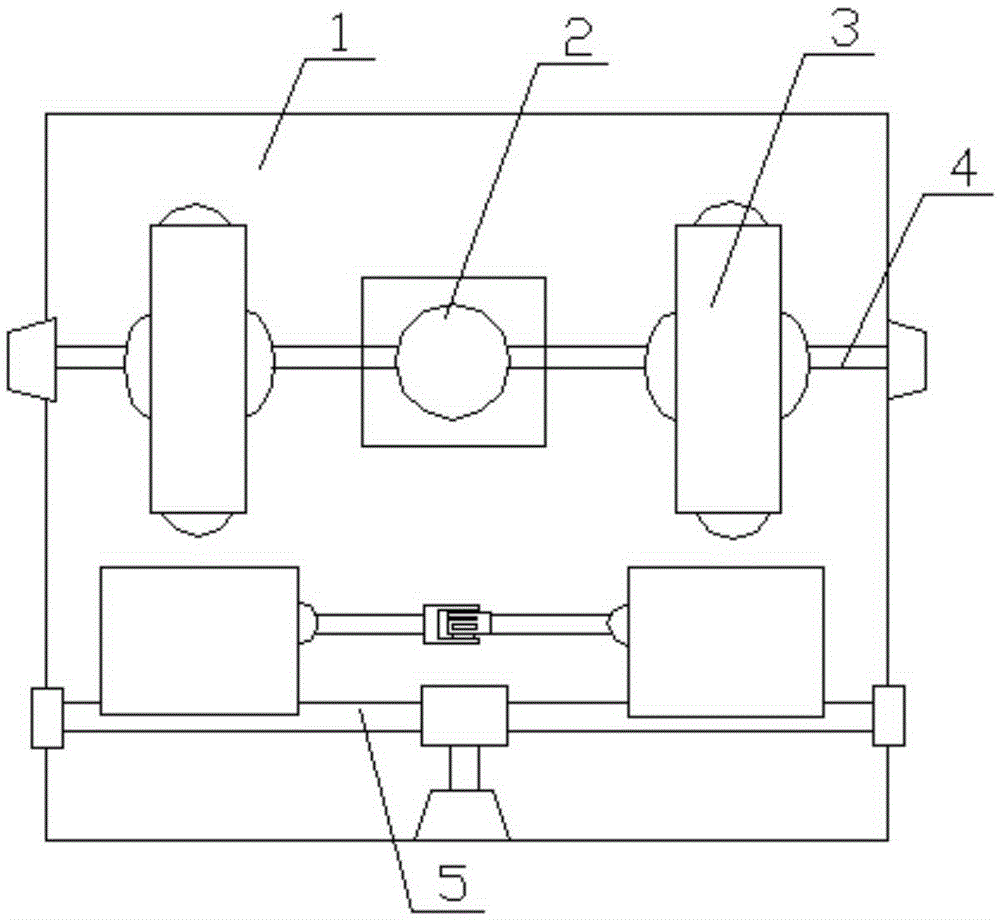

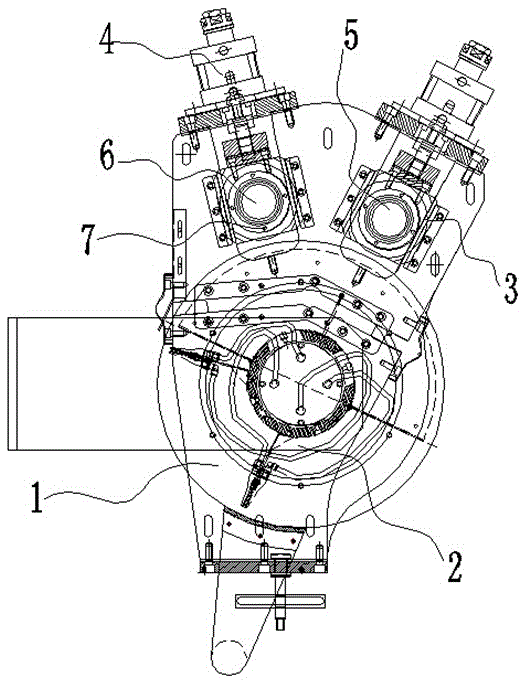

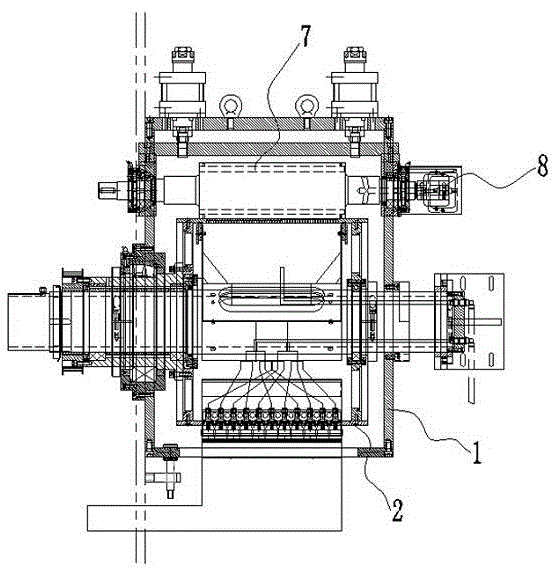

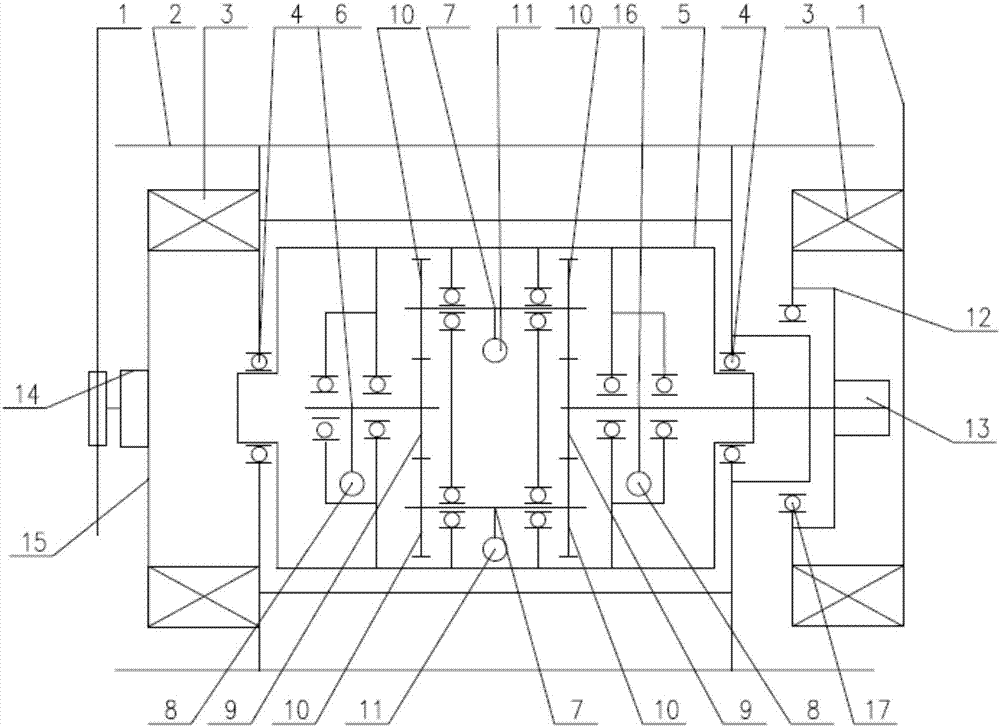

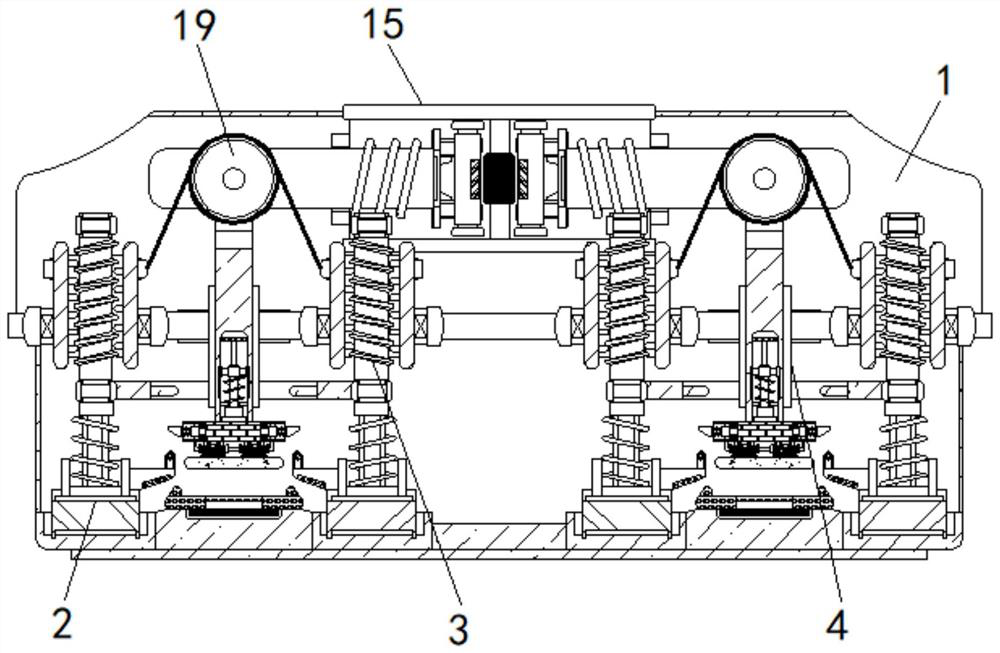

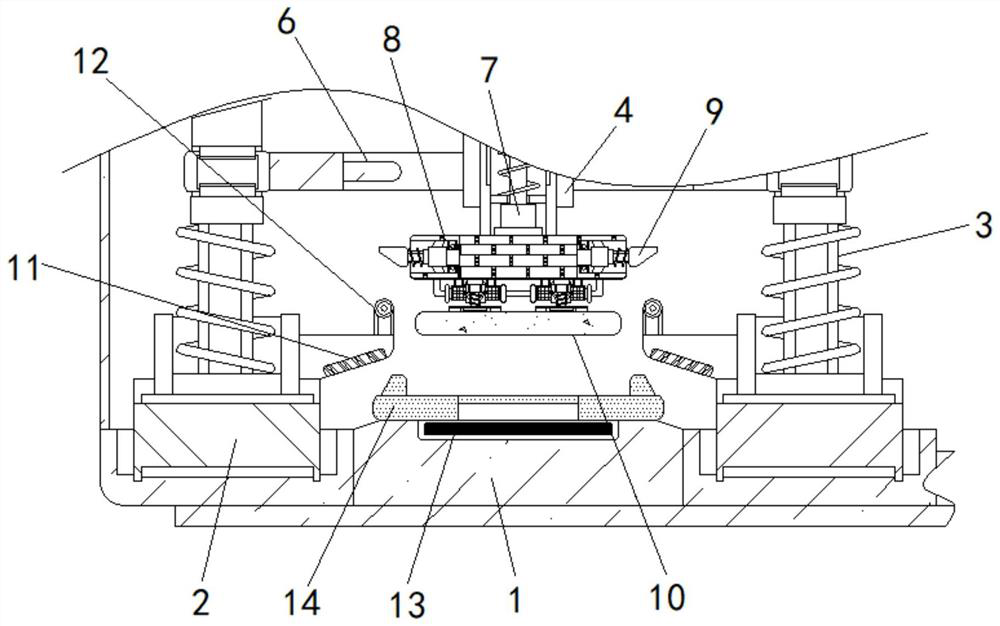

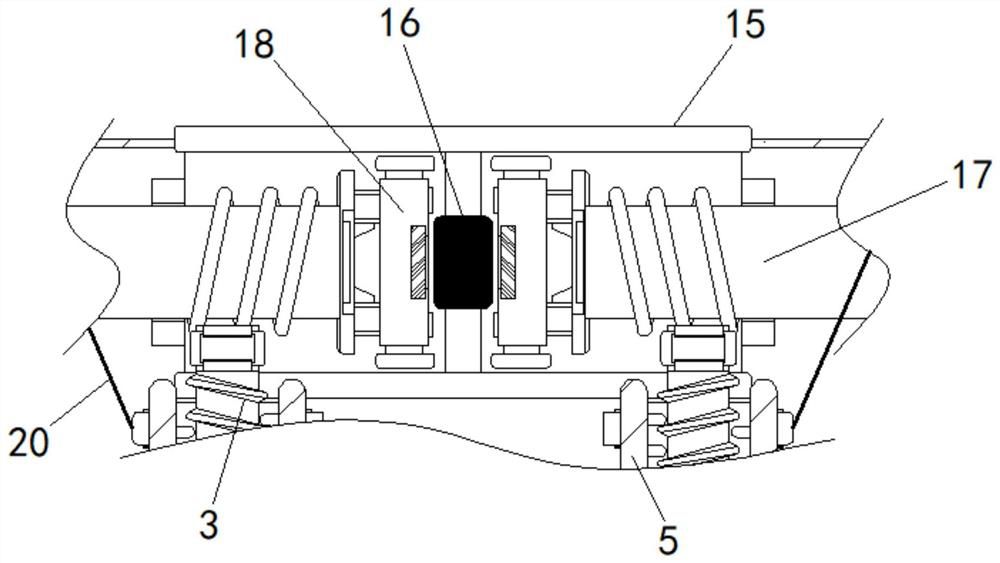

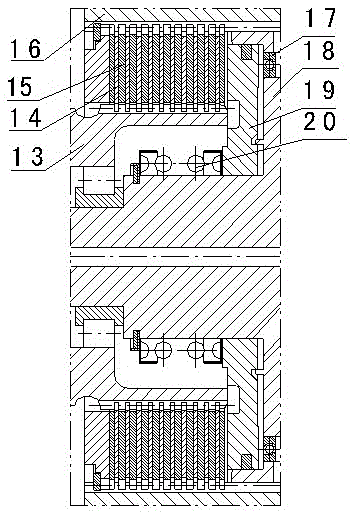

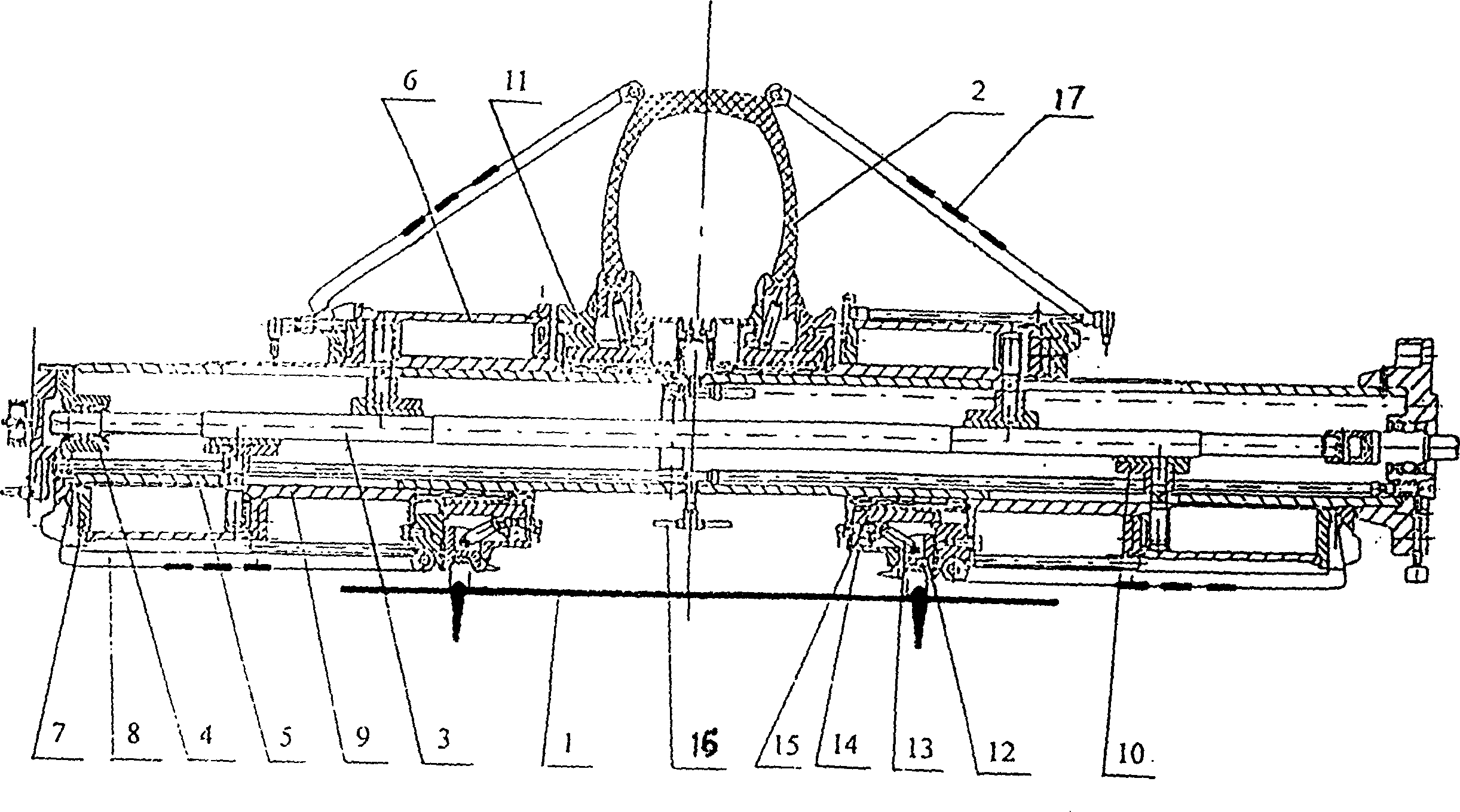

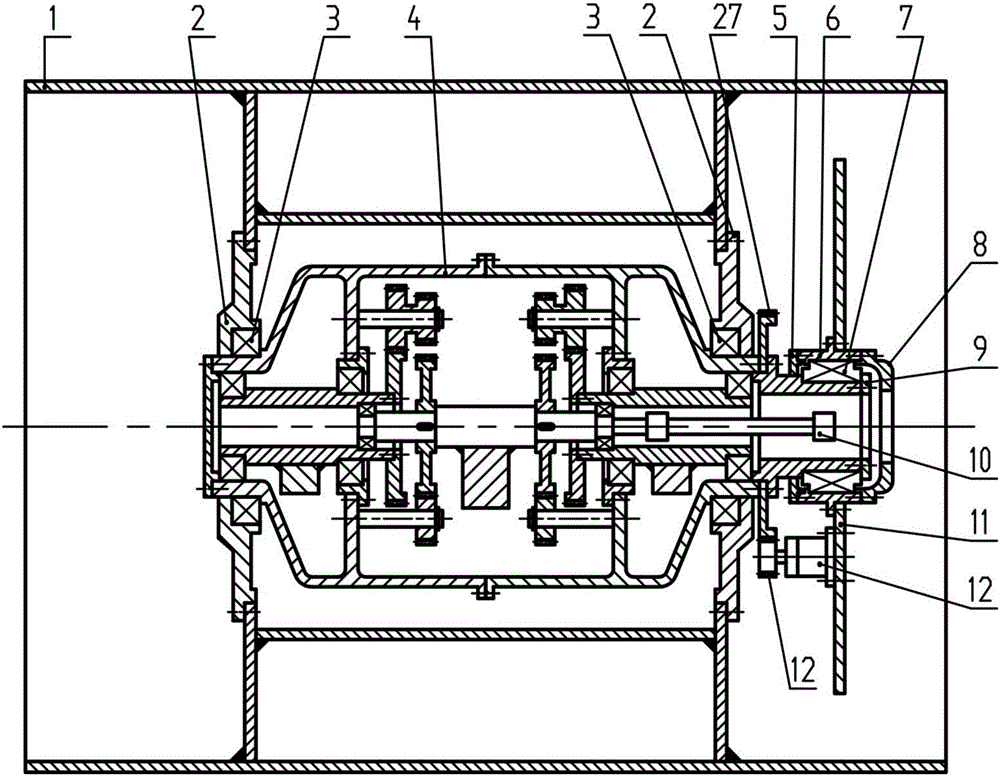

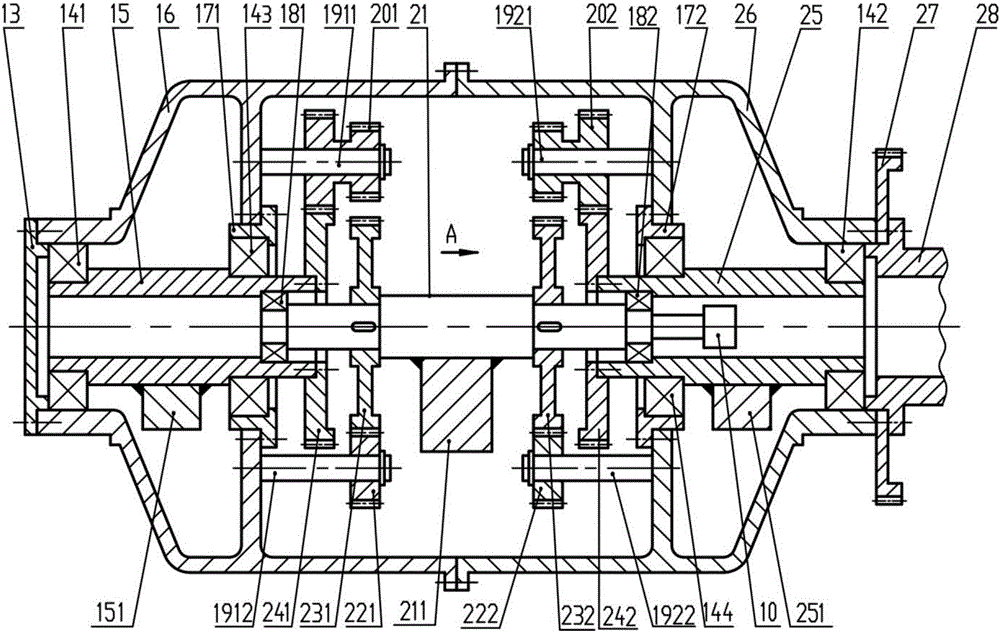

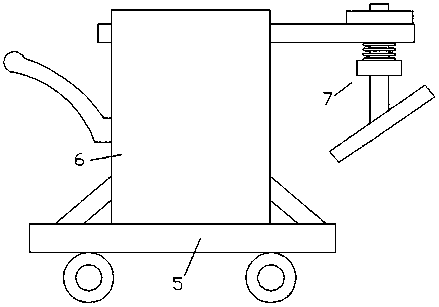

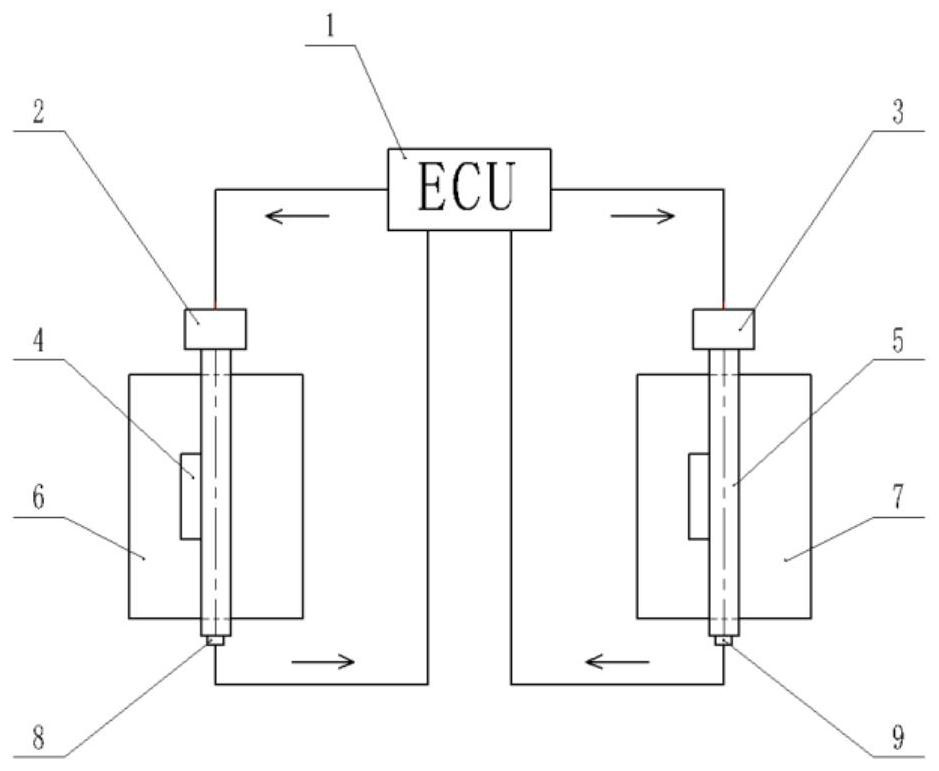

Tandem road roller vibration hydraulic system and control method as well as road roller

ActiveCN103541295AReduce beat vibrationImprove comfortRoads maintainenceComfort levelsVibration motor

The invention provides a tandem road roller vibration hydraulic system and a control method as well as a road roller. The tandem road roller vibration hydraulic system comprises a front wheel vibration system (10), a rear wheel vibration system (20), a detection device (30) and a controller (40), wherein the front wheel vibration system (10) comprises a front wheel vibration motor (11); the rear wheel vibration system (20) comprises a rear wheel vibration motor (21); the detection device (30) acquires vibration frequency of the front wheel vibration motor (11) and the rear wheel vibration motor (21); the controller (40) adjusts the front wheel vibration motor (11) and / or the rear wheel vibration motor (21) according to the vibration frequency of the front wheel vibration motor (11) and the rear wheel vibration motor (21) acquired by the detection device (30), so that the difference of the vibration frequency of the front wheel vibration motor (11) and the rear wheel vibration motor (21) is more than a preset value. According to the tandem road roller vibration hydraulic system, the problems that a beat vibration phenomenon of a road roller is difficultly eliminated and the operating comfort level of a driver is low in the prior art can be solved.

Owner:ZOOMLION HEAVY IND CO LTD

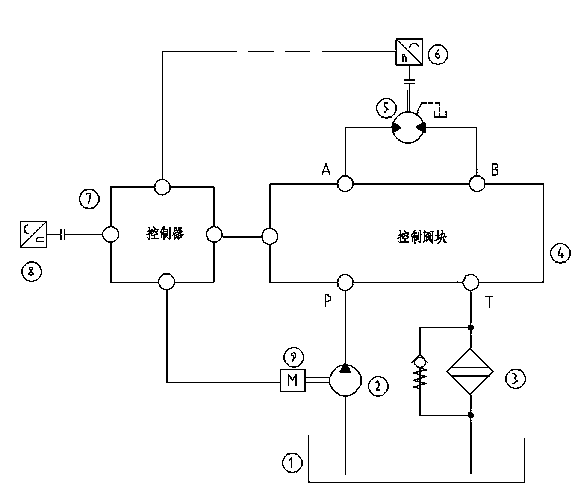

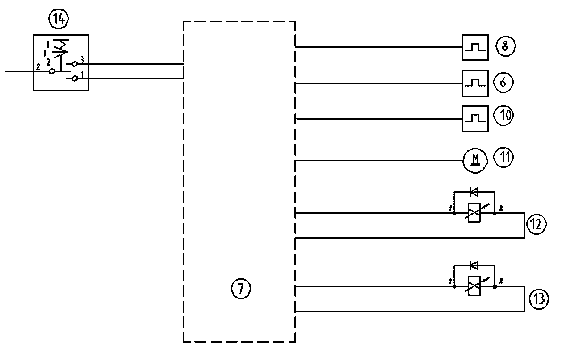

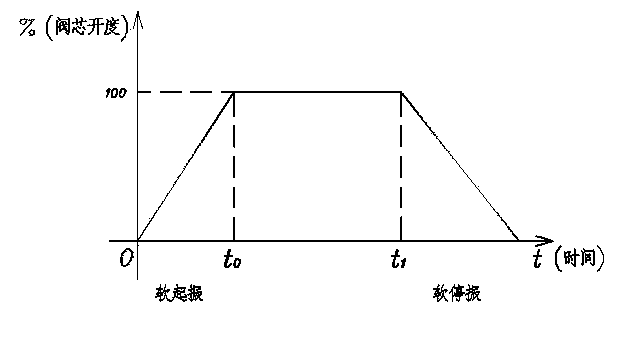

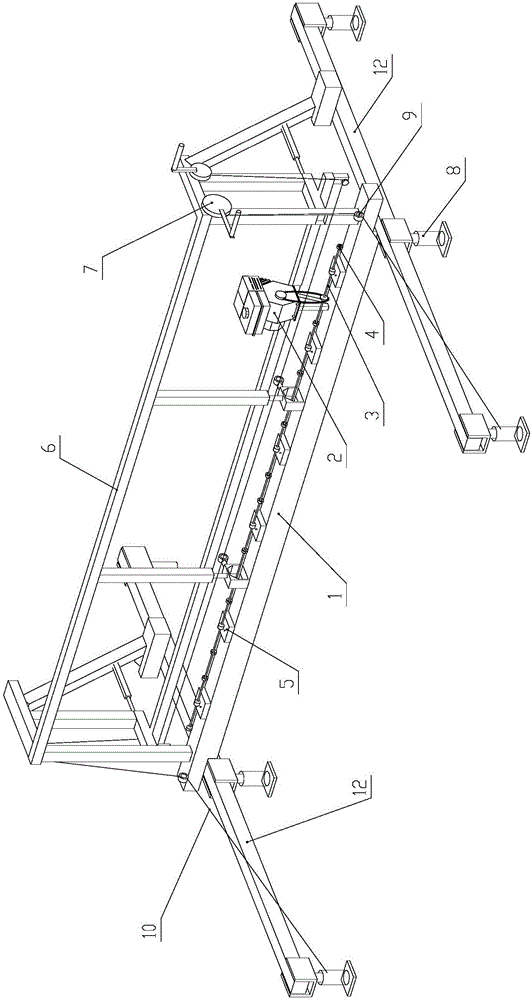

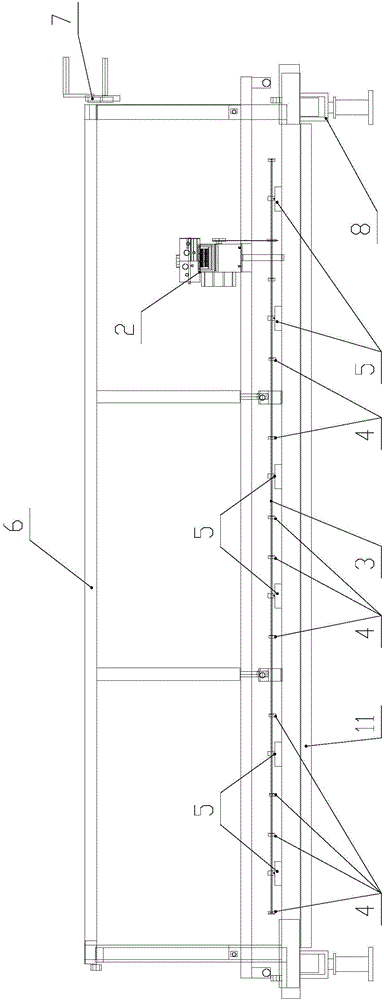

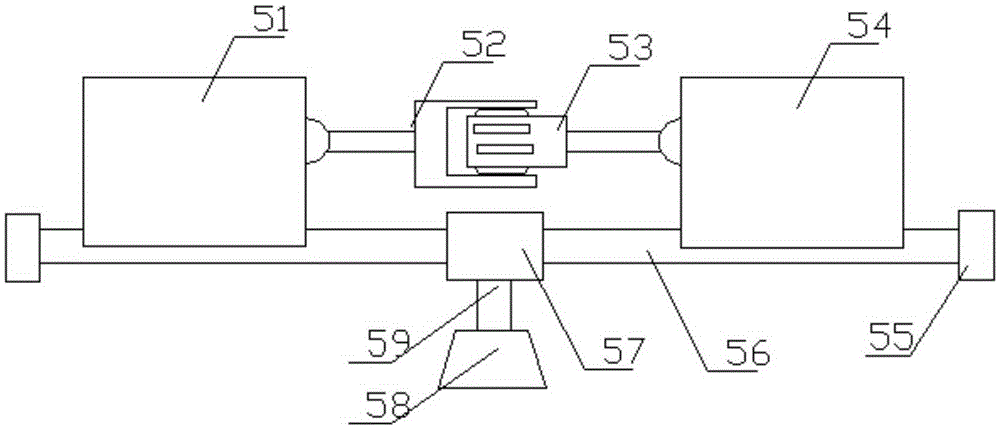

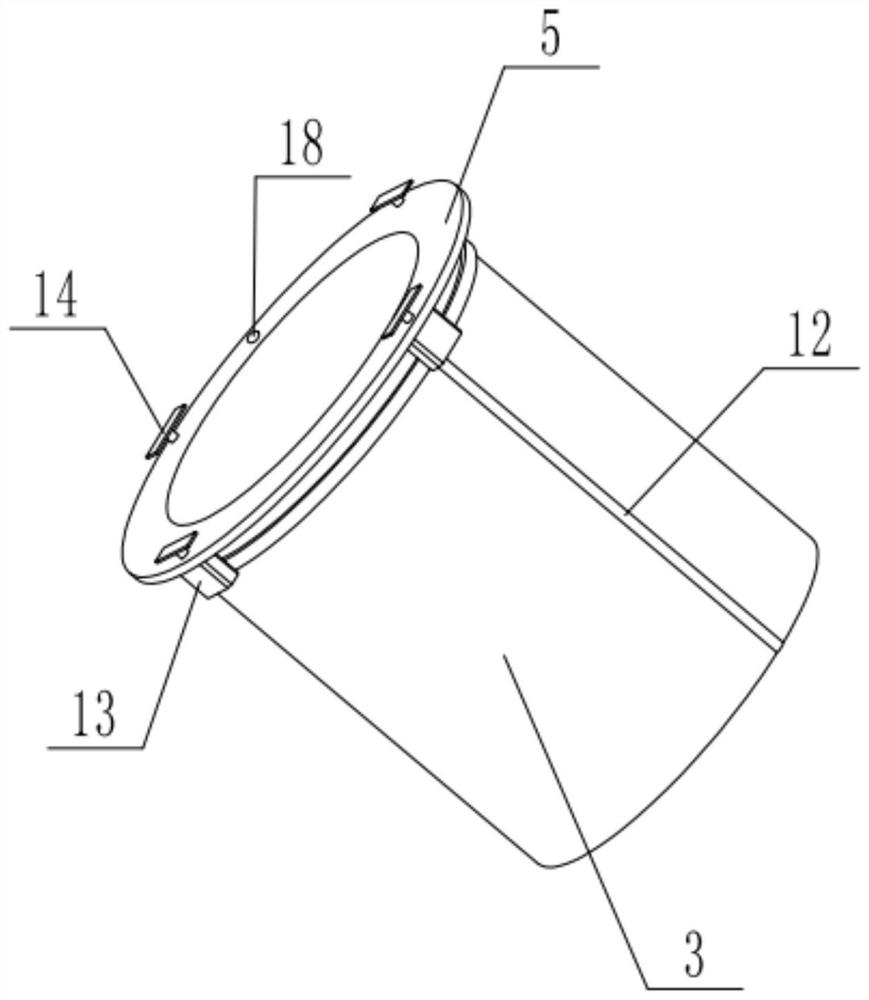

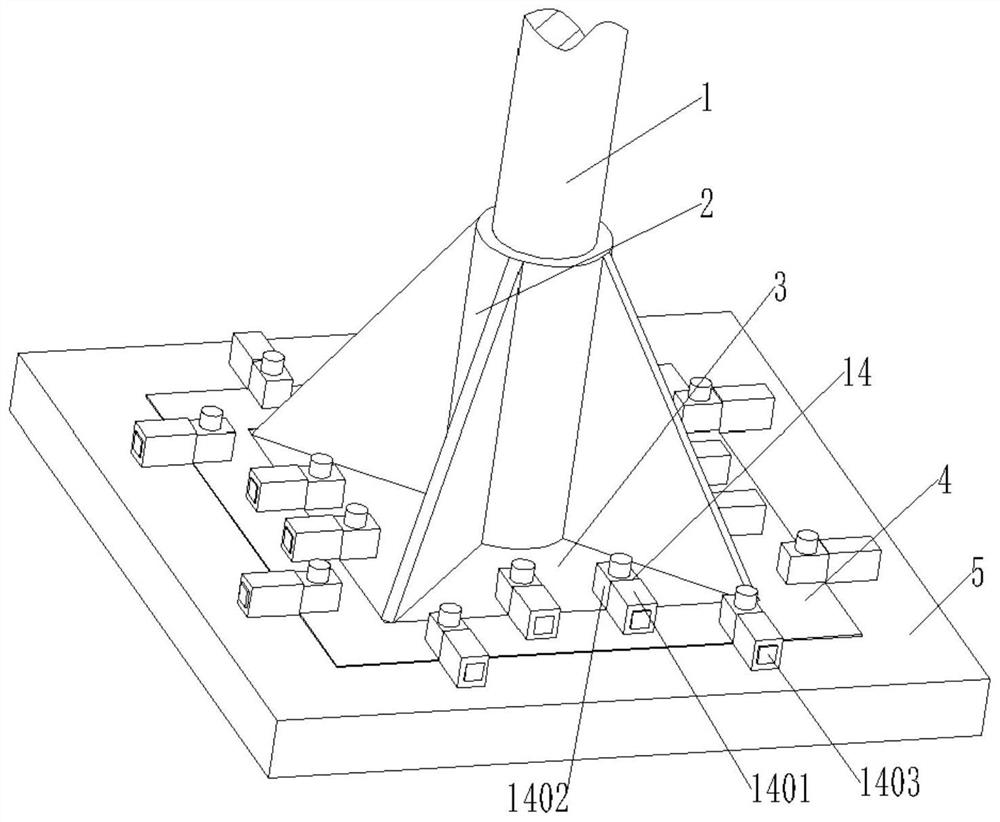

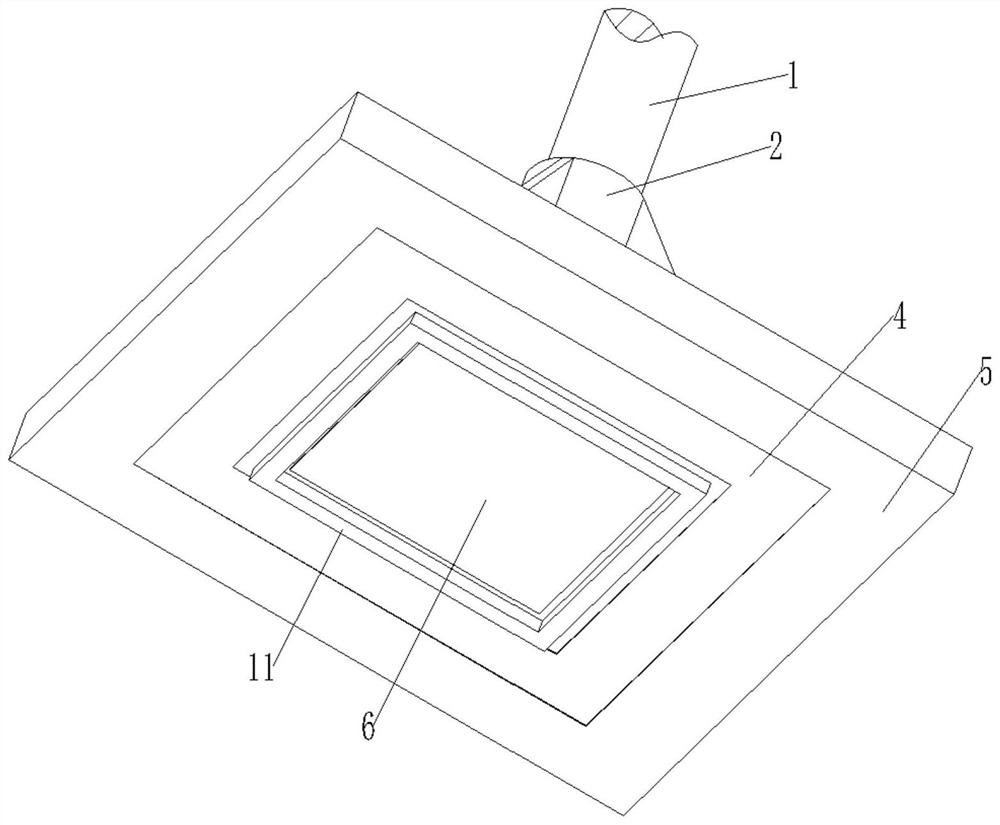

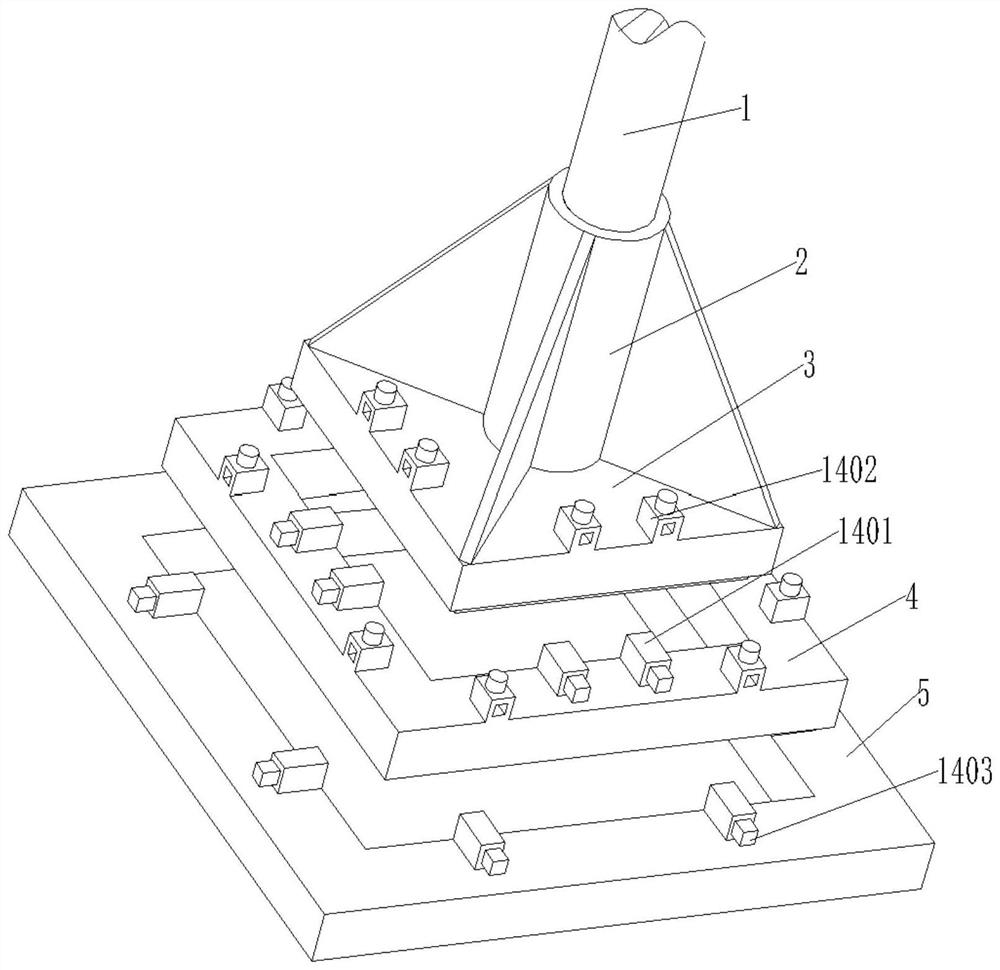

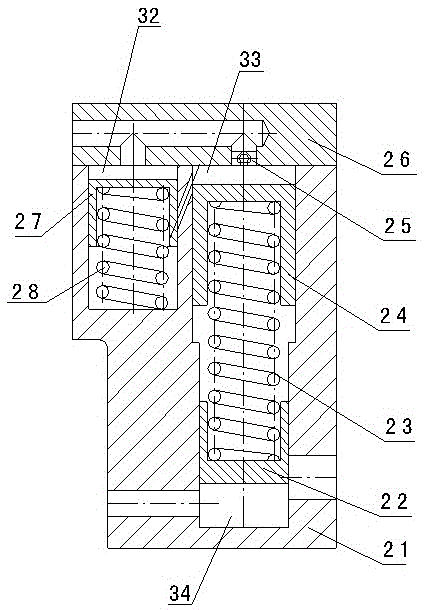

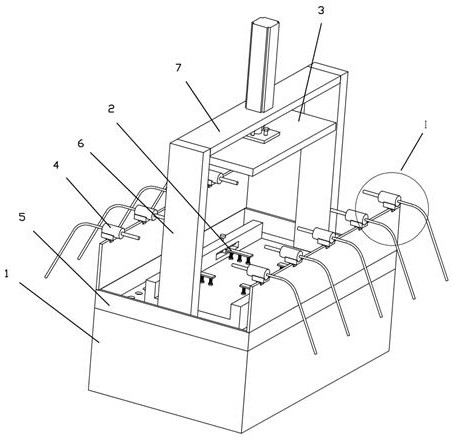

Open type vibration electric proportional control system of road roller

ActiveCN103669178AAchieve full power controlAchieve high efficiency and energy savingRoads maintainenceProportional controlSolenoid valve

The invention relates to an open type vibration electric proportional control system of a road roller, which is characterized in that the open type vibration electric proportional control system comprises a hydraulic system and an electric control system, wherein the hydraulic system comprises a fuel tank (1), a gear pump (2), an oil return filter (3), a control valve block (4), a gear motor (5) and an engine (9); and the electric control system comprises a vibration frequency sensor (6), a controller (7), a running speed sensor (8), an engine speed sensor (10), a throttle performer (11), a high-amplitude vibration proportion solenoid valve (12), a low-amplitude vibration proportion solenoid valve (13) and an amplitude selector switch (14). The open type vibration electric proportional control system of the road roller can implement stepless frequency modulation of the open type vibration system, makes the open type vibration system have soft vibration-starting and soft vibration-stopping functions, can raise compacting quality, can reduce system impact, can implement automation control by an electric control technology, and has advantages of stronger work condition adaptability and low cost.

Owner:柳工无锡路面机械有限公司

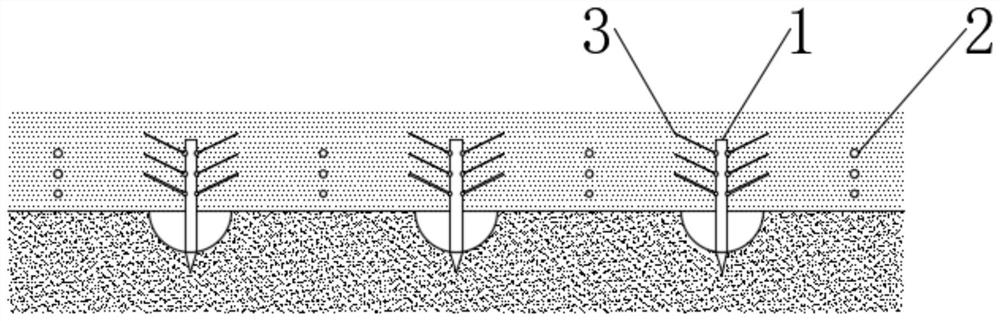

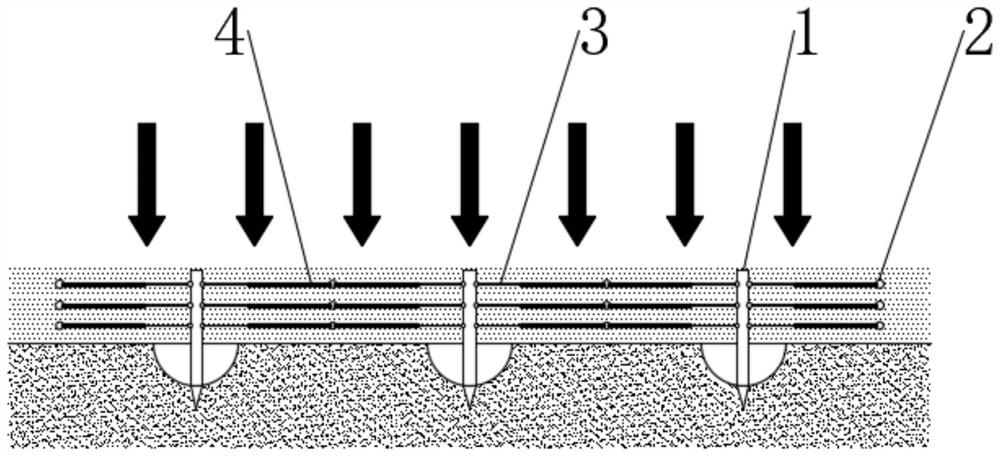

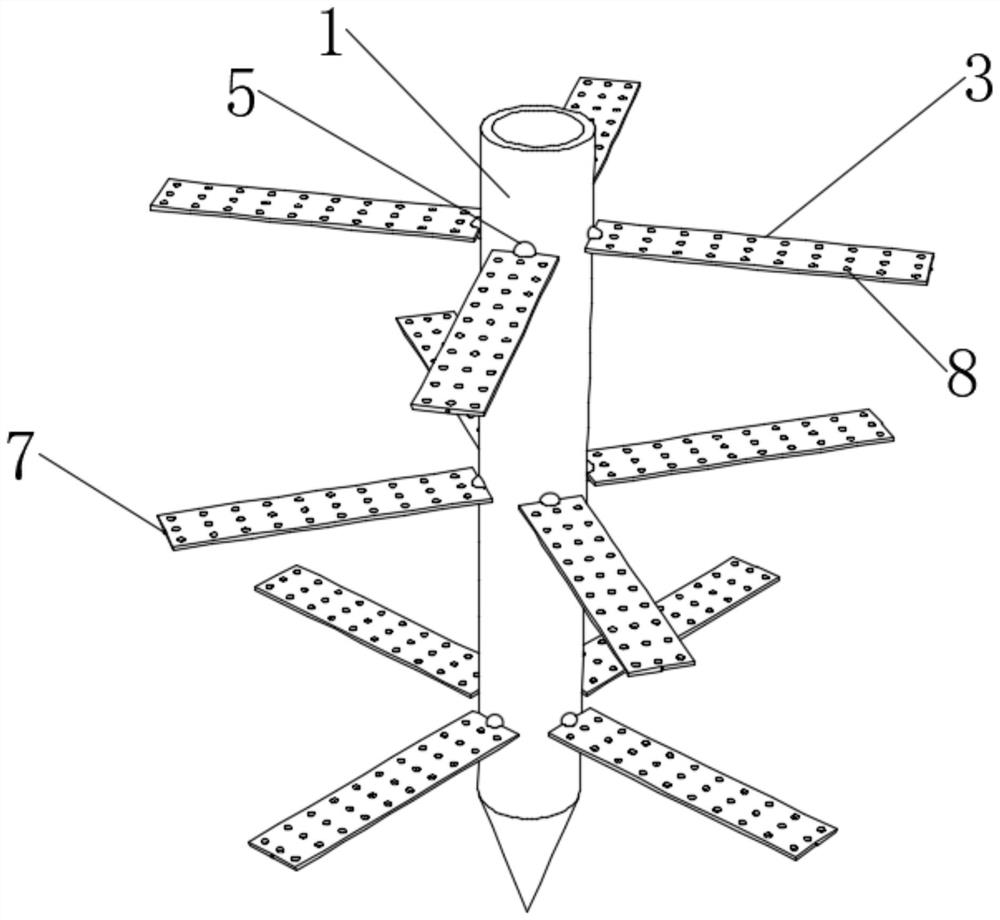

Novel netting type tamping method of filler for roadbed construction

ActiveCN111663388AAvoid drifting and sinkingFirmly connectedMagnetsRoads maintainenceAdhesiveArchitectural engineering

The invention discloses a novel netting type tamping method of a filler for roadbed construction, and belongs to the technical field of building construction. A mode of half pre-buried a tamping-assisting pre-buried rod on a lower side foundation can be realized; the filler matched with an auxiliary tamping plate is laid and filled in a layered manner, and netting node magnetic balls are placed; then, during overall tamping, the auxiliary tamping plate is forced to rotate to assist tamping; meanwhile, a heat release ball is extruded to release heat to trigger netting action after being broken;a migration netting bundle in the auxiliary tamping plate and the netting node magnetic balls are promoted to actively approach and establish connection due to a relationship of a magnetic attractionforce; then, local tamping is carried out on the tamping-assisting pre-buried rod to extrude the migration netting bundle extending into the filler so that a fracturing compaction promoting ball on asurface is forced to break locally; and a self-extending gap opening rod is used as a guide to form a material conveying hole in the filler, a water-based adhesive in the fracturing compaction promoting ball moves and spreads in the filler along the material conveying hole, and a binding force and compactness between the fillers are remarkably improved after curing.

Owner:安徽重标建筑工程有限公司

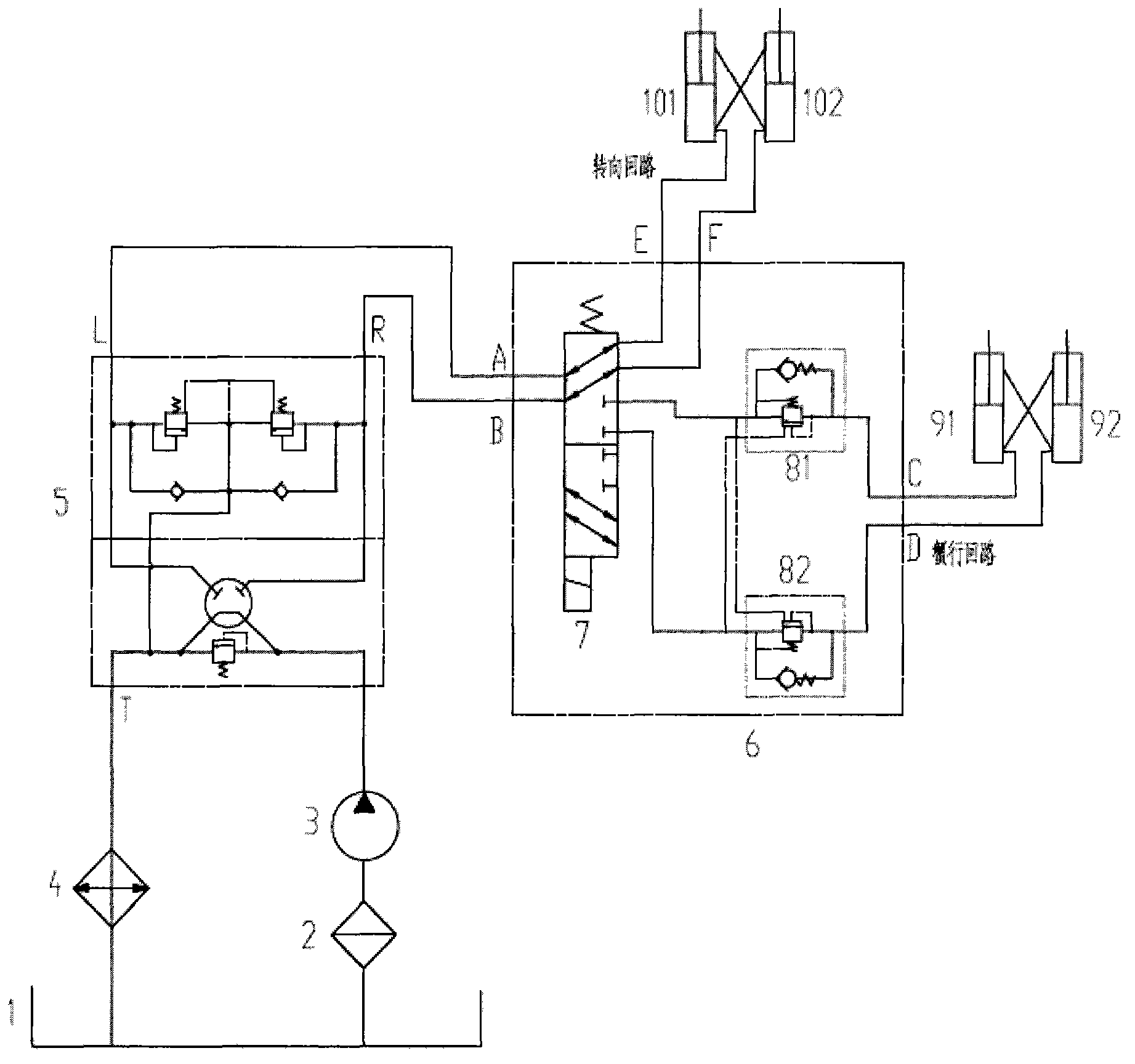

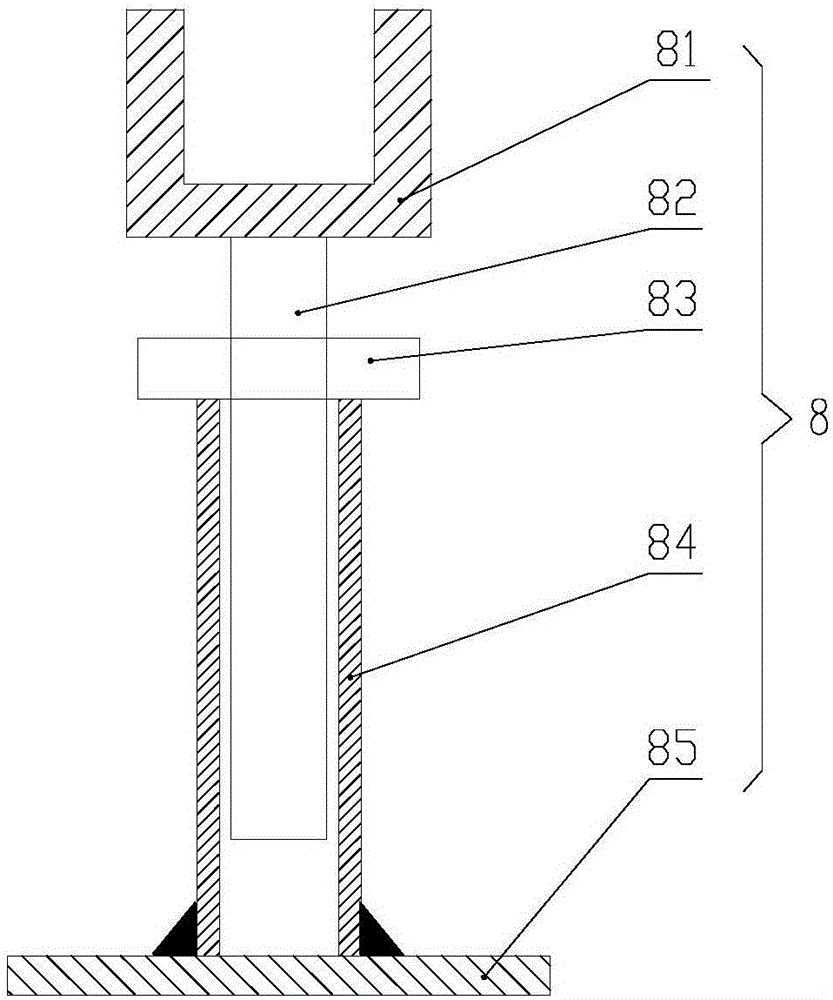

Lockable hydraulic crab steering system for double-drum rollers

ActiveCN103452936ACompact layoutLow costServomotor componentsRoads maintainenceFuel tankHydraulic pump

The invention belongs to the field of hydraulic steering techniques for double-drum rollers, and particularly relates to a lockable hydraulic crab steering system for double-drum rollers. The steering system comprises an oil tank, a hydraulic pump, a steering gear, a crabbing valve, a first crabbing cylinder, a second crabbing cylinder, a first steering cylinder and a second steering cylinder; after passing through the hydraulic pump, the steering gear and the crabbing valve, the oil in the oil tank is divided into a steering loop and a crabbing loop, and then flows back into the oil tank via the steering gear; the steering loop is connected in parallel with the crabbing loop; the crabbing valve comprises a two-position six-way electromagnetic reversing valve, a first balance valve and a second balance valve; the steering loop is connected with the two-position six-way electromagnetic reversing valve; and the crabbing loop is connected with the two-position six-way electromagnetic reversing valve respectively through the first balance valve and the second balance valve. The arrangement of the steering system is compact, steering operation and crab steering operation can be realized, moreover, the linear running of a double-drum roller can be guaranteed, and the efficiency of operation and the quality of rolling can be increased.

Owner:XCMG CONSTR MACHINERY

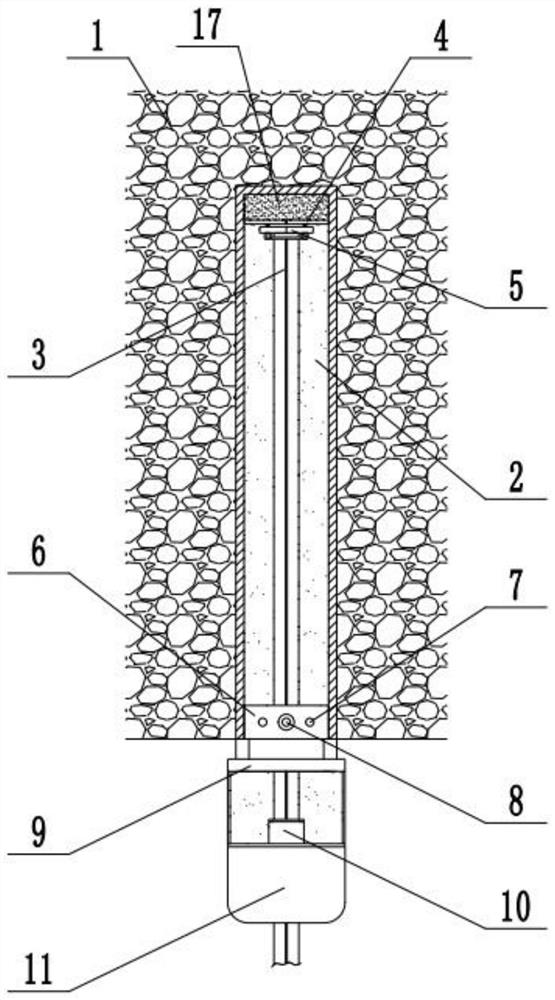

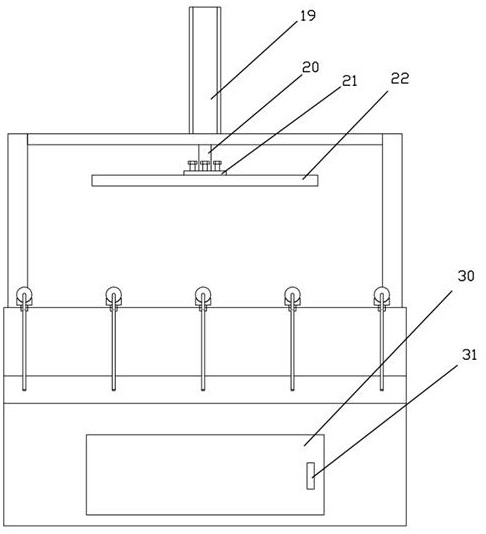

Concrete vibration device

InactiveCN106121244AAchieve compactionImprove compaction qualityBuilding material handlingDrive shaftStructural engineering

Owner:朱万银

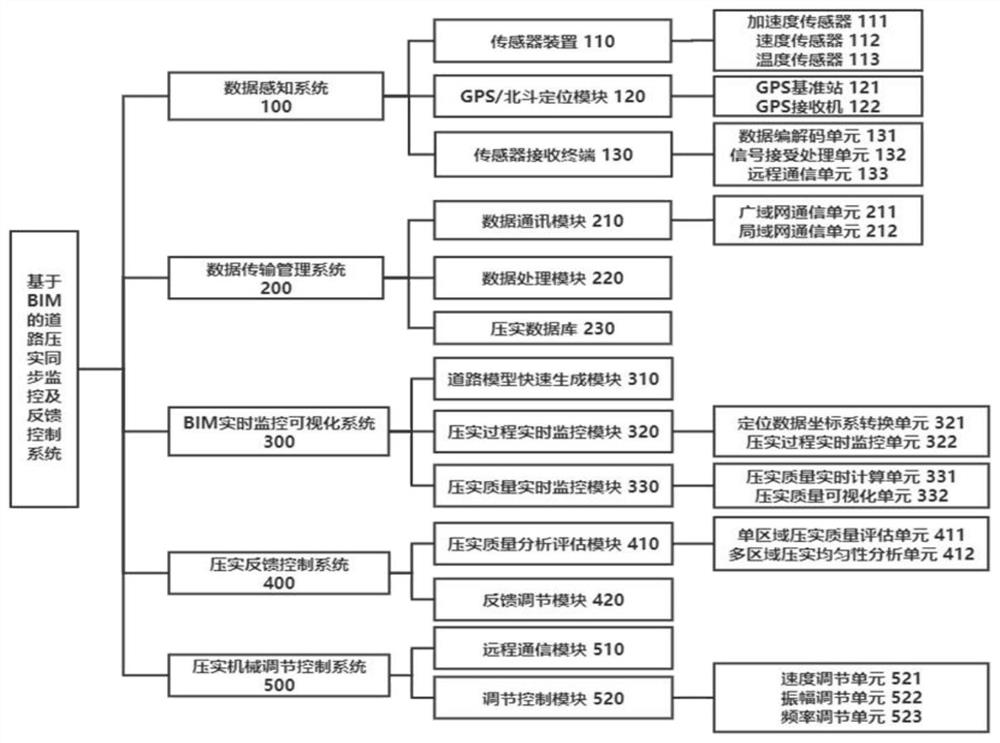

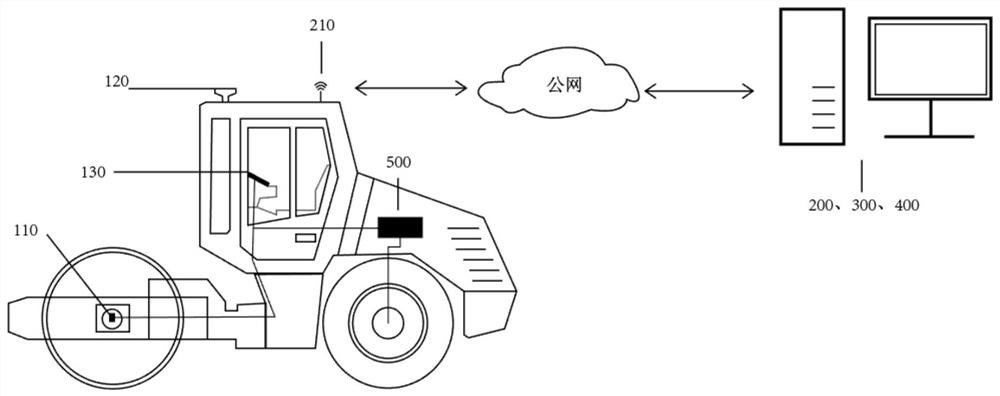

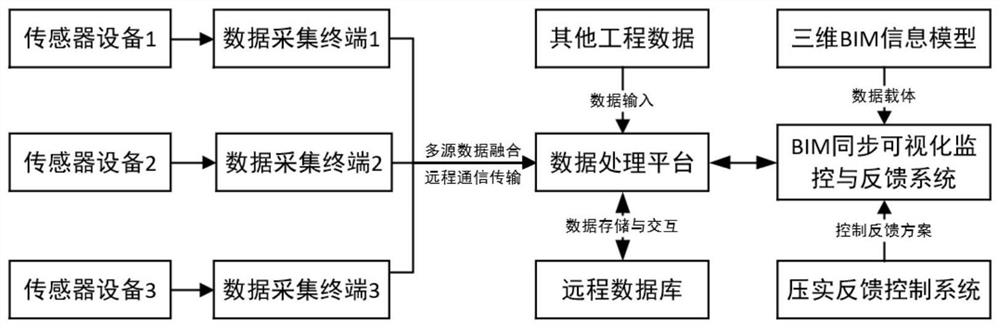

BIM-based road compaction synchronous monitoring and feedback control system

PendingCN112988510AEasy to detectIncreased level of controlDatabase management systemsHardware monitoringControl systemControl engineering

The invention provides a BIM-based road compaction synchronous monitoring and feedback control system. The BIM-based road compaction synchronous monitoring and feedback control system comprises a data sensing system, a data transmission management system, a BIM real-time monitoring visualization system, a compaction feedback control system and a compaction mechanical adjustment control system. According to the invention, a three-dimensional synchronous simulation monitoring and feedback control system is established based on the research of a continuous compaction control technology and by virtue of the powerful three-dimensional visualization capability of a BIM technology, real-time monitoring and calculation analysis of compaction data, a compaction track, compaction times and a compaction quality distribution state are realized; meanwhile, a compaction quality feedback and control system is established, automatic feedback adjustment control of working parameters of the compaction machinery is realized; fine construction of roads is powerfully promoted; the construction information interaction efficiency is improved; and the final quality of compaction construction is ensured.

Owner:SOUTHEAST UNIV

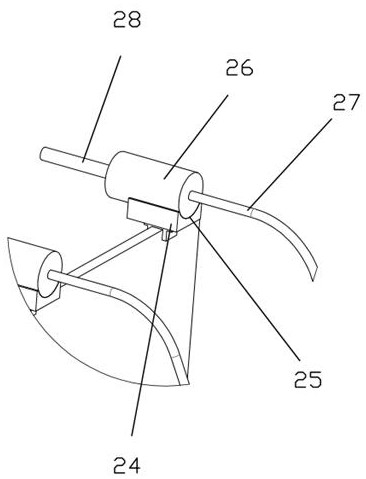

Intermittent impacting type press roller

InactiveCN106612763AReduce porosityAvoid stickingPlantingFurrow making/coveringEngineeringAgricultural machinery

The invention provides an intermittent impacting type press roller, and belongs to agricultural machinery. A swinging rod is hinged and connected onto the bottom of a height regulating frame; a roller frame is hinged onto the lower side part of the swinging rod; a roller shaft is assembled on the roller frame; a non-cylindrical impact press roller is arranged on the roller shaft through a bearing; N lug boss type lifting sections are uniformly distributed and arranged at intervals on the outer surface of the non-cylindrical impact press roller in the direction along the axis line; a plurality of projected transverse edges are arranged on the outer surface of the lug boss type lifting section in the direction along the axis line of the non-cylindrical impact press roller; the two ends of a buffer shock absorber are respectively hinged onto the lower side part and the upper side part of the height regulating frame assembly. The roller has the advantages that the structure is novel, simple and reasonable; the compression intensity on the soil is great; the compression operation quality is high; the use is reliable; the applicability is high.

Owner:JILIN UNIV

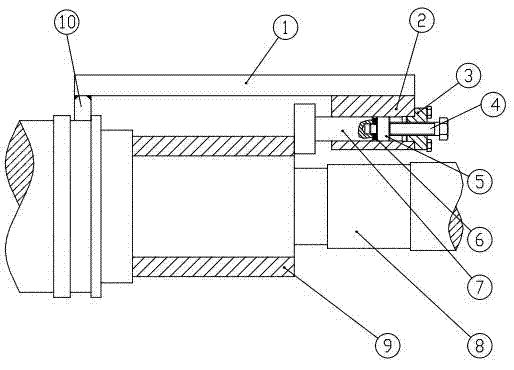

Clamp for preventing shrinkage fit from shifting

InactiveCN102398238ANo shiftThere will be no situation where the cooling cannot be resetWork holdersMetal working apparatusMalletMechanical engineering

The invention discloses a clamp for preventing a shrinkage fit from shifting. The middle part of the clamp is rectangular flat steel. One end of the clamp is fixed with the steel flat while the other head is welded with a steel block provided with a circular hole. A pressure head, a disc spring and a pin are arranged in the circular hole of the steel block of the clamp in series. A bump of the pin head is inserted into the hole in the rear of the pressure head. A lid is fixed on the end surface of the steel block through a closing bolt and a central screwed hole of the lid is screwed to a limiting bolt. The rear end of the limiting bolt leans against the rear end surface. Materials required by the invention are easy to prepare and the invention is convenient to process. When the clamp is installed on a shaft, no tolerance fit is required so that the clamp is easy to install and disassemble, and convenient to use without a specially-assigned person. Because the pressing force applied by the clamp is persistent, the situation that the workpiece is cooled and not able to reset due to the spacing interval of mallet hitting manually can be avoided; and potential danger due to the shaft which erects up can be avoided, too. The invention not only reduces the working hours and improves the pressing quality, but also guarantees the safety under the premise that the shrinkage fit work does not shift.

Owner:SEC ELECTRIC MACHINERY

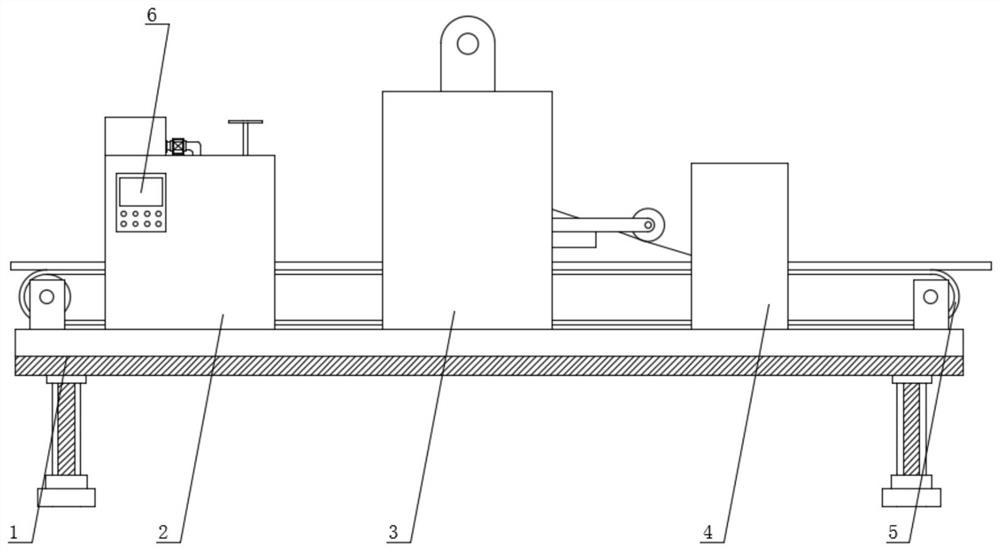

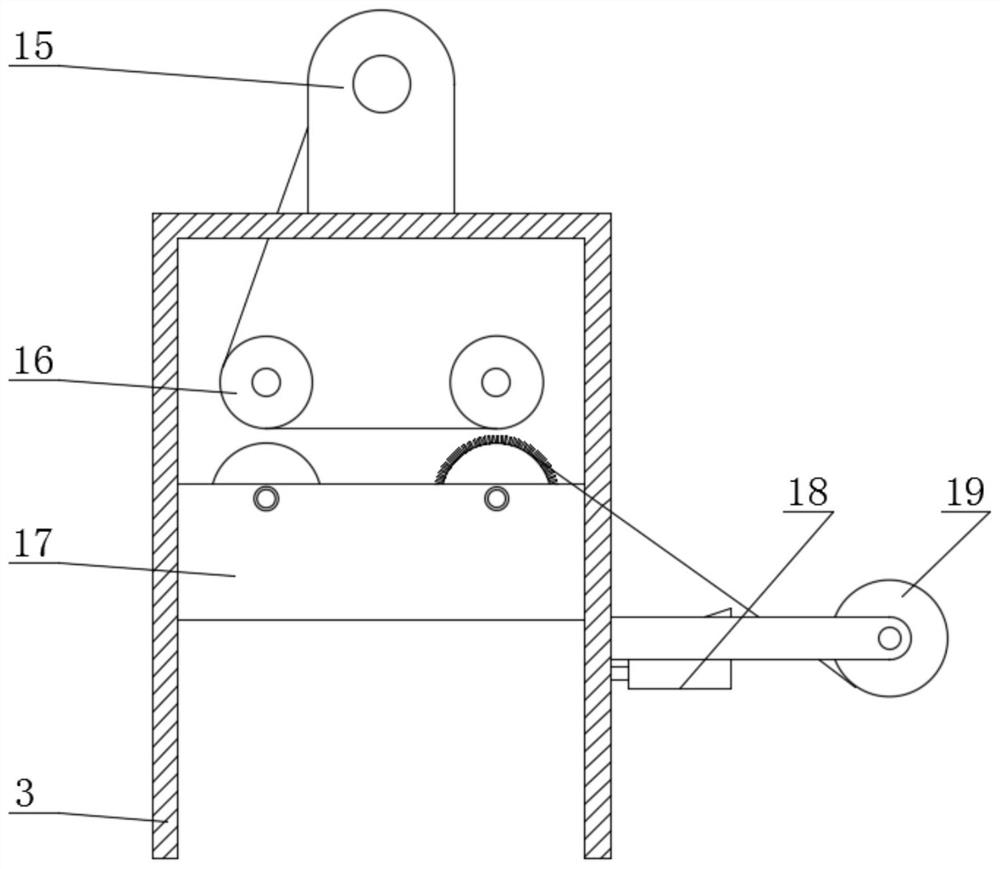

Double-drum yarn compacting machine

The invention relates to the technical field of artificial down production devices, in particular to a double-drum compacting machine. The double-drum compacting machine comprises a main machine case and further comprises a load bearing part arranged at the lower portion of the main machine case, a transmitting part, a motor and compacting parts. The load bearing part comprises a rotating base, a guide rod, a gathering piece, a beam, clamped connection blocks, a first carrying drum arranged at one end of the upper side of the beam, a second carrying drum, a first connecting piece and a second connecting piece. A first installation hole is formed in the rotating base in a through manner in the axial direction of the rotating base. A clamped connection positioning groove is concavely formed in the side wall of each clamped connection block. The first connecting piece comprises a main connecting rod and an outer transmitting cover. The second connecting piece comprises a conveying rod, a first transmitting head and shifting ridges. The double-drum compacting machine is convenient to operate and adjust, high in compacting efficiency and good in compacting quality.

Owner:南通通州江华纺织有限公司

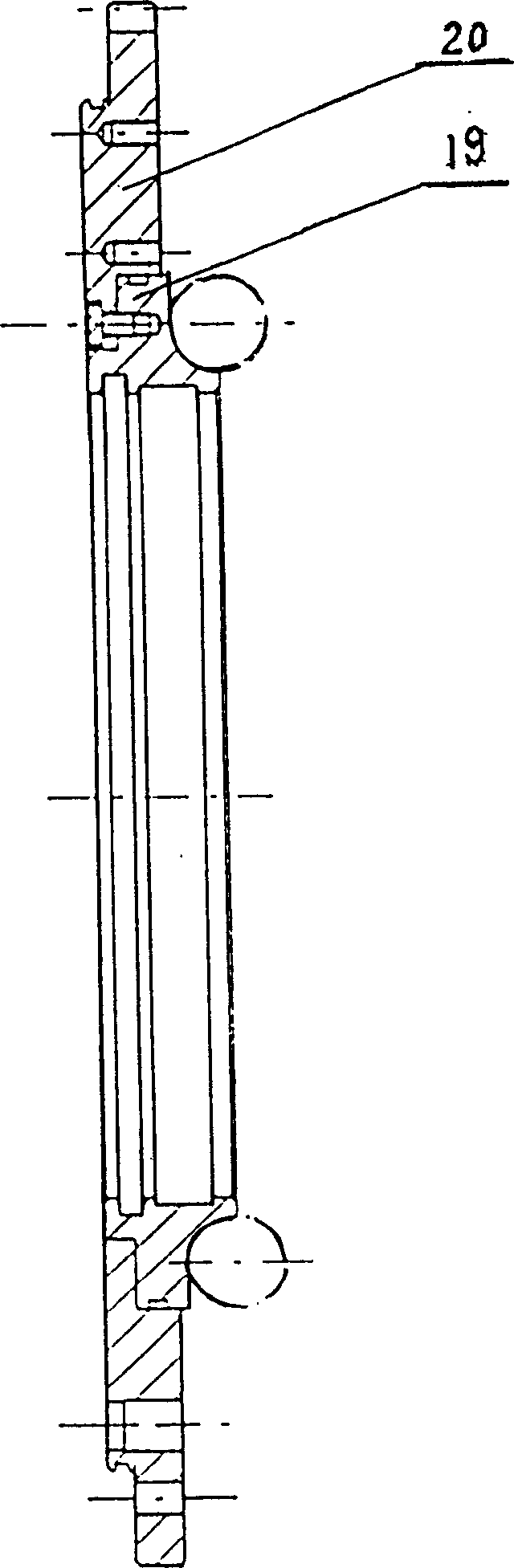

Medium-length hole charging and returned powder recycling device for blasting

PendingCN112880495AReduce the amount of dropImprove recycling efficiencyBlastingPistonEnvironmental geology

The invention relates to the technical field of blasting charging, and particularly discloses a medium-length hole charging and returned powder recycling device for blasting. The medium-length hole charging and returned powder recycling device for blasting comprises a positioning ring and a PLC, wherein the positioning ring can be placed in a blasting hole, an air guide ring is arranged inside the positioning ring, an air pump communicates with the air guide ring, a plurality of clamping pistons communicating with the air guide ring are arranged on the positioning ring, a recycling bag is arranged on the positioning ring, a limiting sleeve is arranged inside the recycling bag in a penetrating mode, a feeding pipe is slidably arranged inside the limiting sleeve, a compaction base is arranged at the end, located inside the blasting hole, of the feeding pipe, an air inlet pipe is arranged on the outer wall of the feeding pipe, a plurality of compaction air cylinders communicating with the air inlet pipe are arranged on the compaction base, the air inlet pipe communicates with the air pump, the compaction air cylinders and the air pump are both electrically connected with the PLC, and the working ends of the compaction air cylinders penetrate through the compaction base and are fixedly connected with auxiliary compaction plates. The medium-length hole charging and returned powder recycling device aims to solve the problem that when explosives are placed in a blasting hole in traditional mining blasting, the explosives are not recycled when falling out of the blasting hole.

Owner:庄培新

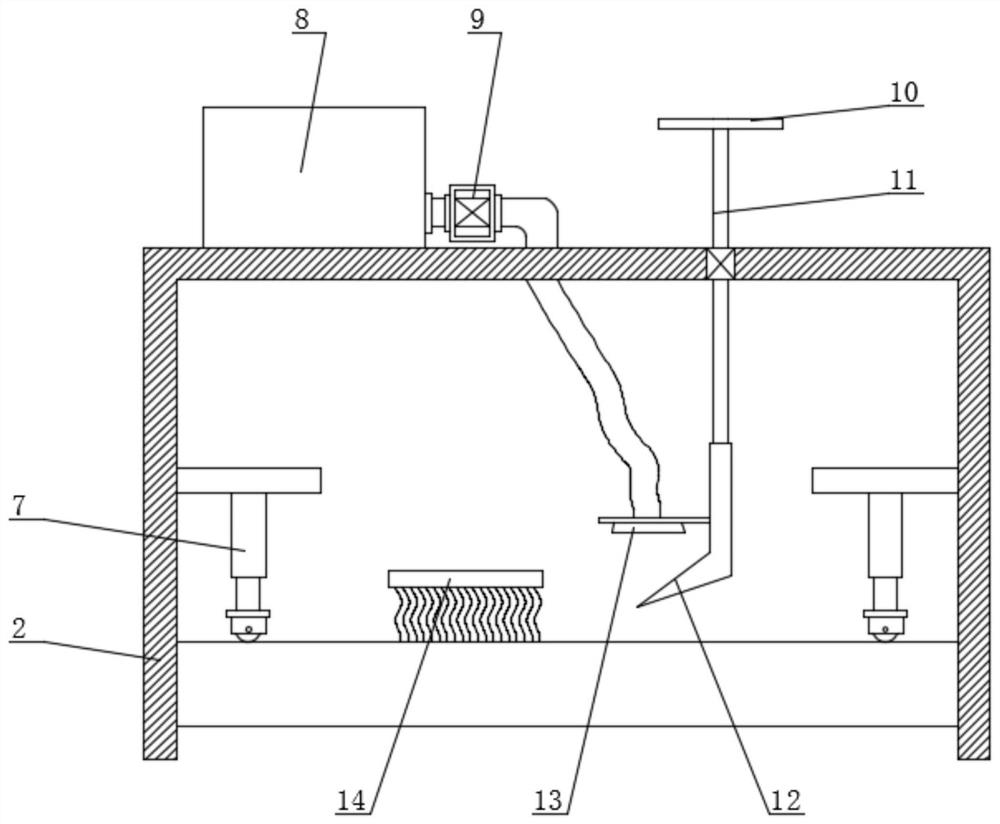

Cotton core transfer and compaction integrated device

InactiveCN105596149AImprove compactionImprove compaction qualityAbsorbent padsBaby linensFiberPower circuits

The invention relates to a cotton core transfer and compaction integrated device and a compaction method. The cotton core transfer and compaction integrated device comprises a transfer wheel arranged in an installation frame, two compaction roller assemblies arranged above the transfer wheel, air cylinder pressure devices arranged above the compaction roller assemblies, and a negative pressure sucking assembly arranged on the side face of the installation frame. The negative pressure sucking assembly is matched with the transfer wheel and used for forming a negative pressure air distributing area on the cotton core compaction working side of the transfer wheel. One of the two compaction roller assemblies is an embossing roller, and the other compaction roller assembly is a smooth roller. A plurality of electric heating tubes are evenly distributed and arranged in the embossing roller, a plurality of electric heating tubes are evenly distributed and arranged in the smooth roller, a rotary collector ring is arranged at one end of the embossing roller, a rotary collector ring is arranged at one end of the smooth roller, and the electric heating tubes are connected with a power circuit through the rotary collector rings. The cotton core transfer and compaction integrated device can heat fibers in a cotton core to be fluffy and then compacted, and thus the compaction effect and compaction quality of the cotton core are effectively improved; meanwhile, the heating temperatures of the electric heating tubes are adjusted to adapt to processing of cotton cores with different material performances, the compaction effect of cotton cores made of different materials is ensured, and adaptability is high.

Owner:ZHEJIANG YONGCHUANG MACHINERY

Perpendicular vibration road roller

InactiveCN107059560AReduce wasteReduce or even avoid wasteRoads maintainenceVertical vibrationEngineering

The present invention proposes a vertical vibratory road roller, which includes a frame, rollers on both sides are arranged on the frame, a driving device is arranged between the rollers and the frame, and a driving device is arranged on the frame. Vertical vibration driving device, the vertical vibration driving device is connected with a vibration device, the invention can realize the vertical vibration of the steel wheel, reduce or even avoid the waste of pressure in the horizontal direction, improve the rolling efficiency and compaction quality, and realize energy saving.

Owner:青岛科泰重工机械有限公司

Steel plate type tamping machine for welding of accessories of excavator

PendingCN111608167AIncrease the areaImprove compaction efficiencyMechanical machines/dredgersSoil preservationMaterial resourcesMachine

The invention discloses a steel plate type tamping machine for welding of accessories of an excavator. The tamping machine is welded and connected to a drill bit of the excavator through a steel plateso as to become a small machine with a tamping function. By adopting the machine within the range of 0.5 meter on a retaining wall and a culvert passage wall back, the tamping efficiency is improvedto a certain extent, time is saved for a next procedure of construction, and consumption of manpower and material resources is reduced to a great extent. By arranging a first expansion frame plate anda second expansion frame plate, the area of the steel plate can be increased according to actual situations, and therefore construction can be realized according to actual demands, and construction efficiency is improved. By arranging a connecting and fixing structure, the steel plate, the first expansion frame plate and the second expansion frame plate are conveniently and firmly connected, fixed and detached. Through the linkage action between an extrusion frame and T-shaped extrusion blocks, an extrusion reinforcing plate has a quite good reinforcing effect on the tamping operation of thesteel plate, construction tamping quality can be improved, and then construction quality is improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

Supercapacitor pole piece compaction equipment of new generation technology

InactiveCN113035595AImprove compaction quality and speedKeep cleanCapacitor manufactureHybrid/EDL manufactureCapacitanceInternal cavity

The invention relates to the technical field of manufacturing of new energy automobile energy storage devices, and discloses supercapacitor pole piece compaction equipment of a new generation technology. The supercapacitor pole piece compaction equipment comprises a shell, wherein symmetrical positioning seats are fixedly connected to the two sides of the bottom of an inner cavity of the shell, telescopic worms are fixedly connected to the upper ends of the positioning seats, a bearing part is arranged between and fixedly connected with the telescopic worms in an inner cavity of the shell, adjusting frames connected to the telescopic worms in a sleeving mode are rotationally connected to the left side and the right side of the bearing part correspondingly, and guide columns are fixedly connected to the sides, close to the bearing part, of the telescopic worms. According to the supercapacitor pole piece compaction equipment of the new generation technology, the magnitude of magnetic attraction force of a magnetic block to an electromagnetic plate is controlled by changing the light quantity of an indicator light received by a photoresistor, so a guide column can drive a pressurizing plate part to perform one-time forming rapid extrusion on a pole piece; and therefore, the compaction quality and speed of the pole piece are effectively improved, and the compaction effect of the pole piece is effectively improved.

Owner:广州创开科技有限公司

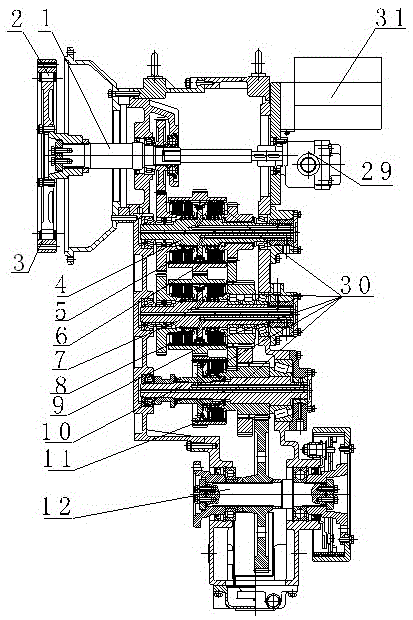

A multi-gear road mechanical gearbox with flexible shifting

The invention discloses a gearbox and particularly to a multi-gear road surface mechanical gearbox allowing flexible gear shifting. The multi-gear road surface mechanical gearbox allowing the flexible gear shifting comprises an input component, a forward gear component, a reverse gear component, a third gear component and an output component; an elastic coupling is arranged on the input component; the elastic coupling comprises a separable internal tooth ring; the forward gear component comprises a forward gear clutch and a first gear clutch; the reverse gear component comprises a reverse gear clutch and a second gear clutch; the third gear component comprises a third gear clutch; an output gear which is arranged on the output component is meshed with a third gear of the third gear clutch; a check valve is arranged on a rotating oil cylinder; the pressure fluid enters into a working oil chamber through the rotating oil cylinder; a pressure spring is arranged on the rotating oil cylinder. The multi-gear road surface mechanical gearbox allowing the flexible gear shifting has the advantages of being advance and reasonable in structure and high in reliability, achieving continuous impact-free gear shifting and being convenient and comfort to operate.

Owner:XCMG CONSTR MACHINERY +1

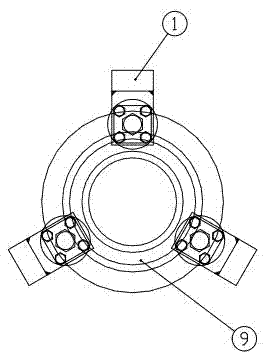

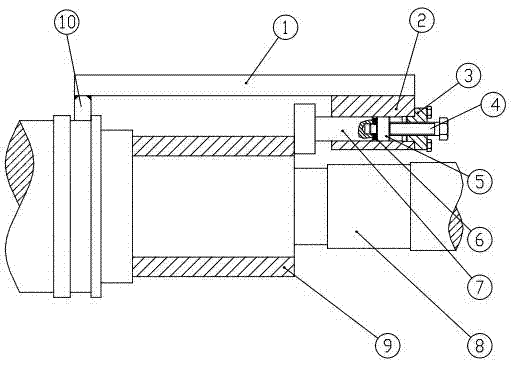

Mechanical shaping drum

A mechanical shaping drum including a carcass fastening mechanism features that the said mechanism has a cylinder-piston driven connecting rod unit which is composed of cylinder, piston, connecting rod of piston, sectorial block, guide spline and sealing plate. Its advantages are firmly fixing the type blank to the mechanical shaping drum, high antiwear performance and durability of the mechanical shaping drumo and low cost of production.

Owner:TIANJIN SAIXIANG TECH

Surface film laminating device for paper packaging box processing

InactiveCN113399330AEasy to cleanEasy to blockCleaning using toolsCleaning using gasesEngineeringAir blower

The invention discloses a surface film laminating device for paper packaging box processing. The surface film laminating device comprises a device body, wherein a conveying mechanism is arranged on the top surface of the device body, and a cleaning box is arranged at the top of the device body. According to the surface film laminating device, the cleaning box is arranged, dust on the surface of a packaging box can be conveniently cleaned before film laminating. During work, a worker places the packaging box on the conveying mechanism to move, then the conveying mechanism drives the packaging box to move into the cleaning box, and therefore the packaging box is limited by a limiting mechanism. Then, in the moving process, a brush plate in the cleaning box cleans the film laminating face of the packaging box. At the moment, the worker starts an air blower through a control panel, so that a dust suction hood collects the cleaned dust under the action of the air blower. The dust is collected into a collecting box through a dust suction pipe, and a first scraper is arranged on one side of the dust suction hood. The mode is easy to operate, and the packaging box is convenient to clean, so that the later film laminating quality is ensured.

Owner:江西优选时代包装有限公司

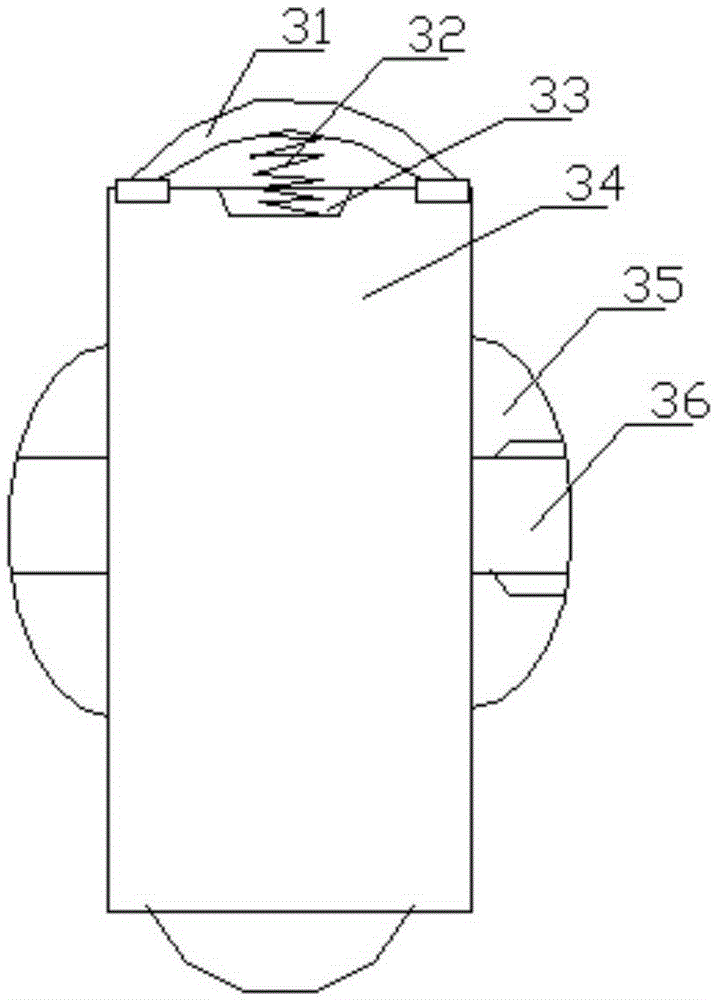

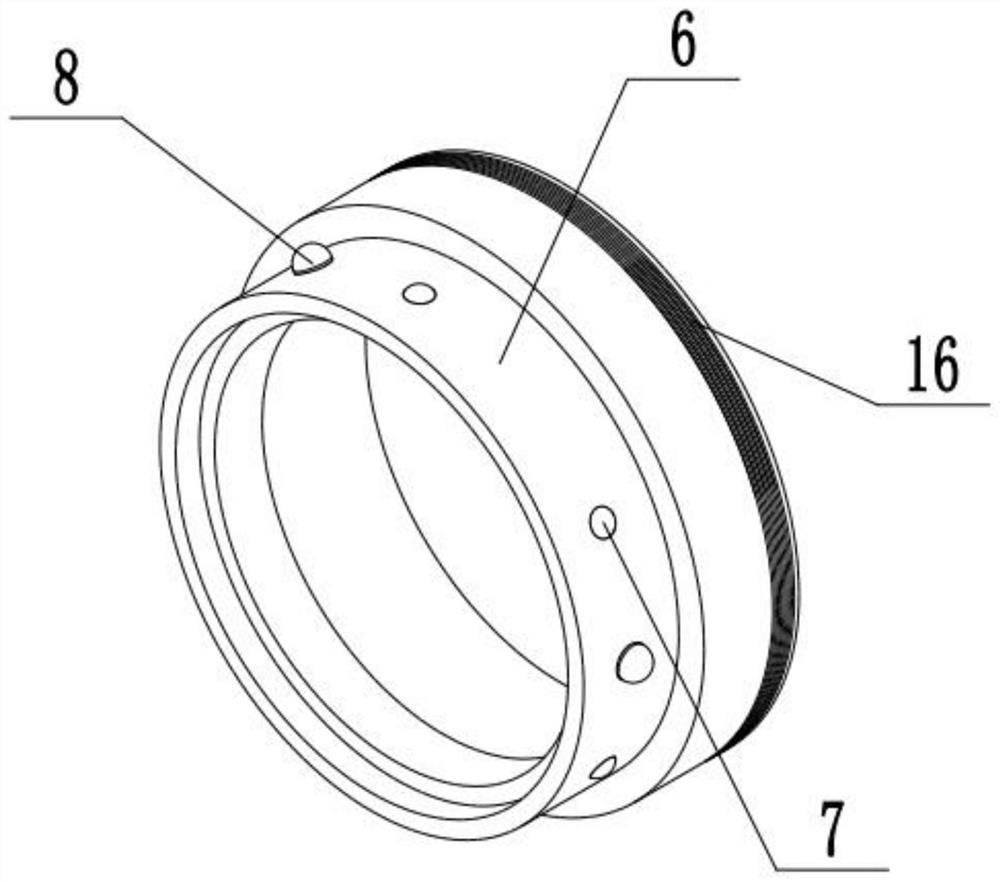

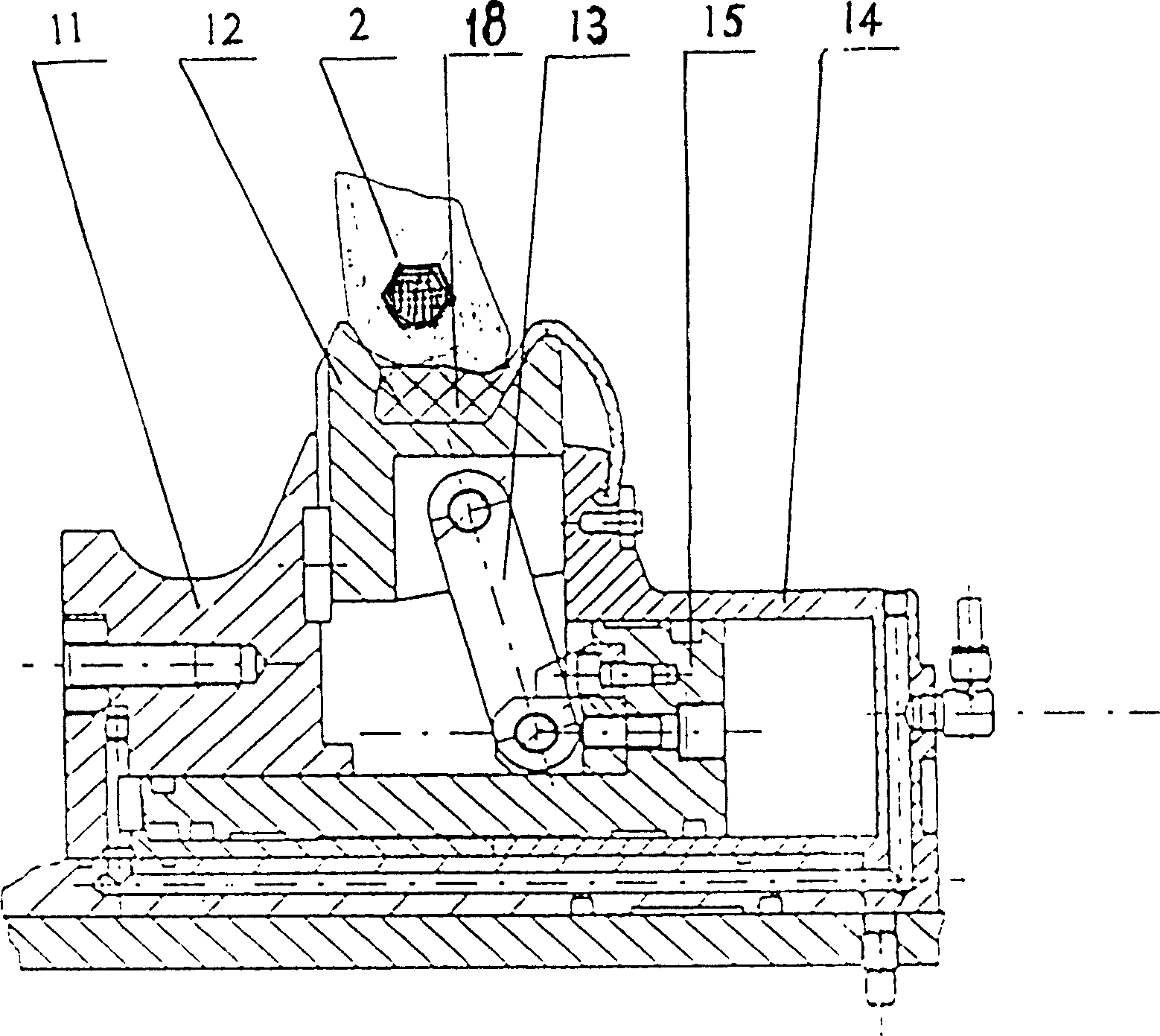

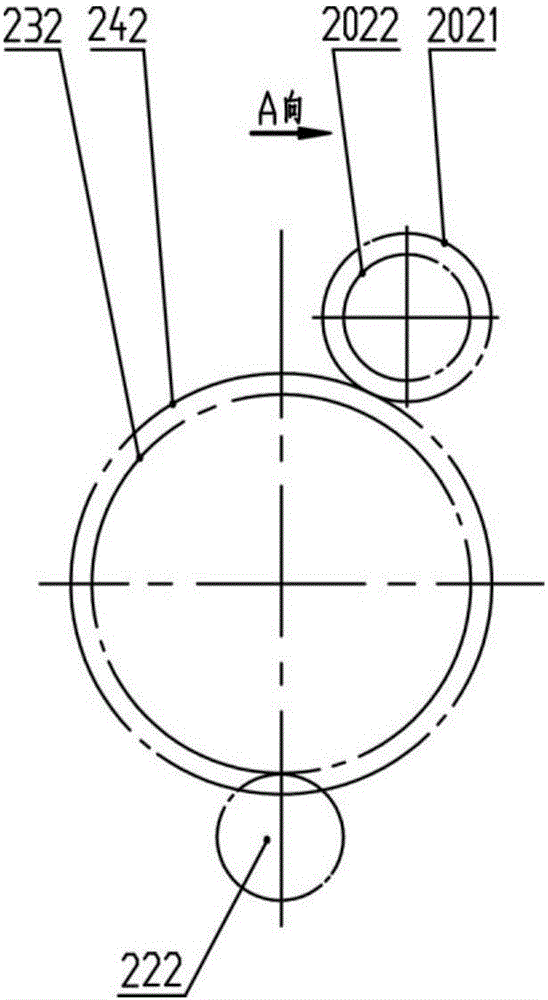

Vibrating drum with adjustable vibrating compacting force

InactiveCN106284032AEasy to convertImprove compaction qualityRoads maintainenceEngineeringIntelligent control

The invention provides a vibrating drum with adjustable vibrating compacting force. The vibrating drum comprises a drum body and a vibrating chamber, and the vibrating chamber is installed on the drum body through large bearing pedestals and supporting bearings and comprises a left vibrating chamber and a right vibrating chamber which are symmetrically arranged; a left vibrating shaft provided with a small eccentric block is installed in the left vibrating chamber through first large vibrating bearings, a right vibrating shaft provided with a small eccentric block is installed in the right vibrating chamber through second large vibrating bearings, and the left vibrating shaft and the right vibrating shaft are of the same structure and are connected through a middle vibrating shaft provided with a large eccentric block. By means of the mechanism, the vibrating modes of a vibrating roller can be conveniently and reliably switched, the compacting force can be automatically adjusted, and the different requirements of a compacted material for the compacting force in the initial stage of compacting and at the end of compacting can be met, so that the compacting quality is effectively improved; meanwhile, a foundation is laid for online intelligent control over vibrating parameters.

Owner:青岛科泰重工机械有限公司

Special tamping device for slope surface

InactiveCN107642081AAutomatic control of compaction workImprove stabilitySoil preservationBody movementMechanical engineering

The invention discloses a special tamping device for a slope surface. The special tamping device comprises a movable cart and a tamper body, the tamper body is fixedly mounted at the top of the movable cart, a placement cavity penetrates the end surface of the bottom of the tamper body and is arranged in the tamper body, a first beam and a second beam bilaterally extends and vertically and symmetrically arranged in the placement cavity, left extending tail ends and right extending tail ends of the first beam and the second beam are fixedly connected with the left inner wall and the right innerwall of the placement cavity, a first motor extends into the placement cavity and is fixedly arranged on the end surface of the top of the movable cart of the bottom of the placement cavity, a firstrotating shaft extends upwards and is connected with the top of the first motor in a matched manner, a top extending section of the first rotating shaft sequentially penetrates the second beam and thefirst beam from bottom to top and is rotatably connected with the second beam and the first beam in a matched manner, top extending tail end of the first rotating shaft extends into the placement cavity above the top of the first beam, and a top pressure eccentric wheel is fixedly arranged on the outer surface periphery of the first rotating shaft above the top of the first beam. The special tamping device is simple in structure, convenient to operate and high in tamping efficiency and quality, and working time is reduced.

Owner:毛林杰

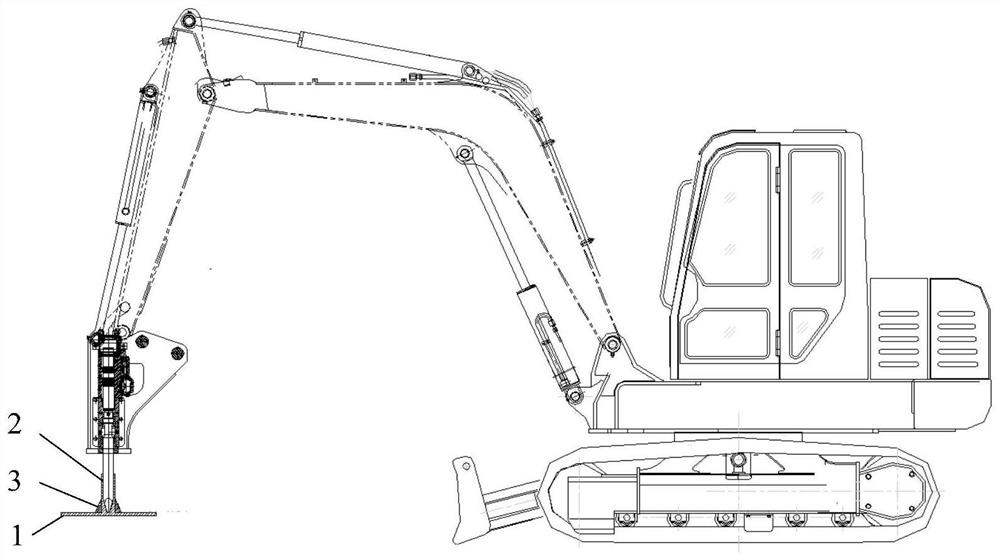

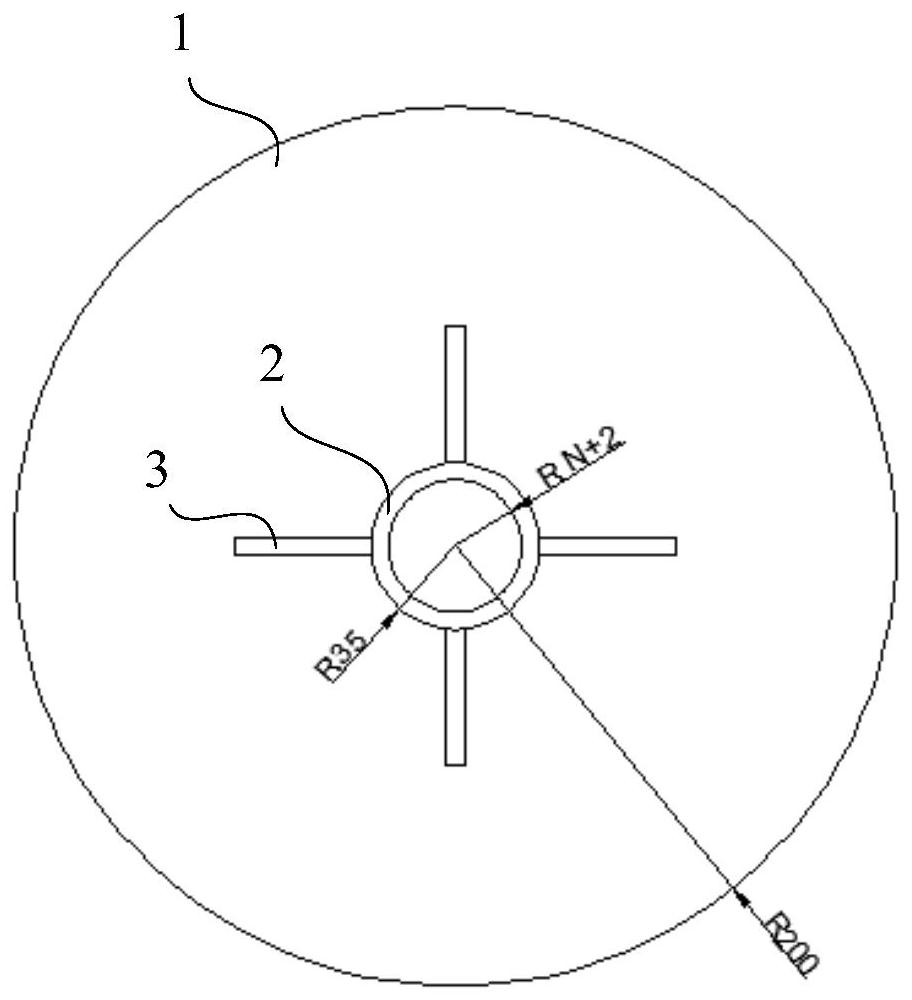

Tamping tool and tamping equipment

PendingCN113417277AFast compactionImprove compaction qualityMechanical machines/dredgersRoads maintainenceArchitectural engineeringExcavator

The invention relates to the technical field of building construction, and discloses a tamping tool and tamping equipment. The tamping tool comprises a pressing plate and a sleeve, wherein the bottom surface of the pressing plate is of a plane structure for compaction; and the central axis of the sleeve is perpendicular to the bottom surface of the pressing plate, the bottom end of the sleeve is fixedly connected with the upper surface of the pressing plate, and an inner hole in the top end of the sleeve is matched with the bottom end of a pickaxe of a breaking hammer. The tamping equipment comprises an excavator cab, the excavator breaking hammer and the tamping tool, wherein the excavator breaking hammer is detachably connected with the sleeve of the tamping tool. According to the tamping tool and the tamping equipment, a small-area can be compacted, and the compaction strength is guaranteed to reach the standard.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

Control method and system for eliminating beat vibration phenomenon of double-steel-wheel road roller

The invention discloses a control method and system for eliminating the beat vibration phenomenon of a double-steel-wheel road roller. The method comprises the steps: acquiring the vibration frequencyof a front steel wheel and the vibration frequency of a rear steel wheel; in response to the fact that the vibration frequency of the front steel wheel and the vibration frequency of the rear steel wheel are not zero, calculating the absolute value of the difference between the two vibration frequencies, and comparing the absolute value with a preset target value; in response to the fact that theabsolute value is larger than or equal to the target value, adjusting the vibration frequency of the front steel wheel or the vibration frequency of the rear steel wheel until the absolute value of the difference value is smaller than the target value, and stopping adjustment; according to the method, the absolute value of the difference value of the vibration frequencies of the two steel wheelsis obtained, the vibration frequency of the steel wheel with the small vibration frequency is controlled to be increased according to the absolute value, the difference value of the vibration frequencies of the two steel wheels is kept within a reasonable range, control is easy, and the whole machine beat vibration phenomenon is eliminated.

Owner:XCMG CONSTR MACHINERY

Automatic sand mold casting device

InactiveCN112276019AAvoid damageImprove distribution uniformityMoulding machine componentsMoulding machinesStructural engineeringIndustrial engineering

The invention discloses an automatic sand mold casting device, and belongs to the technical field of sand mold casting. The automatic sand mold casting device comprises a fixed box body, a balance placement assembly, a tamping assembly and a cleaning assembly, an extension edge is fixed at the upper end of the fixed box body, the cleaning assembly is fixed at the upper end of the extension edge, vertical plates are fixed on the inner sides of two ends of the extension edge, a transverse rod is fixed to the upper ends of the two vertical plates, the tamping assembly is fixed to the transverse rod, the balance placement assembly is arranged below the tamping assembly, and a workbench is fixed to the bottom of the balance placement assembly and fixed to the upper end of the fixed box body. According to the casting device, the heights of the two ends of an adjusting block can be adjusted through screwing-in of tensioning screws, then the placing levelness of the whole sand mold can be adjusted, the distribution uniformity of sand is improved, and the mold manufacturing quality is improved.

Owner:安徽省含山县林头郑孙铸造厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com