Cotton core transfer and compaction integrated device

A one-piece, cotton core technology, applied in medical science, clothing, underwear, etc., can solve problems such as inability to adjust, achieve the effect of improving embossing effect, improving compaction effect and compaction quality, and avoiding texture deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

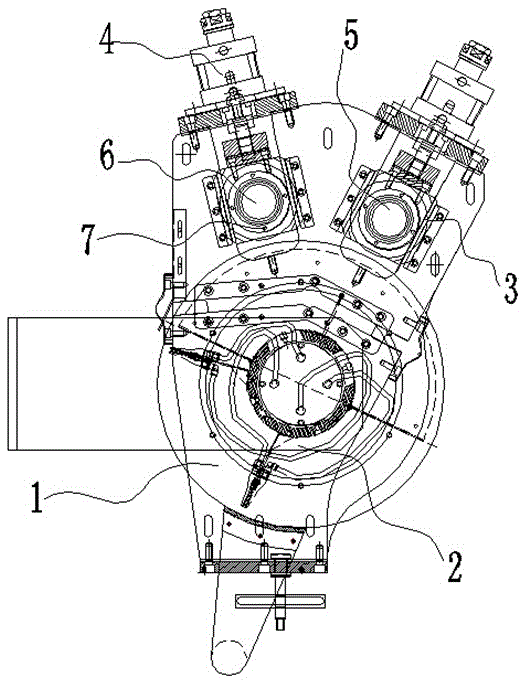

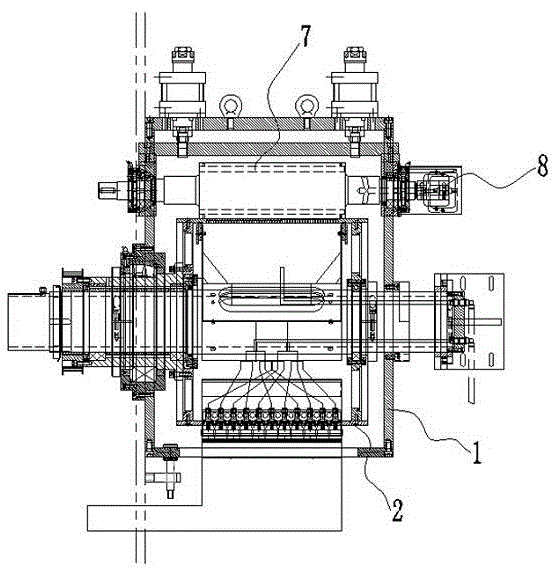

[0012] Refer to attached figure 1 , 2 . An integrated device for cotton core transfer and compaction, which includes a transfer wheel 2 arranged in a mounting frame 1, two pressure roller assemblies 3 arranged above the transfer wheel 2, and an air cylinder pressurization device arranged above the pressure roller assembly 3 4. The negative pressure adsorption assembly (not shown in the figure) located on the side of the installation frame 1, the negative pressure adsorption assembly cooperates with the transfer wheel 2 and forms a negative pressure air distribution area on the working side of the compacted cotton core of the transfer wheel 2; The structures of mounting frame 1, transfer wheel 2, pressure roller assembly 3, cylinder pressurizing device 4 and negative pressure adsorption assembly are all prior art, do not repeat them here; The pressure roller in two pressure roller assemblies 3, one is The embossing roller 6, the other is the smooth roller 5, the setting of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com