Tandem road roller vibration hydraulic system and control method as well as road roller

A technology of hydraulic system and vibration system, which is applied in the field of road machinery, and can solve the problems of low operating comfort for drivers and difficulty in eliminating the beating vibration of road rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

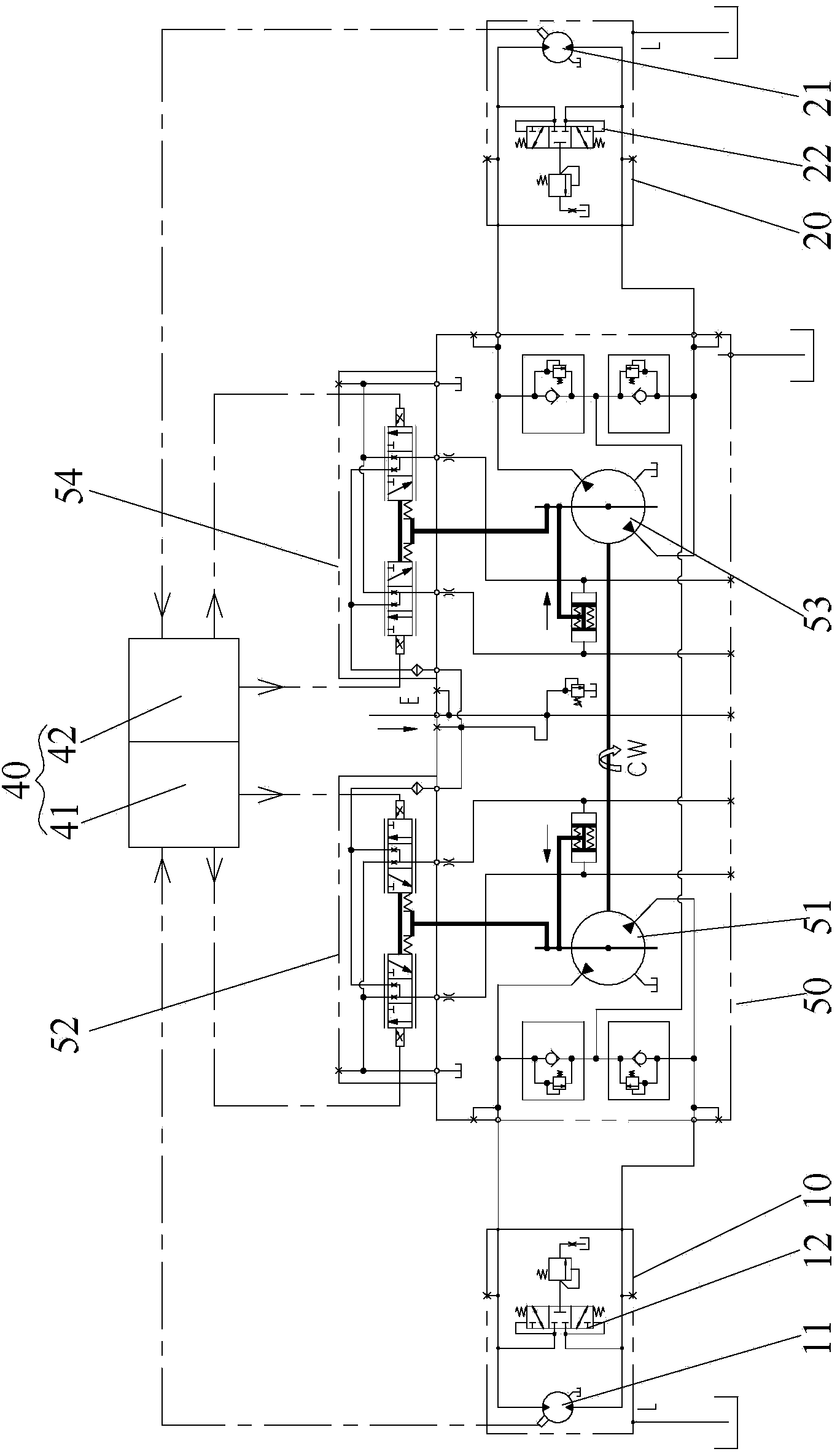

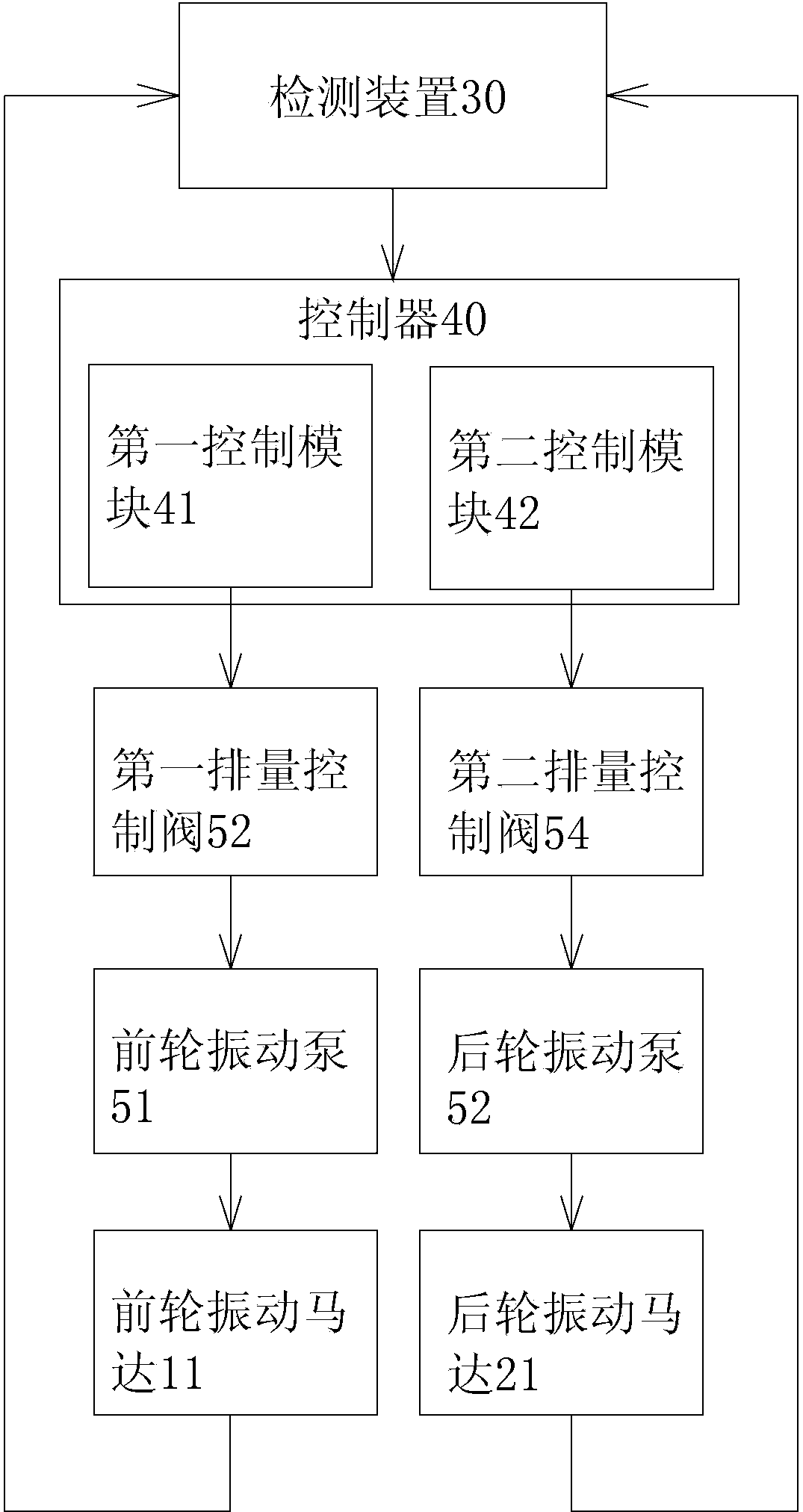

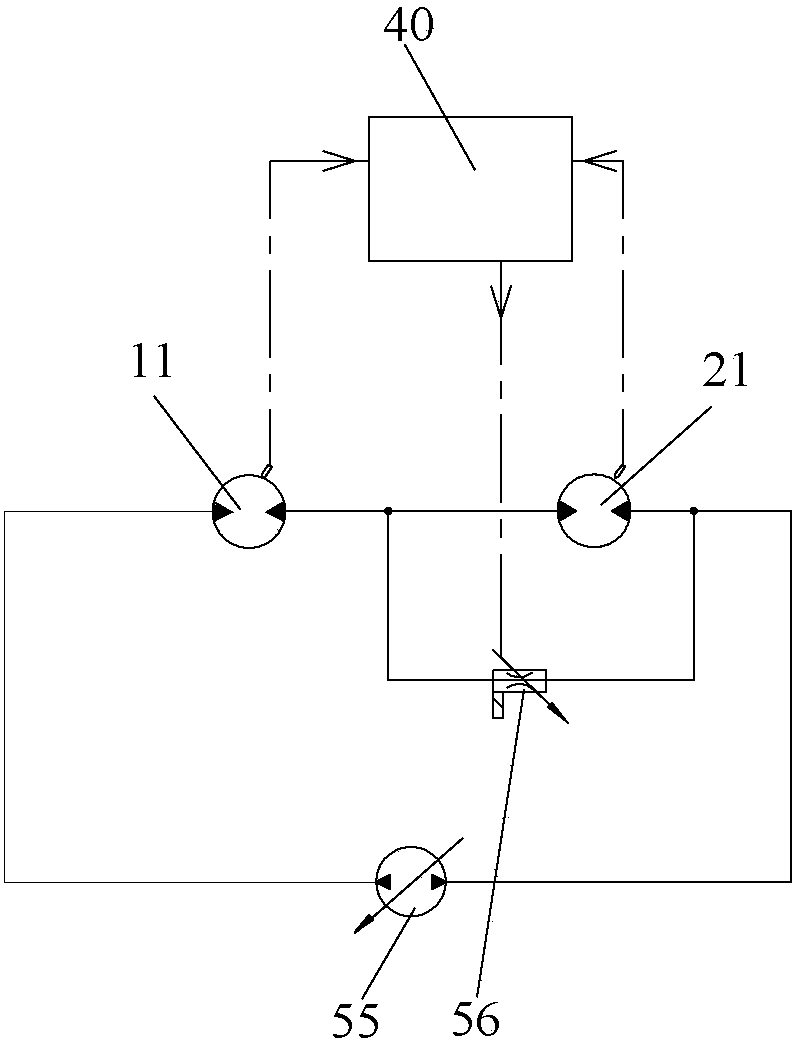

[0030]see in conjunction figure 1 and figure 2 As shown, according to the first embodiment of the present invention, the vibration pump system 50 includes a front wheel vibration pump 51 , a first displacement control valve 52 , a rear wheel vibration pump 53 and a second displacement control valve 54 . The front wheel vibration pump 51 is connected to the front wheel vibration system 10 and is used to provide the front wheel vibration system 10 with hydraulic oil required for vibration. The first displacement control valve 52 is connected to the front wheel vibration pump 51 and controls the displacement of the front wheel vibration pump 51 . The rear wheel vibration pump 53 is connected to the rear wheel vibration system 20 for providing the rear wheel vibration system 20 with hydraulic oil required for vibration. The second displacement control valve 54 is connected to the rear wheel vibration pump 53 and controls the displacement of the rear wheel vibration pump 53 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com