Novel netting type tamping method of filler for roadbed construction

A new type of roadbed technology, applied in infrastructure engineering, roads, circuits, etc., can solve problems such as falling off, weak bonding force of the lower side roadbed, low compaction quality, etc., achieve good thermal conductivity, avoid thermal conductivity decline, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

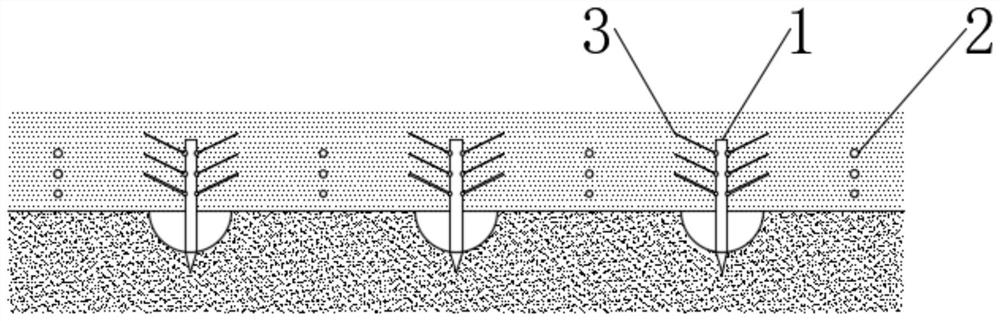

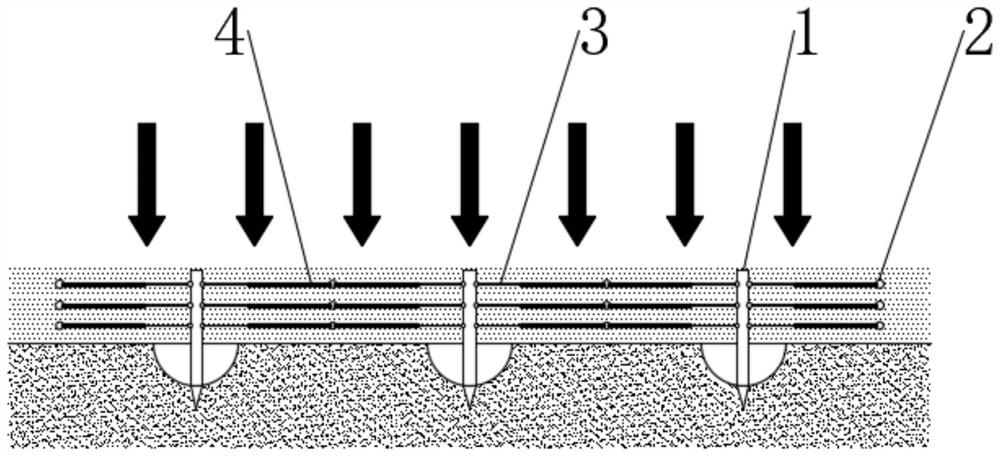

[0050] see Figure 1-2 A novel netting type compaction method for fillers used in roadbed construction, comprising the following steps:

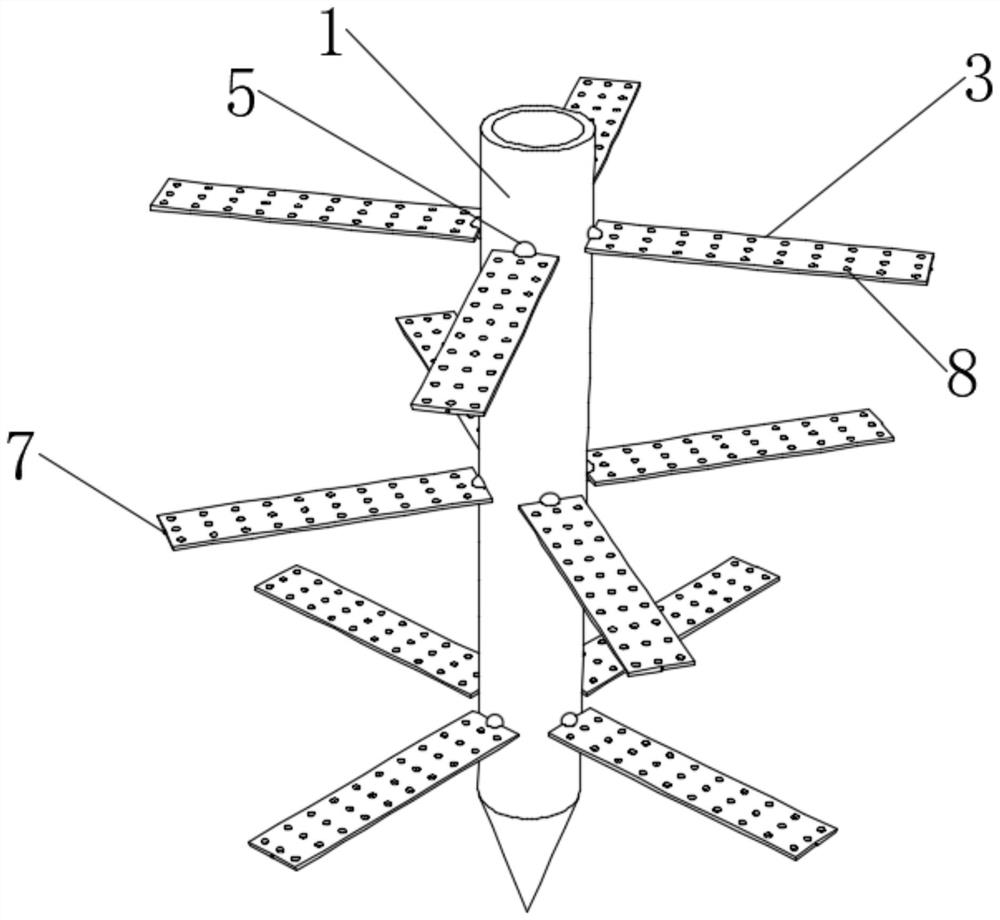

[0051] S1. Reserve or excavate a plurality of evenly distributed semi-buried pits before compaction, and vertically bury the pre-embedded rods 1 to assist compaction in the semi-buried pits;

[0052] S2. Start layering and filling the filler. On each layer of filler, place multiple pieces of netting node magnetic balls 2 that are evenly distributed around the tamping pre-embedded rods 1, and the netting node magnetic balls 2 between the upper and lower layers are staggered;

[0053] S3. Mark the pre-embedded rod 1 on the top layer of filler, and then use a large-scale compaction machine to compact the filler as a whole;

[0054] S4. Excavate part of the filler at the marked place to observe whether the pre-embedded rod 1 is fully unfolded. If it is fully unfolded, backfill the excavated seasoning. If it is not fully unfolded, manually promo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com