Low-energy-consumption asphalt concrete pavement hot in-place recycling method

A technology of asphalt concrete and low energy consumption, applied in roads, roads, road repair and other directions, to achieve the effect of reducing porosity, prolonging the life of pavement, and improving the degree of compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

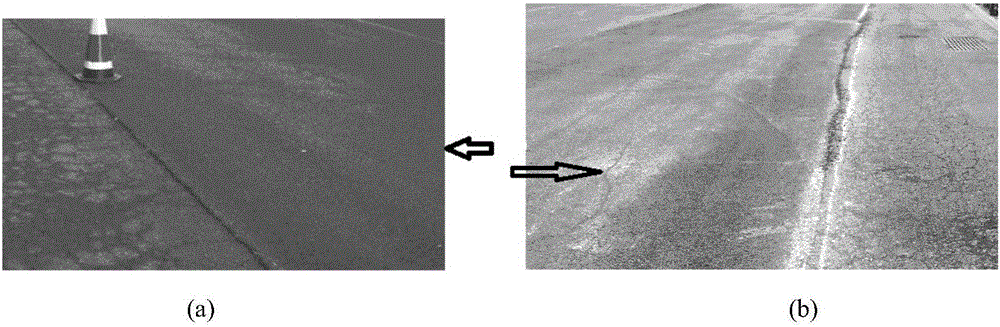

[0039] In-situ hot regeneration of asphalt concrete pavement was carried out on a certain road in Qinhuangdao City, and the original surface damage of the pavement (such as potholes, cracks, ruts, etc.) accounted for 32.6% of the pavement. On the day of construction, the weather was good, with no rainfall, the atmospheric temperature was above 25°C, and the road surface temperature was above 40°C. There was no precipitation within 2 days before construction, and there was no water accumulation in the old asphalt pavement samples taken before construction.

[0040] Hot-in-place regeneration includes the following steps:

[0041] (1) Clean the road surface and draw guide lines

[0042] The cross slope of the hot-in-place regeneration construction road surface still adopts the original road surface cross slope, and the guide line is drawn outside the width of the road surface to be treated, or the edge line of the road surface is used as the guide line to ensure that the construc...

Embodiment 2

[0056] In-situ thermal regeneration of asphalt concrete pavement for a certain road in Quzhou City. The original surface damage of the pavement (such as potholes, cracks, ruts, etc.) accounted for 28.4% of the pavement, and seriously aged road sections accounted for 33.2%. On the day of construction, the weather was good and there was no rainfall. ℃ and above, there is no precipitation within 3 days before construction, and there is no water in the old asphalt pavement samples taken before construction.

[0057] Hot-in-place regeneration includes the following steps:

[0058] (1) Clean the road surface and draw guide lines

[0059] The transverse slope of the hot-in-place regeneration construction still adopts the original road surface transverse slope, and draws the guiding line outside the width of the road surface to be treated, or uses the edge line of the road surface as the guiding line to ensure that the construction equipment runs straight and the regeneration constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com