Special tamping device for slope surface

A tamping device and slope surface technology, which is applied in the fields of soil protection, construction, infrastructure engineering, etc., can solve the problems of inability to tamp the slope surface, increase the working time, increase the economic cost, etc., and achieve simple structure and reduce work The effect of saving time and reducing economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

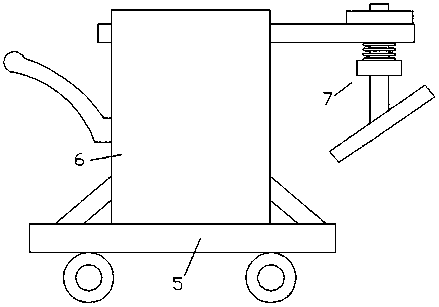

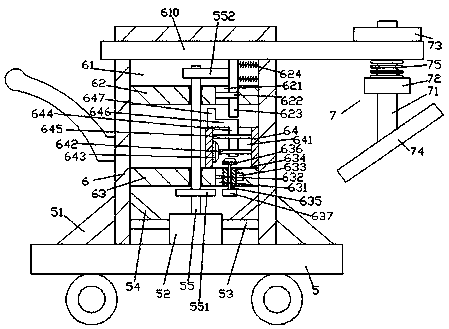

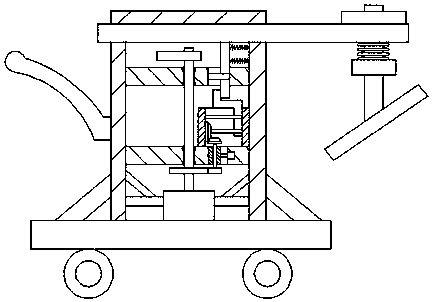

[0021] Such as figure 1 — Figure 4 As shown, a special tamping device for a slope surface of the present invention includes a mobile body 5 and a tamping body 6 fixedly installed on the top of the mobile body 5 , the tamping body 6 is provided with a The placement chamber 61 on the end face, the first crossbeam 62 and the second crossbeam 63 extending left and right are symmetrically arranged inside the placement chamber 61, and the extension ends on the left and right sides of the first crossbeam 62 and the second crossbeam 63 are respectively connected with The inner walls of the left and right sides of the placement chamber 61 are fixedly connected, and the top end surface of the mobile vehicle body 5 at the bottom of the placement chamber 61 is fixedly provided with a first motor 52 extending into the placement chamber 61. The first motor 52 The top is connected with the first rotating shaft 55 extending upwards, and the top extension of the first rotating shaft 55 runs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com