Test method for measuring maximum dry density of soil and stone mixture of road subgrade

A technology of maximum dry density and test method, which is applied in the preparation of test samples, measuring devices, specific gravity measurement, etc., can solve the problems such as difficult to accurately measure the height of the test piece, the surface of the test piece is difficult to flatten, and the moisture content of the material changes greatly. Effect of increasing indoor standard density, reliable results, and increasing compaction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

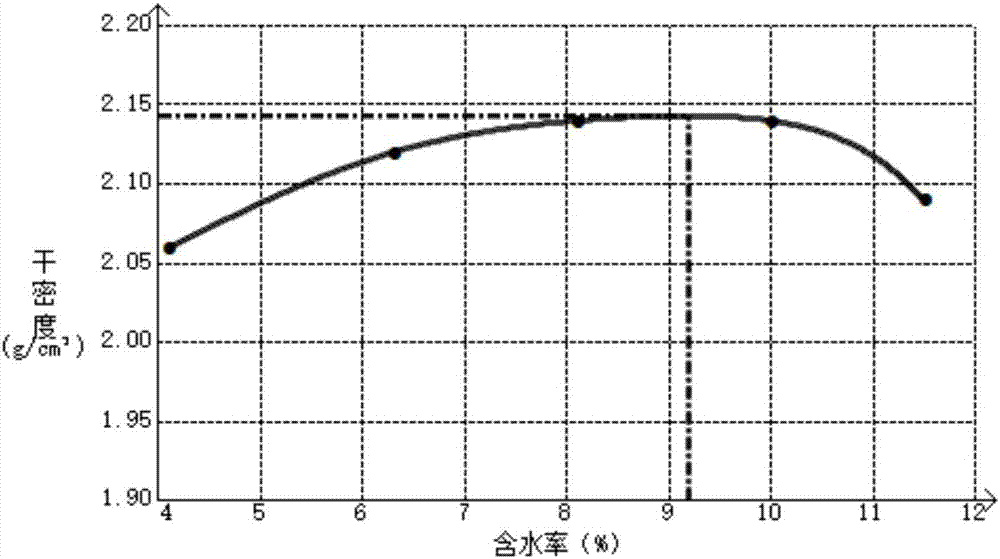

[0043] Embodiment 1 (soil-rock ratio is 60:40)

[0044] The test method of the maximum dry density of the mensuration roadbed soil-rock mixture of the present embodiment is carried out through the following steps:

[0045] Step 1: Take out a sufficient amount of soil-rock mixture from the pile pulled back from the construction site, place it on several medium-sized iron pans, and then place it in an oven for heating and drying. The temperature of the oven is set at 105 ℃, drying for 6 hours;

[0046] Step 2, take out the iron box containing the dried test materials from the oven, and put it in the open space of the laboratory to cool down for 30 minutes; pour the soil-rock mixture into the material sieve corresponding to the sieve holes of 0-60mm After adding an appropriate amount of soil and stone, cover the sieve cover and place it on a shaker for sieving; after vibrating for about 10 to 15 minutes, remove the sieve from the shaker to remove particles with a size above 40mm...

Embodiment 2

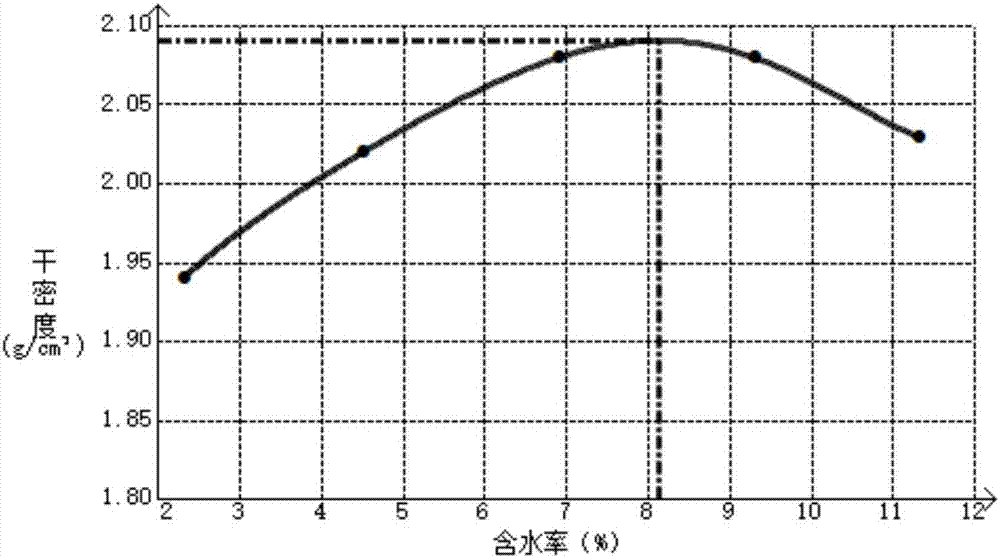

[0060] Embodiment 2 (soil-rock ratio is 50:50)

[0061] The test method of the maximum dry density of the mensuration roadbed soil-rock mixture of the present embodiment is carried out through the following steps:

[0062] Step 1: Take out a sufficient amount of soil-rock mixture from the pile pulled back from the construction site, place it on several medium-sized iron pans, and then place it in an oven for heating and drying. The temperature of the oven is set at 105 ℃, drying for 6 hours;

[0063] Step 2, take out the iron box containing the dried test materials from the oven, and put it in the open space of the laboratory to cool down for 30 minutes; pour the soil-rock mixture into the material sieve corresponding to the sieve holes of 0-60mm After adding an appropriate amount of soil and stone, cover the sieve cover and place it on a shaker for sieving; after vibrating for about 10 to 15 minutes, remove the sieve from the shaker to remove particles with a size above 40mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com