Power matching control system for novel energy-saving double-drum vibratory roller

A technology of vibratory rollers and control systems, which is applied to electrical program control, program control in sequence/logic controllers, roads, etc., and can solve problems such as increasing the cost of using vibratory rollers, affecting the quality of operations at the start-up stage, and deteriorating dynamic characteristics. , to achieve the effect of improving comprehensive control performance, novel design, and restraining inertial impact load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

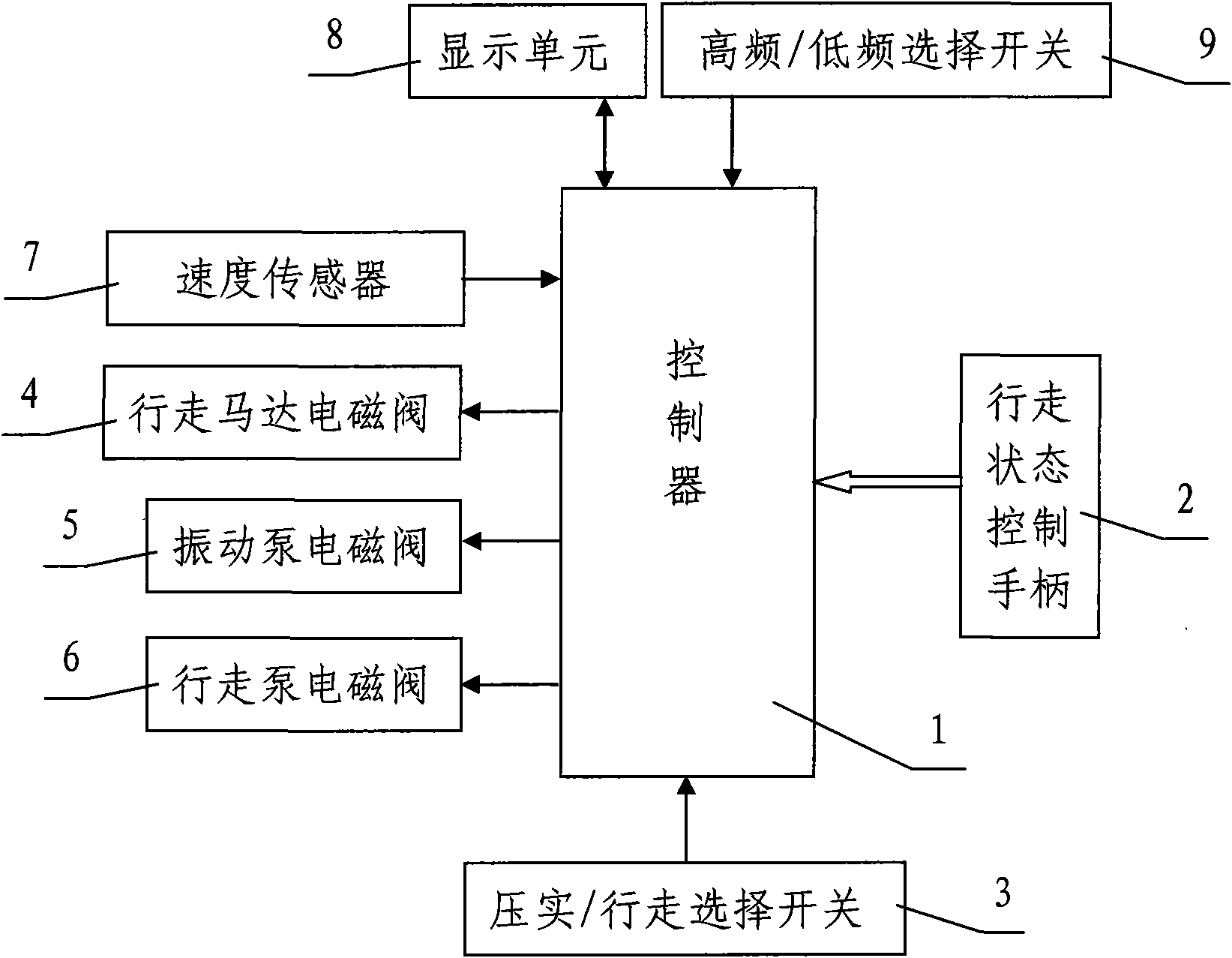

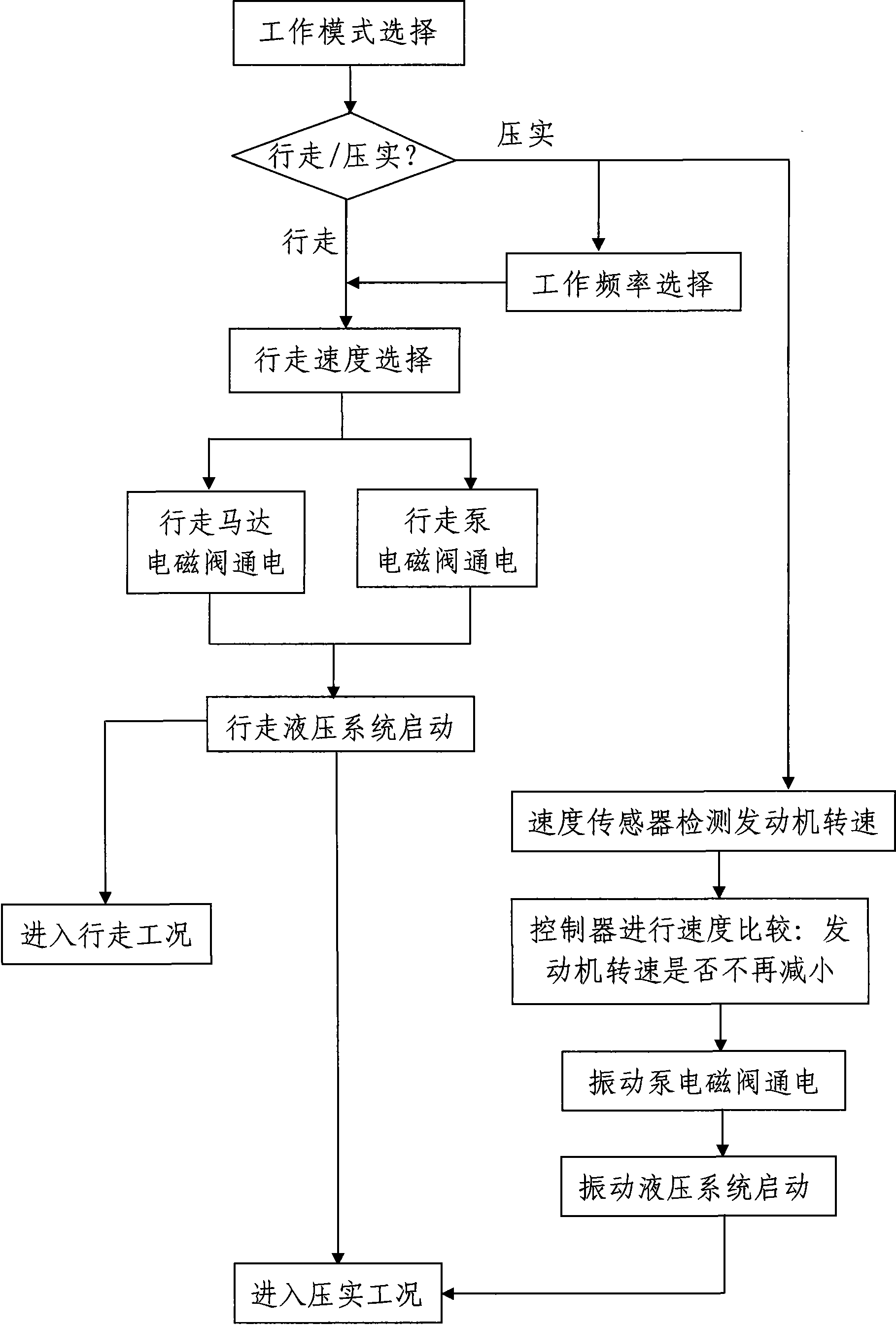

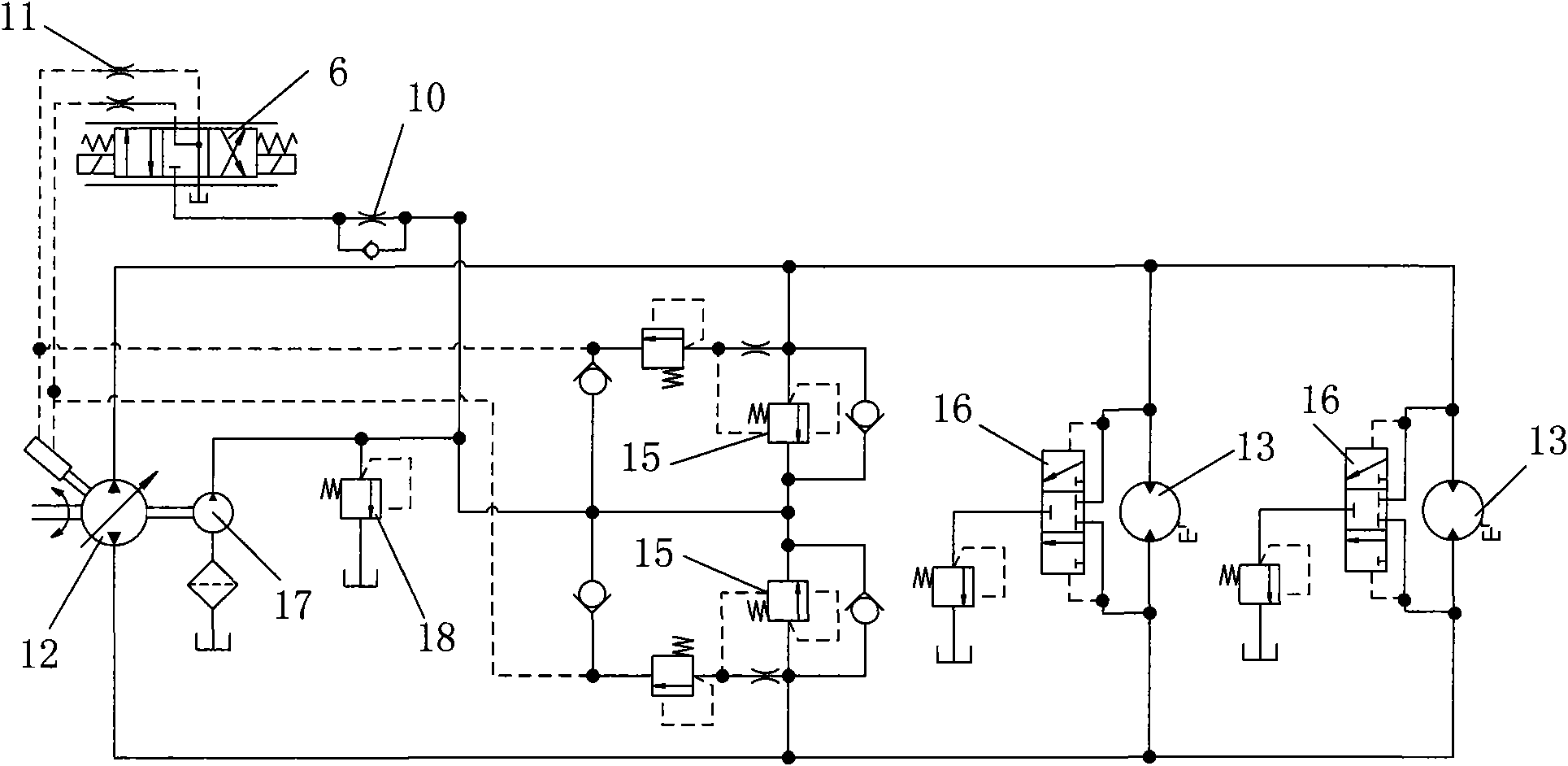

[0035] Such as figure 1As shown, the present invention includes a controller 1, a walking state control device for controlling and adjusting the walking speed and the forward and backward direction of the double-drum vibratory roller, and a device for controlling and adjusting the working frequency during the compaction operation of the double-drum vibratory roller. A frequency adjustment switch, a compaction / travel selection switch 3 for selecting the traveling state and the compacting state of the double-drum vibratory roller, and a speed sensor 7 for detecting the engine speed of the double-drum vibratory roller in real time. The walking state control device, frequency adjustment switch and compaction / walking selection switch 3 are all connected to the controller 1 . In addition, the present invention also includes a display unit 8 connected to the controller 1 .

[0036] The traveling pump solenoid valve 6 and the traveling motor solenoid valve 4, which control the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com