Control method and system for eliminating beat vibration phenomenon of double-steel-wheel road roller

A technology of a control system and a control method, applied in the field of road rollers, can solve problems such as difficulty in eliminating the vibration phenomenon, and achieve the effects of eliminating the vibration phenomenon of the whole machine, improving the operation comfort and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

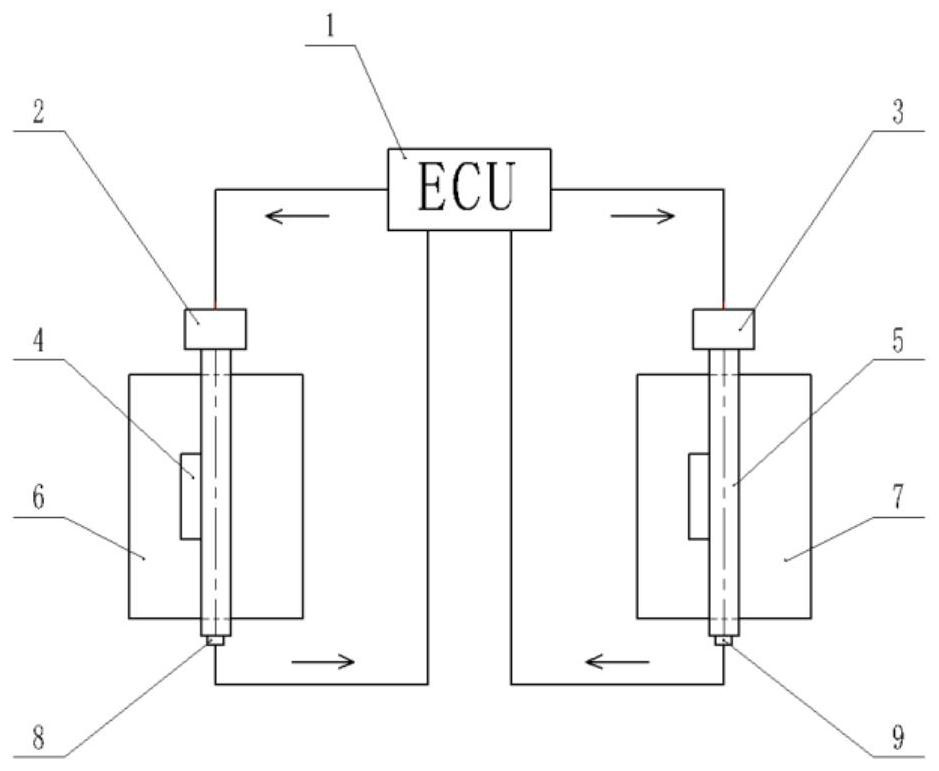

[0035] In order to eliminate the vibration phenomenon, the absolute value of the frequency difference between the front and rear steel wheels is used as a reference in the present invention, and a control method and system for adjusting the vibration frequency can be realized by adjusting the hydraulic oil flow rate, so that the vibration frequency difference between the front and rear steel wheels Maintain within the set range to ensure the normal operation of the equipment.

[0036] The purpose of the present invention is to eliminate the beating vibration phenomenon produced when the two steel wheels of the double-drum roller vibrate at the same time, and compare the absolute value of the vibration frequency difference between the front and rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com