BIM-based road compaction synchronous monitoring and feedback control system

A feedback control system, real-time monitoring technology, applied in hardware monitoring, database management system, image data processing and other directions, can solve the problems of limited detection points, detection time lag, lack of real-time performance, etc., to improve detection and control level, reduce Human decision-making cost and error, the effect of continuous detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

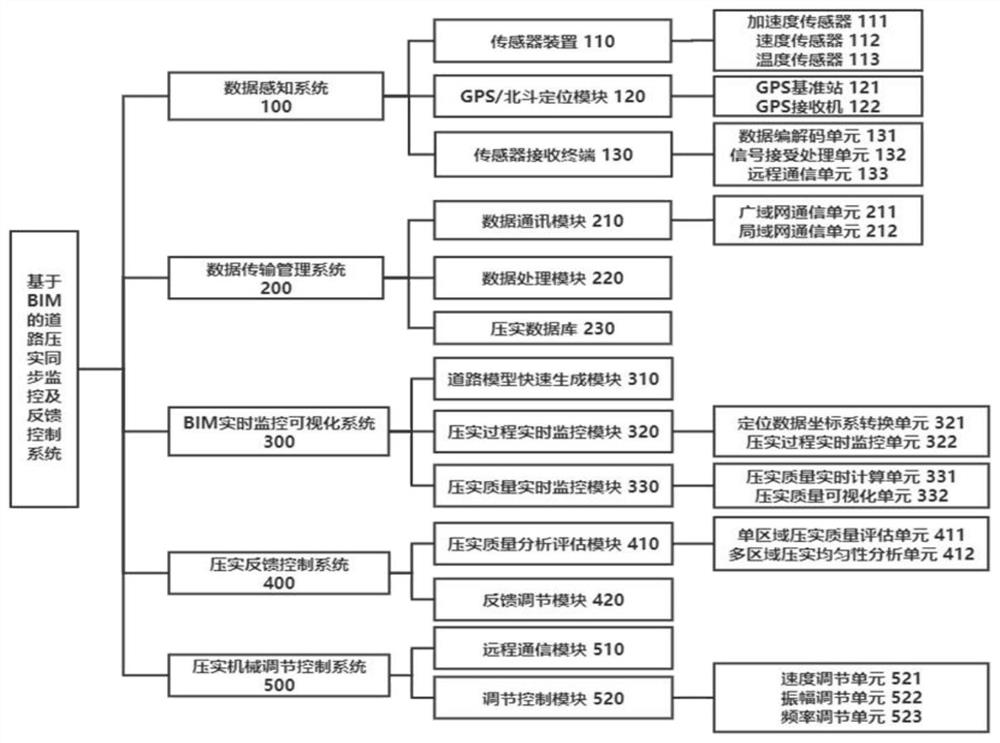

[0049] attached figure 1 A schematic structural diagram of a BIM-based road compaction synchronous monitoring and feedback control system provided by Embodiment 1 of the present invention, including the following components: data perception system 100, data transmission management system 200, and BIM real-time visual monitoring system 300 , a compaction feedback control system 400 , and a compaction machinery adjustment control system 500 .

[0050] as attached figure 1 As shown, the data sensing system 100 includes a sensor device 110, a GPS / Beidou positioning module 120 and a sensor receiving terminal 130. The system is deployed on a single road roller for collecting real-time compaction data information.

[0051] In this embodiment, the on-site compaction data information in the road compaction process is collected in real time by the sensor device 110, which includes: the real-time vertical vibration acceleration response signal of the road roller collected by the acceler...

Embodiment 2

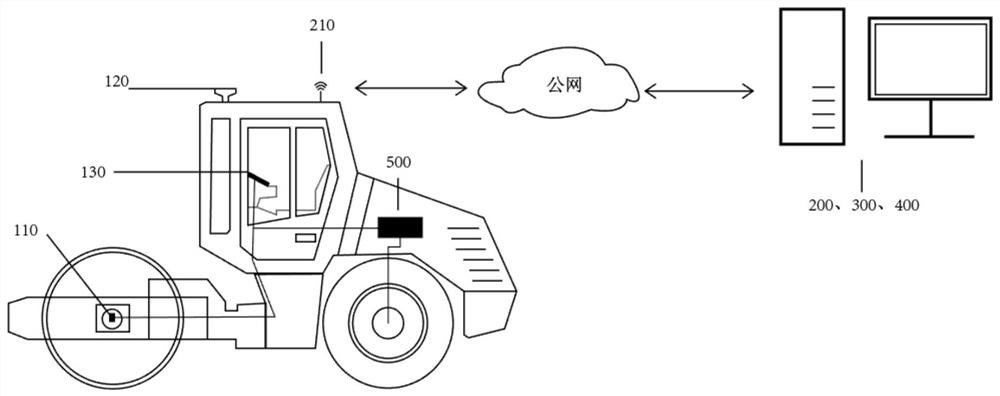

[0066] Embodiment 2 of the present invention provides a schematic diagram of a deployment scheme of a BIM road compaction synchronous monitoring and feedback control system, as shown in the attached figure 2 shown. The deployment scheme relies on a BIM-based road compaction synchronous monitoring and feedback system, which adopts the BIM-based road compaction synchronous monitoring and feedback control system in the first embodiment above.

[0067] as attached figure 2 Shown is a schematic diagram of the deployment of each system module. The data sensing system 100 is deployed and installed on a single road roller. The system includes: a sensor device 110 , a GPS / Beidou positioning module 120 , and a sensor receiving terminal 130 . Among them, the sensor device 110 is installed on the intermediate shaft of the vibrating roller of the road roller, the GPS / BeiDou positioning module 120 is installed on the top of the road roller cab, and the sensor receiving terminal 130 is in...

Embodiment 3

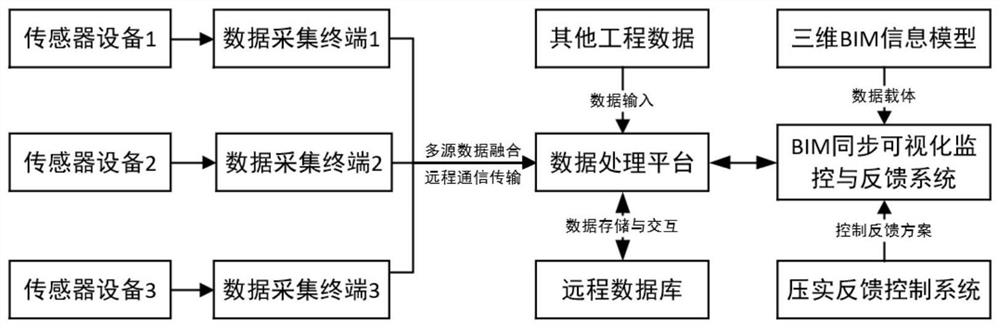

[0071] Embodiment 3 of the present invention provides a flow of real-time data collection, transmission interaction, and feedback adjustment in a working state of the system. The process relies on a BIM-based road compaction synchronous monitoring and feedback system, which adopts the BIM-based road compaction synchronous monitoring and feedback control system in the above-mentioned embodiment 1, and the system deployment method adopts the above-mentioned embodiment 2 System deployment structure.

[0072] as attached figure 2 A schematic diagram of the deployment of each system module is shown. When a single vibratory roller starts to work, the entire data sensing system starts to work, figure 2 The 110 sensor devices in the center integrate three-axis acceleration sensors, speed sensors, and infrared temperature sensors, and will collect the forward speed data of the road roller, the vibration acceleration data of the vibrating wheel, and the temperature data of the road ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com