Leather collar under pin and sipnning frame using same

A technology of the apron and straight part, which is applied in the field of the lower pin of the apron in the drafting mechanism of the spinning frame, which can solve the problems of not being able to effectively control the sliver, weakening the strength of the main drafting zone, and insufficient control of the sliver.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

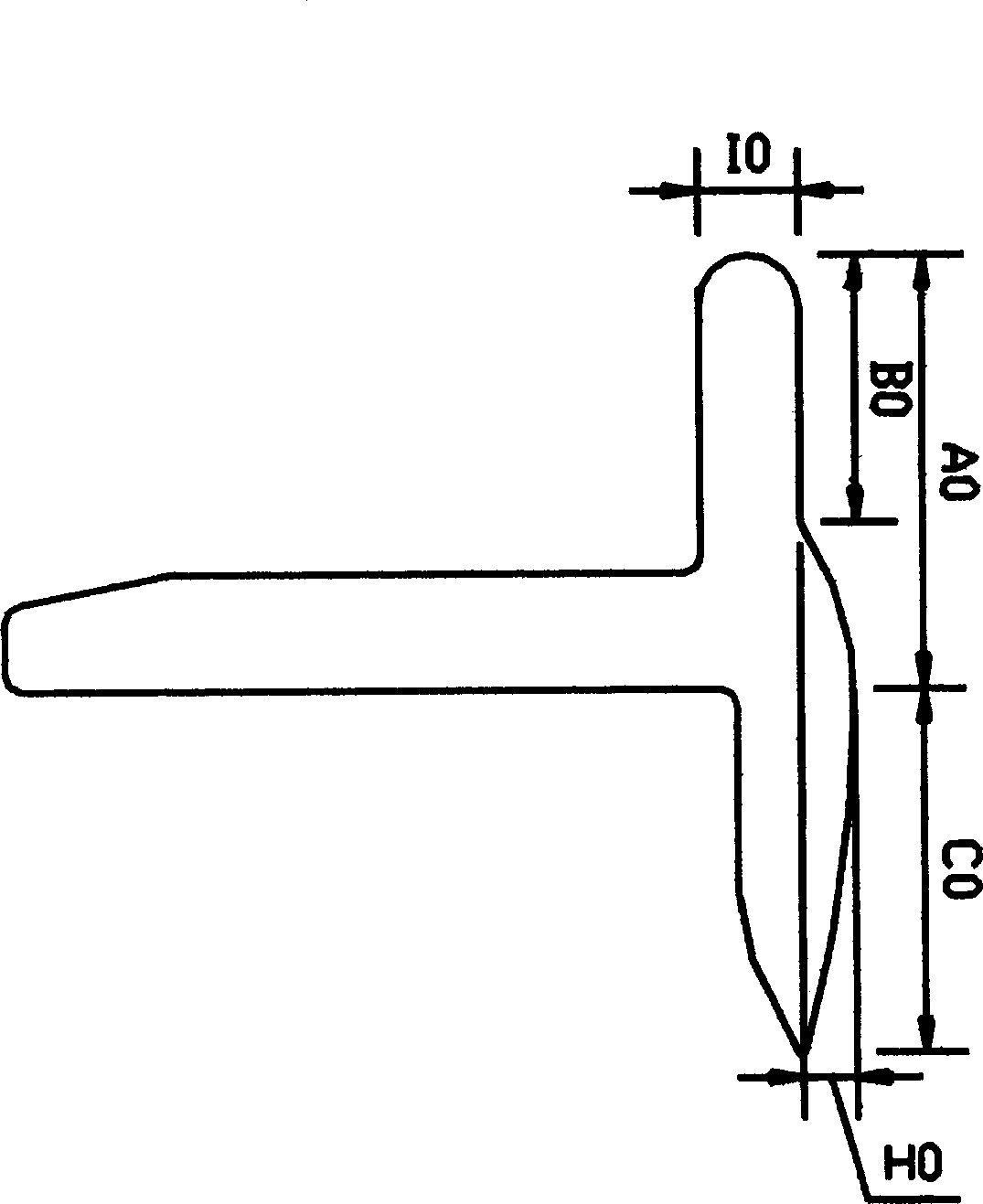

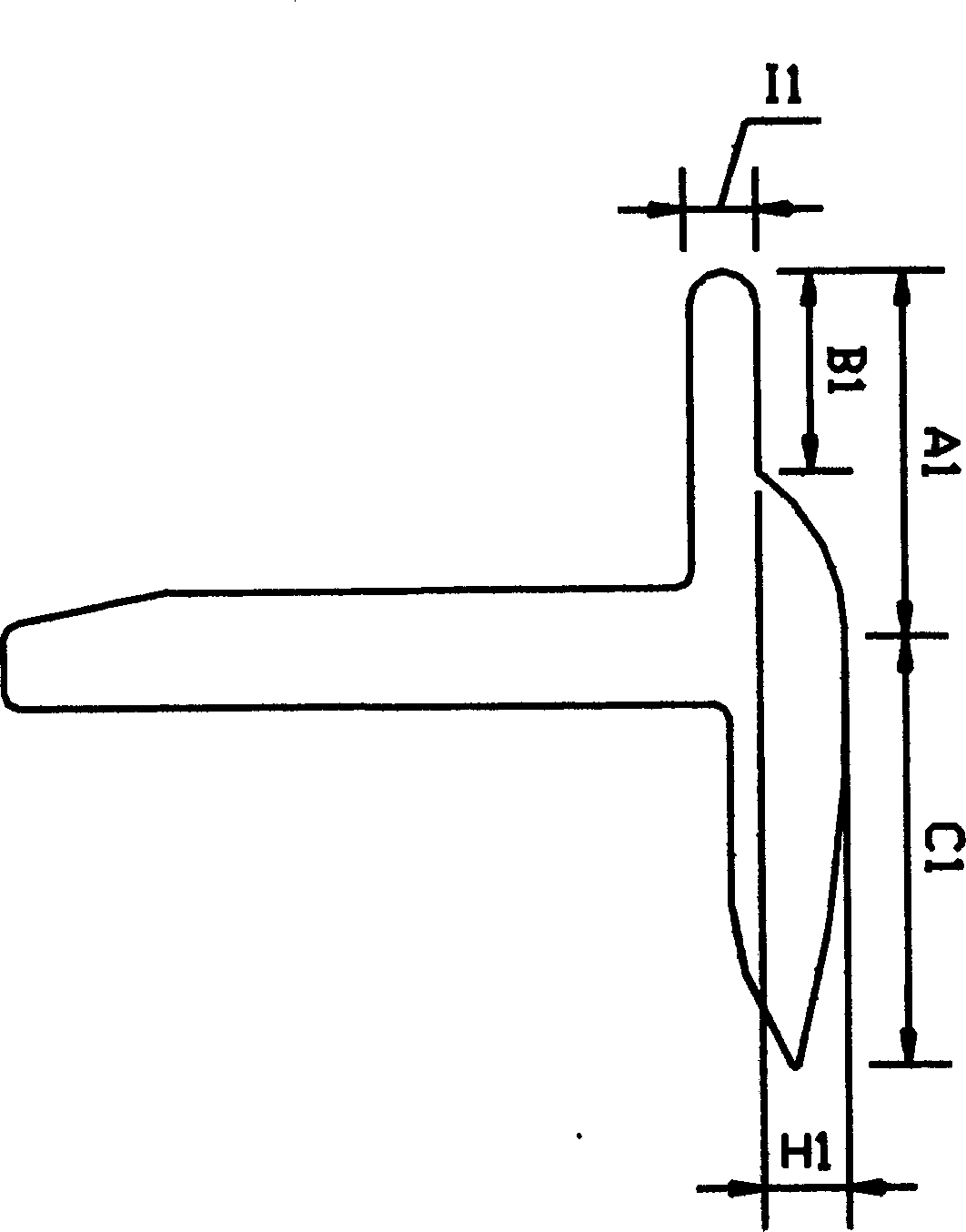

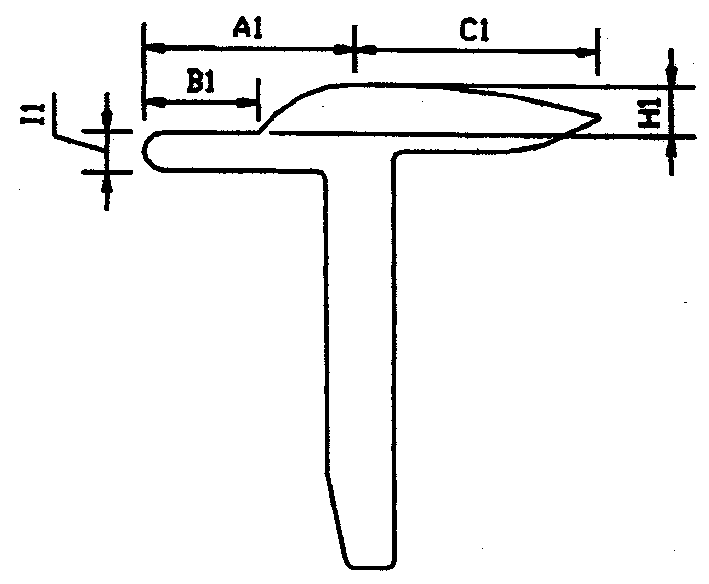

[0014] Experimental model: A512V, DVX pneumatic pressure; spinning 40 counts of combed cotton yarn; the structural size of the lower pin using the apron is: the length of the straight part B1 is 6 mm; the length of the curved part connected with the straight part B1 is 18 mm, and the distance A1 from the highest point to the front edge of the straight part is 11 mm, and the distance C1 from the highest point to the tail end of the lower pin of the apron is 13 mm; the thickness I1 of the straight part is 2 mm, and the height between the curved part and the straight part The difference H1 is 2.5 mm. The experimental results are shown in Table 1:

[0015] indicators

(%)

dry

cv

detail

-50

detail

-40

detail

-30

rough place

+100

Thick place

+70

Thick place

+50

Thick place

+35

Neps

+280

Neps

+200

original sales

13.01

4

126.6

1337

0

2.4

29

295

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com