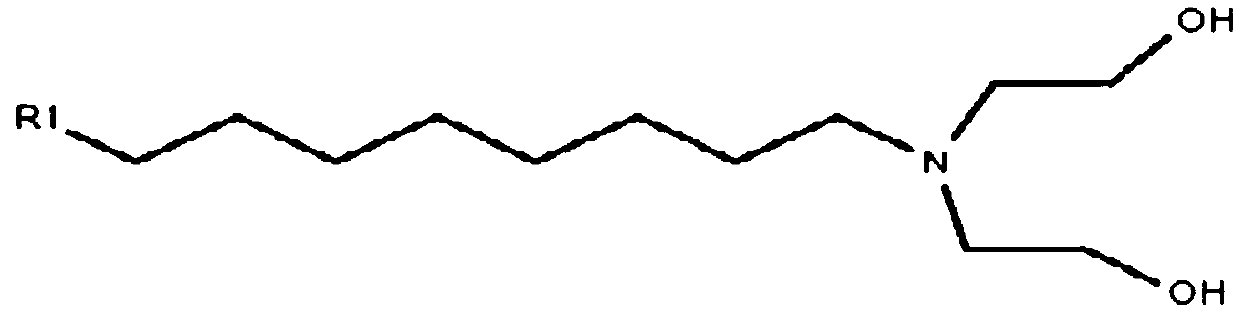

Polypropylene composition with high surface tension and preparation method thereof

A polypropylene composition and high surface technology, applied in the field of polypropylene composition and its preparation, can solve the problems of damage to the properties of the polypropylene composition, large addition amount of polar modifier, complicated preparation process, etc., and achieve improved spray coating. The effect of improving compatibility, improving compatibility and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention also discloses a preparation method of a polypropylene composition with high surface tension, comprising the following steps:

[0038] According to the mass ratio of water: silane coupling agent is 1 ~ 2: 1, the silane coupling agent solution is prepared, and at the same time, the filler is put into the stirring container, the temperature is set at 100 ~ 110 ° C, the speed is 600 ~ 800 rpm, according to the silane coupling agent The addition ratio is 1.0-1.5wt%, and the silane coupling agent solution is sprayed on the filler at least three times. After each spraying, the stirring container is started to treat for 6-8 minutes, and the treated filler is fully dried at 60-80°C to obtain Surface-modified fillers, multiple sprays and high-speed mixing can distribute the silane coupling agent solution evenly on the filler surface to the maximum extent, thereby significantly improving the combination of fillers and matrix resins and improving the performance of mo...

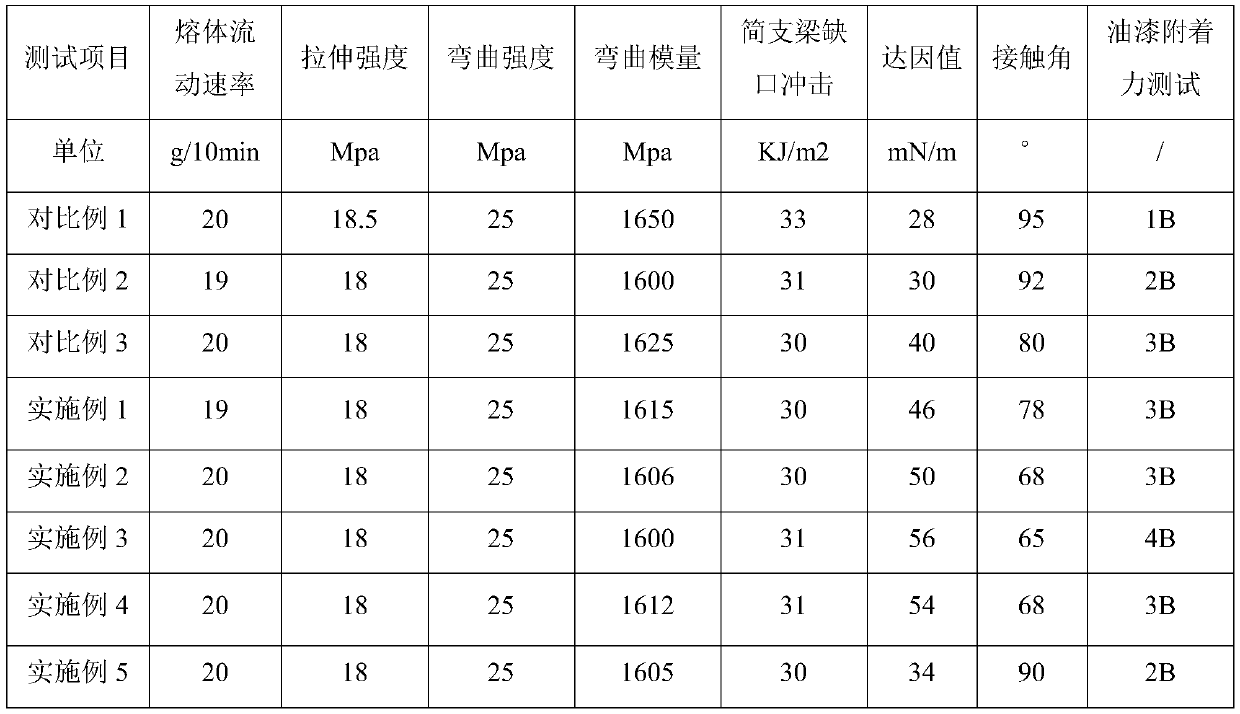

Embodiment 1

[0054] 15 parts of M60T, 31 parts of K7227, 20 parts of 1215C, 20 parts of modified talcum powder, 10 parts of toughening agent, 1 part of self-made polar modification aid with polar groups, 2 parts of maleic anhydride grafted Polypropylene, 0.2 parts of 1010, 0.2 parts of 168, 0.2 parts of EBS, and 0.4 parts of carbon black were put into a high-speed mixer with a speed of 600 R / min and mixed for 6 minutes, and the mixed materials were put into a twin-screw extruder to extrude and pelletize. The material rate is 450kg / h, the screw speed is 500rpm, the temperature setting of each zone of the extruder is 180, 210, 220, 210, 210, 200, 210, 210, 200°C, and the vacuum degree is maintained at -0.06~-0.08MPa;

Embodiment 2

[0056] 15 parts of M60T, 30 parts of K7227, 20 parts of 1215C, 20 parts of modified talcum powder, 10 parts of toughening agent, 2 parts of self-made polar modification additives with polar groups, 2 parts of maleic anhydride grafted Polypropylene, 0.2 parts of 1010, 0.2 parts of 168, 0.2 parts of EBS, and 0.4 parts of carbon black were put into a high-speed mixer with a speed of 600 R / min and mixed for 6 minutes, and the mixed materials were put into a twin-screw extruder to extrude and pelletize. The material rate is 450kg / h, the screw speed is 500rpm, the temperature setting of each zone of the extruder is 180, 210, 220, 210, 210, 200, 210, 210, 200°C, and the vacuum degree is maintained at -0.06~-0.08MPa;

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com