Long-acting antibacterial water-resistant environment-friendly inner wall putty composition

A technology of interior wall putty and composition, applied in the direction of filling slurry, etc., can solve the problems of high biohazard, poor long-term effect, poor antibacterial effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] The preparation method of the long-acting antibacterial and water-resistant environmental protection interior wall putty of the present invention comprises the following steps:

[0105] The various components of the composition described in claim 1 are mixed to obtain the long-acting antibacterial and water-resistant environmental protection interior wall putty.

[0106] In a specific embodiment, the long-acting antibacterial and water-resistant environmental protection interior wall putty is made by the method comprising the following steps:

[0107] a) Put the pure water and the thickener into the dispersion tank, and control the rotation speed at 1700-1800 rpm to obtain a uniform dispersion;

[0108] b) Slowly add the dispersant, wetting agent, and defoamer into the dispersion tank in turn for 15 minutes;

[0109] c) then add the pH regulator and stir for 1 minute;

[0110] d) Then control the rotation speed at 1400-1500 rpm, and disperse for 20 minutes;

[0111] ...

Embodiment 1~3

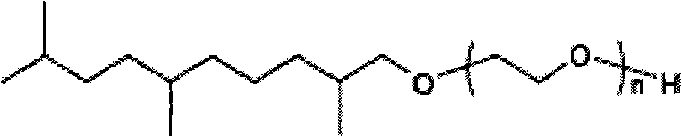

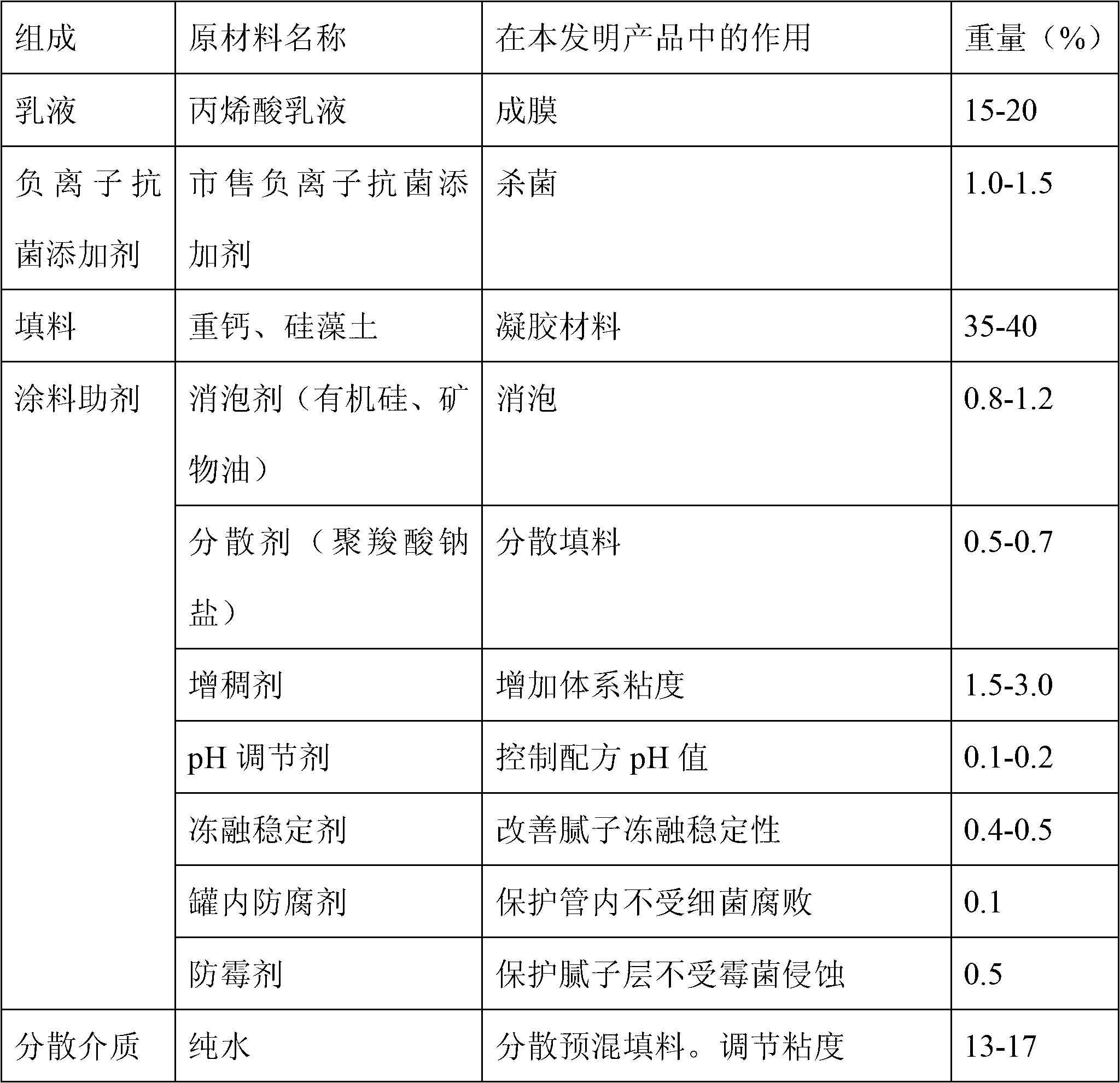

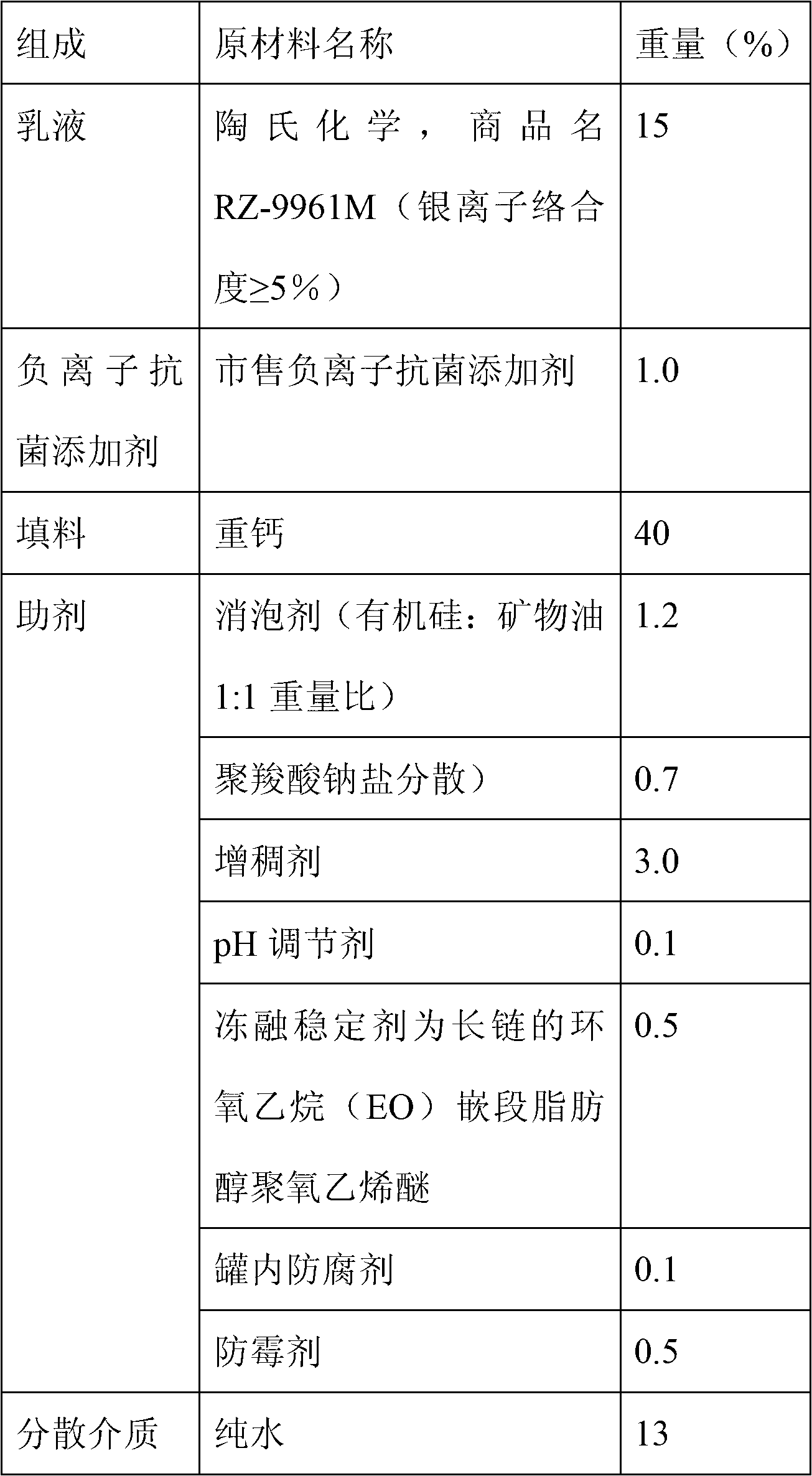

[0130] Prepare the raw materials for preparing the product of the present invention according to the weight percentages in Tables 1a-c.

[0131]

[0132]

[0133]

[0134]

[0135] First put pure water and thickener into the dispersion tank, the speed is controlled at 1700-1800 rpm; slowly add the dispersant, wetting agent, and defoamer into the dispersion tank for 15 minutes; then add the pH regulator , stir for 1 minute; then control the speed at 1500-1800 rpm, disperse for 20 minutes; then add a small amount of pure water to cool down; then add emulsion; then add freeze-thaw stabilizer; then add defoamer, anti-mold agent, preservative in the tank, and negative ion antibacterial additives are dispersed for 2 minutes; then fillers are added and dispersed for 30 minutes; finally, pure water is added to adjust the viscosity to (100-102) KU, and the finished product is made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com