Bicolor spraying technology for semi-trailer body

A technology for semi-trailers and car bodies, which is applied to coatings, spray booths, spray devices, etc., can solve the problems of layering and peeling off of the color topcoat, affecting the spraying quality, and poor corrosion resistance, so as to reduce spraying costs, slow down discoloration, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

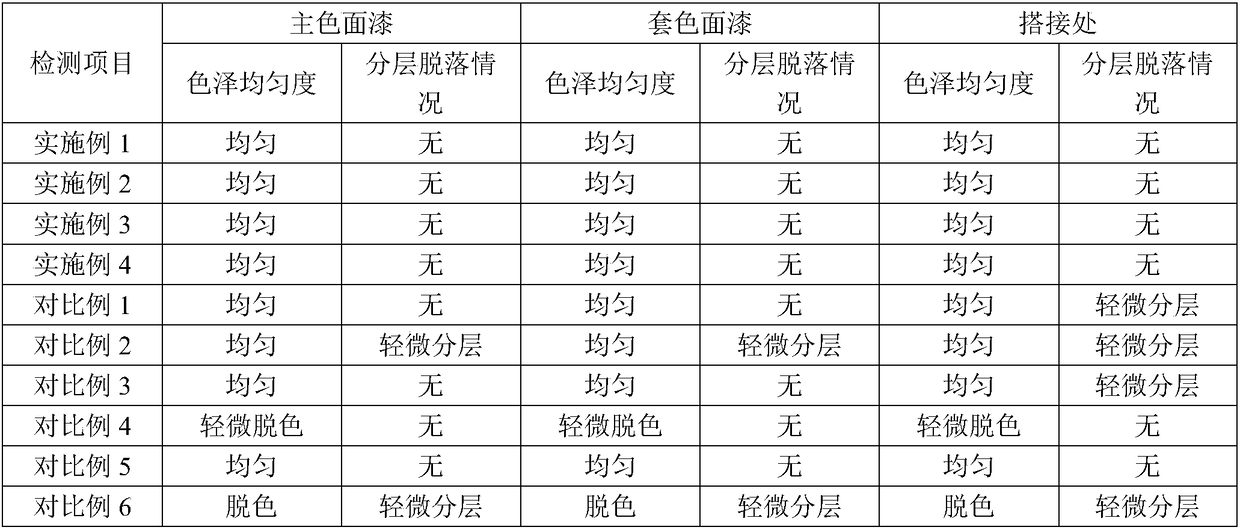

Examples

Embodiment 1

[0037] A two-color spraying process for a semi-trailer body includes the following steps:

[0038] (1) Topcoat pretreatment: mix the base paint, curing agent, and thinner, and add the main color additives, so that the weight ratio of the base paint, curing agent, thinner, and main color additives is 90:16:8 :5. Mix thoroughly and evenly to obtain the main color paint; mix the basic paint, curing agent, and diluent, and add the color additive to make the weight ratio of the basic paint, curing agent, diluent, and color additive 90: 16:8:5, mix well and evenly, get over-colored paint;

[0039] (2) Body surface pretreatment: Place the semi-trailer in the spraying and drying integrated room, and the humidity of the spraying and drying integrated room during the spraying and drying of the body is 60%, and the area that does not need spraying treatment is covered with a masking cloth , Take phosphoric acid diluent to spray the spraying area, the molar concentration of phosphoric acid in...

Embodiment 2

[0045] A two-color spraying process for a semi-trailer body includes the following steps:

[0046] (1) Topcoat pretreatment: mix the base paint, curing agent, and thinner, and add the main color additives, so that the weight ratio of the base paint, curing agent, thinner, and main color additives is 105:22:11 :12. Mix thoroughly and evenly to obtain the main color paint; mix the base paint, curing agent, and thinner, and add the color additive to make the weight ratio of the basic paint, curing agent, diluent, and color additive 105: 22:11:13, mix thoroughly and evenly to obtain over-colored paint;

[0047] (2) Pretreatment of the body surface: place the semi-trailer in the spraying and drying integrated room, and the humidity of the spraying and drying integrated room during the body spraying and drying is 50%, and the area that does not need spraying treatment is covered with a masking cloth , Take phosphoric acid diluent to spray the spraying area, the molar concentration of ph...

Embodiment 3

[0053] A two-color spraying process for a semi-trailer body includes the following steps:

[0054] (1) Topcoat pretreatment: mix the base paint, curing agent, and thinner, and add the main color additives, so that the weight ratio of the base paint, curing agent, thinner, and main color additives is 95:18:10 :7. Mix thoroughly and evenly to obtain the main color paint; mix the basic paint, curing agent, and diluent, and add the color additive to make the weight ratio of the basic paint, curing agent, diluent, and color additive 95: 18:10:6, mix well and evenly, get over-colored paint;

[0055] (2) Pretreatment of body surface: Put the semi-trailer in the spraying and drying integrated room, and the humidity of the spraying and drying integrated room during the body spraying and drying is 40%, and the area that does not need spraying treatment is covered with a masking cloth , Take phosphoric acid diluent to spray the spraying area, the molar concentration of phosphoric acid in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com