Two-dimensional code bottle cap and manufacturing method thereof

A manufacturing method and two-dimensional code technology, applied in the field of bottle caps, can solve the problems of difficult process of spraying opaque materials covering two-dimensional code patterns, difficult to stimulate consumers' desire to buy, and unsatisfactory use, so as to reduce one process and manufacture The process is minimal and the effect of saving spraying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

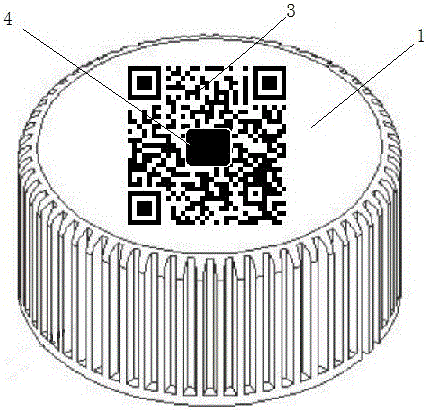

[0043] Such as figure 1 , figure 2 , image 3 , Figure 7 As shown, a bottled mineral water is produced.

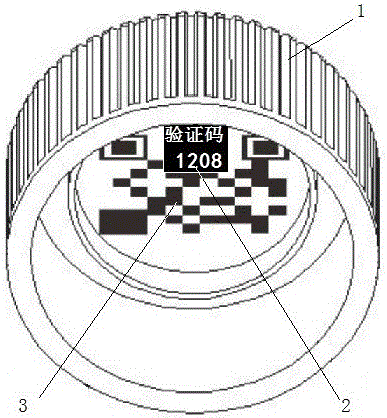

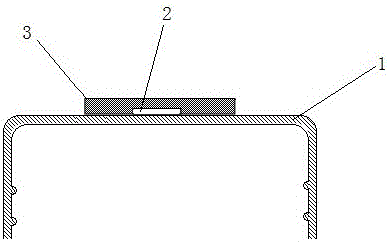

[0044] While the bottled mineral water manufacturer is filling the production line, on the front of the translucent bottle cap (1) of each bottled mineral water, a white color consisting of four random numbers is spray-printed sequentially from the inside to the outside. The verification code (2) mirrors the ink layer, and the unique black two-dimensional code (3) positively resembles the ink layer. The first nozzle of the inkjet printer can be used to print the verification code (2) the image ink layer first, and then the second nozzle of the inkjet printer can be used to print the two-dimensional code (3) the positive ink layer; use the two-dimensional code (3) Just like the ink layer, the verification code (2) is covered and kept secret by the mirror image ink layer, so that the verification code (2) information cannot be seen clearly (that is, cannot be recognize...

Embodiment 2

[0051] In order to make it easier for consumers to see the characters of the verification code (2) from the back of the bottle cap (1), such as Figure 4 As shown, on the front of each translucent bottle cap ⑴, a red verification code composed of four random numbers is printed sequentially from the inside to the outside. The unique black two-dimensional code (3) is just like the ink layer.

[0052] In this way, after the bottled mineral water is sold, consumers can destructively open (i.e. unscrew) the translucent bottle cap (1), and the naked eye can read the light-colored background paint more clearly from the back of the translucent bottle cap (1). Verification code (2) information on layer (6).

[0053] If you are interested in participating in the promotion, you can do so as Figure 8 As shown, further enter the verification code (2) information from the verification webpage (5) to obtain marketing points, marketing prizes, marketing red envelopes or check the authentic...

Embodiment 3

[0055] can also be like Figure 5 , Figure 6 As shown, on the front of each translucent bottle cap ⑴, a white verification code ⑵ mirrored ink layer and a unique black QR code composed of four large random numbers are printed sequentially from the inside to the outside. ⑶ Just like the ink layer, instead of setting the ink block ⑷.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com