Setting method of robot spray gun trajectory in copper plate spraying operation

A technology in robots and operations, applied in the field of setting the trajectory of a robot spray gun, can solve problems such as cumbersome locks, and achieve the effects of reducing spraying costs, improving coating uniformity and quality, and improving nozzle efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The setting method of robot spray gun trajectory in the copper plate spraying operation of the present invention comprises the following steps:

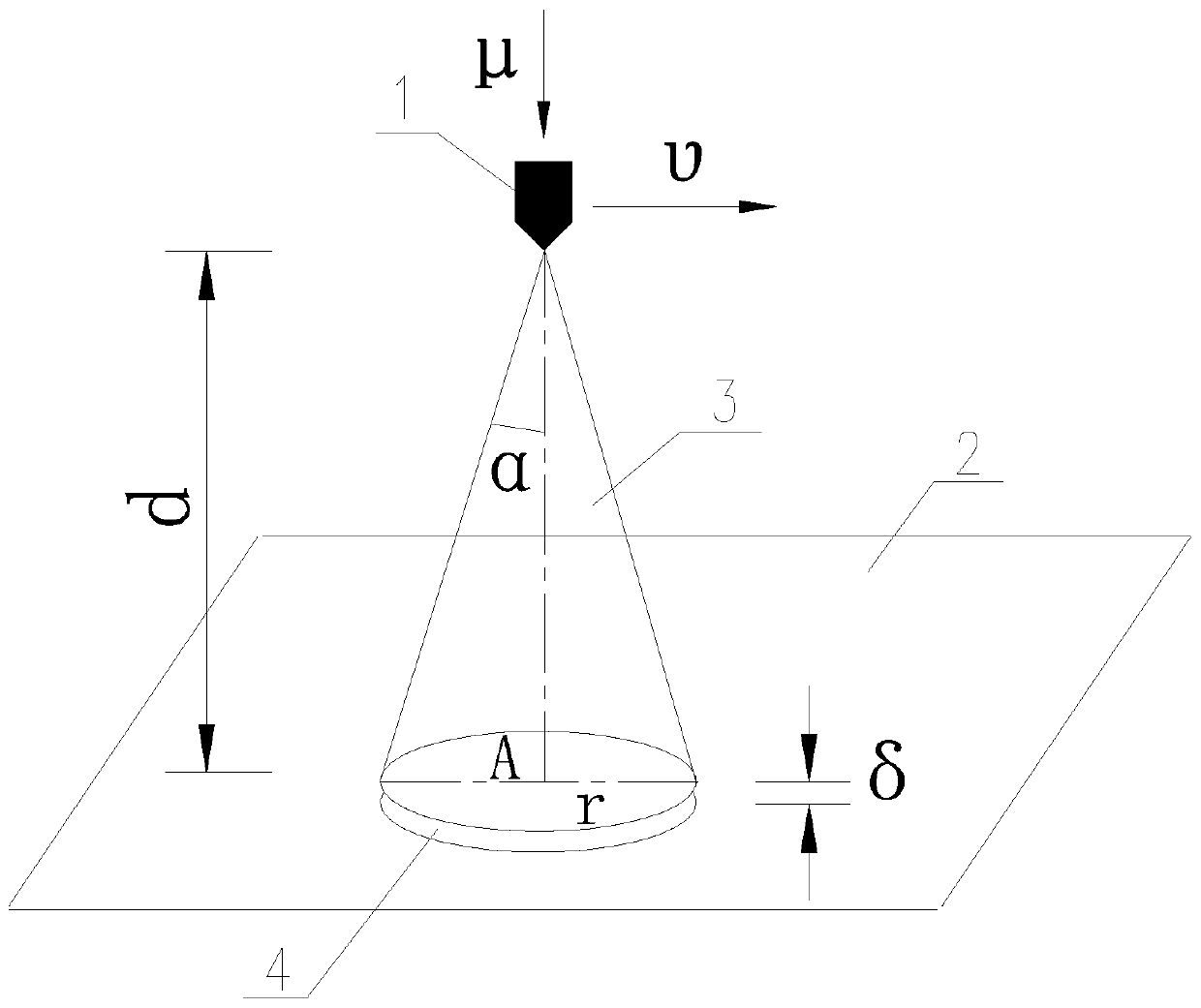

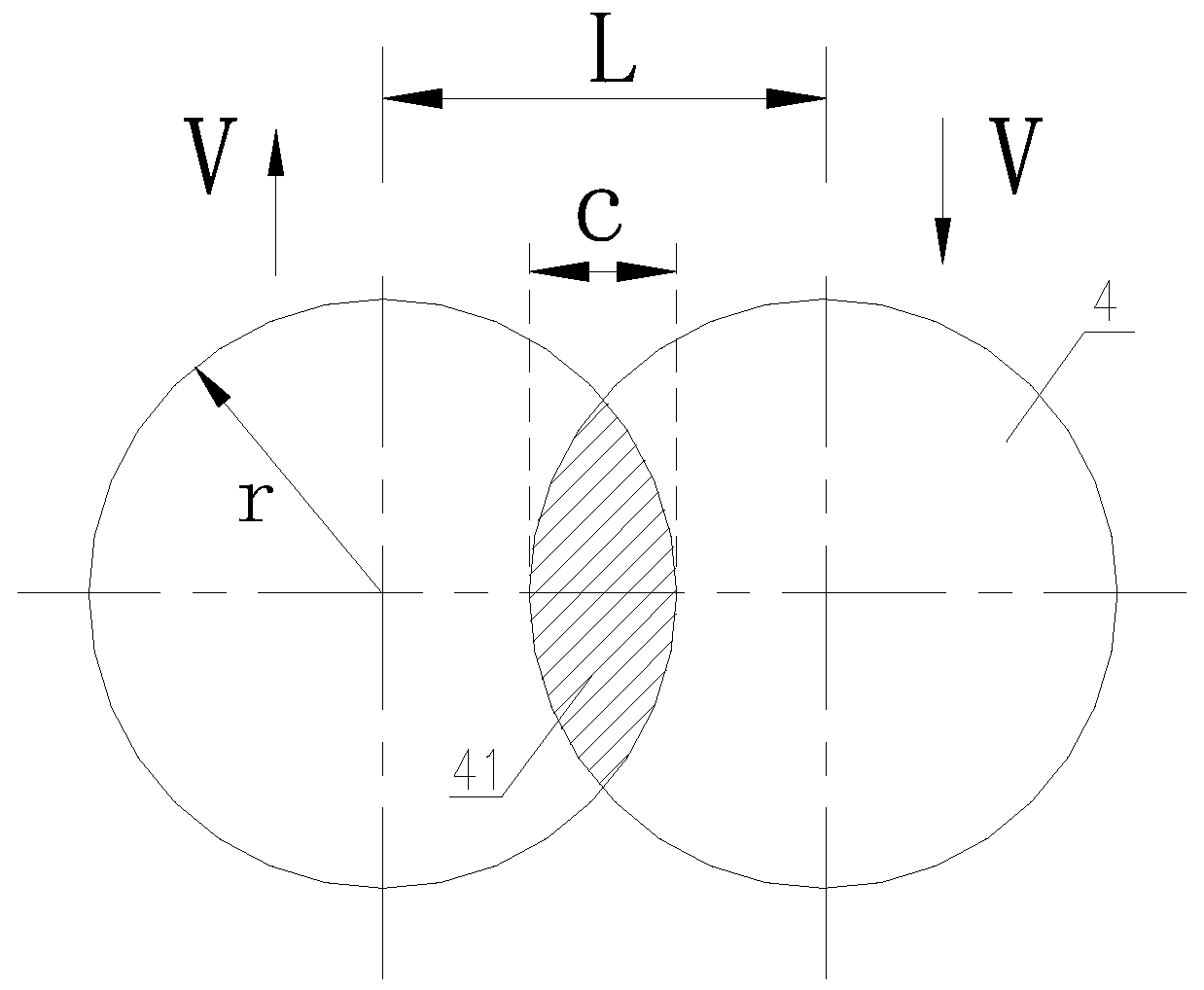

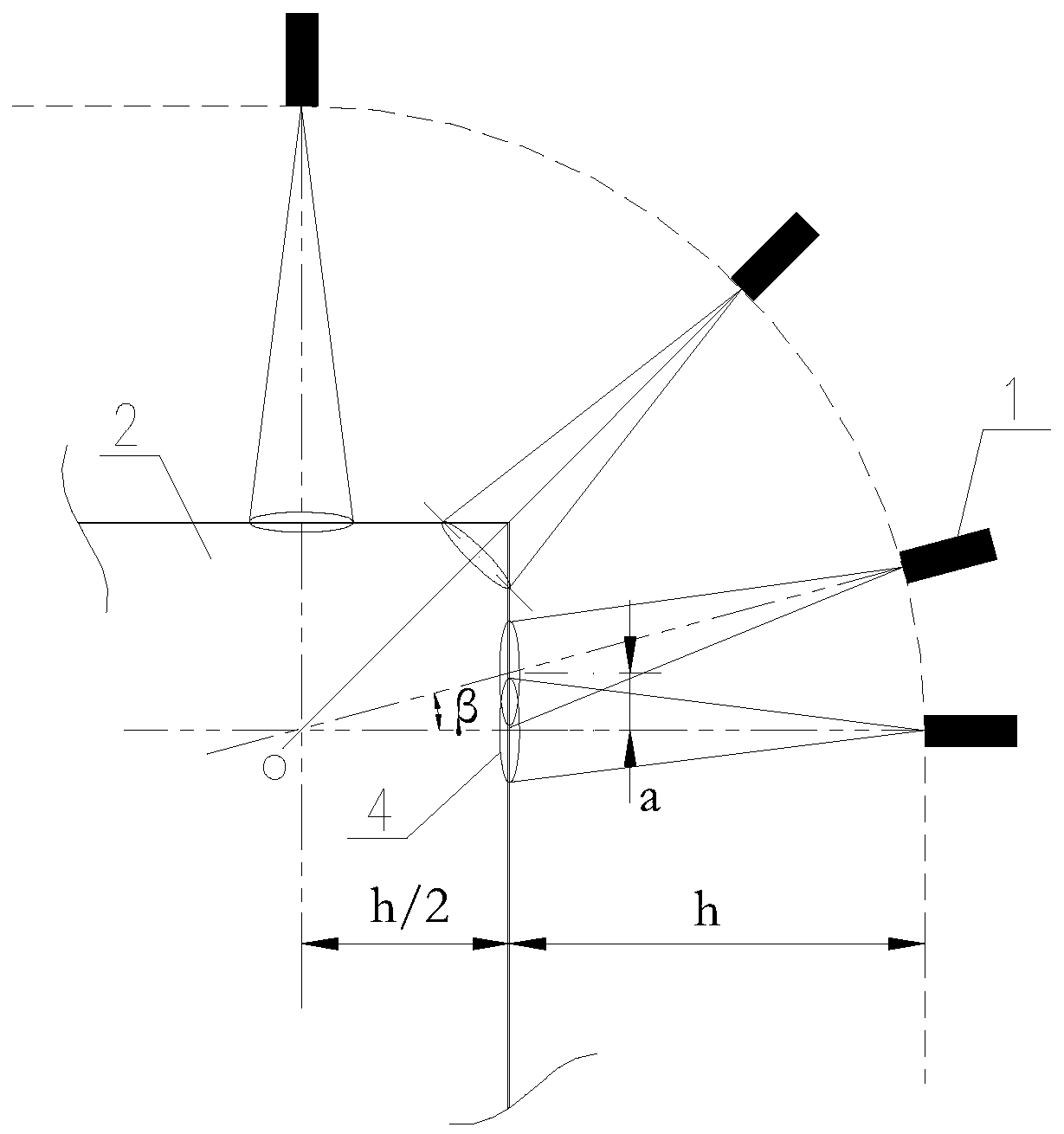

[0015] Step 1, such as figure 1 As shown, in the spraying area of the spraying gun, the geometric model of the spraying process of the robot spraying gun 1 is a spraying cone 3, that is, the spraying medium from the spraying gun 1 to the surface of the copper plate 2 forms a cone. The distance from the surface of the copper plate 2 is d, the moving speed of the spray gun 1 is υ, the spraying angle is α, and the spraying area is a circular area 4 with a conical bottom surface, then the area of the circular area is A=πr 2 , where r is the radius of the circle, radius r = d*tanα, to obtain a coating with a thickness of δ, in order to determine the thickness distribution model of the spray deposition, the robot conducts a single linear reciprocating spray on the copper plate for experimental research, in a specific Under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com