Fuel nozzle testing platform

A fuel nozzle and test platform technology, applied in the field of aero-engines, can solve the problem of inability to test the fuel manifold, and achieve the effects of reducing material and production costs, strong applicability, and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

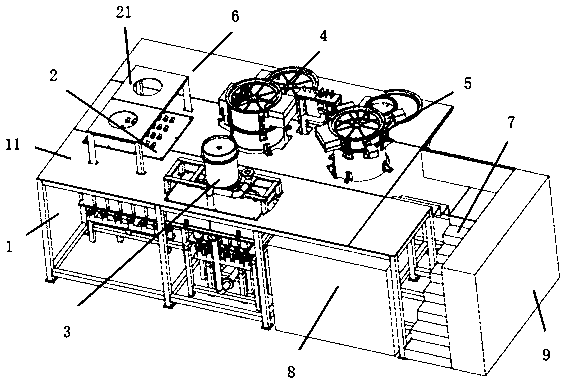

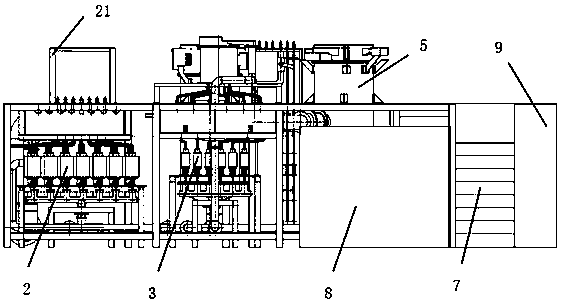

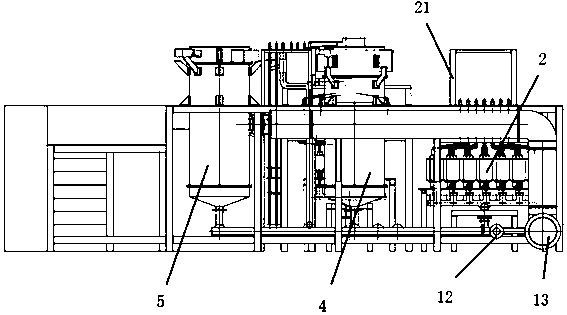

[0042] Such as Figures 1 to 3 As shown, a fuel nozzle test platform is provided, which includes a cuboid bench 1 with a floor 11, a manifold test device 2 that penetrates the floor 11, a distribution unevenness test device 3, a spray cone angle manual measurement device 4 and Spray cone angle automatic measuring device 5, conventional fuel oil system, ventilation and air system, measurement and control system and electrical control system etc. are also arranged under the floor.

[0043] The main pipe test device 2 and the distribution unevenness test device 3 are vertically arranged, the spray cone angle manual measurement device 4 and the spray cone angle automatic measurement device 5 are arranged side by side near the long side of the rectangular floor 11, the main pipe test device 2, the uneven distribution The degree test device 3, the spray cone angle manual measuring device 4 and the spray cone angle automatic measuring device 5 form a U-shaped path, and the width of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com