Double-oil-circuit fuel nozzle

A fuel nozzle and dual oil circuit technology, which is applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of large spray cone angle of fuel nozzles and wide fuel supply range of aero-engine combustion chambers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific embodiments. The following implementations are only descriptive, not restrictive, and cannot limit the scope of protection of the present invention.

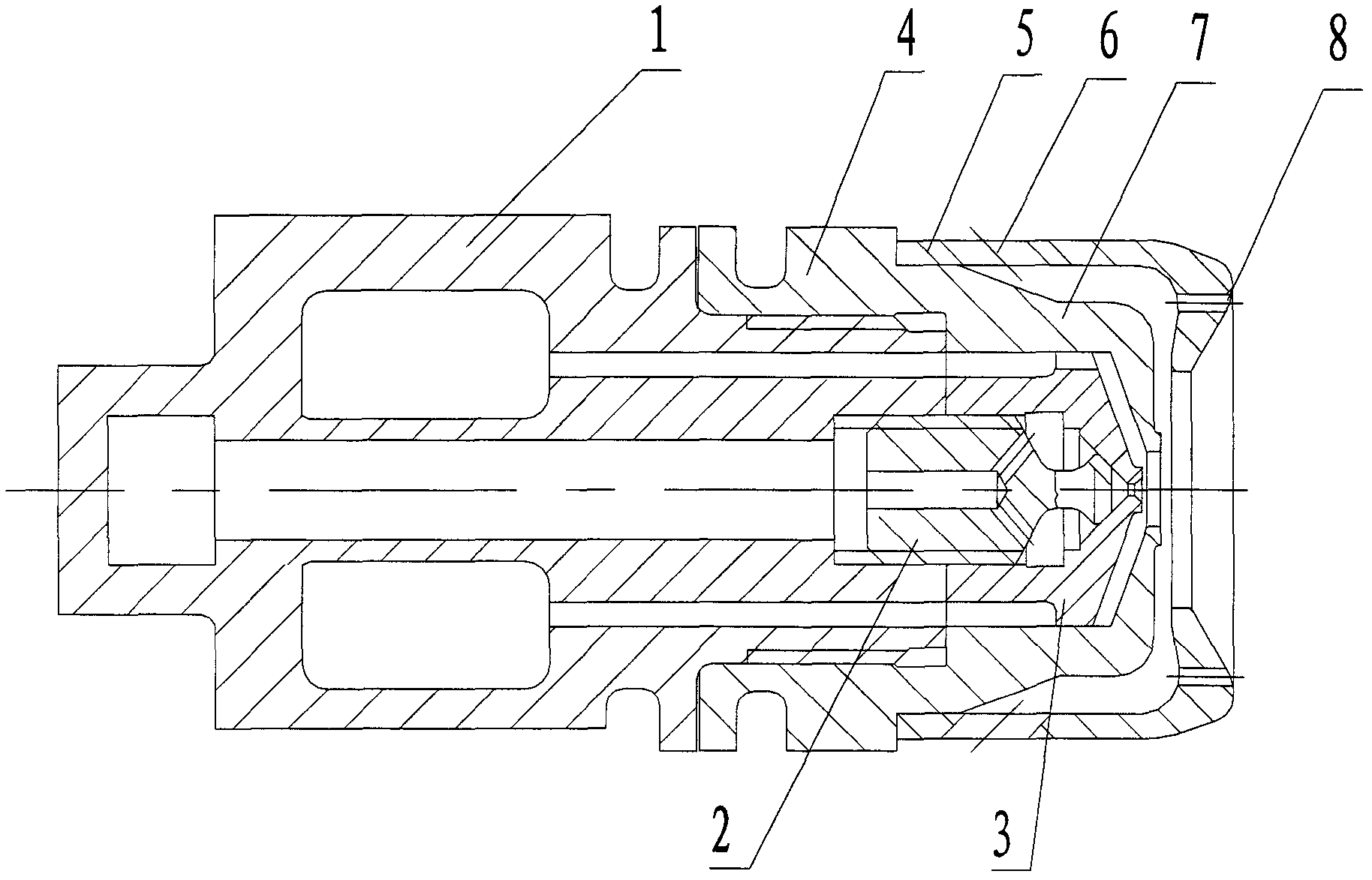

[0022] Such as figure 1 As shown, a dual oil path fuel nozzle of the present invention is mainly composed of a nozzle housing 1, a secondary oil path swirler 2, a main oil path swirler 3, and a main oil path nozzle 4. The secondary oil path swirler 2 Installed in the main oil passage cyclone 3, and then installed on the nozzle housing 1 together, and then install the main oil passage nozzle 4 outside the main nozzle cyclone 3.

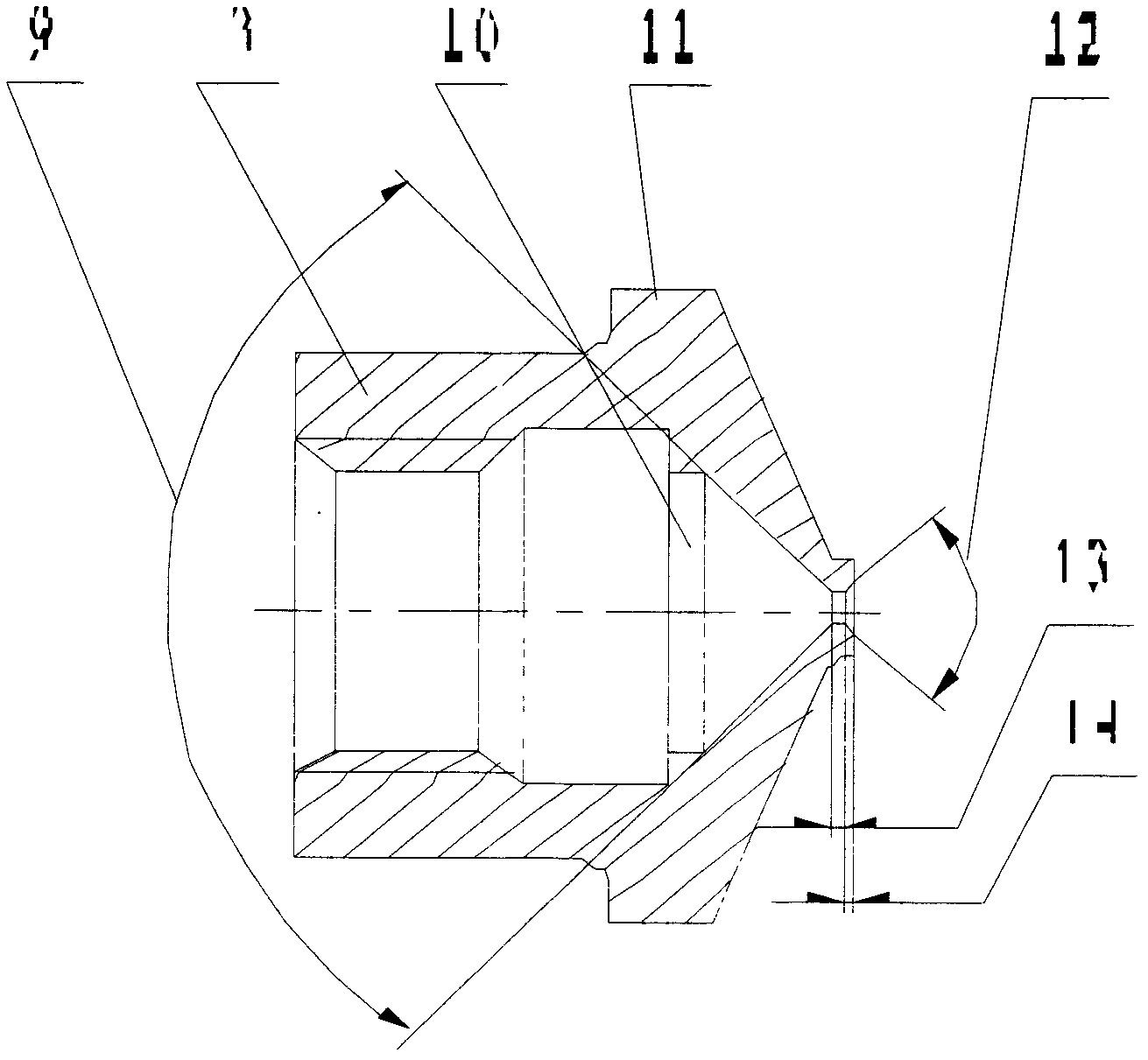

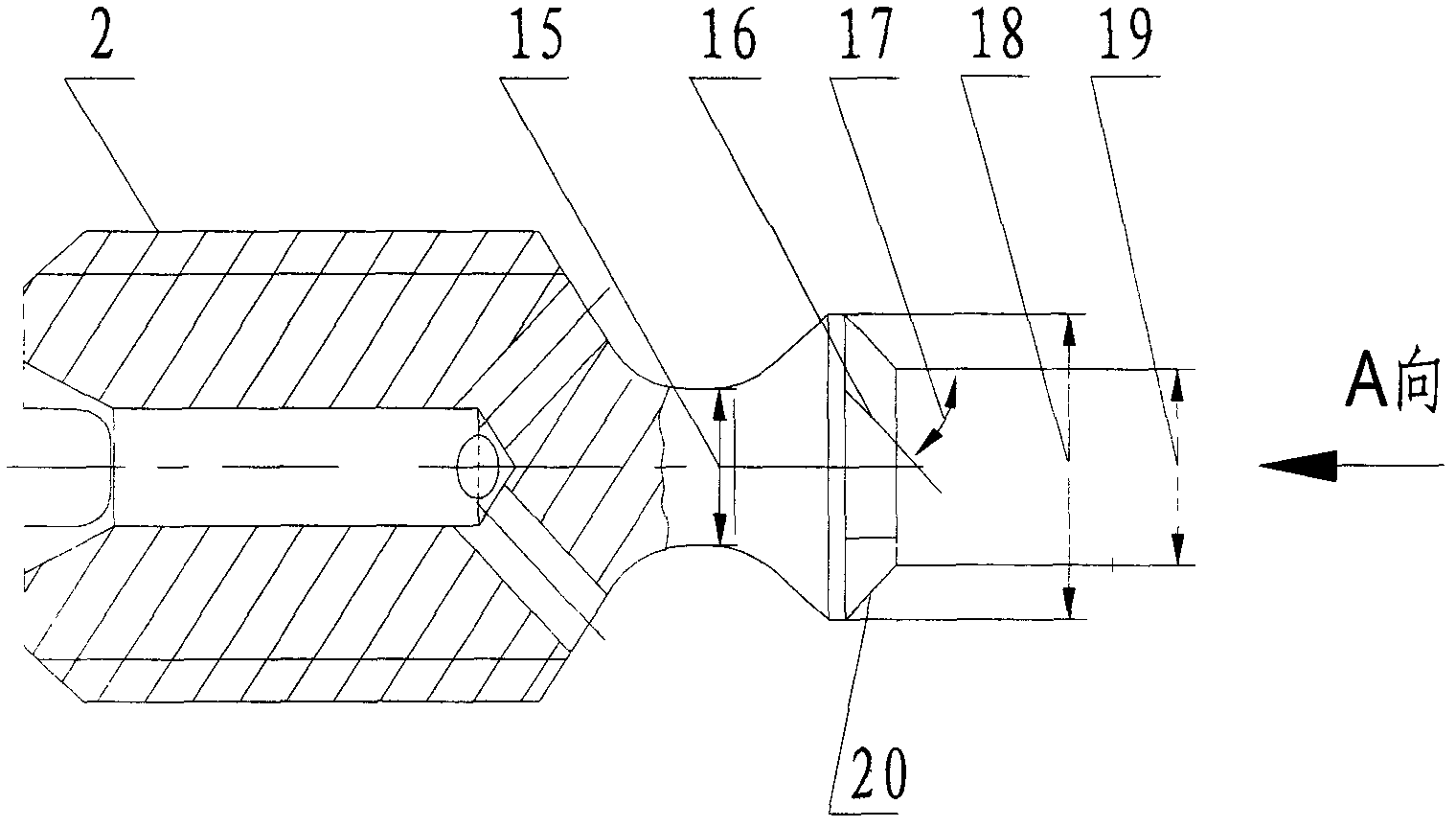

[0023] Such as figure 1 figure 2 , image 3 with Figure 4 As shown, the main oil passage nozzle 4 is composed of a gas hood 5 and a main oil passage nozzle body 7. The gas hood 5 is attached to the main oil passage nozzle body 7; the gas hood 5 is designed to blow off the surface carbon of the nozzle Nozzle air inlet 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com