Stable single-component epoxy surface mount adhesive in room temperature storage and preparation method thereof

An epoxy patch, one-component technology, applied in the direction of epoxy resin adhesive, adhesive, adhesive type, etc., can solve problems such as failure, shortened service life of patch adhesive, increase of viscosity of patch adhesive, etc., to achieve Good printability and consistency, high wet strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Epoxy 128 41 parts

[0028] Resorcinol epoxy resin 10 parts

[0029] Polymerized amine epoxy resin curing agent EH4070s 26 parts

[0030] Diethylenetriamine 1 part

[0031] Dithiosalicylic acid 1.0 parts

[0032] Organic bentonite 5 parts

[0033] Magnesium oxide 15 parts

[0034] Big red powder 1.0 parts

[0035] Preparation method: Accurately weigh various raw materials according to the proportion of the above formula, now add epoxy resin, reactive diluent, filler, pigment, and stabilizer into the reaction kettle in sequence, stir evenly, then add latent curing agent, and wait until uniformly stirred , add thixotropic agent, disperse evenly, and carry out vacuum defoaming treatment.

Embodiment 2

[0037] Epoxy 128 31 parts

[0038] Epoxy resin E44 7 parts

[0039] Glycerin glycidyl ether 14 parts

[0040] Imidazole curing agent PN40 18 parts

[0041] 3 parts of imidazole curing agent PN-H

[0042] Caffeic acid 1.0 parts

[0043] Fumed silica 7 parts

[0044] Calcium carbonate 18 parts

[0045] Big red powder 1.0 parts

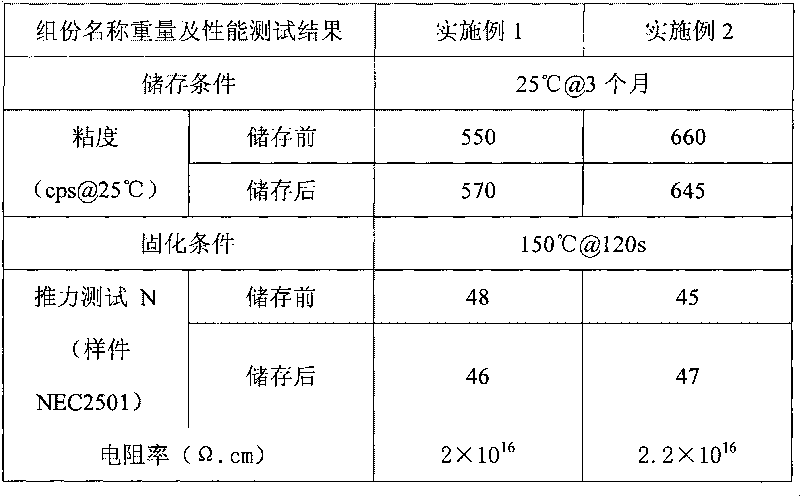

[0046] Preparation method: Accurately weigh various raw materials according to the proportion of the above formula, now add epoxy resin, reactive diluent, filler, pigment, and stabilizer into the reaction kettle in sequence, stir evenly, then add latent curing agent, and wait until uniformly stirred , add thixotropic agent, disperse evenly, and carry out vacuum defoaming treatment. The embodiment listed in table 1 and its curing characteristics and storage performance test results show that: the patch adhesive of the present invention has fast curing speed, high bonding strength, good room temperature stability, and long storage time, which brings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com