Hypermixing Fluid Ejector

a technology of fluid ejector and ejector, which is applied in the direction of machines/engines, combustion types, lighting and heating apparatus, etc., can solve the problems of severe limitation of reducing to practice, no direct means of completing the brayton cycle of the ramjet, and creating sonic inlet conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

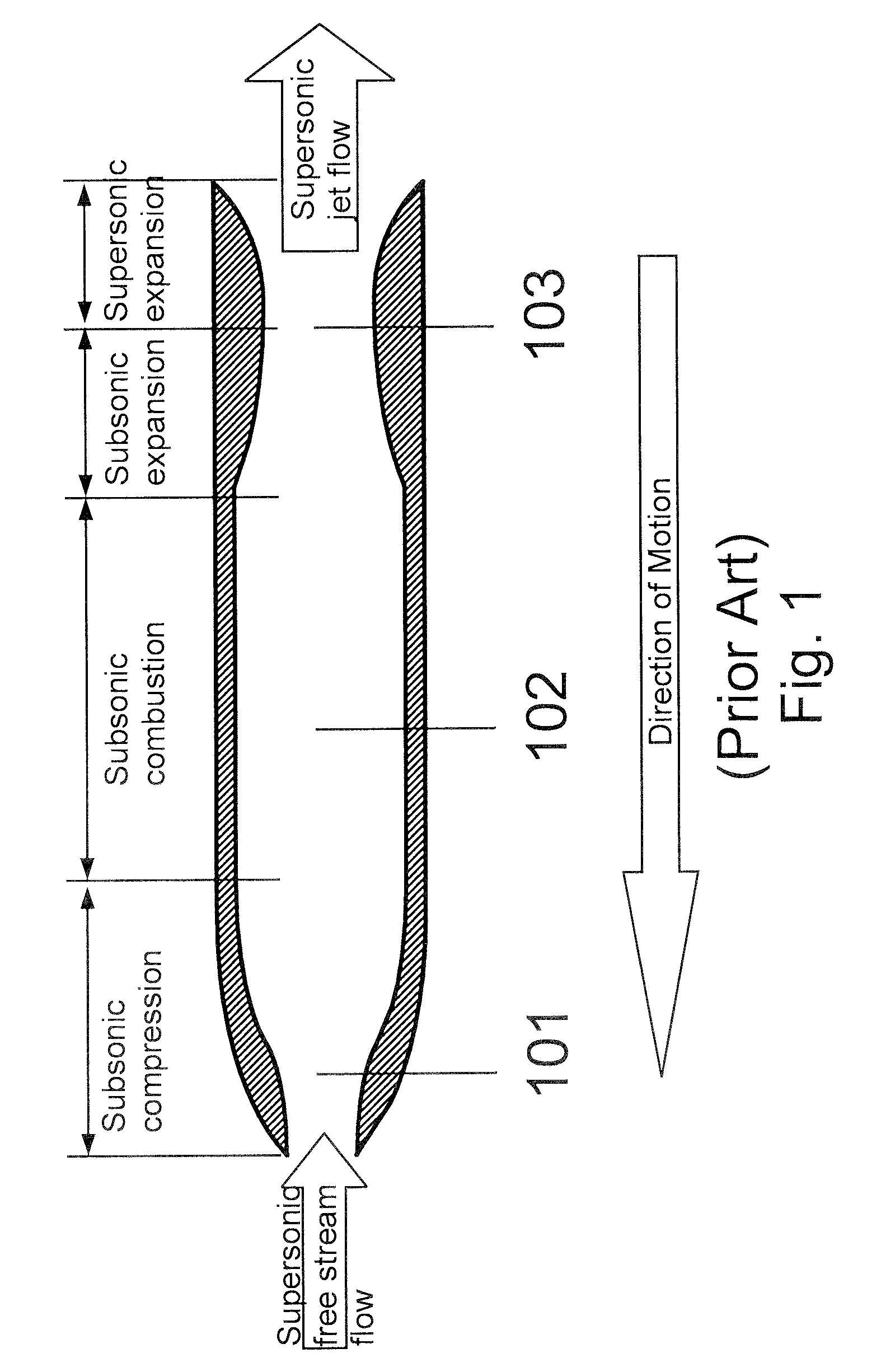

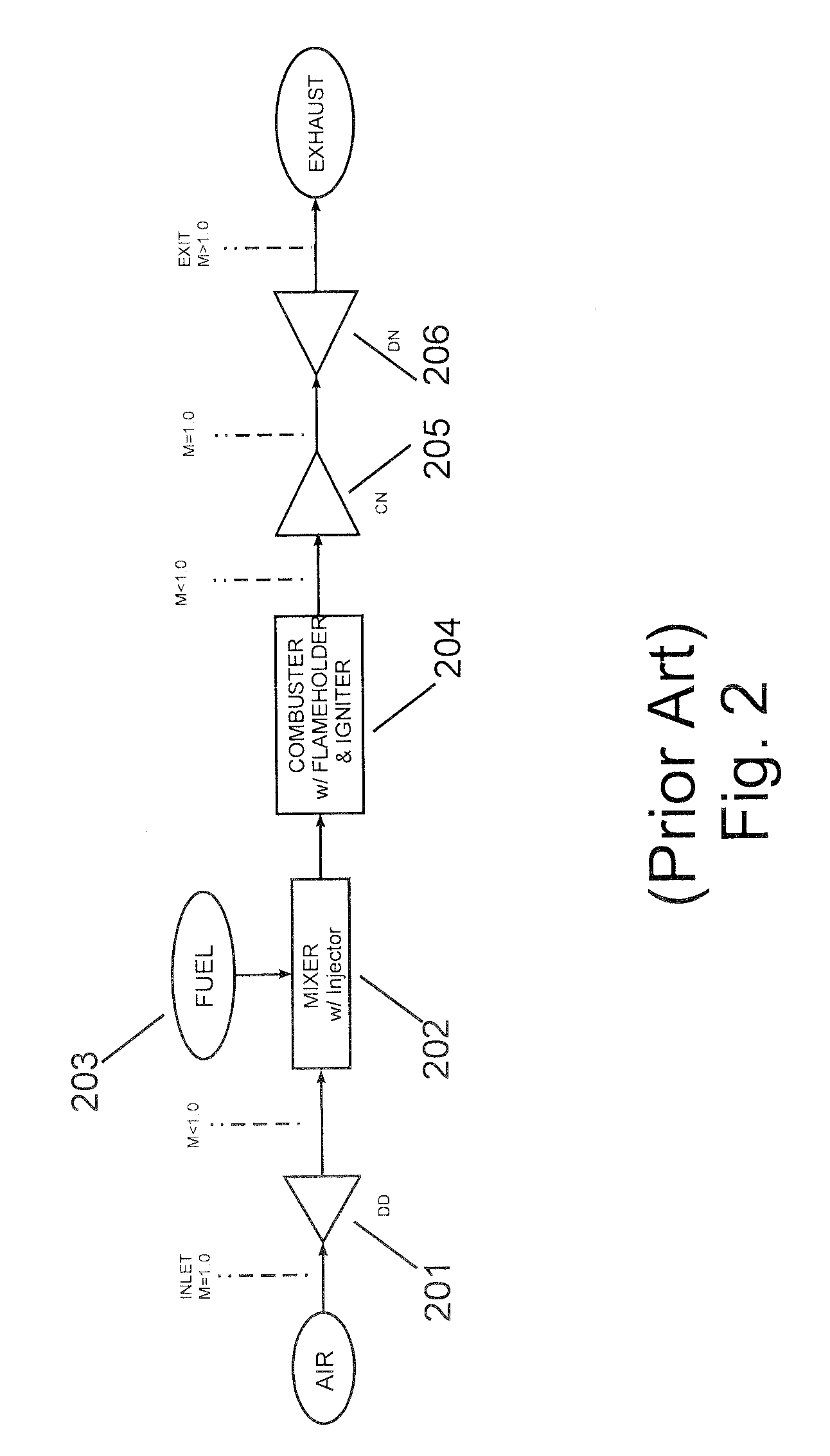

[0039]The most obvious benefit of ramjet theory is the simplicity of design and construction. However, there are no ramjet engines made available to the marketplace for general application. The few working examples are limited to military applications for expendable weaponry. The limiting issue for ramjet application is the ramjet conundrum.

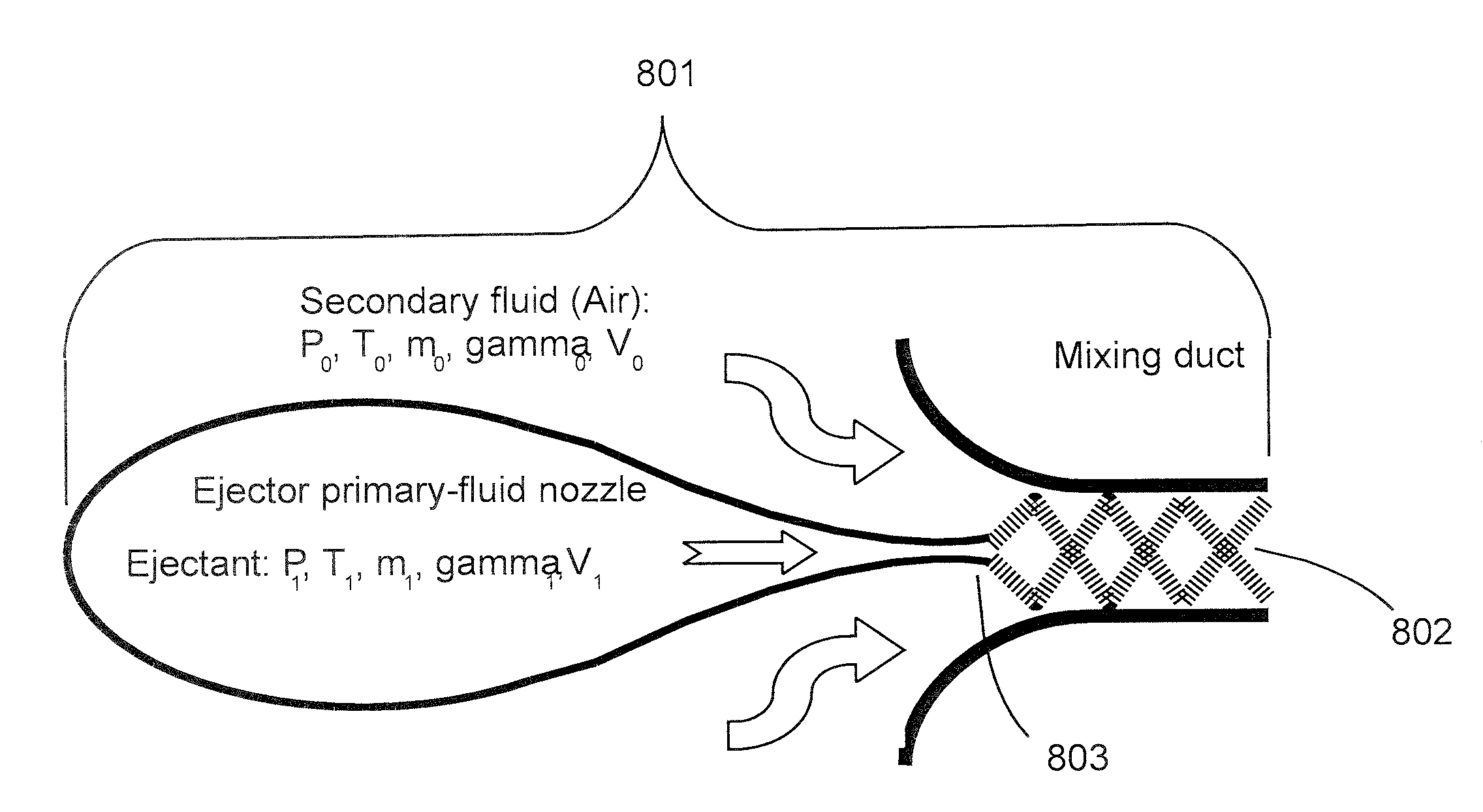

[0040]The present invention solves the ramjet conundrum by artificially creating sonic conditions at the ramjet inlet by means of a pumping ejector used to force air through the subsonic diffuser at the front of the ramjet.

[0041]The term “ejector ramjet” within the art of propulsion includes a broad array of configurations that comprise any combination of an ejector with a ramjet. The ejector can be mated to the ramjet in any location and be either integral or accessory and have either reactive or inert fluids. The ramjet can be a classical Fono type or supersonic-combustion type. Components are combined to solve specific propulsion problems. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com