GDI gasoline engine spray wall-impingement parameter automatic extraction method and system based on machine vision

A technology of machine vision and automatic extraction, which is applied in the direction of instrumentation, image data processing, calculation, etc., can solve problems such as blurred structure boundaries, large influence of human factors, time-consuming and laborious, etc., to avoid errors in straight line extraction and ensure accuracy , the effect of accurate extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

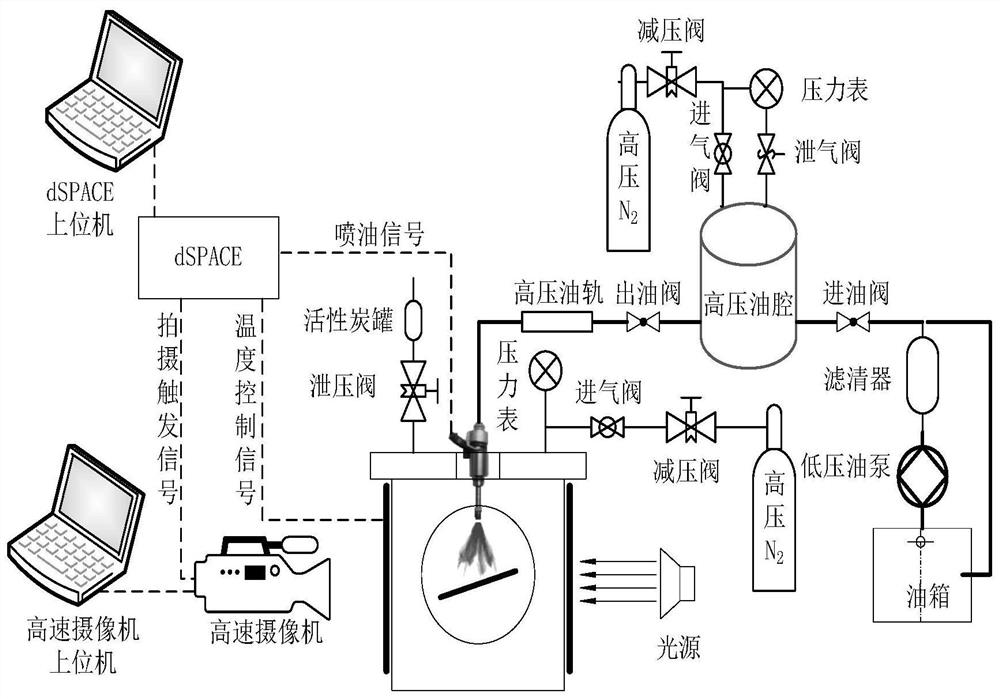

[0083] 1GDI spray wall image hardware acquisition device

[0084] The spray wall image acquisition system is mainly composed of a visual container fixing device, a high-speed photography system, a control system and a computer image processing system. Based on a self-designed visual spray wall-impacting bomb device, V611 high-speed camera is used, and the rapid prototyping tool dSPACE is used to realize the overall control of fuel injection and high-speed camera. The shadow method of direct shooting using reflected light can realize the shooting of the image of the spray hitting the wall, and connect to the host computer through the data line to record and save the required image. The system device is as follows: figure 1 shown. The resolution used in the experiment is 512 pixels × 480 pixels, and the sampling frequency is 20000fps.

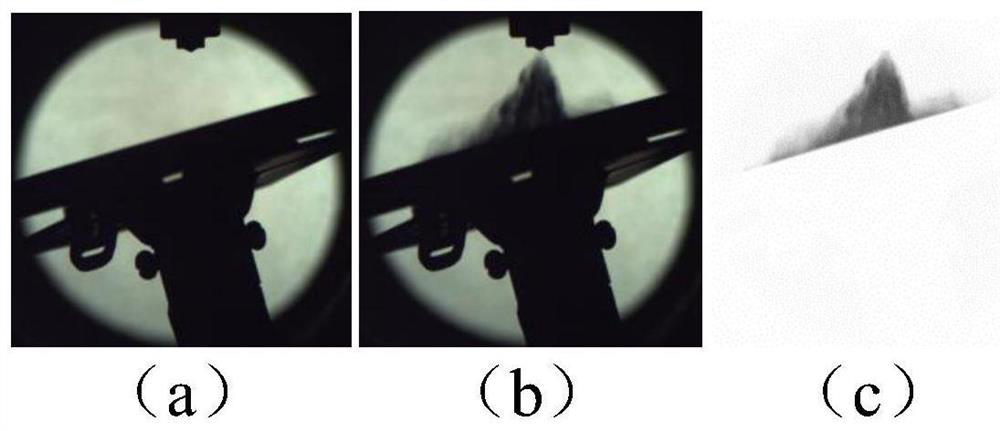

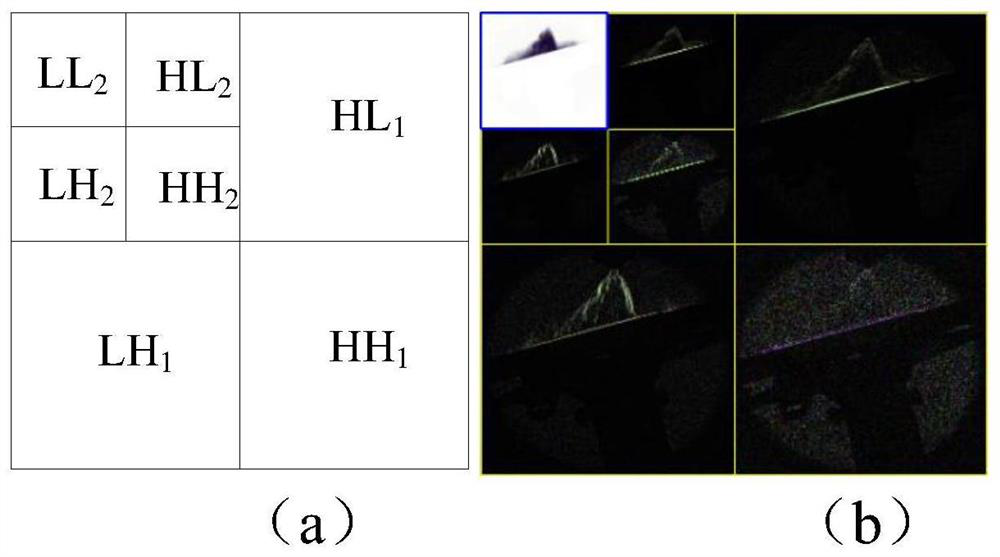

[0085] 2 Image preprocessing of spray impingement wall

[0086] The image of the spray hitting the wall collected by the high-speed camera co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com