Spark plug with precombustion chamber structure

A technology of spark plugs and pre-combustion chambers, which is applied in the field of engines, can solve problems such as the decrease of combustion rate, achieve the effects of increasing expansion ratio, increasing turbulence intensity, and reducing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

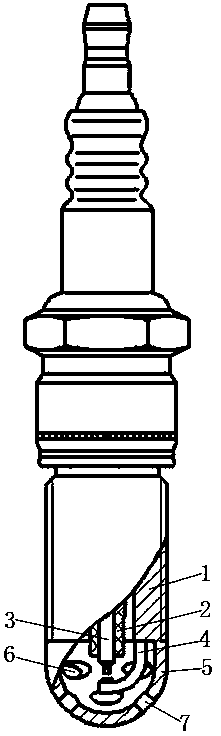

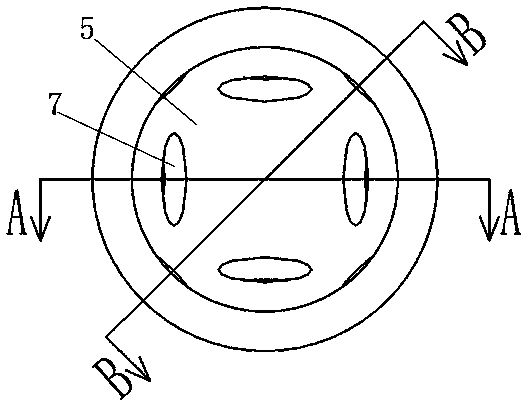

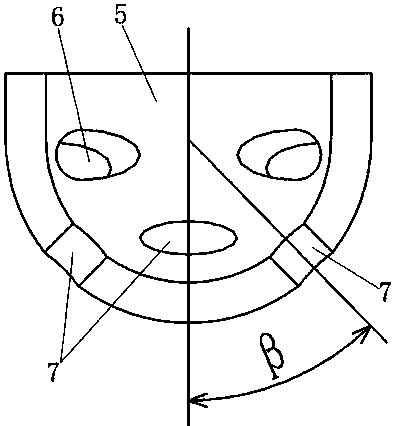

[0017] Such as Figure 1 to Figure 4 Shown is a spark plug with a pre-combustion chamber structure, the spark plug includes a tubular metal shell 1, an insulator 2 fixed in the metal shell 1, a central hole arranged in the insulator 2, and an insulator installed in the central hole The center electrode 3 and the side electrode 4 connected to the metal shell 1 form a spark plug gap between the center electrode 3 and the side electrode 4, and the lower end of the metal shell 1 is connected with a pre-chamber shell 5, and the pre-chamber shell 5 and The lower end of the metal shell 1 encloses a pre-chamber, and the spark plug gap is located in the pre-chamber chamber. The pre-chamber housing 5 is provided with a plurality of upper injection holes 6 uniformly arranged around the central axis of the spark plug and a plurality of nozzles around the central axis of the spark plug....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com