Atomizer anti-drift method and anti-drift atomizer

An atomizing nozzle and anti-floating technology, which is applied in the direction of spray device, spray device, spray discharge device, etc., can solve the problem of inability to determine the best axial position of the gas nozzle, the atomization effect, the electrostatic effect and safety are difficult to guarantee, and the short circuit or high-voltage breakdown, etc., to achieve the effect of improving atomization effect and anti-drift performance, enhancing safety and enhancing penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

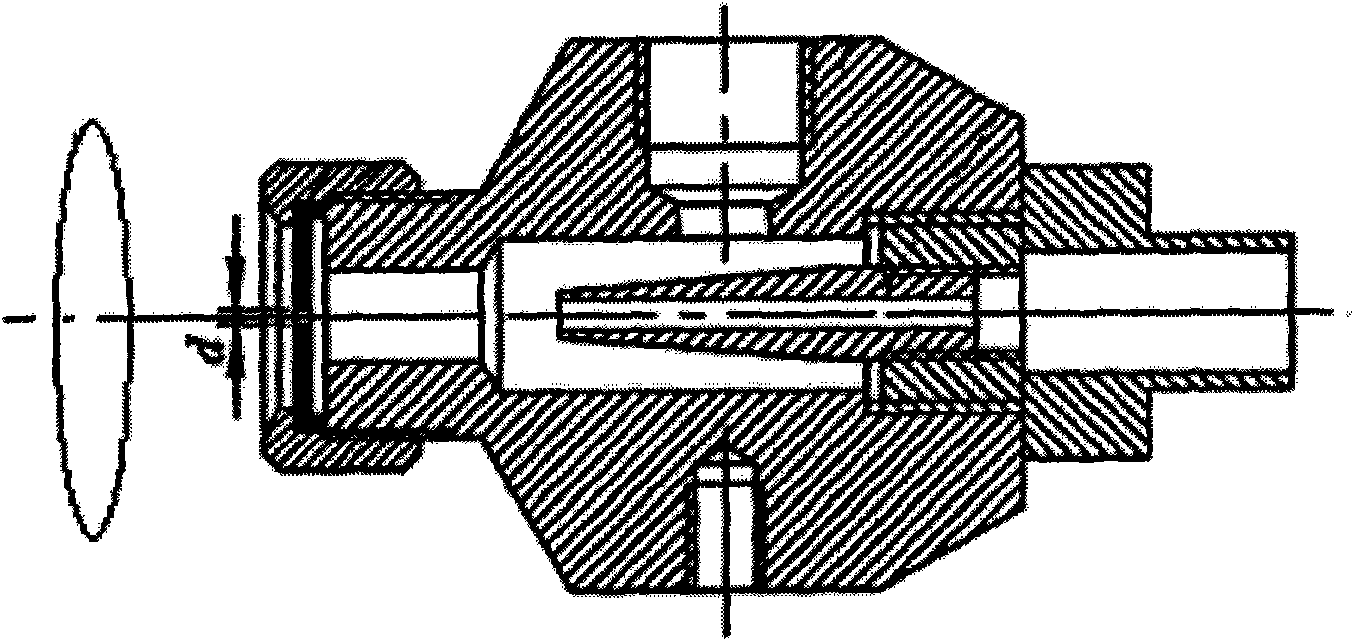

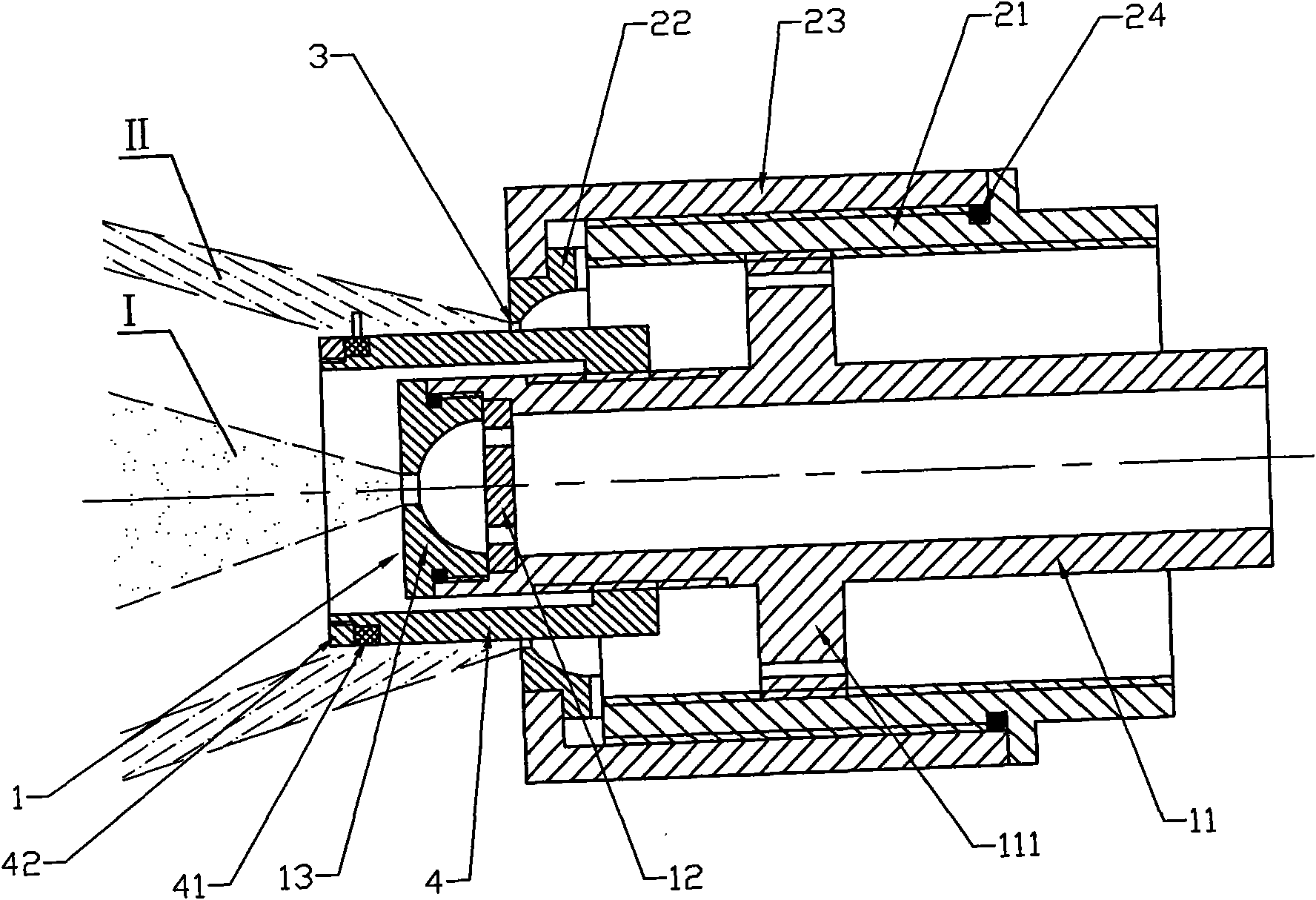

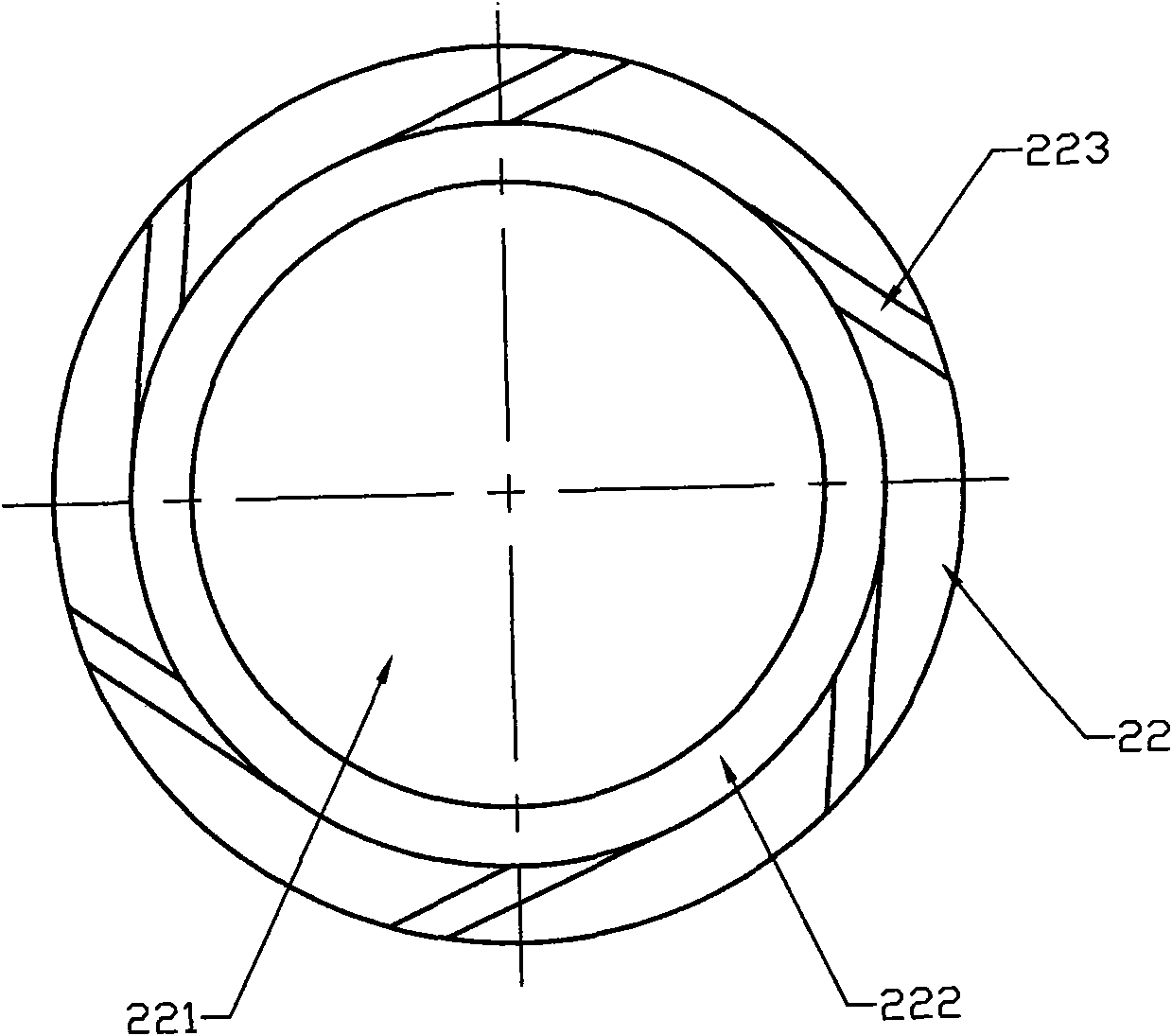

[0016] Such as figure 2 , 3 As shown, the anti-drift atomizing nozzle of the present invention includes an atomizing nozzle 1 capable of atomizing and spraying liquid medicine and an airflow pipe 21 coaxially sleeved on the periphery of the liquid flow pipe 11 of the atomizing nozzle, and the front end of the airflow pipe A swirl sheet 22 is provided, and the gap between the central hole 221 of the swirl sheet and the outside of the atomizing nozzle forms an annular airflow nozzle 3, and the spray cone angle of the airflow is larger than the atomization cone angle formed by the atomization of the liquid flow.

[0017] In the embodiment of the present invention, the swirl piece 22 is positioned at the front end of the airflow pipe 21 and is clamped and fixed by the airflow pipe seat 23 threadedly connected with the airflow pipe 21. The gap between the airflow pipe 21 and the airflow pipe seat 23 is covered by an O-ring 24 Sealing, the liquid flow pipe 11 is coaxially socketed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com