Double-oil-channel centrifugal nozzle structure adopting integrated design of main oil channel and auxiliary oil channel

A technology of auxiliary oil circuit and main oil circuit, applied in the direction of mechanical equipment, fuel injection device, engine components, etc., can solve the problems of combustion oscillation, poor reliability, low combustion efficiency, etc., and achieve the effect of avoiding interference and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

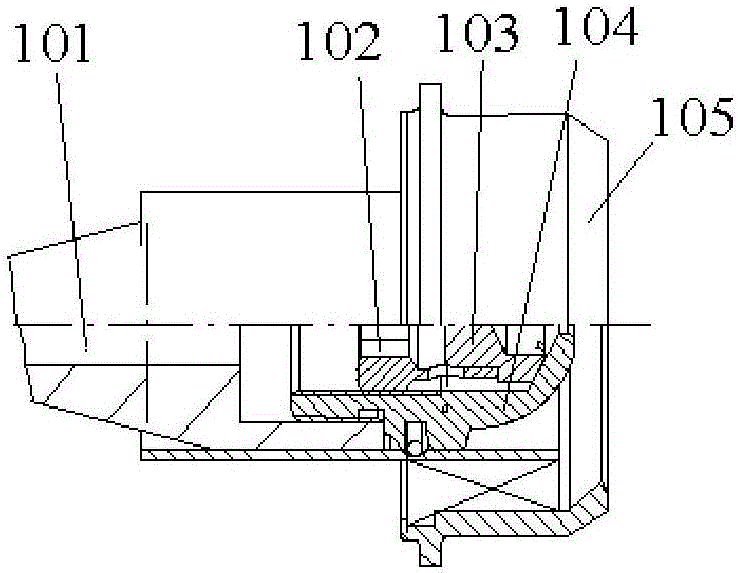

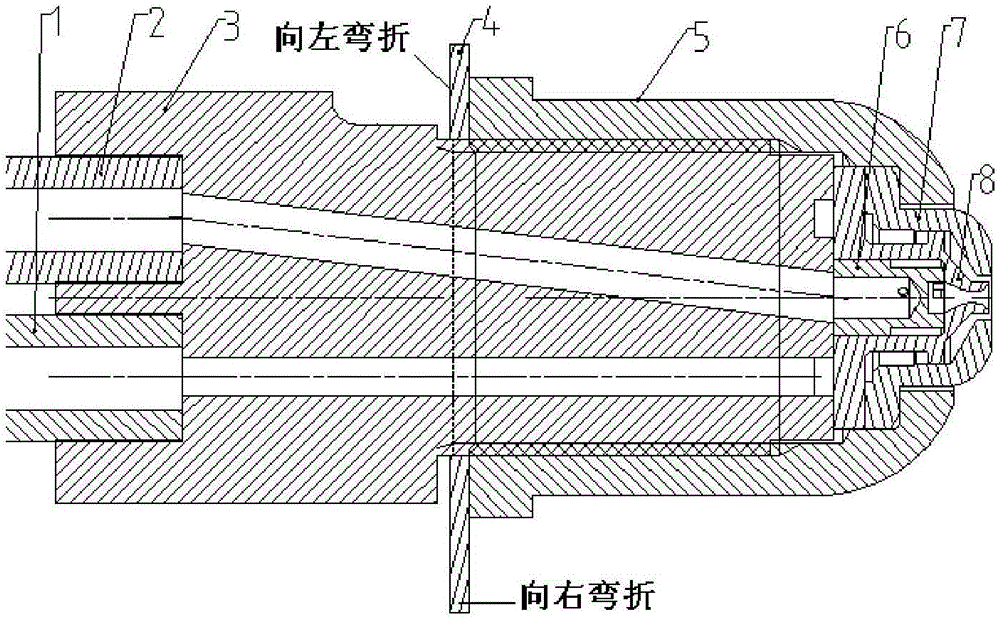

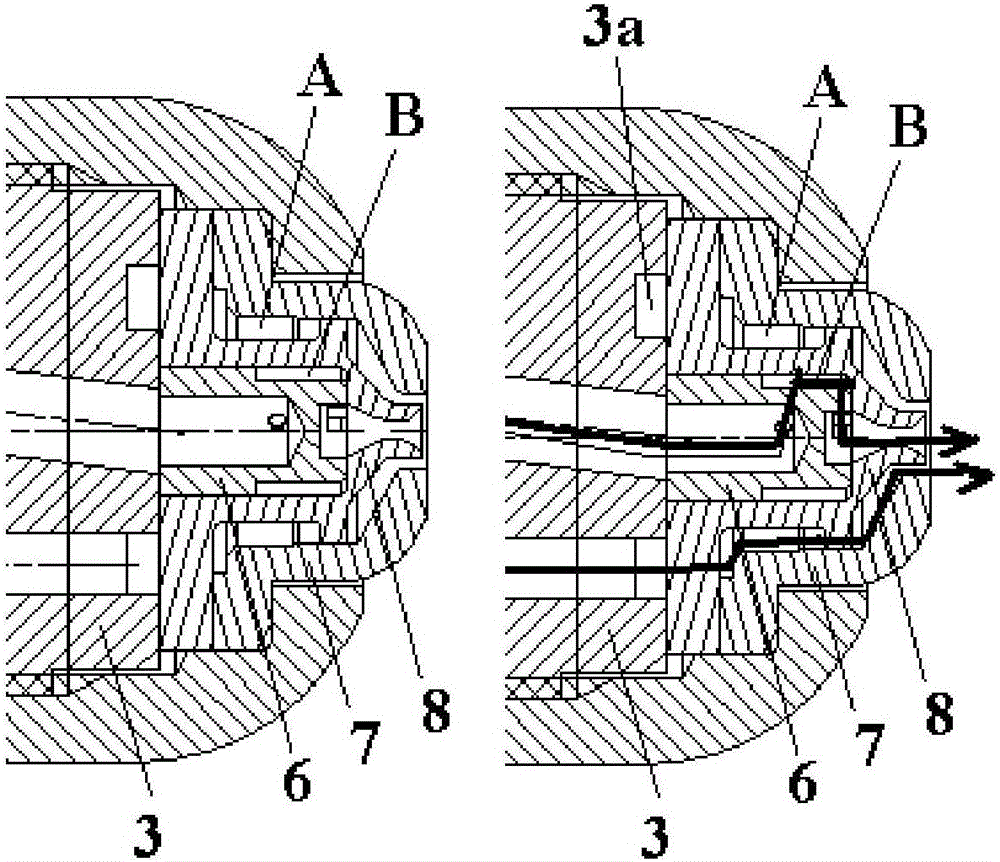

[0032] In order to solve the above technical problems, the present invention provides a dual oil circuit centrifugal nozzle structure with integrated design of main and auxiliary oil circuits, which includes: main oil pipe 1, auxiliary oil pipe 2, nozzle rod 3, locking plate 4, fixing nut 5, auxiliary Oil circuit swirler 6, main oil circuit nozzle 7 and auxiliary oil circuit nozzle 8; as figure 2 As shown, the fuel in the main oil circuit and the auxiliary oil circuit flows into the nozzle rod 3 from the main oil pipe 1 and the auxiliary oil pipe 2 respectively;

[0033]There are two oil passages in the nozzle rod 3, the main oil passage and the auxiliary oil passage. Among them, the auxiliary oil passage is inclined,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com