Metal part polishing device

A technology for metal parts and mounting rods, which is applied in the field of metal parts grinding devices, can solve the problems of the impact of grinding processing, the inability to grind cylindrical metal parts, and the inability to completely absorb and collect metal dust, so as to achieve strong applicability and avoid uniform grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

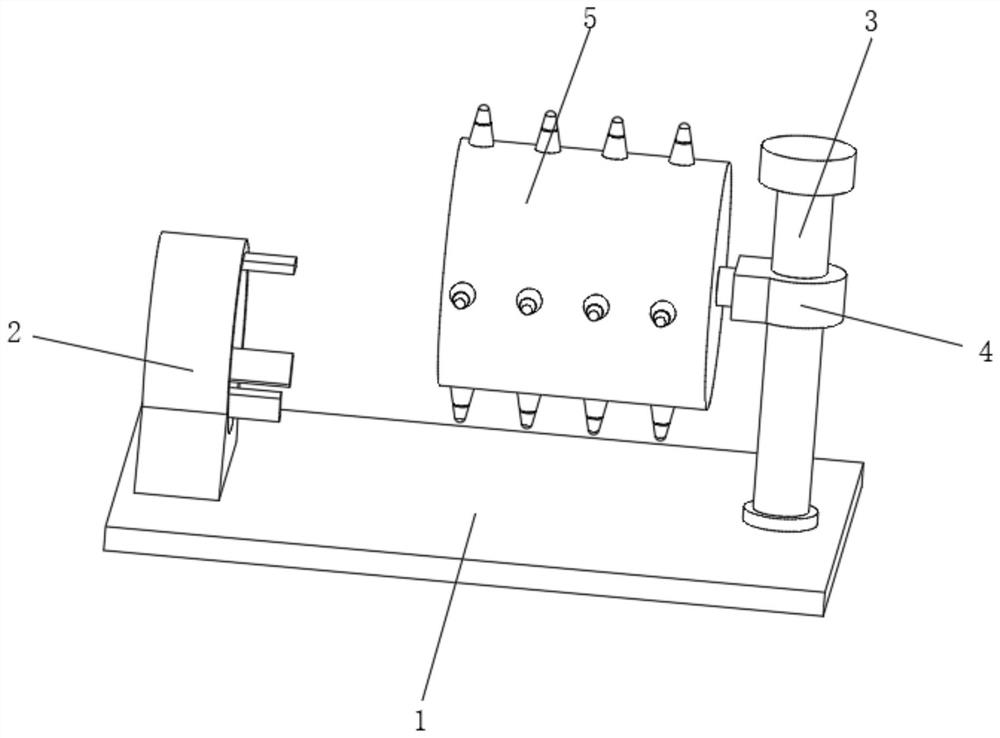

[0041] Such as Figure 1-4 As shown, the present invention provides a technical solution: a metal parts grinding device, including a support base plate 1, a three-jaw chuck 2 is fixedly connected to the left side of the top of the support base plate 1, and a three-jaw chuck 2 is fixedly connected to the middle position on the right side of the support base plate 1 top. Limiting pole 3, the outer surface of the limiting pole 3 is covered with a drive supporter 4, the left output end of the drive supporter 4 is fixedly connected with a surface grinding cylinder 5, and one side of the surface grinding cylinder 5 is fixedly connected with a grinding adjustment Mechanism 8, which completely covers the metal parts in the equipment for processing, reduces the pollution of metal dust to the processing environment during the processing. The positions between the collecting and guiding mechanisms 7 are uniform and equidistantly fixedly connected with the active supply mechanism 6;

[0...

Embodiment 2

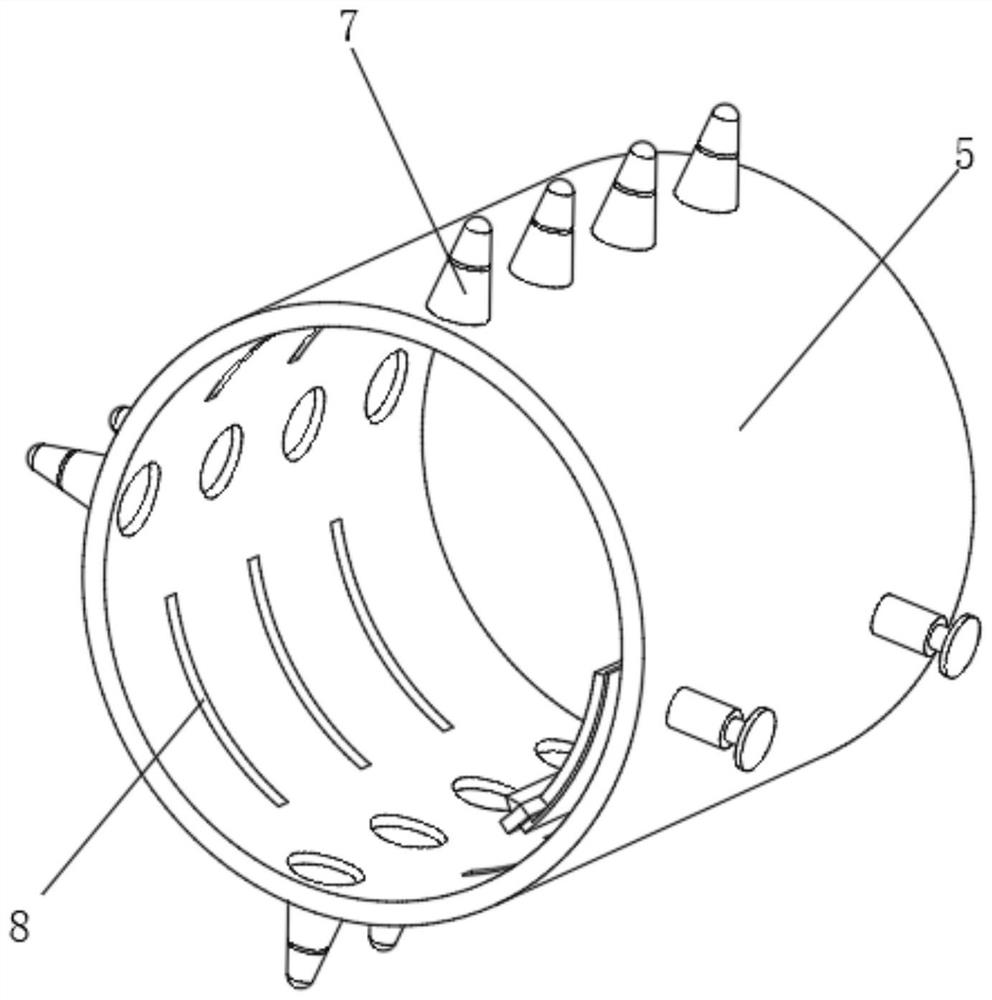

[0046] Such as Image 6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a metal piece grinding device, the collection guide mechanism 7 includes a conical collection groove 71, and the conical collection groove 71 is located outside the surface grinding cylinder 5 A mounting bolt tube 72 runs through one end, and one end of the mounting bolt tube 72 outside the conical collecting tank 71 is fixedly connected with a receiving tank 73 . Realize scraping and collecting the liquid on the surface of the metal parts, store it stably under the action of centripetal force during processing, and facilitate workers to recycle the liquid.

[0047] The bottom of the conical collection tank 71 is in fixed communication with the inside of the surface grinding cylinder 5 , and one end of the conical collection tank 71 with a larger diameter is arranged inside the surface grinding cylinder 5 .

[0048] The outer surface of one end of the mounting ...

Embodiment 3

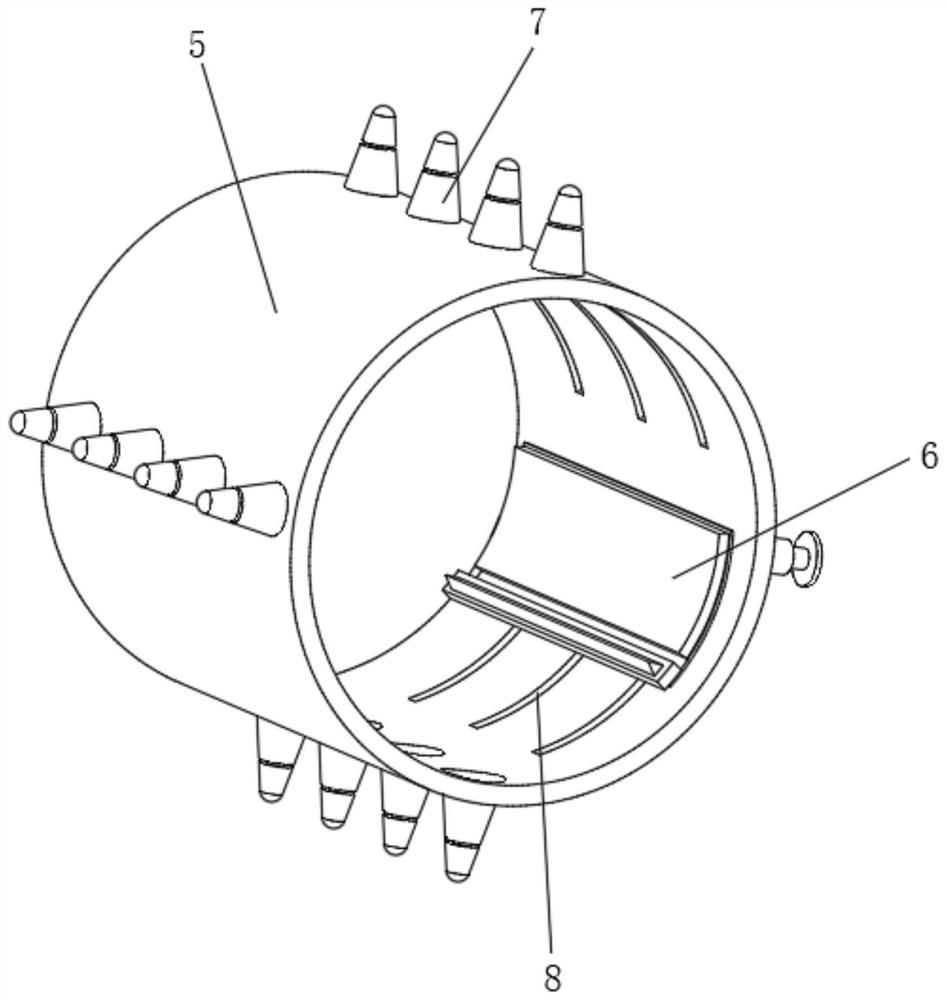

[0051] Such as Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a metal parts grinding device, the active supply mechanism 6 includes a storage inner tank 61, and the left side of the storage inner tank 61 is fixedly connected There is a liquid storage tank 62, and one end of the storage inner tank 61 close to the outside of the surface grinding cylinder 5 is fixedly connected with a one-way water inlet valve pipe 63, and the left side of the bottom of the liquid storage tank 62 is fixedly connected with a liquid discharge port 64. The one-way water inlet valve pipe 63 adopts a one-way valve structure to ensure that the liquid is all ejected when pushing the material, and it is guaranteed that the liquid is fully replenished when pushing backwards.

[0052] The storage inner groove 61 is arranged inside the surface grinding cylinder 5 , and the storage inner groove 61 adopts an arc structure corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com