Staple fiber delivery mechanism for melt blown nonwoven cloth processor

A melt-blown non-woven fabric and conveying mechanism technology, applied in the field of non-woven machinery, can solve the problems of large price constraints, limited disclosure of melt-blown non-woven equipment, loss of market competitiveness of final products, etc., and achieve reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable your examiners, especially the public, to fully understand the technical essence of the present invention, specific implementations are described in detail with reference to the drawings, but all the descriptions of the embodiments do not constitute a limitation to the technical solutions of the present invention.

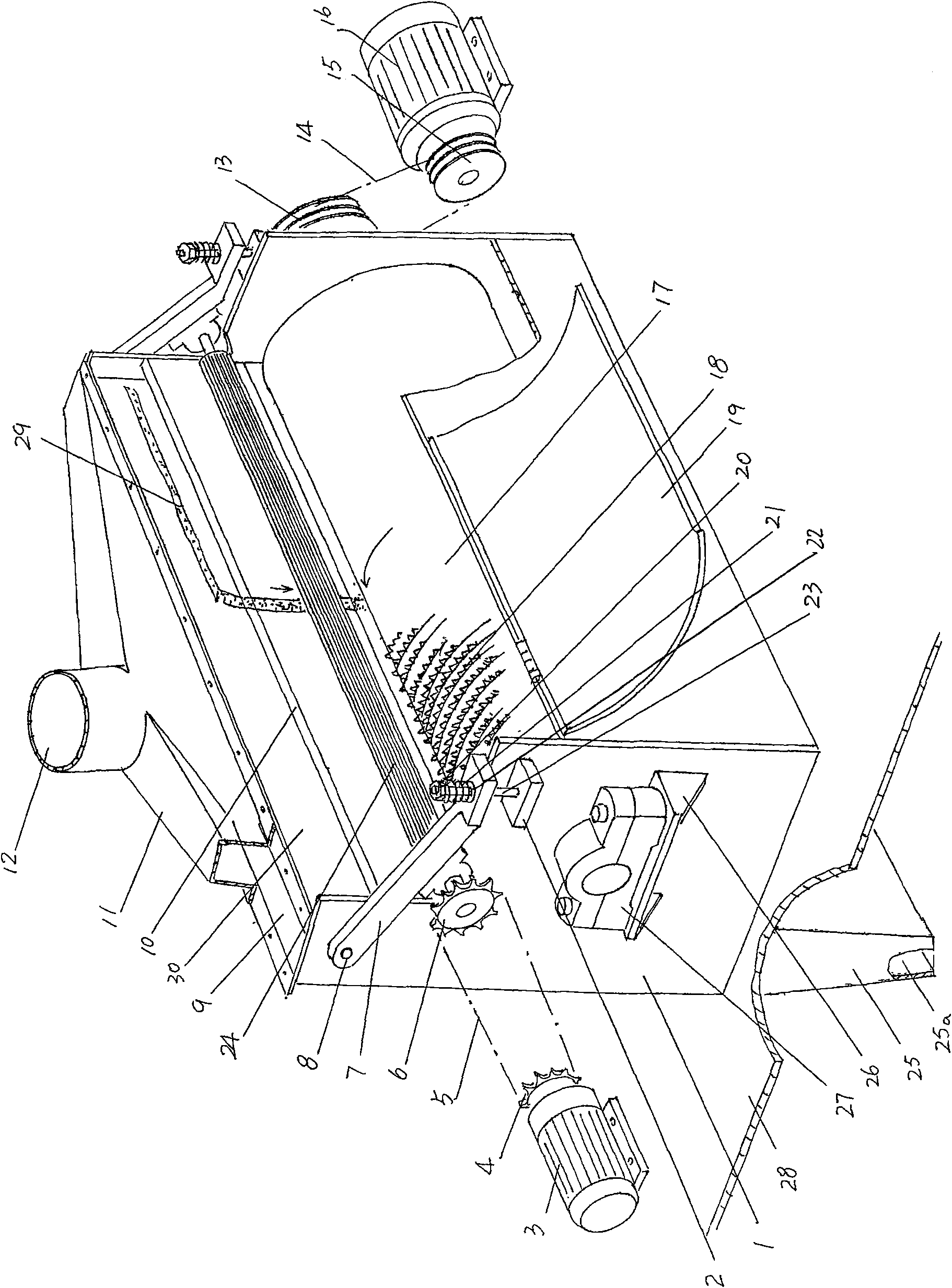

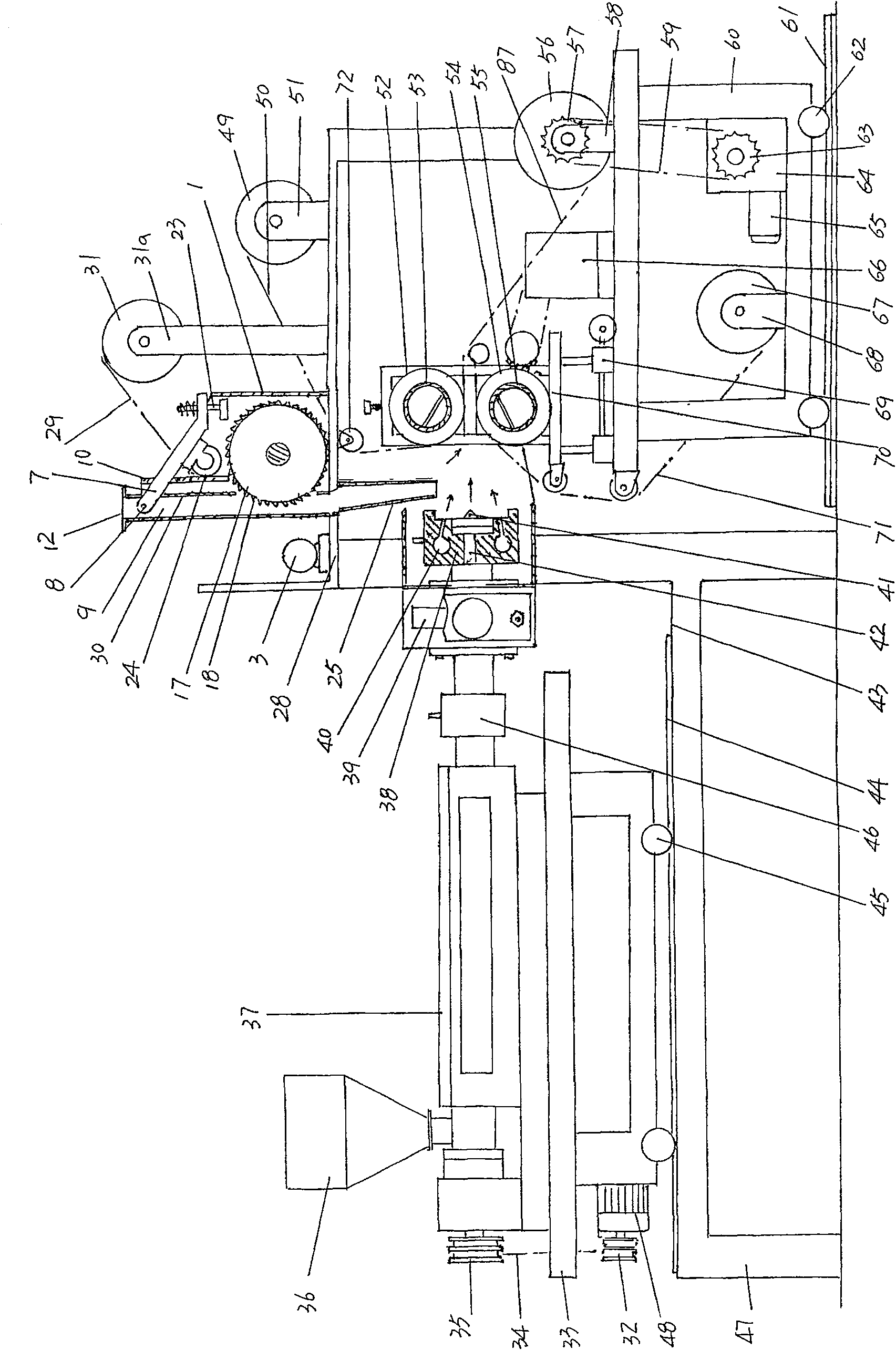

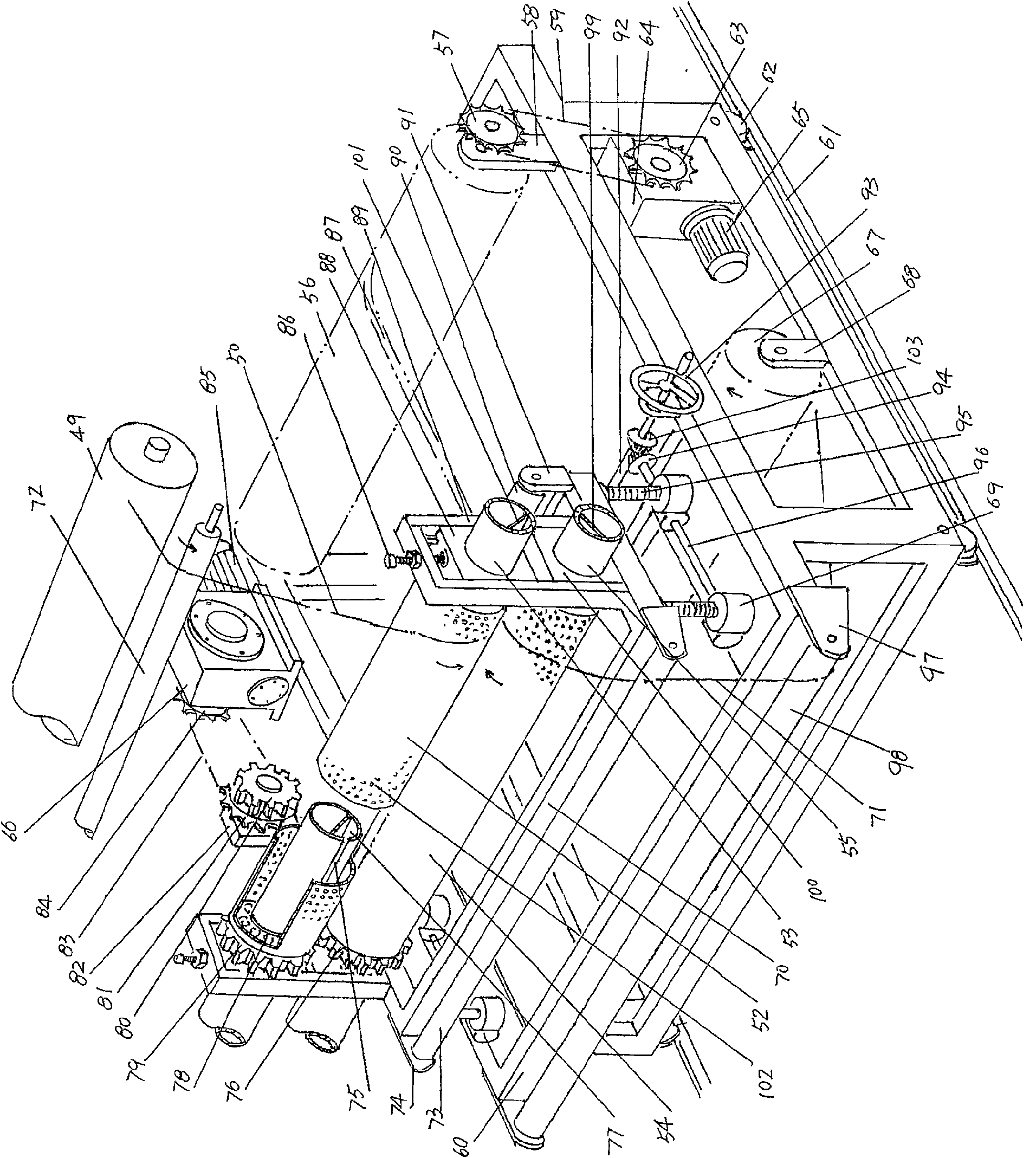

[0020] See you soon figure 1 The box body 1 as a short fiber conveying mechanism is fixedly installed on the work platform 28. The box walls on both sides of the box body 1 in the longitudinal direction, that is, the left and right box walls in the position shown in the figure, are roughly symmetrical, and the combing roller The roller shafts at both ends of the cylinder 17 are pivoted on the two sides of the box wall through the bearing seats 27, and a pair of bearing seats 27 are fixed on the axle seat bracket 26 with bolts or other similar fixing parts. 26 is fixed on the outer wall of the corresponding box wall in the length direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com