Automatic metal thermal spraying device

A spraying device, metal heat technology, applied in the spraying device, the device for coating liquid on the surface, coating, etc., can solve the problems of unguaranteed spraying quality and low work efficiency, so as to improve work efficiency and ensure spraying quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below in conjunction with specific embodiment:

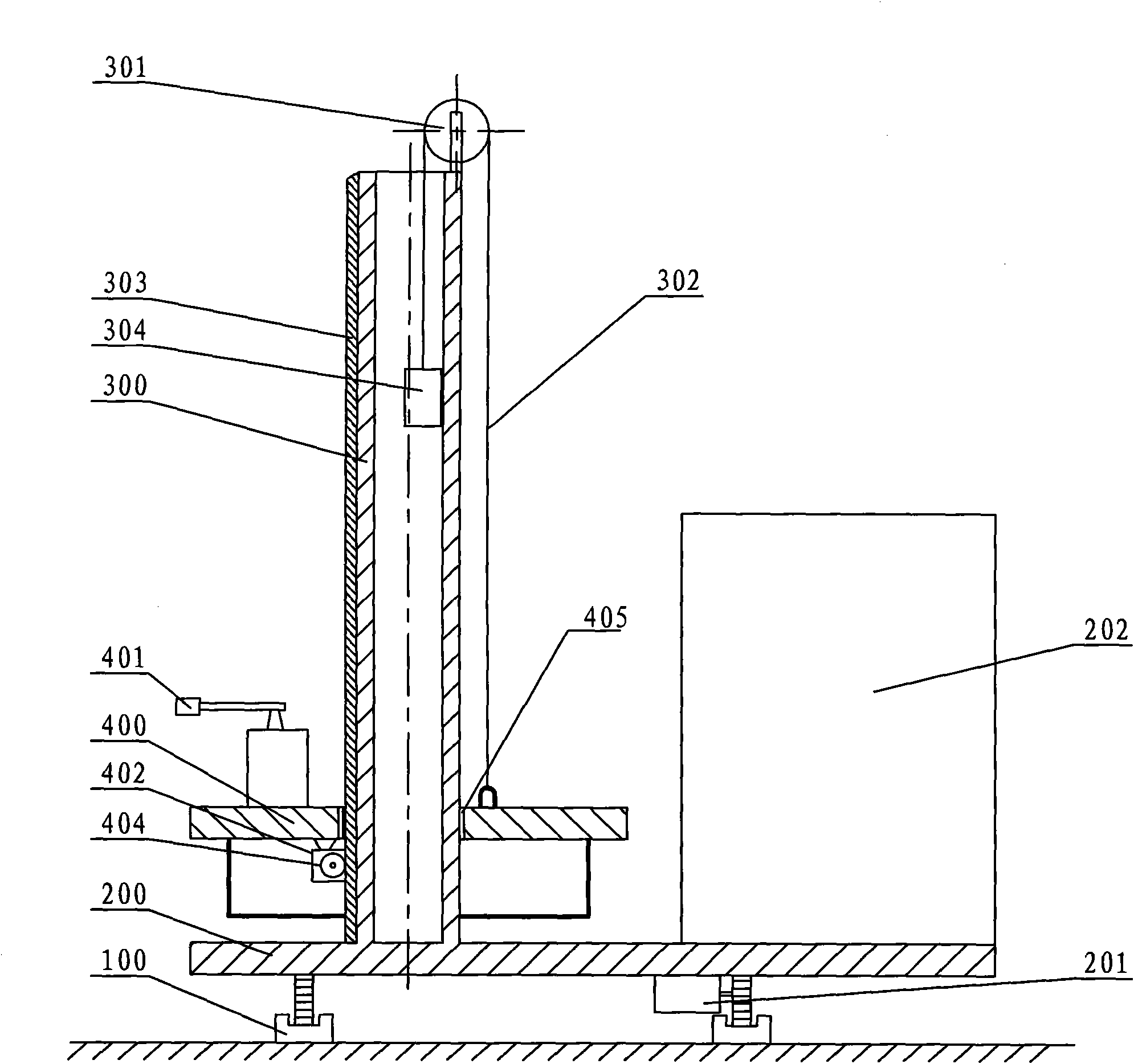

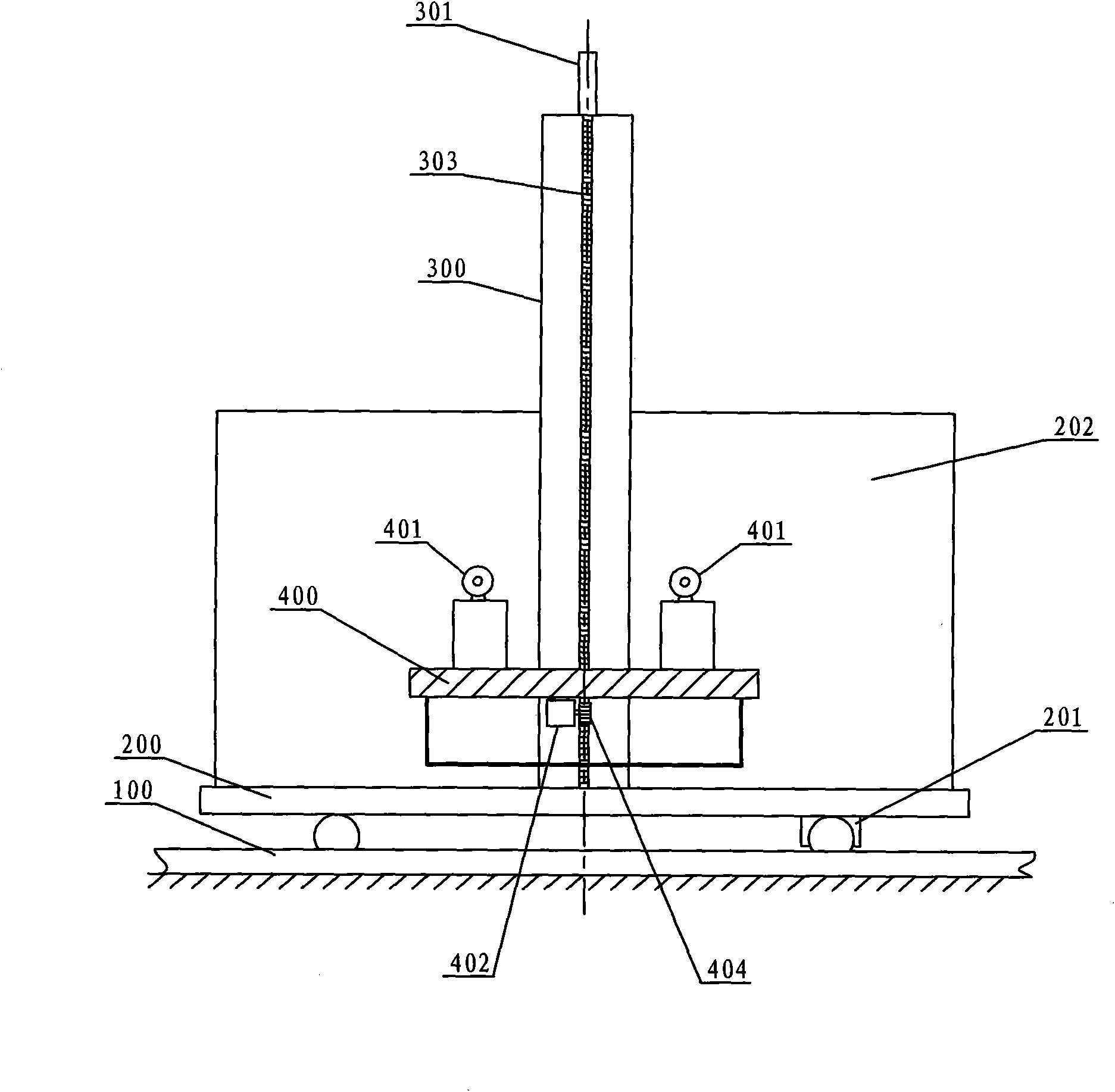

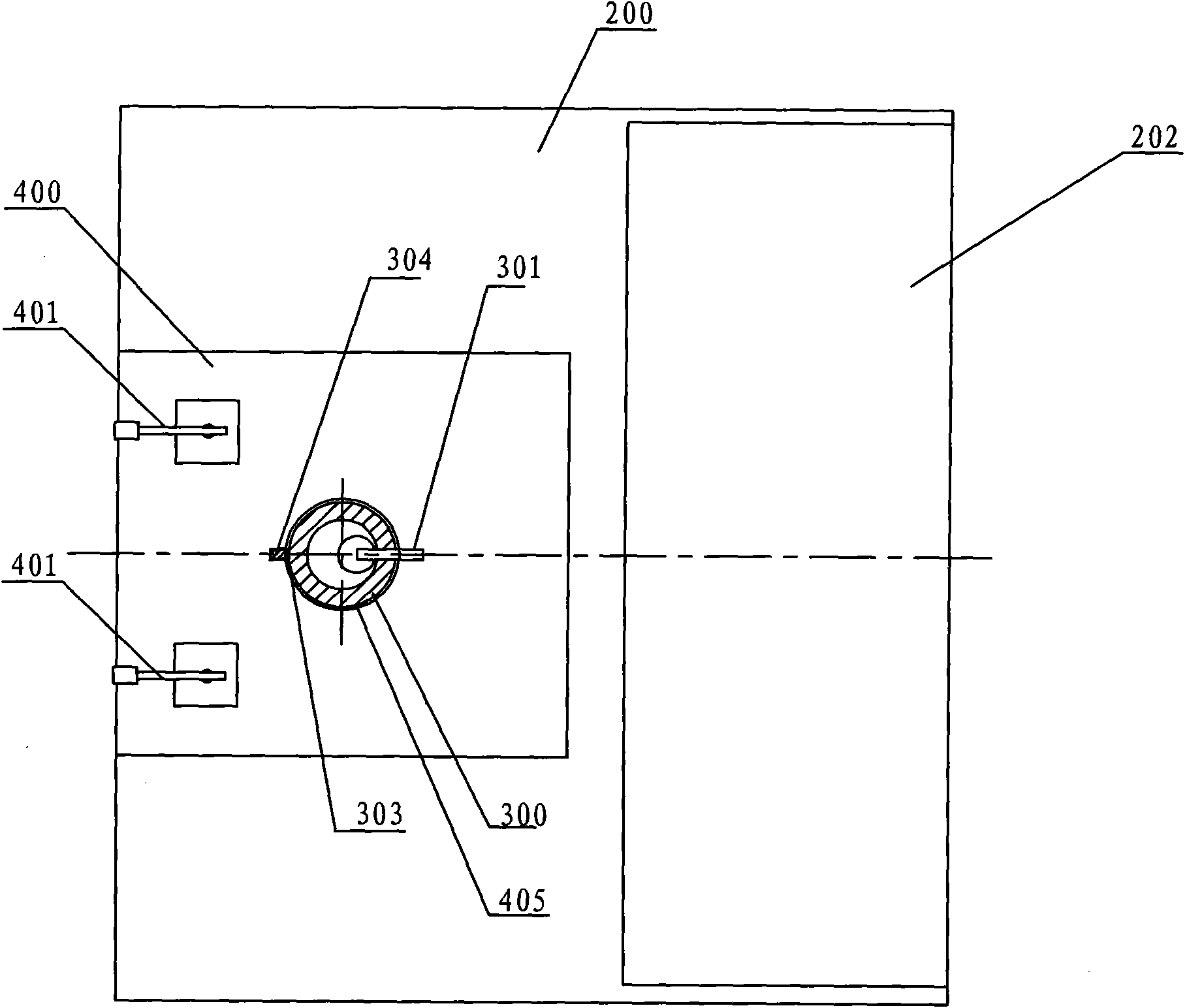

[0021] See figure 1 , figure 2 as well as image 3 , the present invention includes a track 100 , a trolley 200 , a column 300 and a spray gun seat 400 .

[0022] The trolley 200 is equipped with rollers, a traveling motor 201 and a working cabin 202 .

[0023] The traveling motor 201 can drive the rollers to roll along the track 100, so that the trolley 200 reciprocates in the horizontal direction.

[0024] The column 300 is installed vertically on the trolley 200 . A fixed pulley 301 is installed on the top of the column 300 , and a rack 303 is arranged vertically on the surface of the column 300 .

[0025] A spray gun seat 400 is also installed on the column 300 . A spray gun 401 , a lifting motor 402 and a paint roller 403 are installed on the spray gun seat 400 . A gear 404 is installed in the spray gun seat 400 , and the gear 404 meshes with the rack 303 .

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com