Patents

Literature

30results about How to "To achieve the purpose of spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolytic aluminum prebaked anode anti-oxidation insulating coating and preparation method thereof

ActiveCN110964352AHigh strengthHigh purityFireproof paintsAnti-corrosive paintsMetallurgyAluminium oxides

The invention provides an electrolytic aluminum prebaked anode anti-oxidation insulating coating. The electrolytic aluminum prebaked anode anti-oxidation insulating coating comprises the following components in percentage by mass: 60%-75% of a main component, 0.01%-5% of a secondary component, 24%-34% of a nano solvent binding phase and 0.01%-5% of a coating stabilizing phase, wherein the main component comprises amorphous aluminum oxide, nano-scale rho-Al2O3, nano-scale gamma-Al2O3 and nano-scale alpha-Al2O3. The insulating coating prepared by the invention can be cured at normal temperaturefor 6-8 hours after being sprayed to an anode by a spraying machine, the anode coating can form a compact net-shaped structure at the working temperature of 500-800 DEG C, the long-term tolerable temperature is over 900 DEG C, and the physical and chemical properties are stable.

Owner:CENT SOUTH UNIV +1

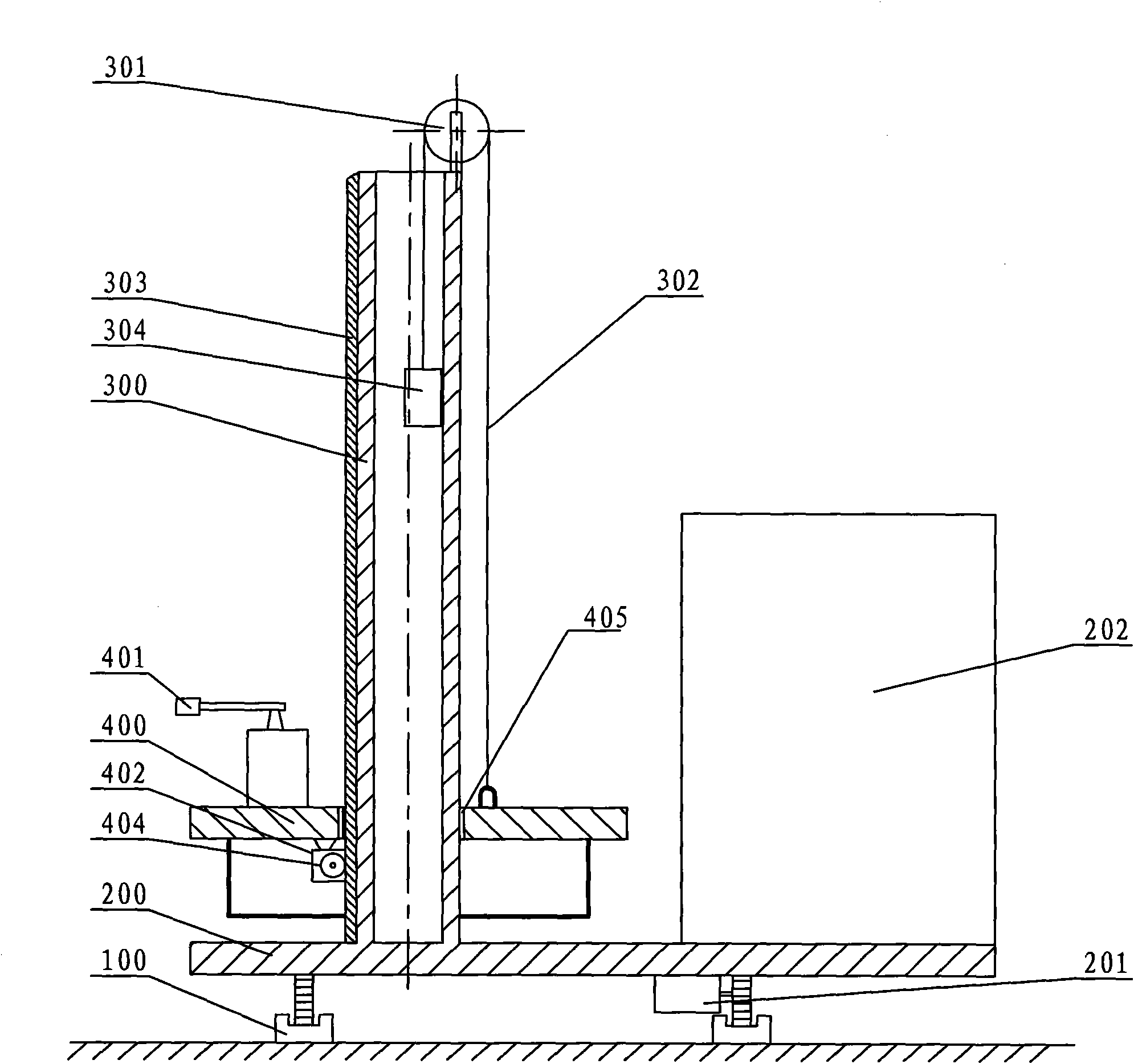

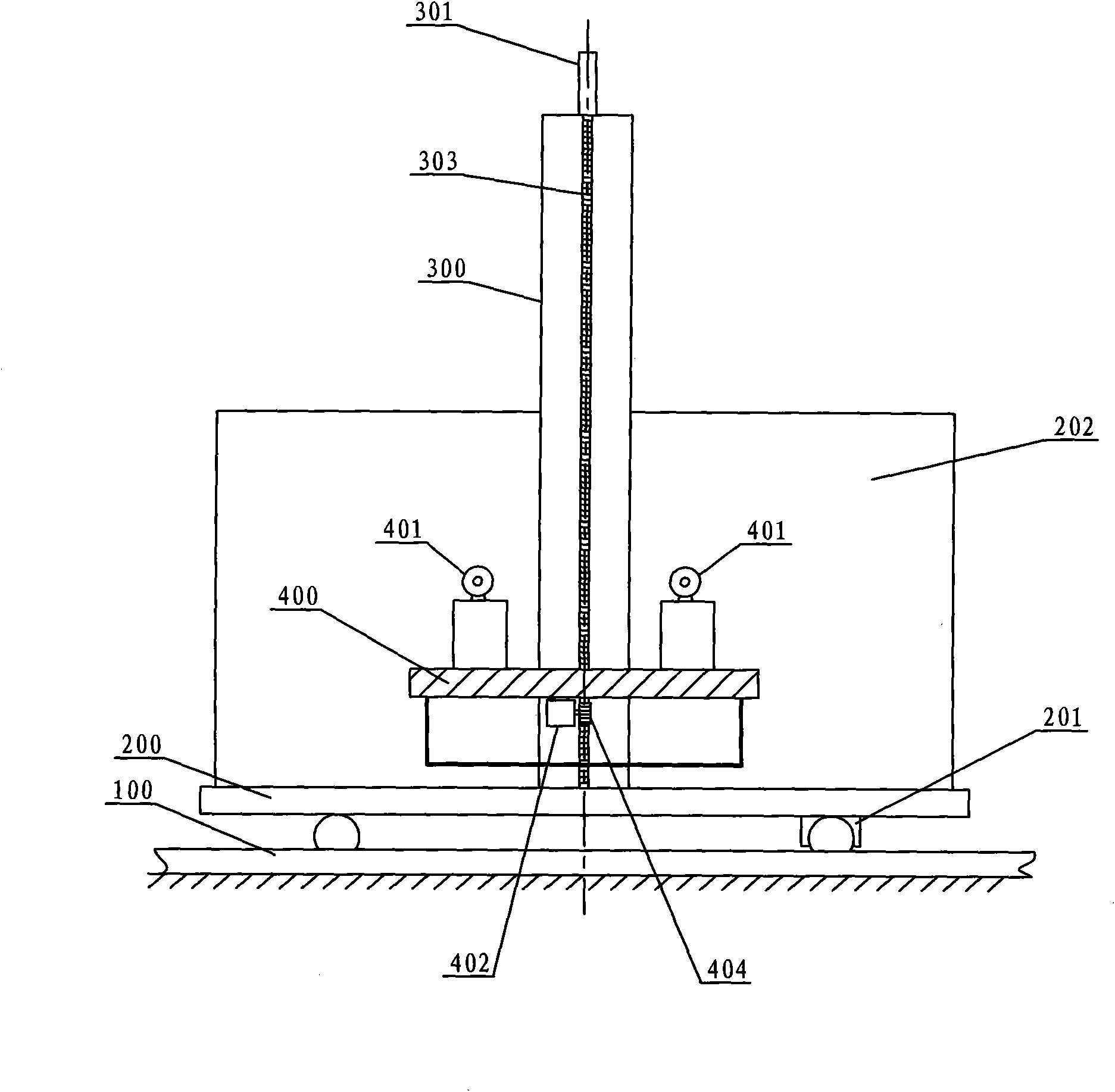

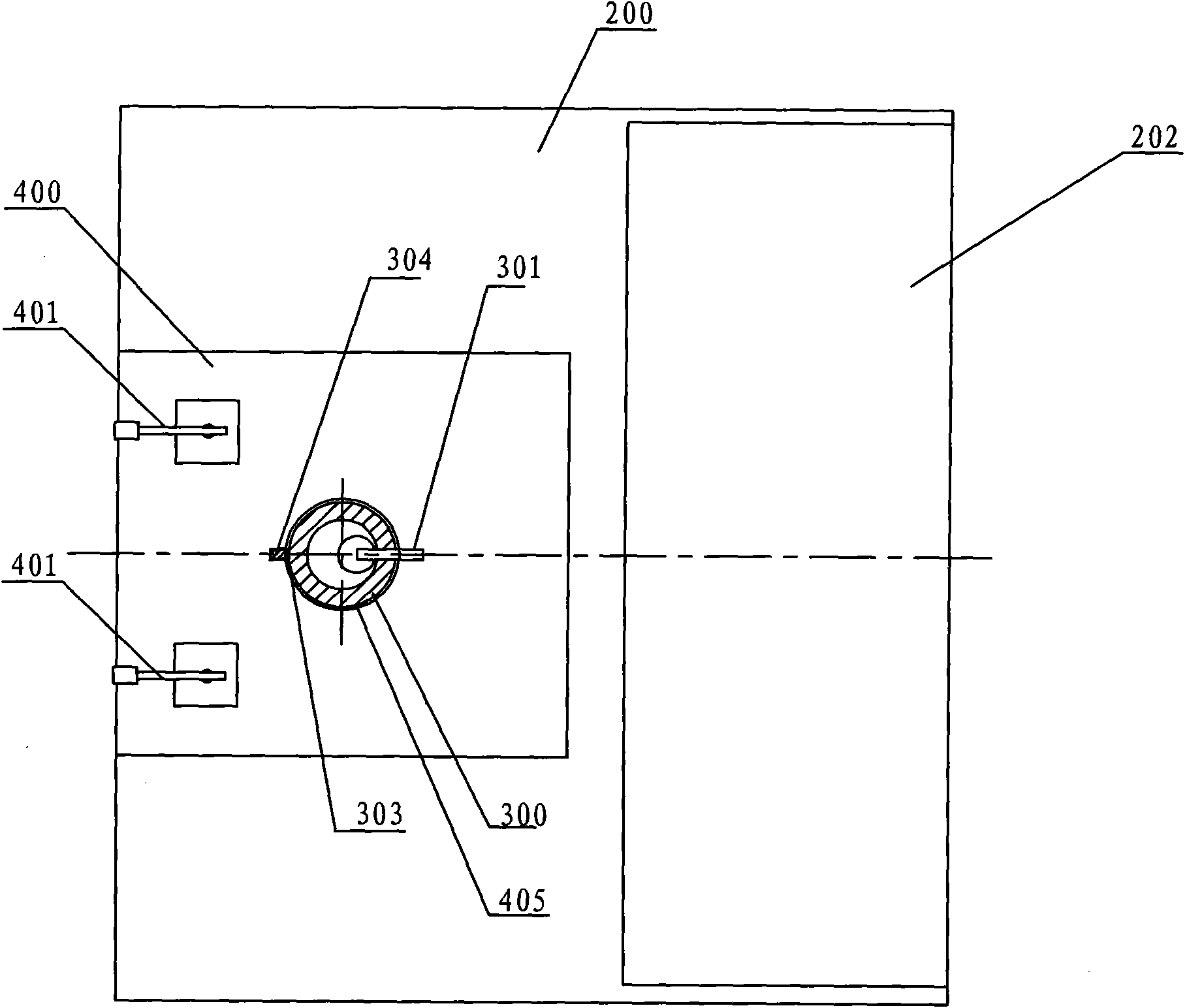

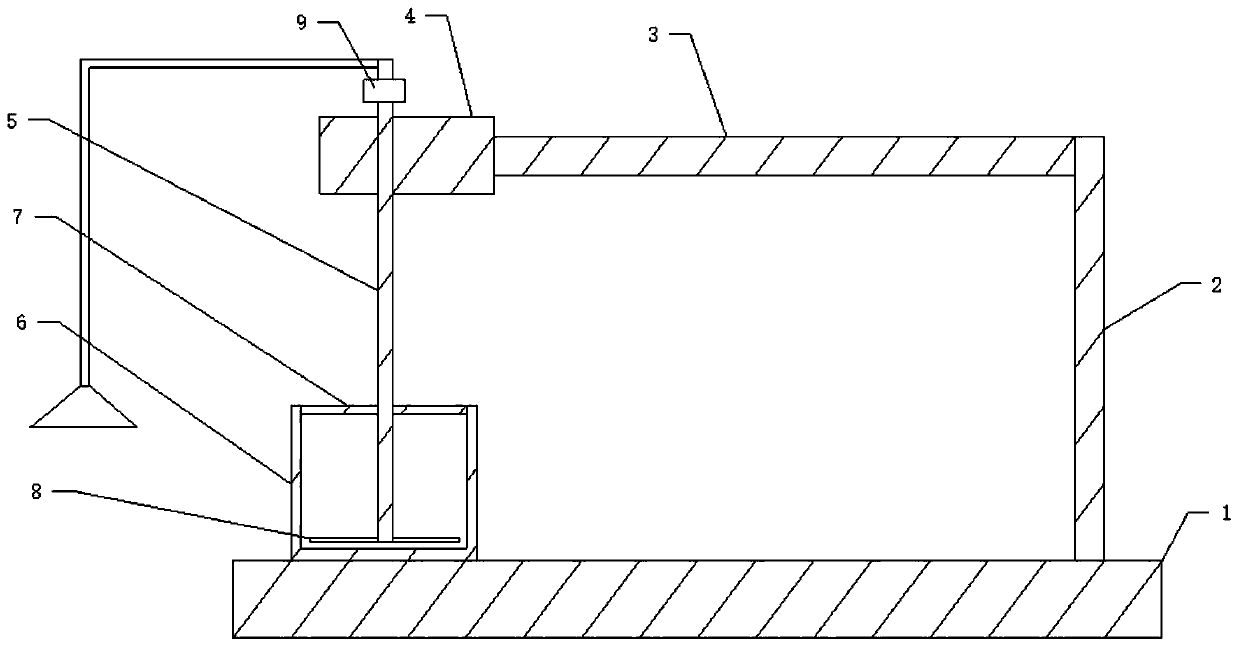

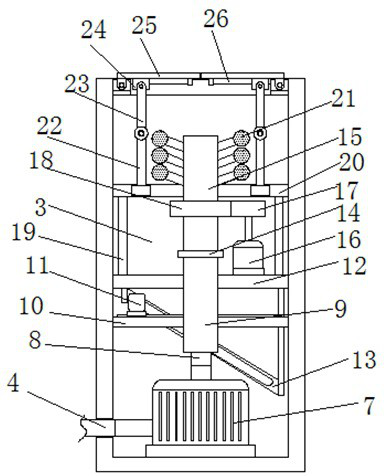

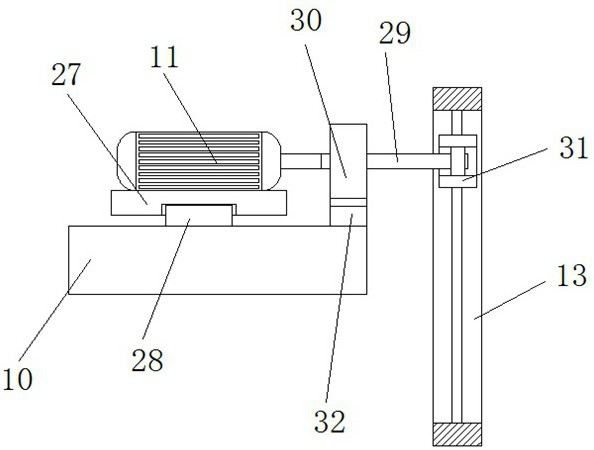

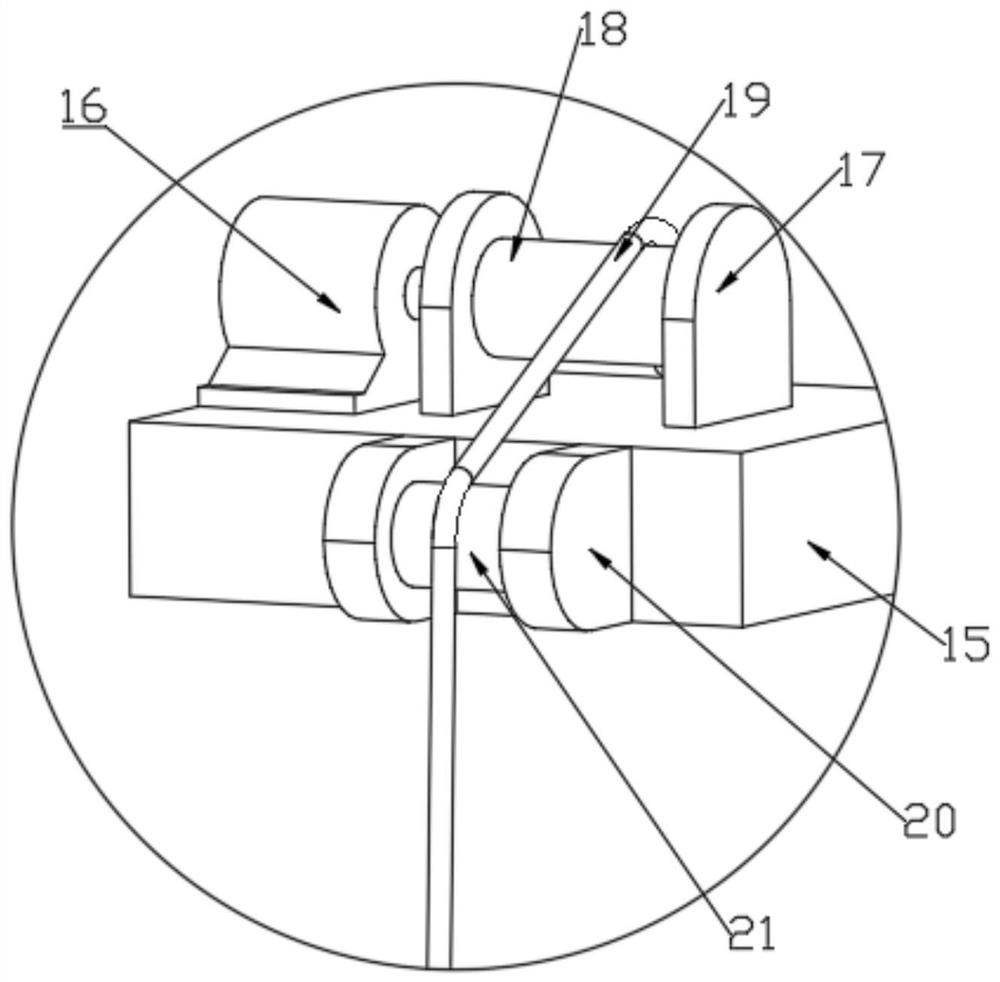

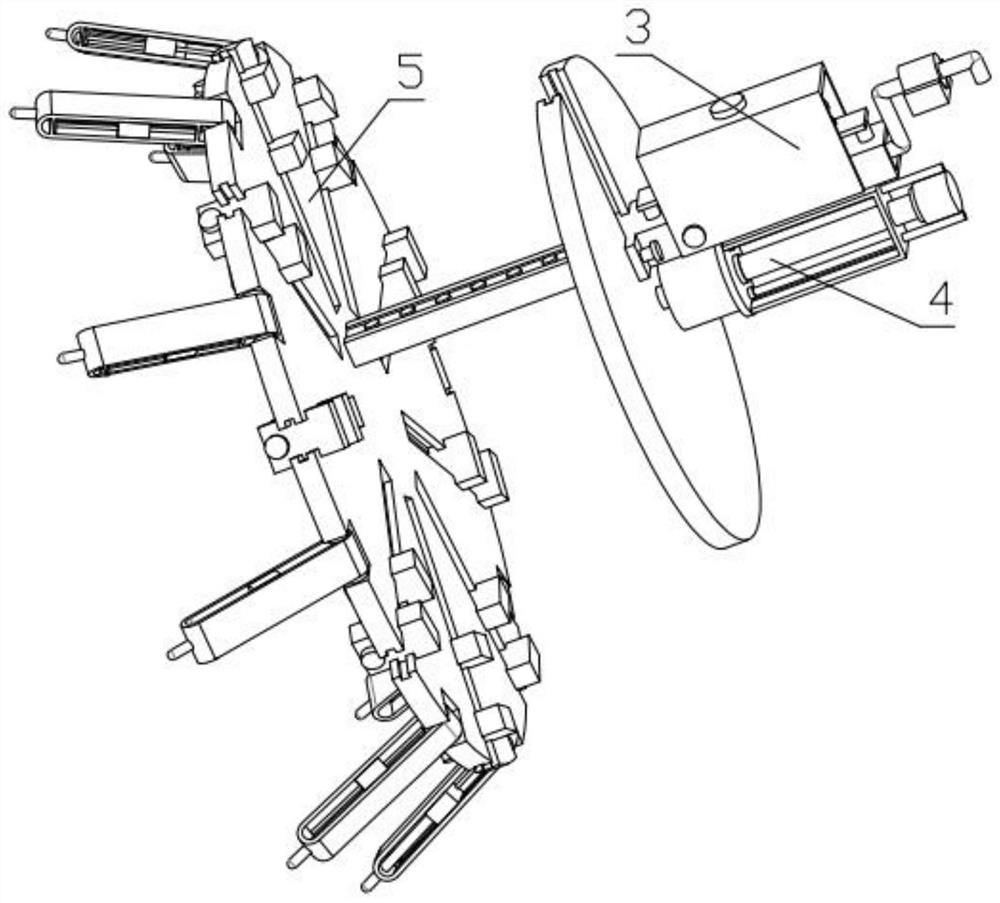

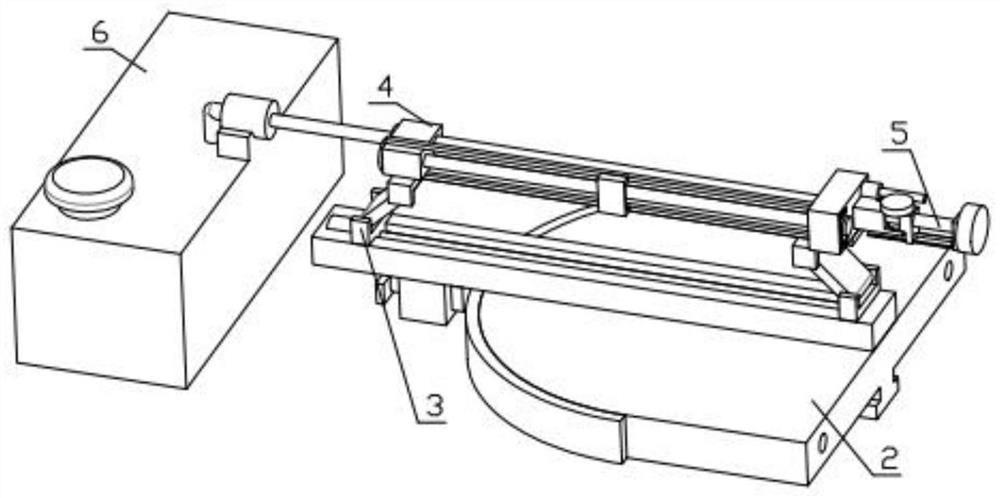

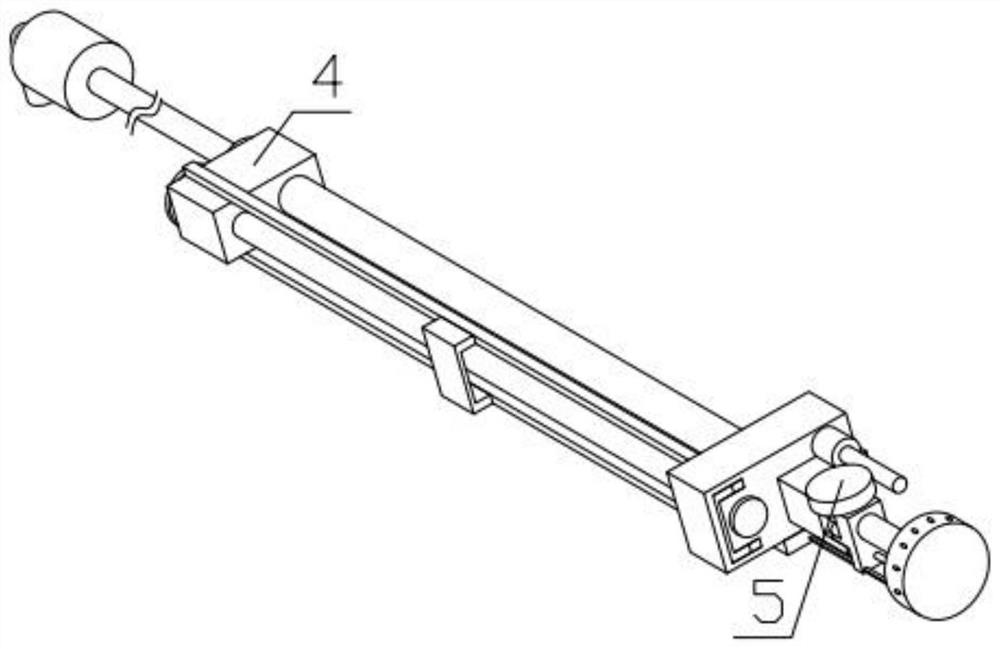

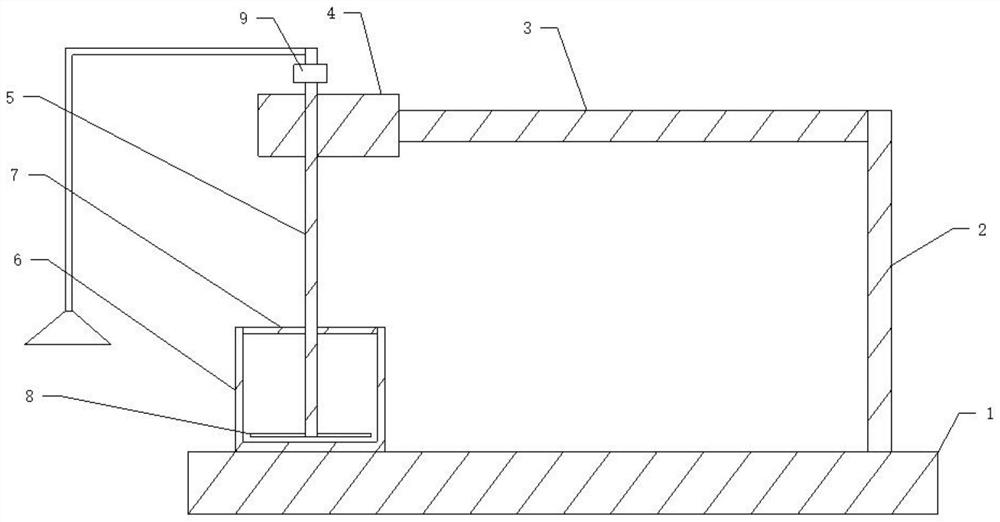

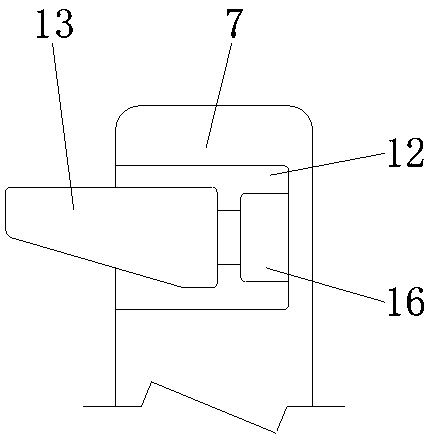

Automatic metal thermal spraying device

InactiveCN101884966AAchieve sprayingTo achieve the purpose of sprayingLiquid surface applicatorsSpraying apparatusThermal sprayingReciprocating motion

The invention discloses an automatic metal thermal spraying device. The automatic metal thermal spraying device applied to the technical field of coating comprises a rail, a trolley, a stand column and a spray gun base, wherein the trolley is arranged on the rail; the stand column is vertically fixed on the trolley; the spray gun base is arranged on the stand column and can move up and down along the stand column; a spray gun is arranged on the spray gun base; a fixed pulley is arranged at the top end of the stand column and wound with a steel wire rope; one end of the steel wire rope is connected with the spray gun base, while the other end is suspended with a balance weight; the surface of the stand column is provided with a rack in vertical direction; the spray gun base is provided with a lifting motor; and a gear which is engaged with the rack is arranged on the lifting motor. The trolley which can reciprocate and the spray gun base adopted by the invention fulfill the aim of automatic metal thermal spraying for a workpiece in a large area, thereby achieving the effects of improving working efficiency and guaranteeing thermal spraying quality.

Owner:SHANGHAI HUNENG ANTI CORROSION & HEAT INSULATION ENG

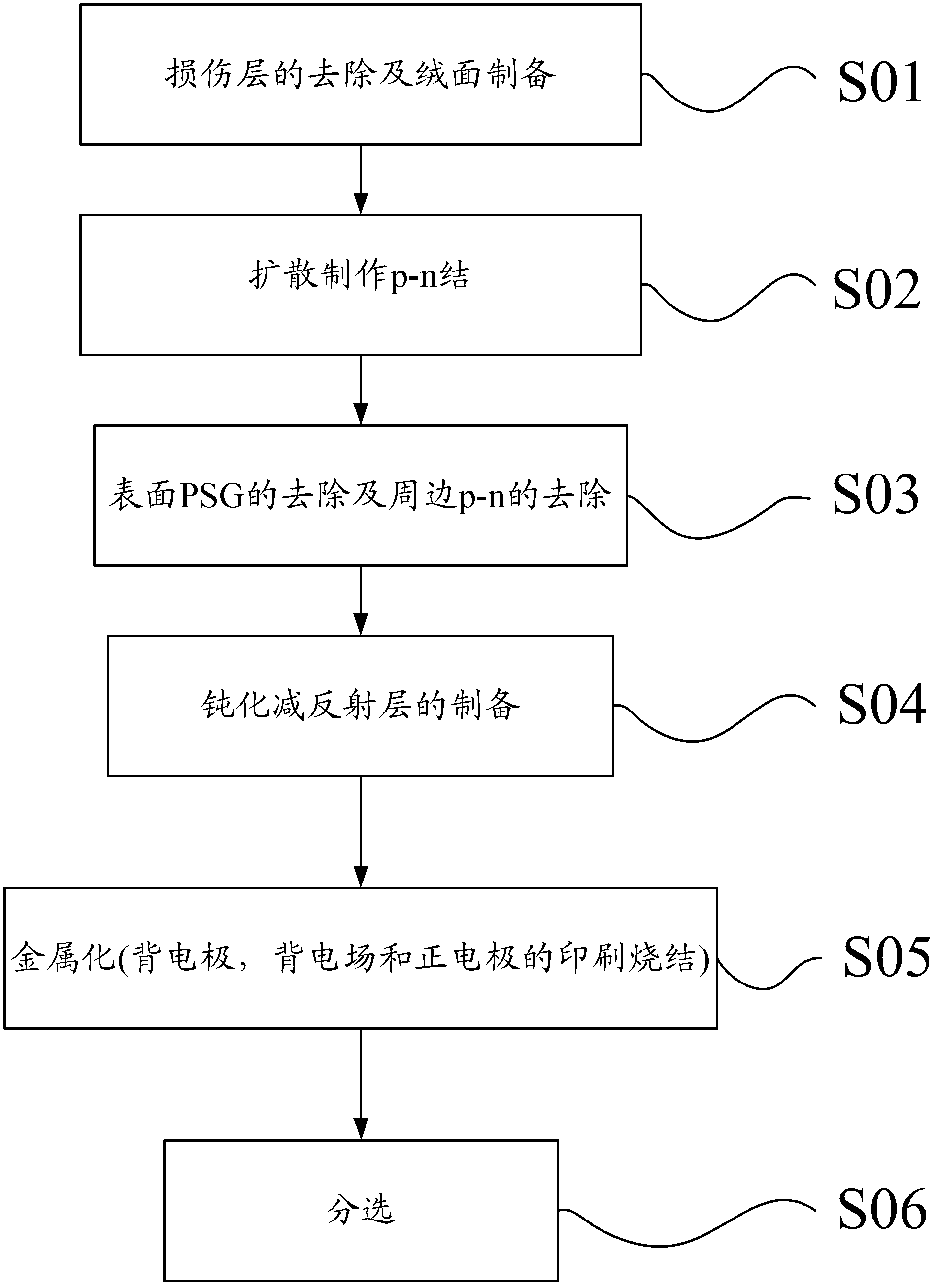

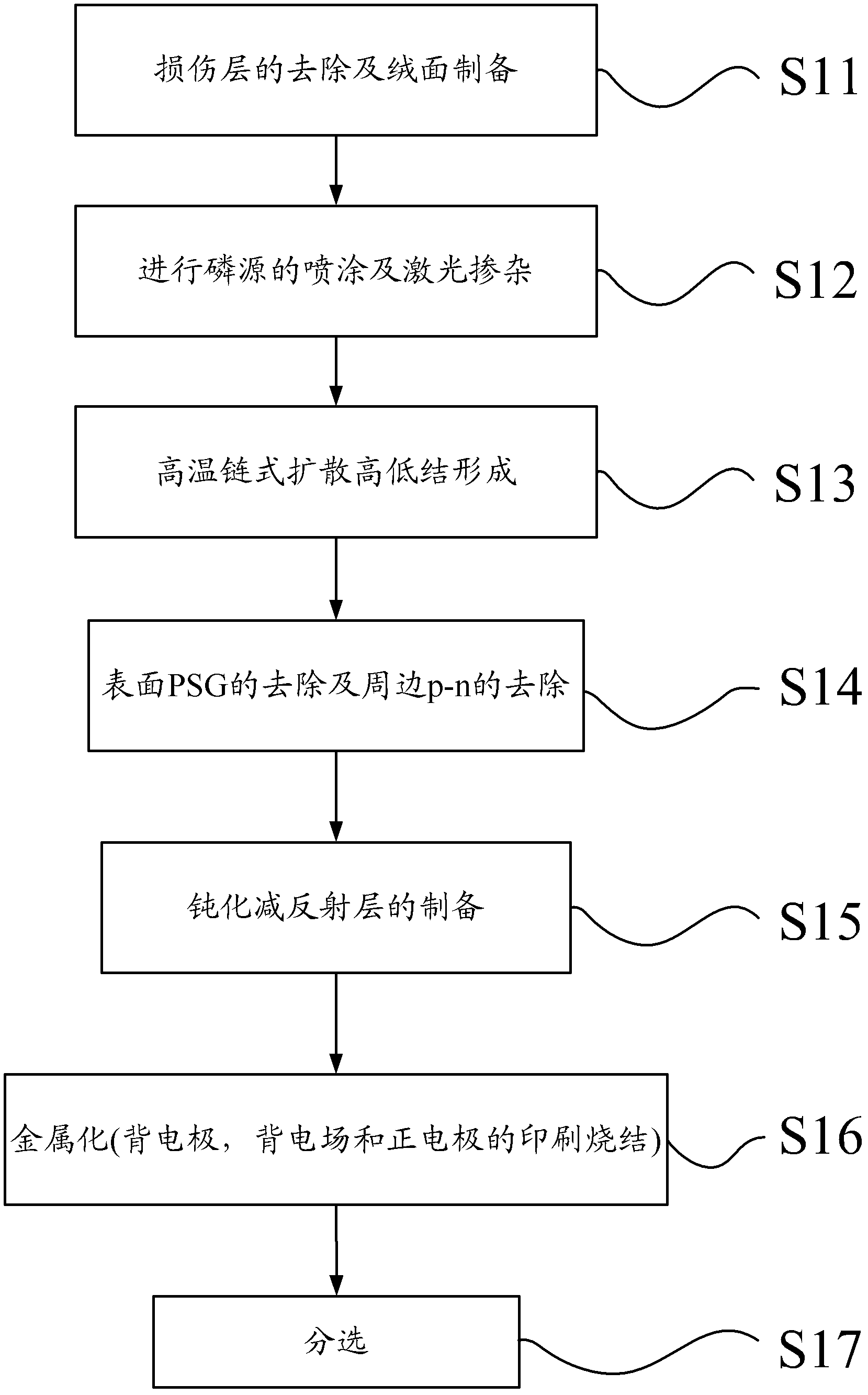

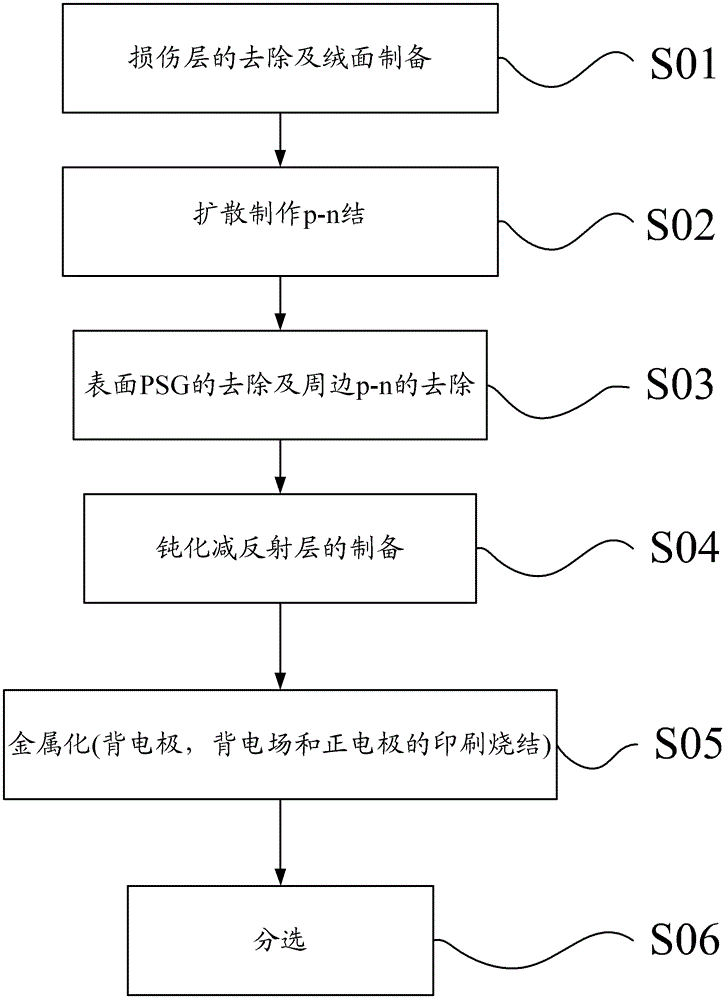

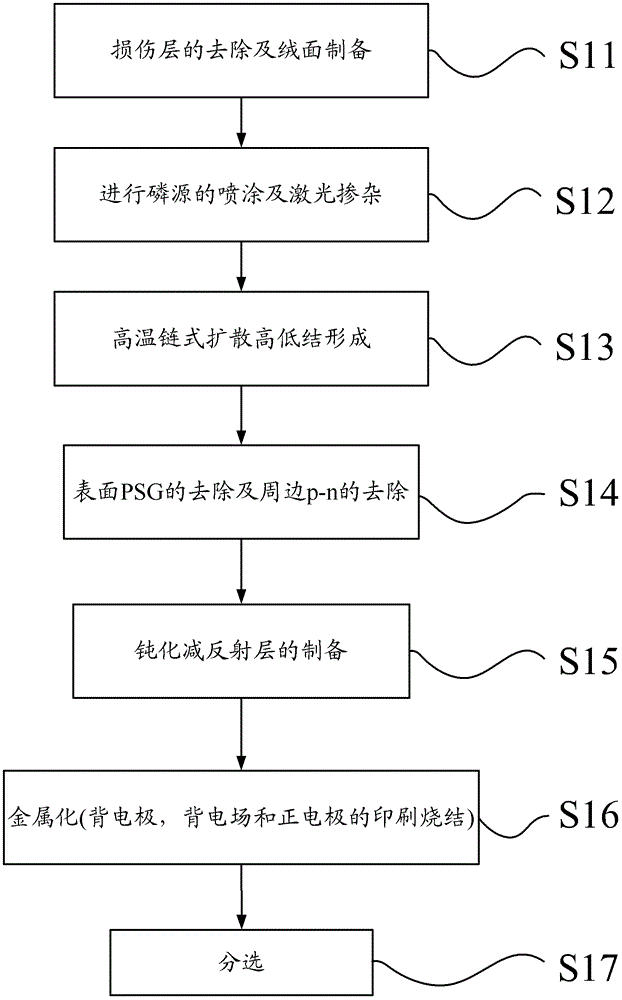

Manufacturing method of selective emitter cell

ActiveCN103367124AConducive to industrial automation productionTo achieve the purpose of sprayingFinal product manufactureSemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention discloses a manufacturing method of a selective emitter cell, and the method comprises the steps: 1) removing the damage layer of a silicon chip and manufacturing a pile face on the surface of the silicon chip; 2) spraying phosphorus source and doping by utilizing laser on the silicon chip after the first step; 3) carrying out high-temperature chain-type diffusion for the sprayed and doped silicon chip to obtain p-n junctions of a zone outside the right positive electrode zone; 4) removing PSG on the surface of and p-n junctions around the silicon chip after the high-temperature chain-type diffusion; 5) depositing a layer of silicon nitride film which plays effects of reflection reduction and passivation on the surface of the silicon chip after the fifth step; 6) printing and sintering a back electrode, a back electric field, and a right electrode on the silicon chip with the silicon nitride film to metallize the electrodes and obtain the selective emitter cell; 7) testing each parameter of the selective emitter cell and grading the selective emitter cell according to the technology standard. The method can effectively improve the conversion efficiency of a solar cell and be used in production conveniently.

Owner:YINGLI ENERGY CHINA

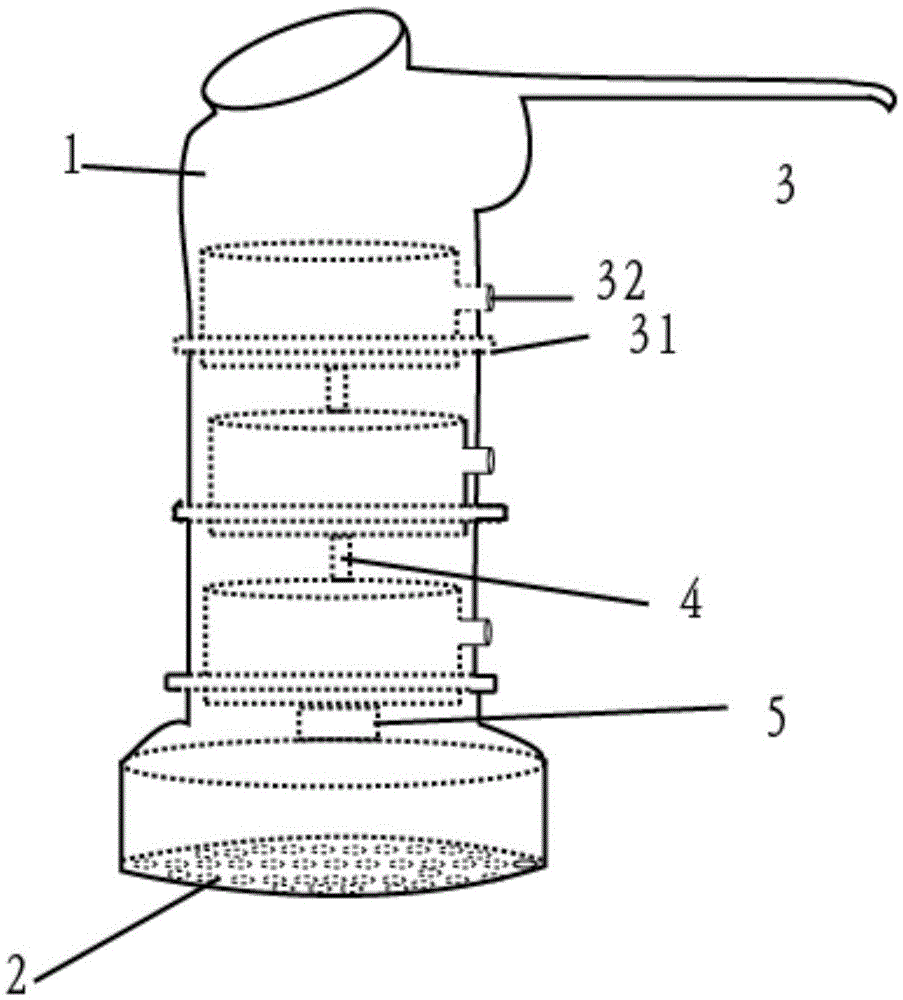

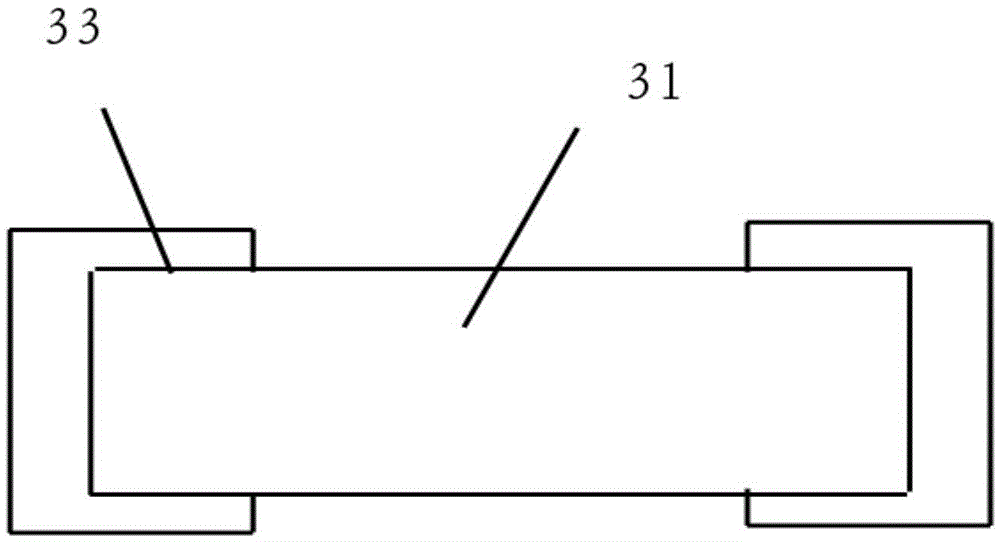

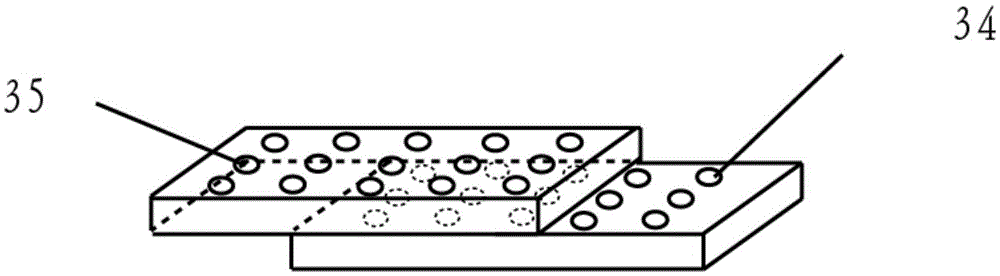

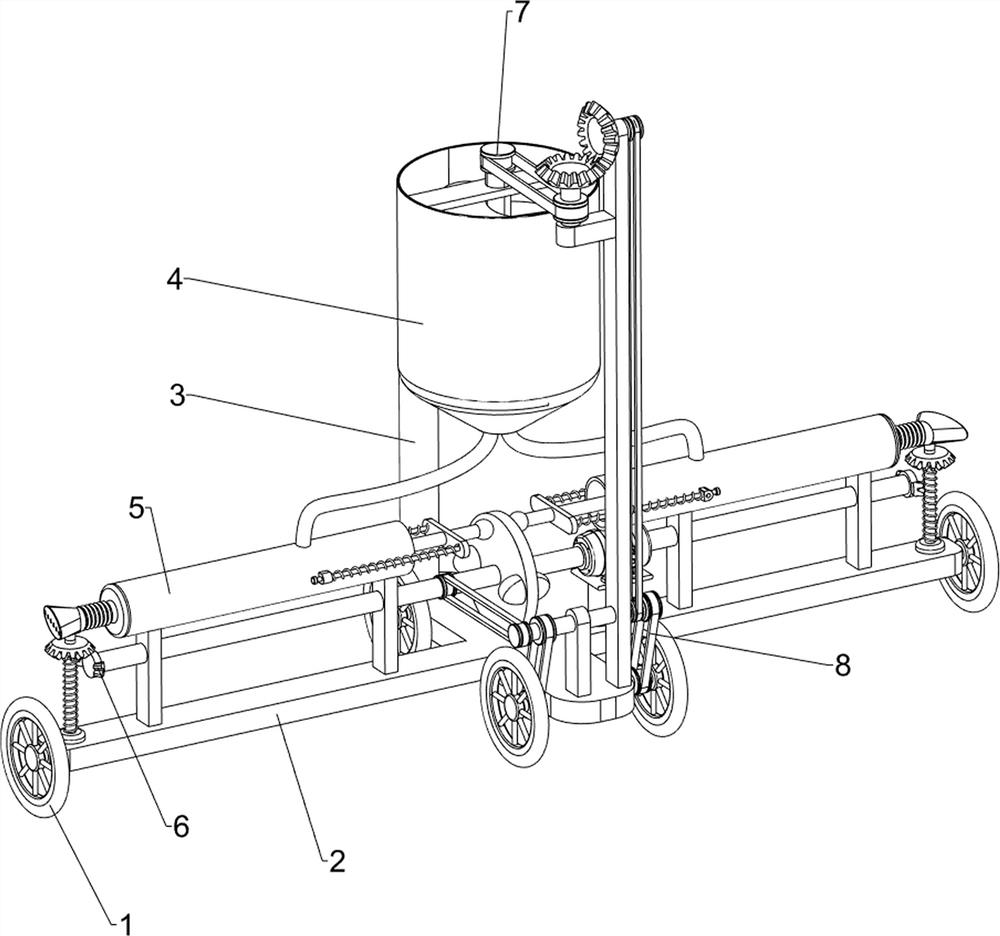

Agricultural spraying device

ActiveCN105594676ATo achieve the purpose of sprayingTo achieve the purpose of terminating sprayingWatering devicesCultivating equipmentsAgricultural engineeringMaterial storage

The invention discloses an agricultural spraying device which comprises a spray head, multiple material storage devices, multiple first support rods and a second support rod. Spray holes are formed in the bottom of the spray head, and the top end of the spray head is opened. A transverse plate is arranged in each material storage device, multiple material seepage holes are formed in the bottom of each material storage device, sliding rails are arranged on the two inner side walls, opposite to each other, of each material storage device respectively, and each sliding rail penetrates through the corresponding inner side wall. The two ends of each transverse plate are inserted into the corresponding sliding rails and connected with the sliding rails in a sliding mode, multiple through holes are formed in the bottom of each transverse plate, seamless contact is kept between the bottom end of each transverse plate and the bottom of the corresponding material storage device, and the thickness of the transverse plates is equal to the height of the sliding rails. The multiple material storage device are vertically arranged, the adjacent material storage devices are connected through the first support rods, one end of the second support rod is connected with the material storage device at the lowest end, and the other end of the second support rod is connected with the spray head. The agricultural spraying device has the advantages of being capable of improving the efficiency and reducing the cost and diverse in function.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

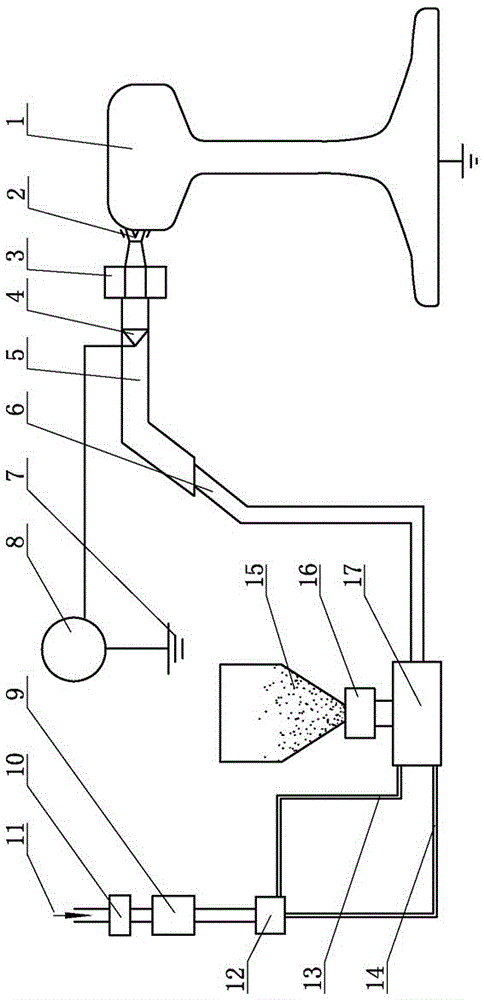

Electrostatic coating device of locomotive-mounted wheel rail friction control material

InactiveCN105728218AIncrease profitDensity controllableRail lubricationRail wetting/lubricationElectrostatic coatingEngineering

The invention discloses an electrostatic coating device of a locomotive-mounted wheel rail friction control material. The electrostatic coating device comprises a high-voltage electrostatic generator, a high-voltage electrode and a powder pump; the powder pump is provided with a secondary wind pressure pipe and a primary wind pressure pipe; a feed port of the powder pump is connected with a supply electromagnetic valve; the supply electromagnetic valve is connected with a storage tank; a discharge port of the powder pump is connected with a powder-air mixing pipe; the powder-air mixing pipe is connected with a nozzle; and the high-voltage electrode is arranged in the nozzle, and is connected with the high-voltage electrostatic generator. The electrostatic coating device has the following advantages: the electrostatic coating device saves such links as heating, stirring and insulation transportation in a solid-liquid-solid coating mode, so that the caused defects are prevented, the device is compact in structure, small in size and more convenient for installation, largely increases the material utilization rate, realizes controllability of coating thickness and density, and can adjust the coating thickness and density through a mode of adjusting primary and secondary wind pressure and voltage of the electrostatic generator according to specific conditions of different curves; and a coating method is more scientific and precise, and greatly improves the coating effect.

Owner:张峰

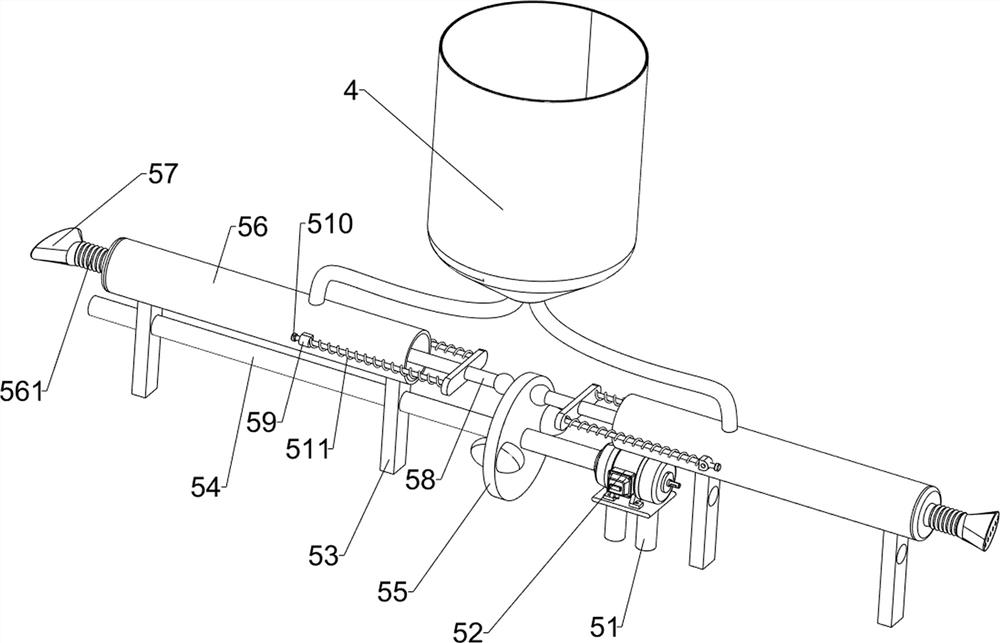

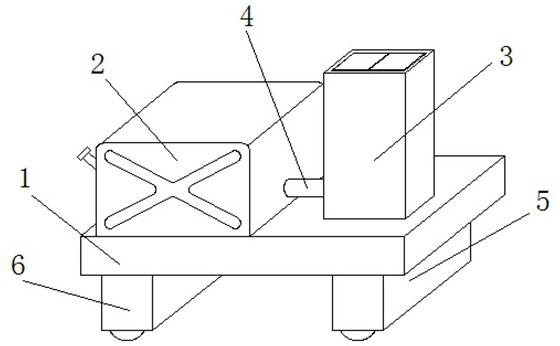

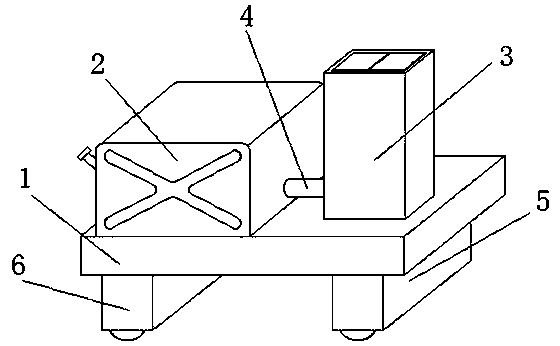

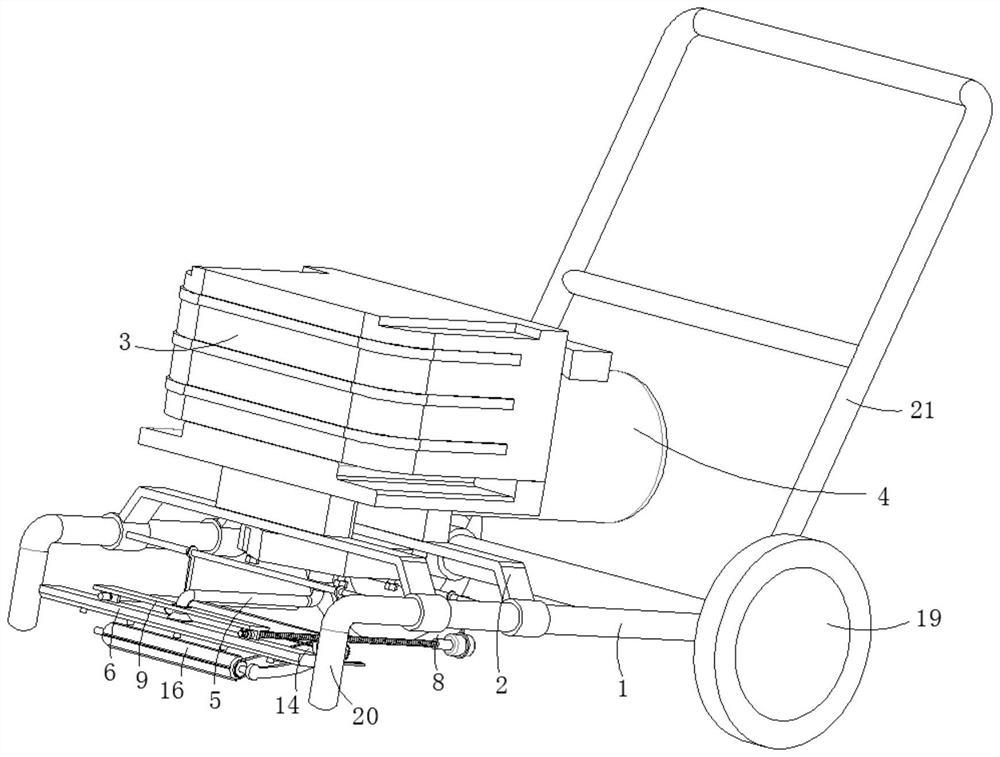

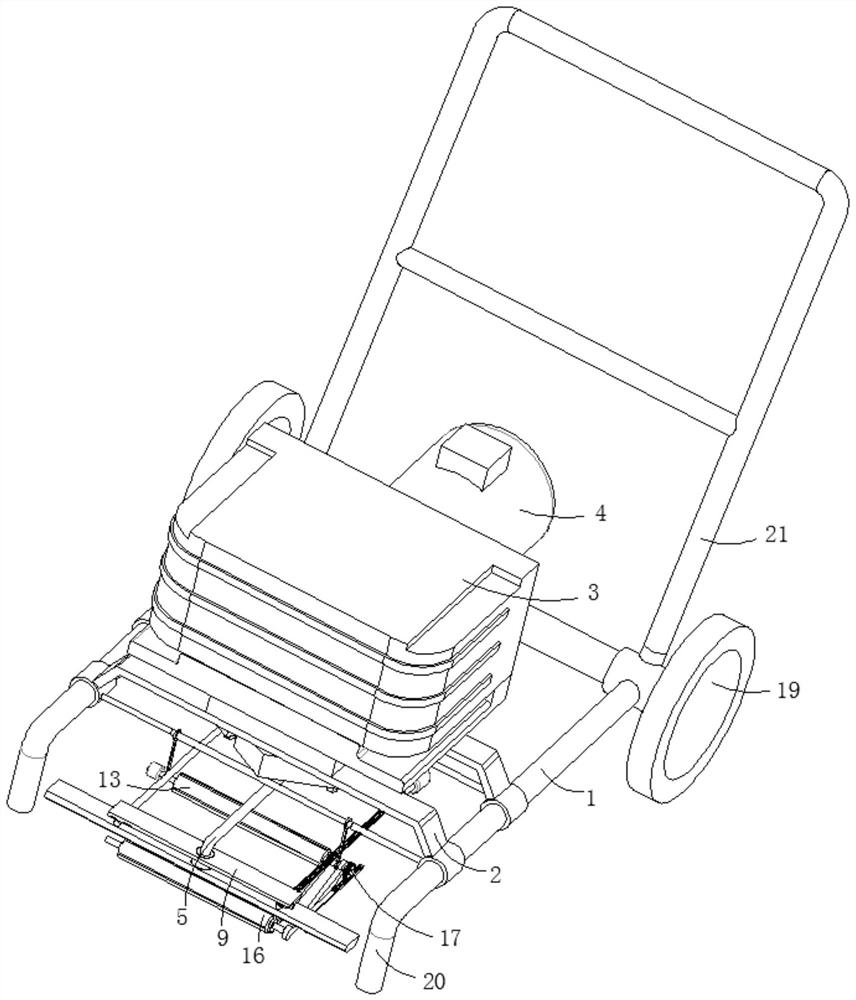

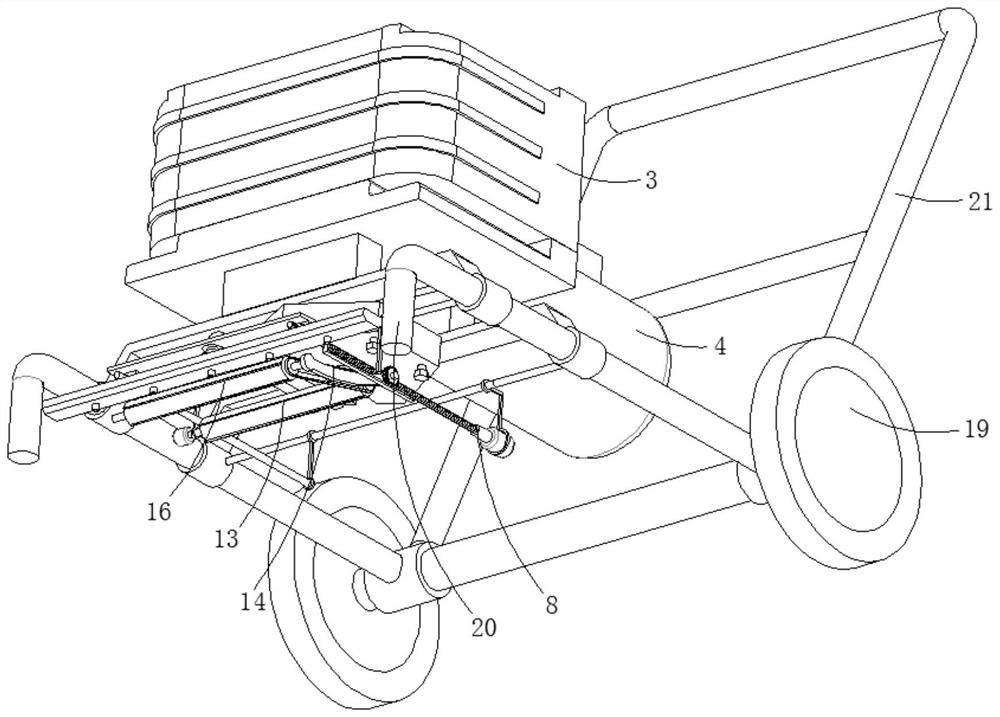

Agricultural portable pesticide spraying device

ActiveCN112586479ATo achieve the purpose of sprayingReduce workloadSpraying apparatusInsect catchers and killersAgricultural scienceAgricultural engineering

The invention relates to a pesticide spraying device, in particular to an agricultural portable pesticide spraying device. The agricultural portable pesticide spraying device provided by the inventioncan be used for automatically stirring pesticide and uniformly spraying the pesticide. The agricultural portable pesticide spraying device comprises wheels, a mounting plate, a supporting column, a discharging frame, a spraying mechanism and a swing mechanism. The wheels are evenly and rotationally arranged at the two sides of the mounting plate; the supporting column is arranged on the mountingplate; the discharging frame is arranged on the supporting column; the spraying mechanism is arranged on the mounting plate; and the swing mechanism is arranged on the mounting plate. Through the design of the spraying mechanism, the purpose of pesticide spraying can be achieved, manual work is replaced with a machine, the workload of a worker is reduced, and meanwhile the pesticide spraying timeis shortened; and through the design of a third transmission assembly, movement of the device can be achieved, and the device can be conveniently moved to a proper position during pesticide spraying by the worker.

Owner:江西天鲜网科技有限公司

Water gun toy and using method thereof

InactiveCN109059634ATo achieve the purpose of sprayingEasy to carryLiquid ejecting gunsFuselageClean water

The invention discloses a water gun toy and a using method thereof. The water gun toy comprises a machine body, a first cavity arranged in the machine body and a second cavity arranged in the machinebody, a first rotating shaft which extends front and back and a second rotating shaft which is position on the right side of the first rotating shaft are rotationally arranged in the second cavity, the tail ends of the front side and the rear side of the first rotating shaft penetrate through the front end wall and the rear end wall of the second cavity and extend out of the machine body to be fixedly provided with first rolling wheels, and first belt wheels which are symmetrical front and back are fixedly installed on the outer surface of the second rotating shaft in the second cavity. According to the water gun toy and the using method thereof, the water gun toy is simple in structure and convenient to operate, through pedaling by an operator, the water gun toy is driven to move, meanwhile, a liquid needing to be sprayed is pressurized, so that the purpose of spraying through the water gun is achieved, meanwhile, a large amount of clean water can be carried by the water gun toy in amore labor-saving mode, the countervailing power of the water gun toy is improved, the water gun toy is convenient to move, moreover, all the working procedures cooperate with one another and do not influence one another, and the practical performance of the water gun toy is improved.

Owner:杭州力松电子科技有限公司

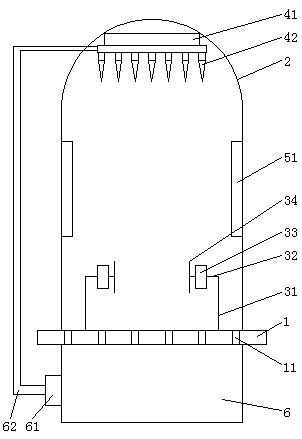

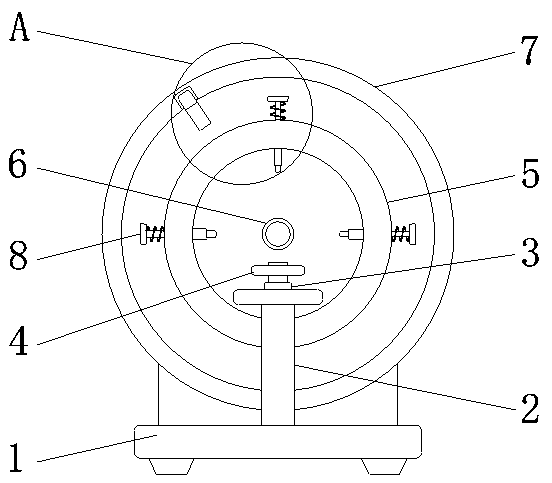

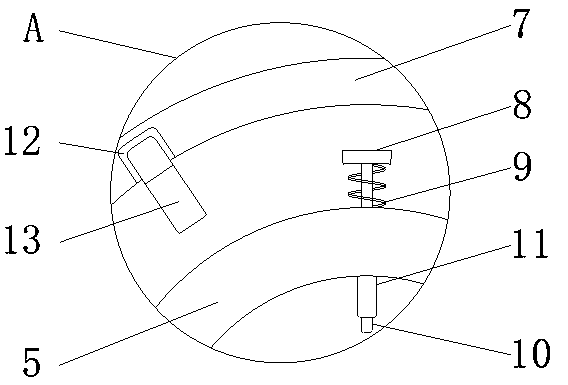

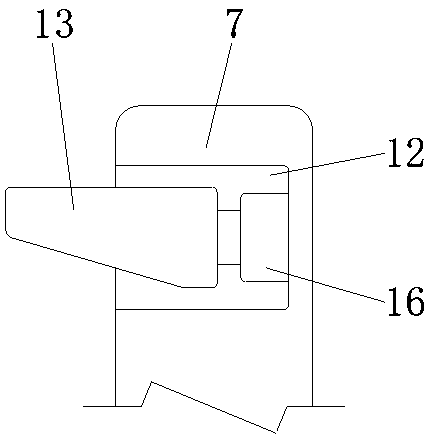

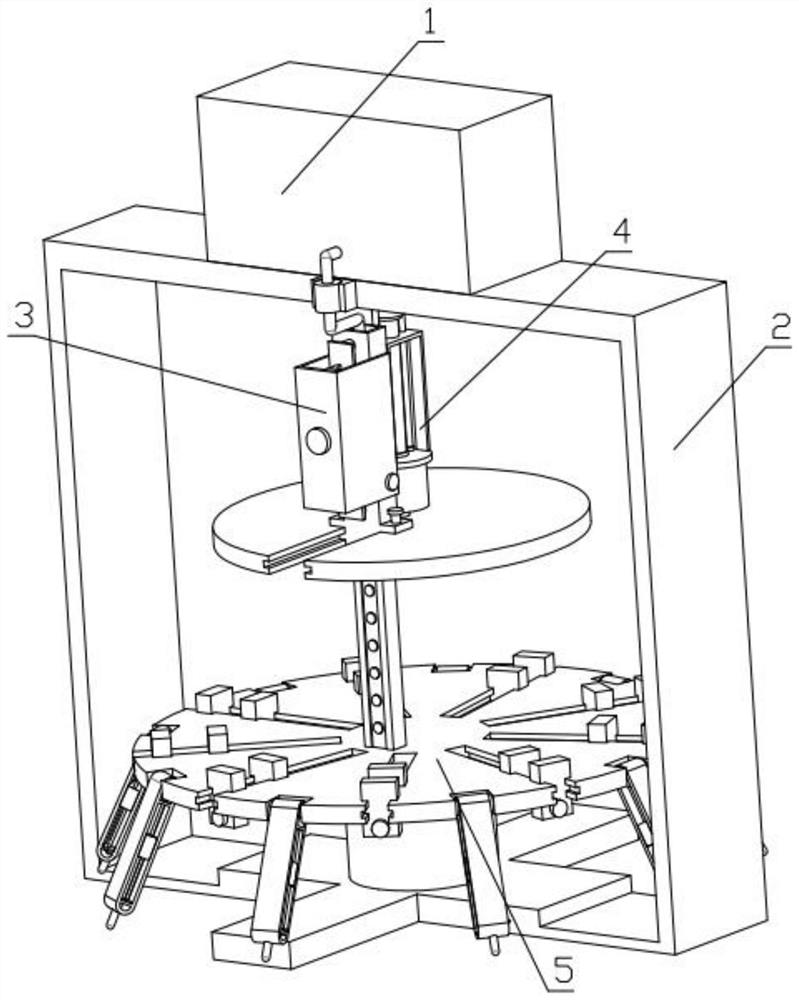

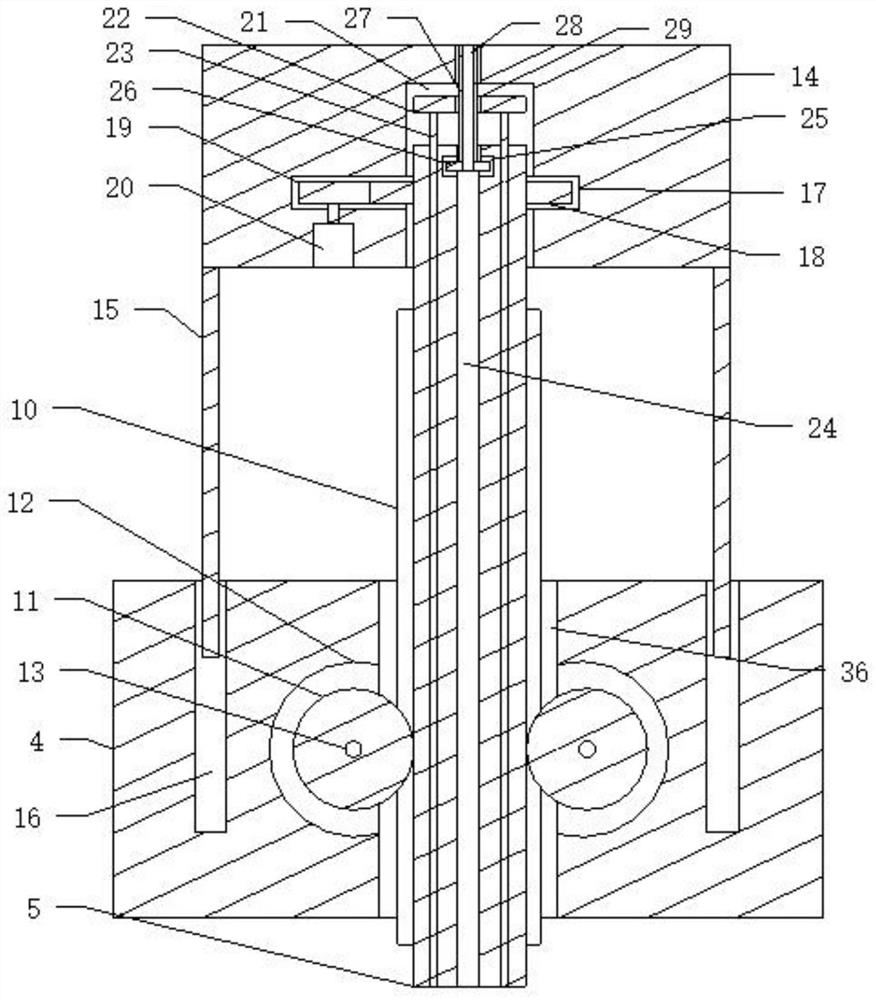

PVC profile spraying device

InactiveCN111318400ATo achieve the purpose of sprayingSpray evenlyPretreated surfacesLiquid spraying apparatusEngineeringMechanical engineering

The invention provides a PVC profile spraying device. The PVC profile spraying device comprises a workbench, a shell, a rotary clamping device, a spraying device body, a curing device and an industrial control host, wherein the spraying device body comprises a mounting plate horizontally arranged in the shell, and spray guns are uniformly arranged on the mounting plate; the curing device comprisesa curing heating device arranged in the shell and a temperature sensor used for detecting the temperature in the shell; and the industrial control host controls the curing heating device to stop heating when the temperature sensor detects that the temperature in the shell reaches or is higher than a set value. The PVC profile spraying device has the beneficial effects that through the arrangementof the spraying device body, the purpose of spraying PVC profiles is achieved; through the arrangement of the rotary clamping device, the purpose of more uniformly spraying the PVC profiles is achieved; and through the arrangement of the curing device, the purpose of curing the PVC profiles while spraying the PVC profiles is achieved.

Owner:株洲兴润高分子新材料有限公司

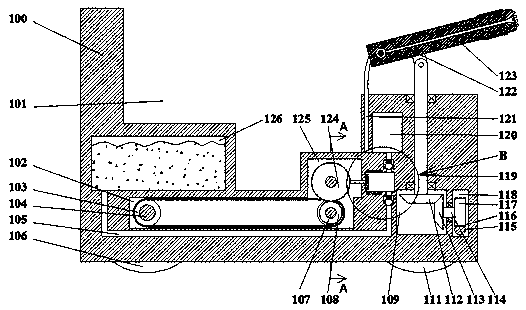

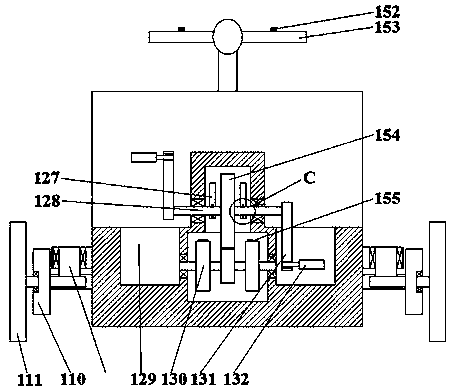

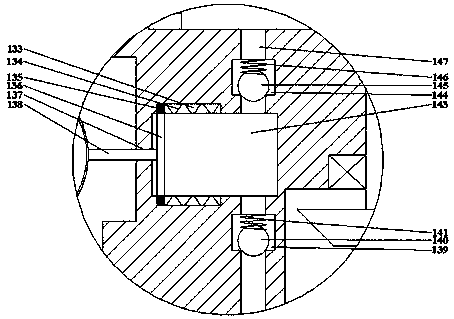

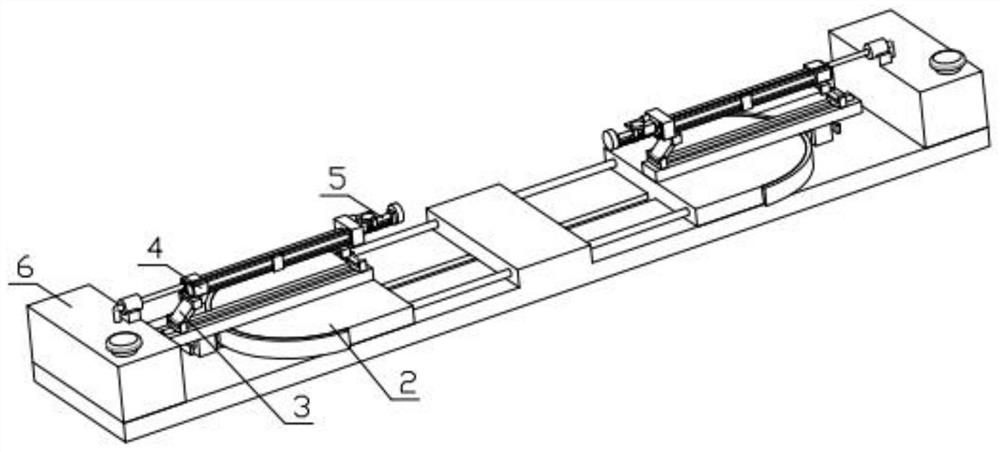

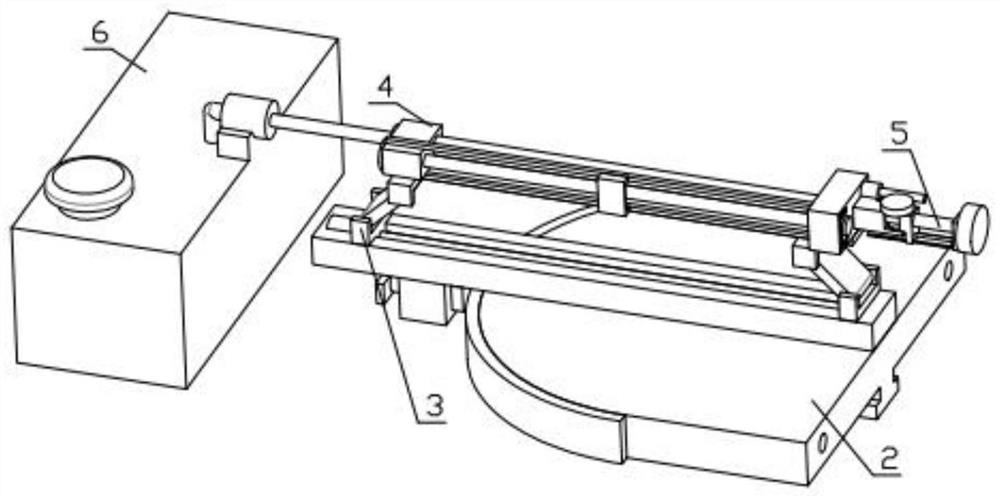

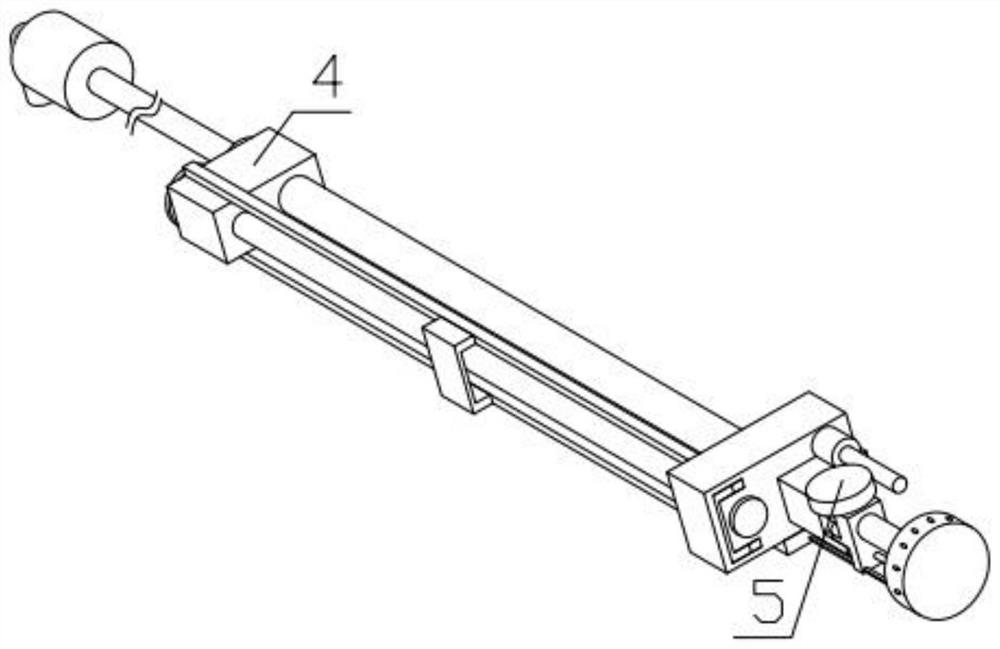

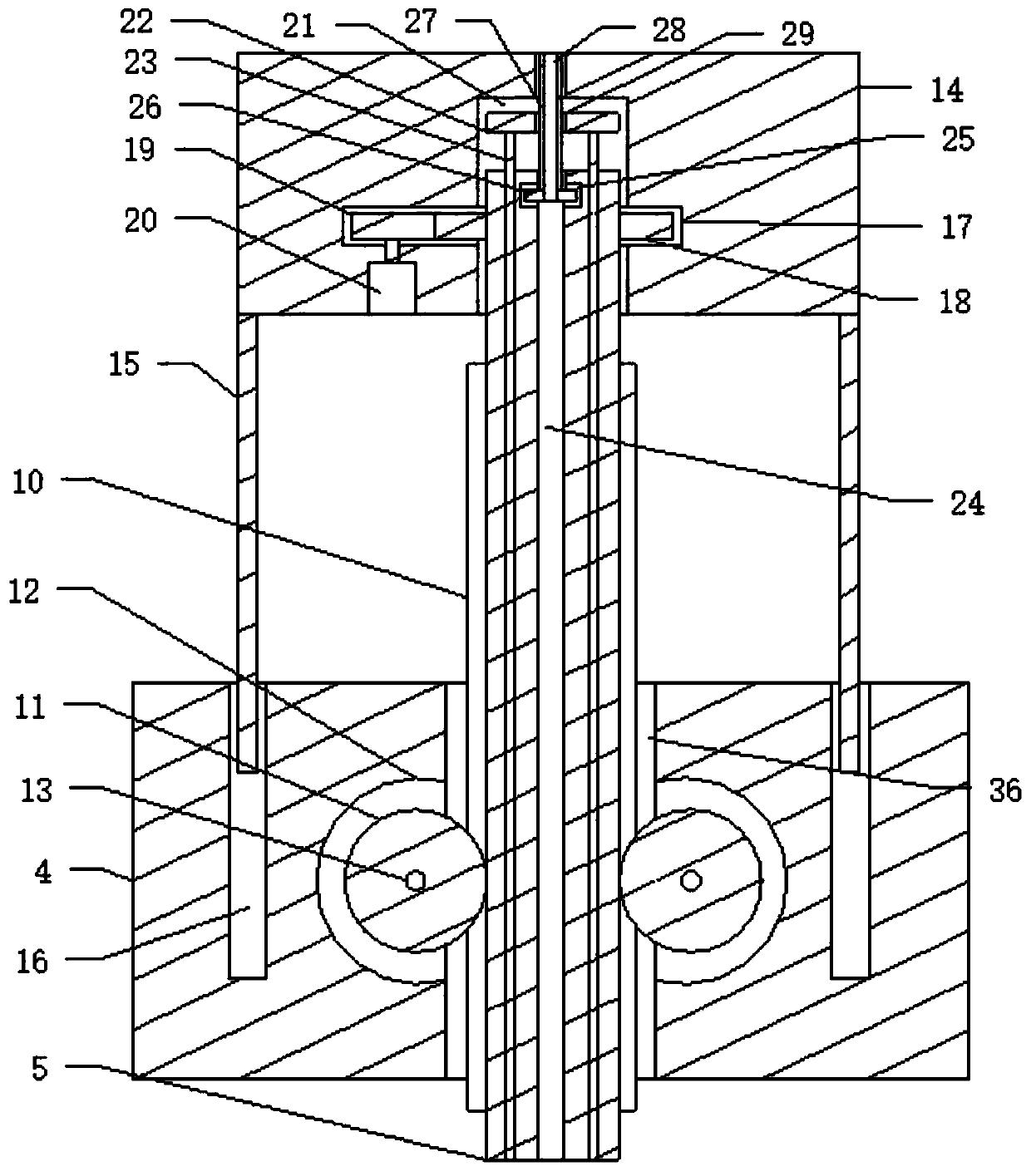

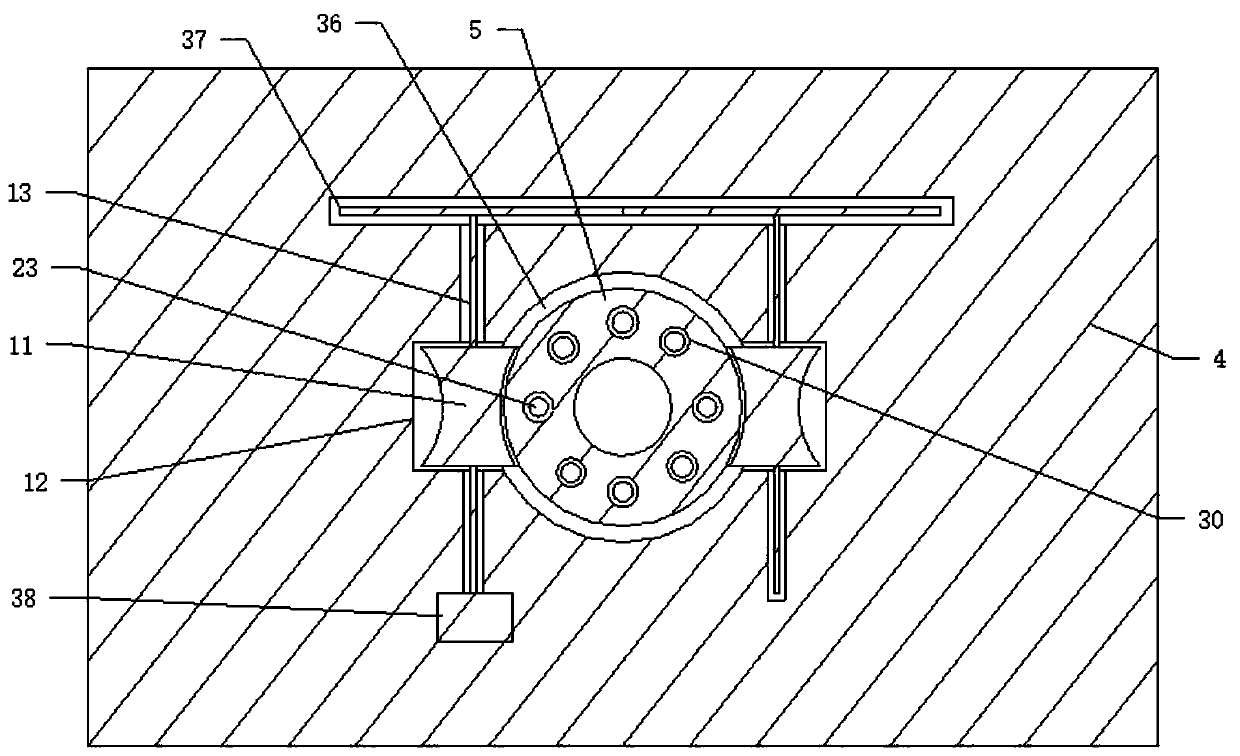

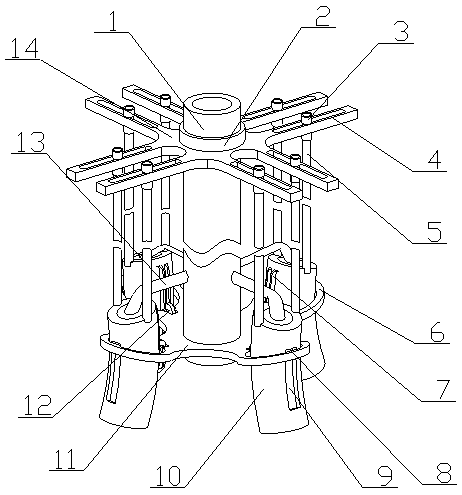

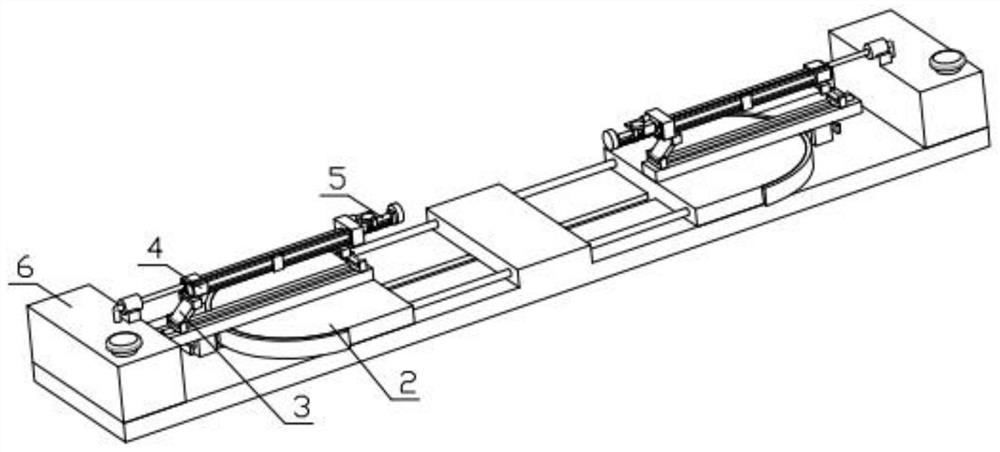

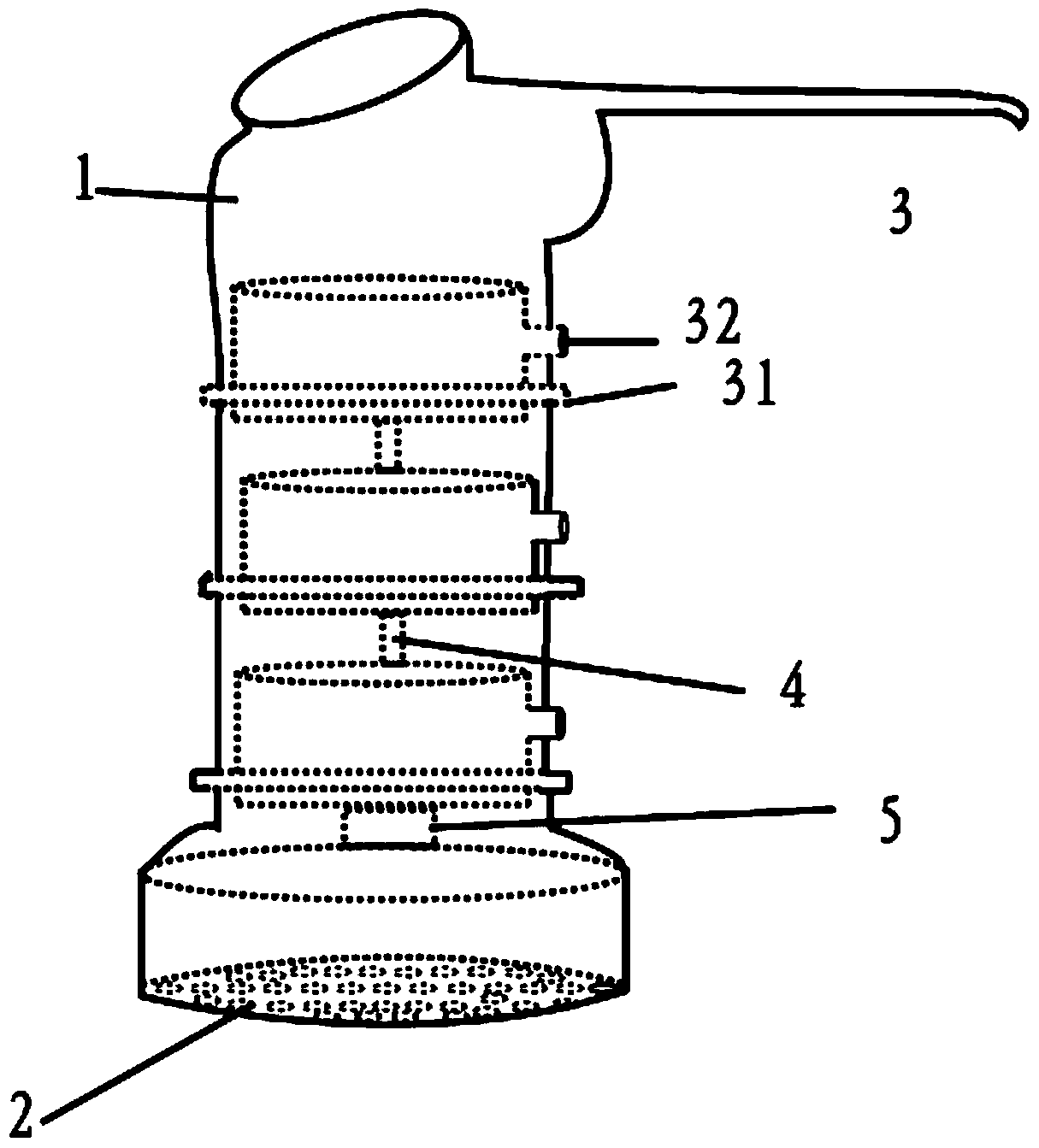

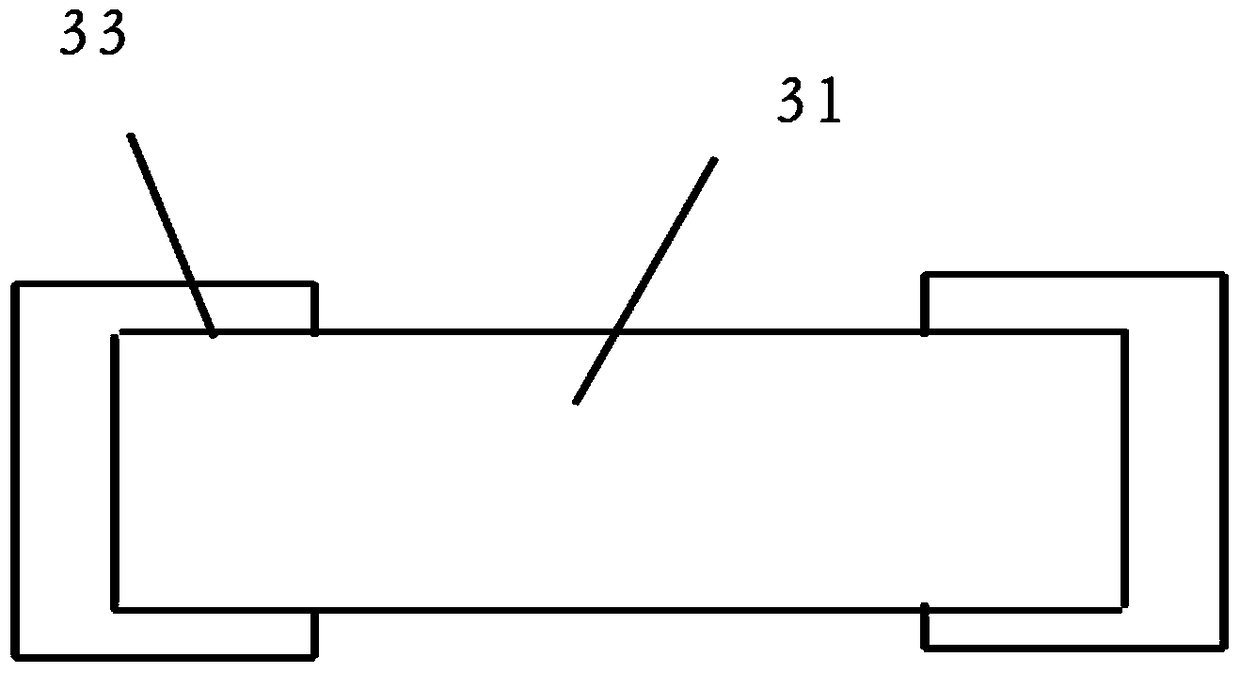

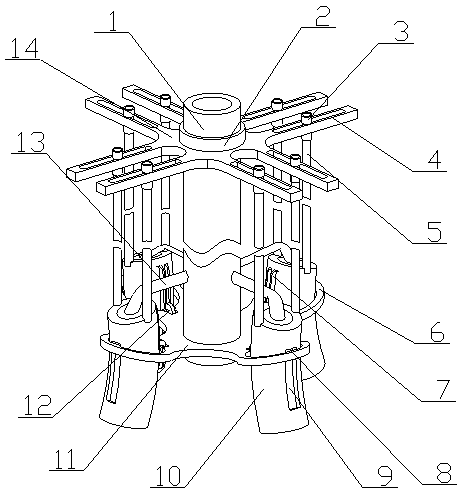

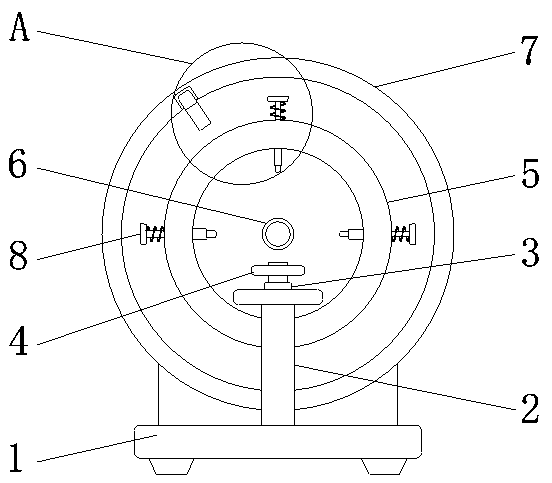

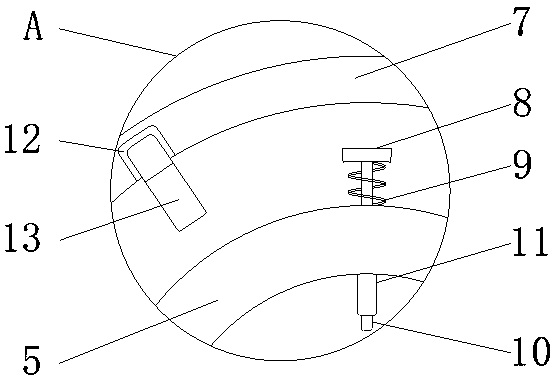

In-pipe spraying device suitable for bent pipe

The invention relates to the related field of building material processing, in particular to an in-pipe spraying device suitable for a bent pipe. The in-pipe spraying device suitable for the bent pipe comprises a spacing adjusting mechanism, an angle adjusting mechanism, a height adjusting mechanism, a propelling mechanism, a bend mechanism and a material box; the angle adjusting mechanism is in threaded connection with the spacing adjusting mechanism; the material box is fixedly mounted on the spacing adjusting mechanism; the height adjusting mechanism is rotationally mounted on the angle adjusting mechanism; the pushing mechanism is fixedly mounted on the height adjusting mechanism; and the bend mechanism is fixedly mounted on the pushing mechanism and fixedly connected with the material box. According to the in-pipe spraying device suitable for the bent pipe, as spraying is conducted in a rotating mode, uneven spraying caused by blocking of individual nozzles is avoided, and the device not only has the function of spraying a straight pipe, but also has the function of spraying the bent position of a pipe fitting.

Owner:河北方泉管道装备有限公司

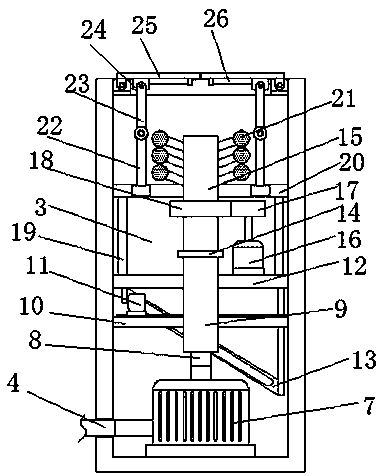

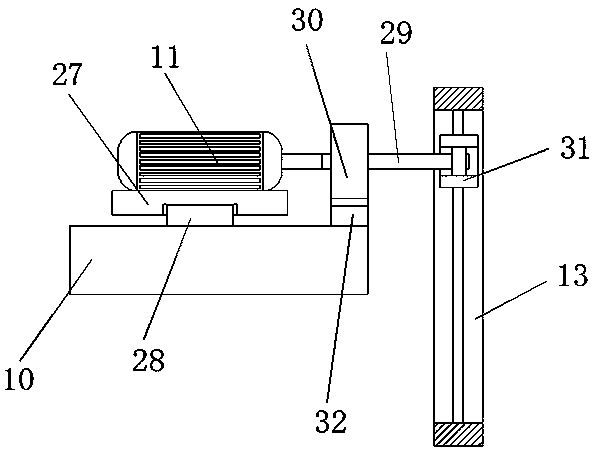

Automatic stirring spraying device for oil paint

ActiveCN109746139APrevent solidificationImprove spraying effectLiquid spraying apparatusMotor driveEngineering

The invention discloses an automatic stirring spraying device for oil paint. A first support is arranged on a fixed base, and a second support is connected to the first support; the end portion of thesecond support is connected with a first control module; the first control module is provided with a sliding lifting shaft; the lifting shaft penetrates through a sealing cover and then slides in anoil paint barrel; the lifting shaft is provided with a swinging stirring support; the other end of the lifting shaft is provided with a third control module sliding on the first control module; the lifting shaft rotates on the third control module; a first motor driving the lifting shaft to rotate is arranged in the third control module; due to sliding of the lifting shaft, the lifting shaft can further slide into the oil paint barrel; and meanwhile, due to swinging of the stirring support, the oil paint can be further stirred, and therefore solidification of the oil paint is avoided, and thespraying effect of the oil paint is further improved.

Owner:贵州永峰涂装科技有限公司

A construction site construction management robot

ActiveCN111074834BExpand the spraying rangeEasy to moveUsing liquid separation agentSpraying apparatusElectric machineryStructural engineering

The present invention belongs to the field of robots, especially a robot for construction management on a construction site. The existing spraying devices are all fixedly installed, so when in use, there is often a certain inconvenience. The following proposals are now proposed, It includes a base, and the bottom of the base is respectively fixed with a mounting cover and a driving cover, and two first wheels are symmetrically rotatably connected in the mounting cover, and the bottom ends of the two first wheels both extend to the bottom of the mounting cover , there are two second wheels connected symmetrically in the driving cover. In the present invention, the purpose of spraying water can be realized by moving a plurality of spray heads to the top of the installation box, and then starting the water pump and the rotating motor. The two first wheels and the two second wheels can realize the free movement of the device, so that various areas of the construction site can be sprayed, so that the content of dust can be effectively suppressed, and the physical injury to construction workers can be greatly reduced.

Owner:合肥速纳工程设计有限公司

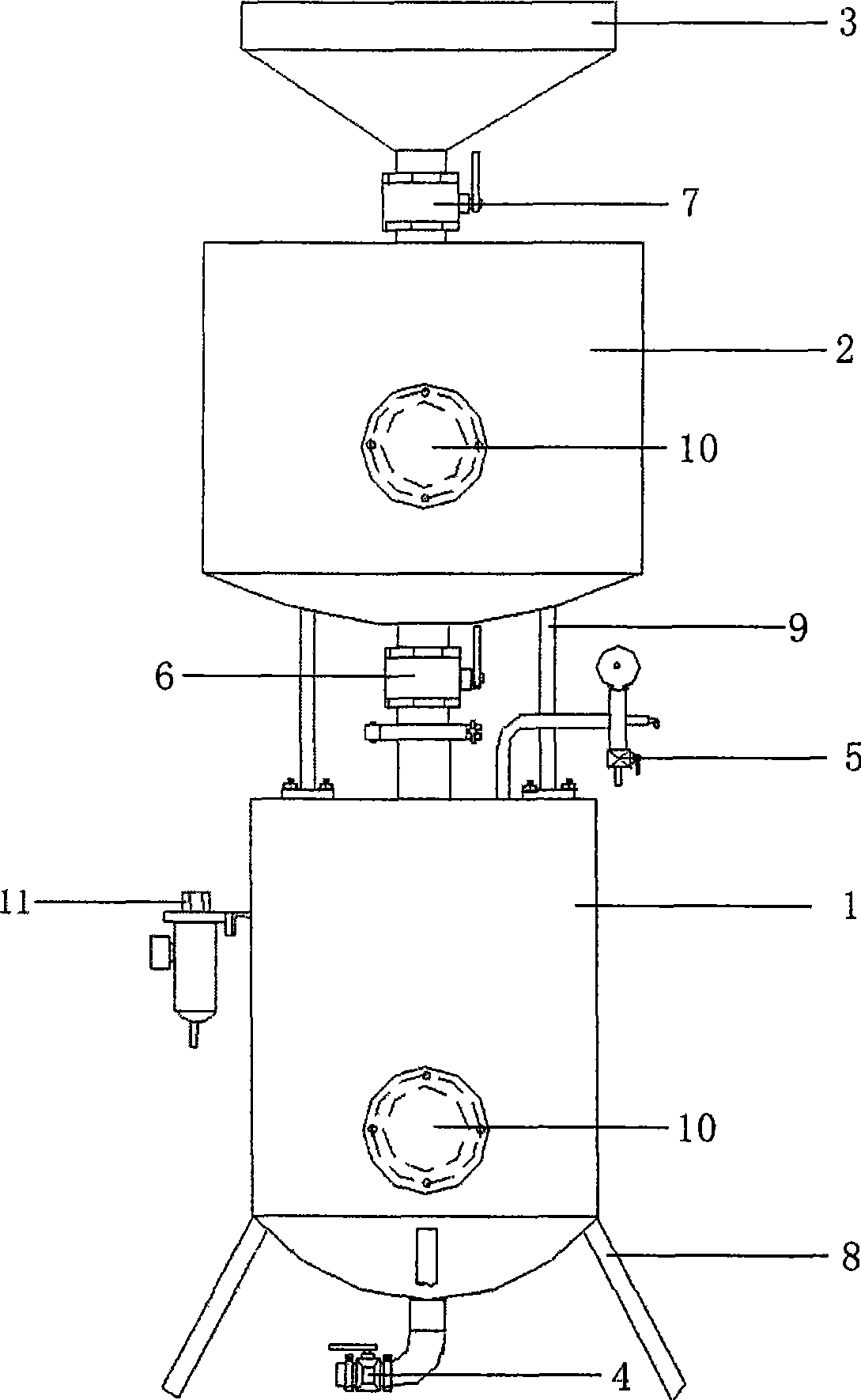

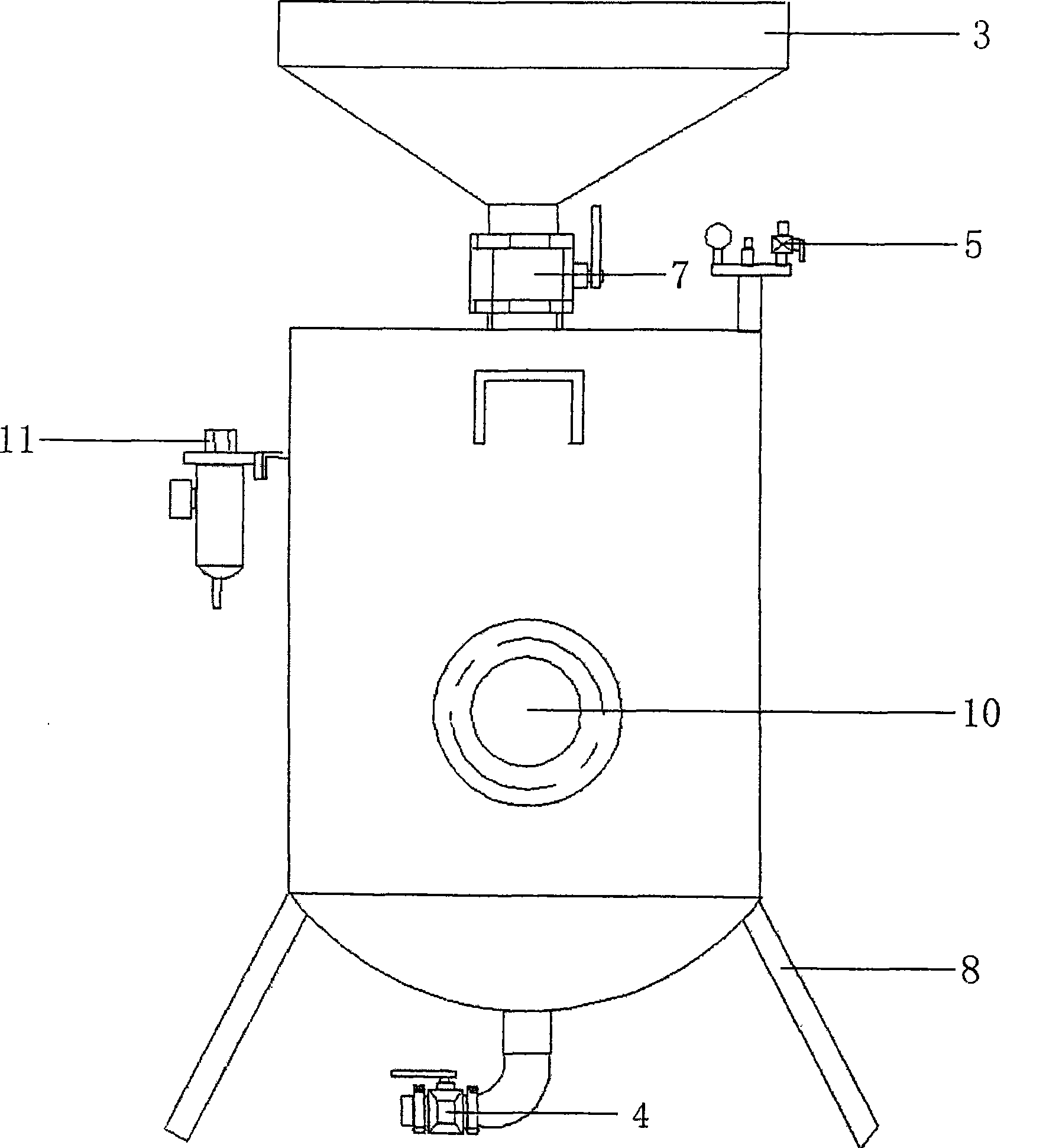

Spraying apparatus for construction coating

InactiveCN101481953ASave moving repeatedlyEliminate stressBuilding constructionsArchitectural engineeringInlet valve

The invention discloses spray equipment for spraying building coatings. The existing construction of spraying the building coatings has the disadvantages of manual operation or nonideal mechanical operation, low construction efficiency, poor spraying quality and nonuniform or uneven coatings on the surface of a sprayed wall body, thereby affecting the shapely appearance and reducing the efficiency. The spray equipment comprises a pressure storage tank, wherein a pre-storage tank is arranged on the upper end of the pressure storage tank, the pressure storage tank and the pre-storage tank are connected by a closed valve, a feed valve is arranged on the opening of the upper end of the pre-storage tank, a discharge valve is installed on the lower end of the pressure storage tank, and an air intake valve for high-pressure air is installed on the upper end of the pressure storage tank. The spray equipment utilizes the air pressure and the gravity of the coatings to spray the coatings, thereby saving energy and reducing the use cost; and besides, a feed delivery pipe can be extended at long bowls, thereby benefiting fast construction.

Owner:巢启

Vehicle production part surface spray-coating device for special-shaped piece

InactiveCN110756347AEasy to spraySolve the problem of inconvenient sprayingLiquid spraying apparatusStructural engineeringWorkbench

The invention discloses a vehicle production part surface spray-coating device for a special-shaped piece. The spray-coating device comprises a supporting base. A supporting plate is connected with the upper surface of the supporting base. A programmable controller is installed on the side face of the supporting base. A first electric telescopic rod is installed at the upper end of the supportingplate. A spray-coating workbench with a clamping structure is connected with the top end of the first electric telescopic rod. A connecting groove is formed in the supporting plate. A slide groove isreserved in the connecting groove. A slider is slidingly connected into the slide groove and connected to a limiting piece. By means of the vehicle production part surface spray-coating device for thespecial-shaped piece, spray-coating can be conveniently performed on the special-shaped piece, the problem that spray-coating is not convenient due to inclined grooves in the special-shaped piece issolved, and spray-coating pipes with different sizes can be selected according to the sizes of the inclined grooves in the special-shaped piece to perform spray-coating.

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

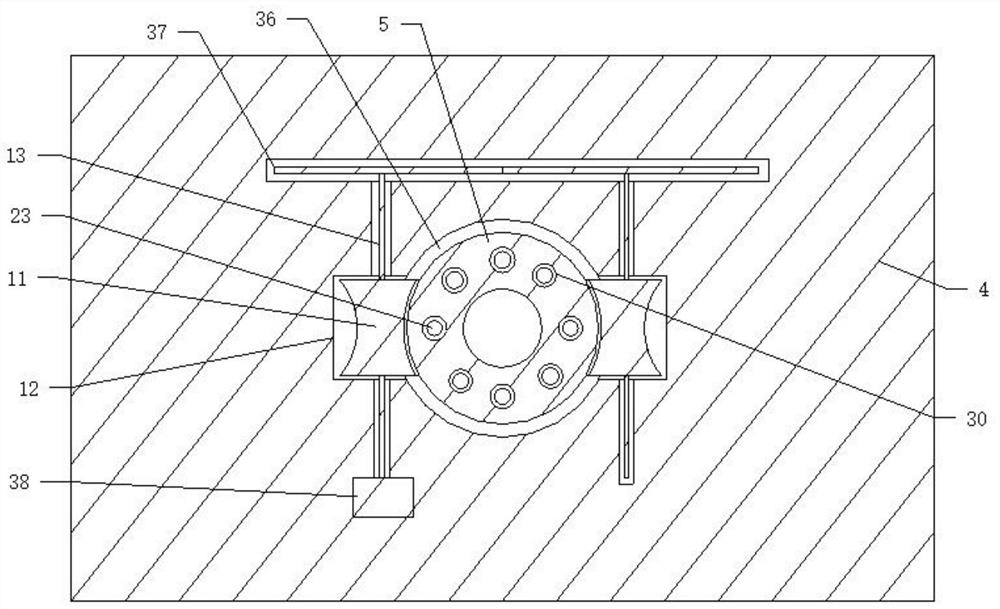

Coal mine supporting variable-angle spray structure

ActiveCN109162734ASimple structureReduce wasteUnderground chambersTunnel liningFixed frameEngineering

The invention relates to a coal mine supporting variable-angle spray structure that uses a sliding ring to change angles of a plurality of arc tubes so as to change the spray angle so that that the spray efficiency of coal mine surrounding rock can be improved effectively. A fixed frame is a concave arc plate; a through hole is formed in a middle portion of the fixed frame; and a plurality of clamping rings are respectively arranged at the outer side of the fixed frame. The clamping rings are arranged obliquely and are connected with the fixed frame at lowest heights; and the clamping rings are made of rigid materials. A plurality of supporting wheels are respectively arranged at the fixed frame and are arranged in the plurality of clamping rings in a one-to-one correspondence manner; andlimiting blocks are arranged at the inner rings of the clamping rings and are opposite to the supporting wheels. One end of a hollow tube is arranged in the through hole of the fixed frame and is connected with the fixed frame and has an enclosed structure. A sliding ring is arranged at the other end of the hollow tube; and a guiding plate is arranged at the sliding ring right above the fixed frame.

Owner:TAIAN TAISHUO STRATUM CONTROL SCI & TECH CO LTD

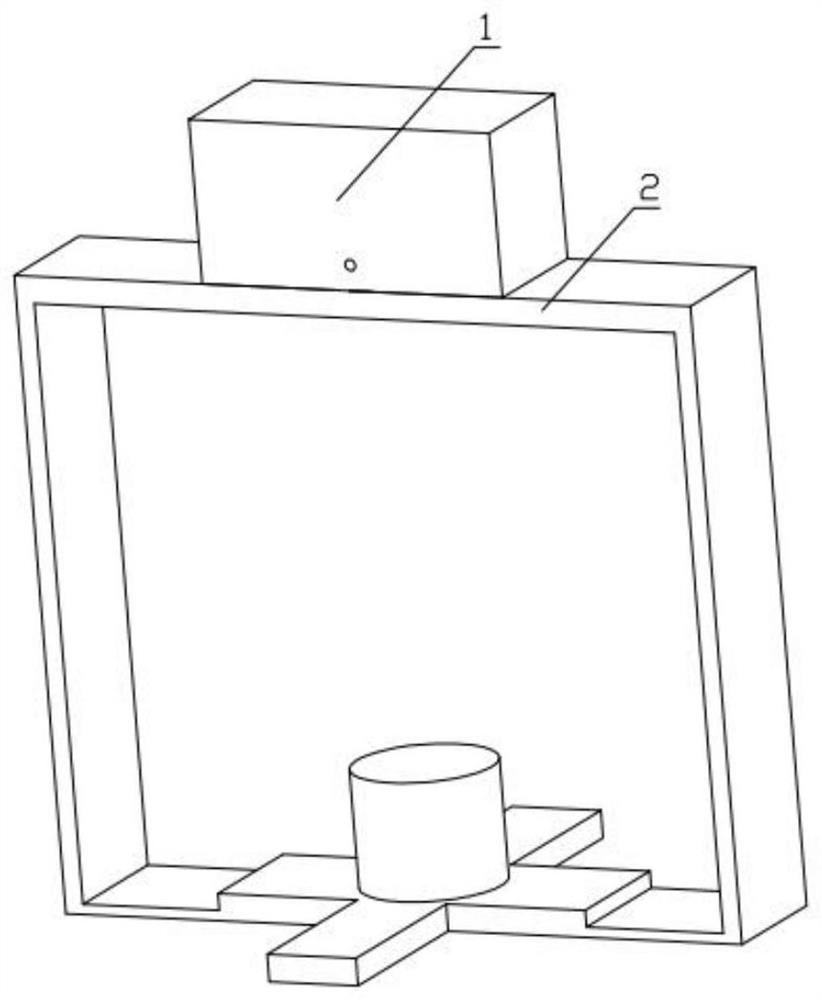

Robot for construction site construction management

ActiveCN111074834ATo achieve the purpose of sprayingInhibitory contentUsing liquid separation agentRoad cleaningElectric machineryStructural engineering

The invention belongs to the field of robots, and especially relates to a robot for construction site construction management. The robot is provided to solve the problem of certain use inconvenience of existing spraying devices which are all fixedly installed. The robot comprises a base, a mounting cover and a driving cover are fixedly mounted at the bottom of the base, two first wheels are symmetrically and rotationally connected into the mounting cover, the bottom ends of the two first wheels extend to the lower part of the mounting cover, and two second wheels are symmetrically and rotationally connected into the driving cover. A plurality of nozzles are moved to a position above the mounting box, and then a water pump and a rotating motor are started, so the purpose of spraying water can be achieved; and free movement of the robot can be achieved through the two first wheels and the two second wheels, so spraying can be conducted on all areas of the construction site, the content of dust can be effectively restrained, and harm to the body of a constructor is greatly reduced.

Owner:合肥速纳工程设计有限公司

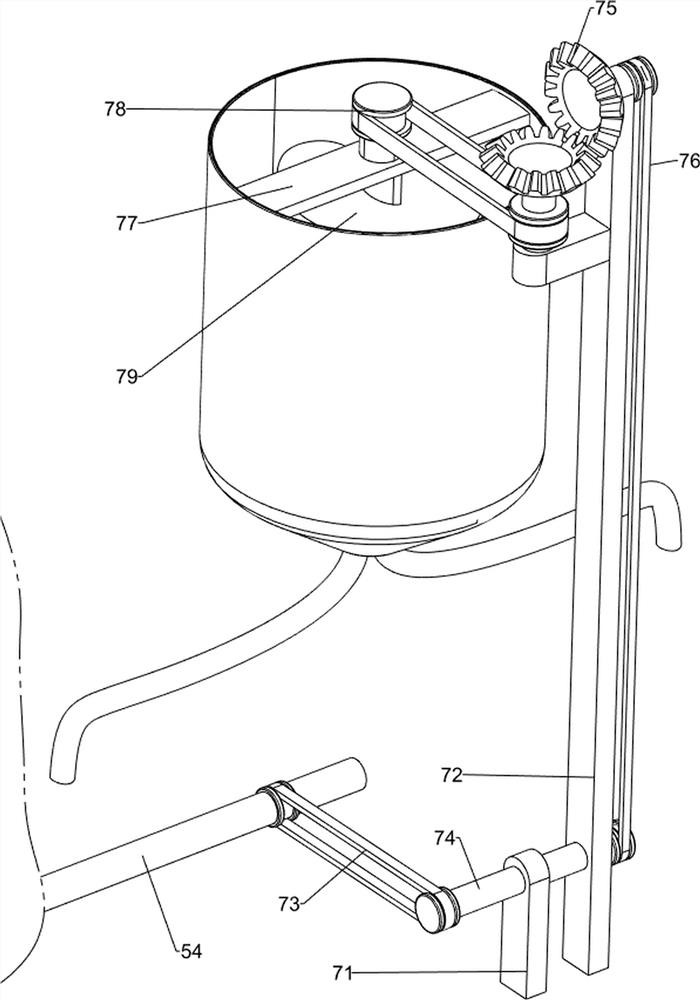

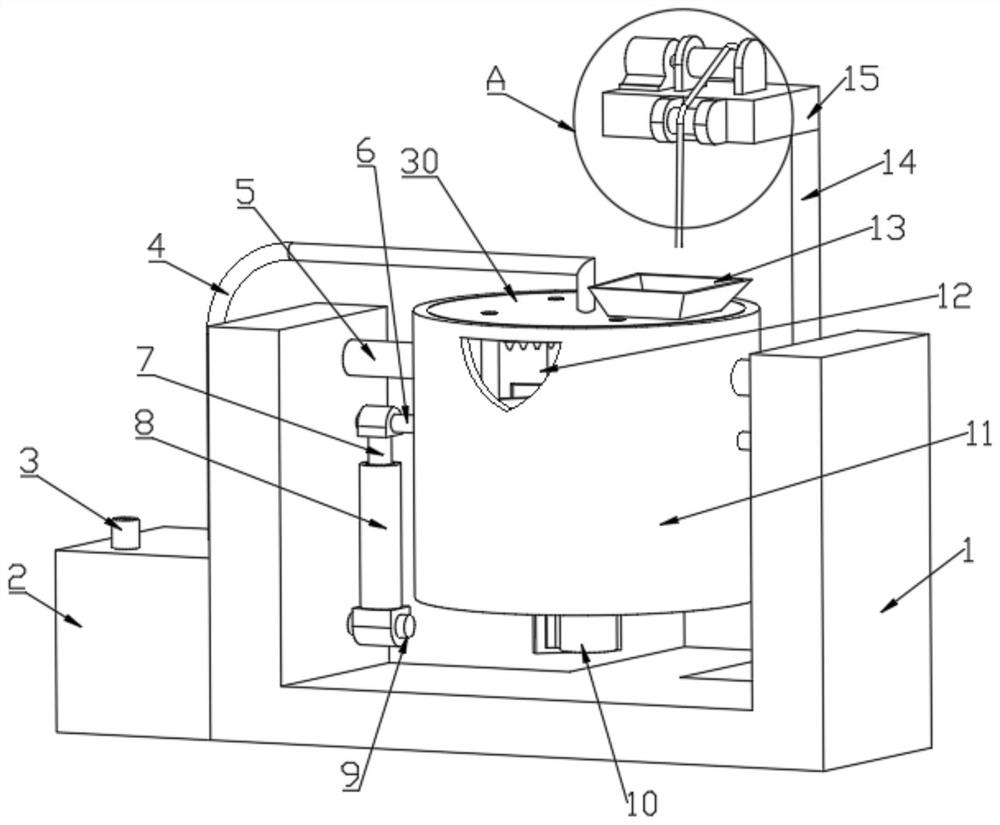

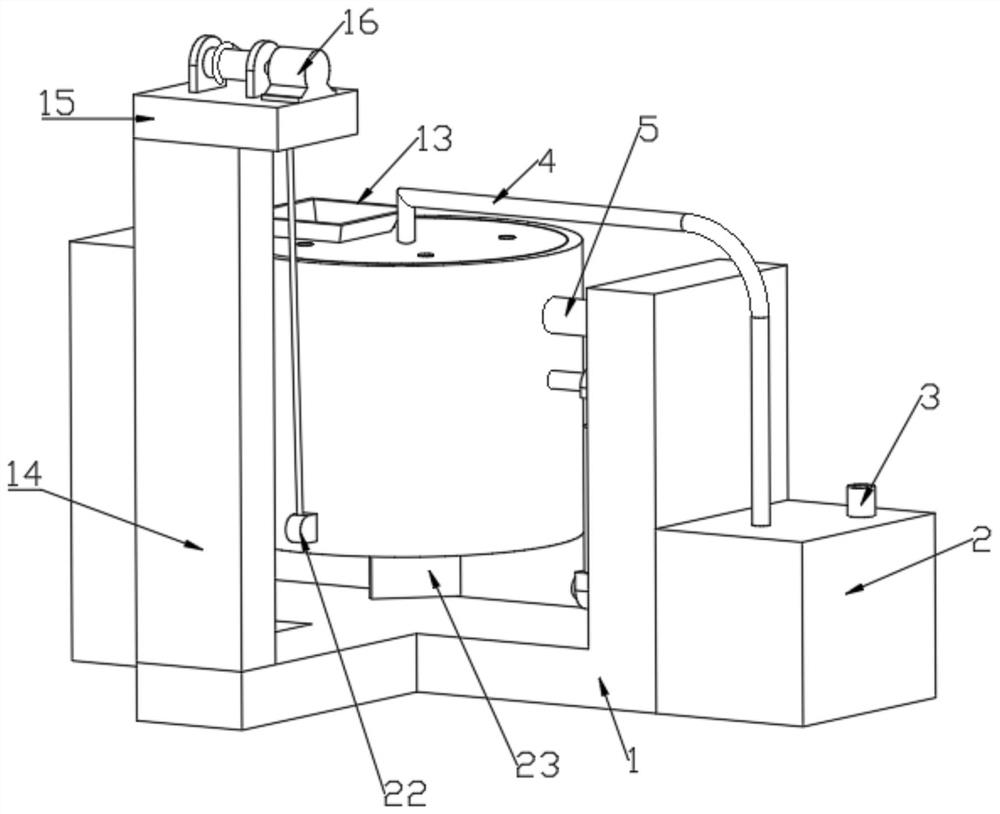

Microbial fertilizer production equipment

InactiveCN112457085ATo achieve the purpose of sprayingAchieve the purpose of mixingBio-organic fraction processingOrganic fertiliser apparatusMicroorganismAgricultural science

The invention discloses microbial fertilizer production equipment in the field of microbial fertilizer production, which comprises a base, a first fixed shaft is rotatably connected in the base, a stirring box is fixedly connected to the side end of the first fixed shaft, an end cover and a rotating disc are rotatably connected in the stirring box, a feeding groove is fixedly connected to the upper end of a cover plate, the lower end of the end cover is rotatably connected with a first rotating shaft and a second rotating shaft, a first motor is fixedly connected to the lower end of the firstrotating shaft, a fixing plate is fixedly connected to the side end of the motor, the upper end of the fixing plate is fixedly connected with the stirring box, stirring blades and a first gear are fixedly connected to the circumferential surface of the first rotating shaft, the first gear is engaged with a second gear, the upper end of the second gear is fixedly connected with a second rotating shaft, the lower end of the cover plate is fixedly connected with a fixed rod, the lower end of the fixing rod is fixedly connected with a sprayer, a discharge hole is formed in the circumferential surface of the stirring box, and the side end of the base is fixedly connected with a third fixed shaft. The microbial fertilizer production equipment has the advantages that the structure is simple, themanufacturing cost is low, and the microbial liquid can be mixed with the to-be-fermented raw materials only through simple operation.

Owner:杨文兰

Accurate arc-shaped plate single-side paint spraying device

ActiveCN112570170AAvoid leaningIncrease frictionLiquid spraying apparatusStructural engineeringMaterials processing

The invention relates to building material processing related devices, in particular to an accurate arc-shaped plate single-side paint spraying device. The accurate arc-shaped plate single-side paintspraying device comprises a material box, a mounting frame, a spraying mechanism, an auxiliary displacement mechanism and an arc-shaped plate positioning mechanism, wherein the material box is fixedlyarranged on the mounting frame; the arc-shaped plate positioning mechanism is fixedly arranged on the mounting frame; the auxiliary displacement mechanism is fixedly arranged on the mounting frame; the spraying mechanism is arranged on the auxiliary displacement mechanism in a sliding mode; and the material box is fixedly connected to the spraying mechanism. The device can be used for installingplates with different radians, has an auxiliary supporting function on the plates, and is capable of preventing the plates from inclining, changing the distance between a spraying component and the plates, and avoiding material waste.

Owner:扬州奥尔斯特机械有限公司

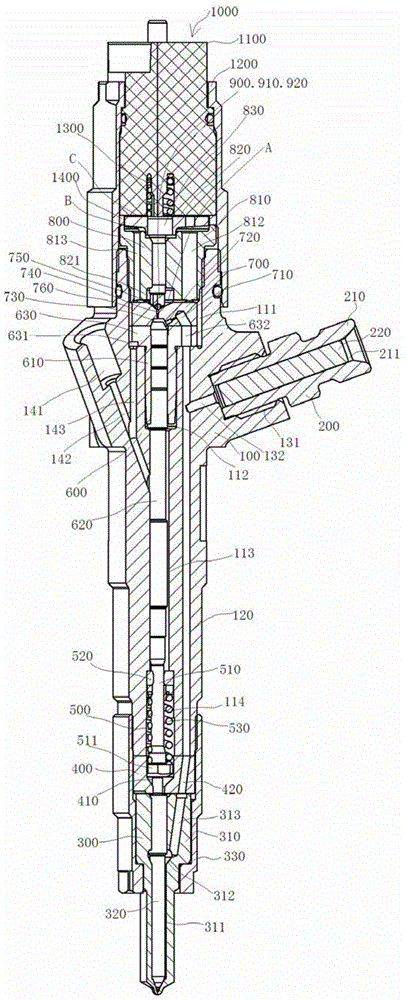

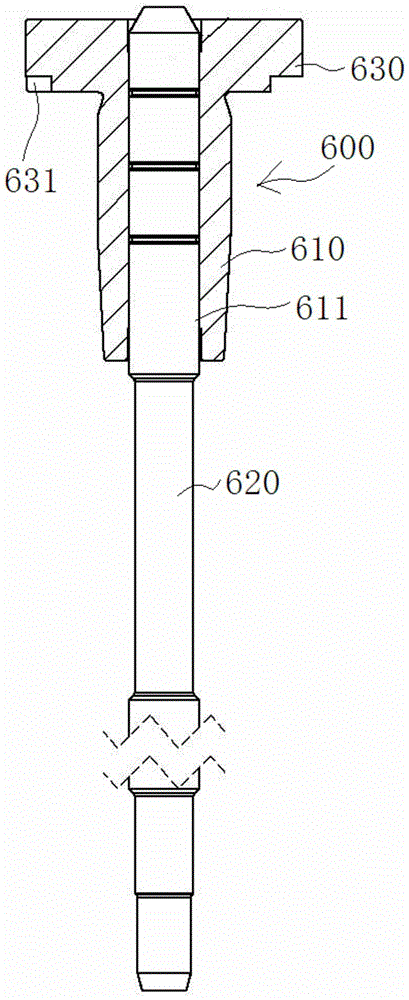

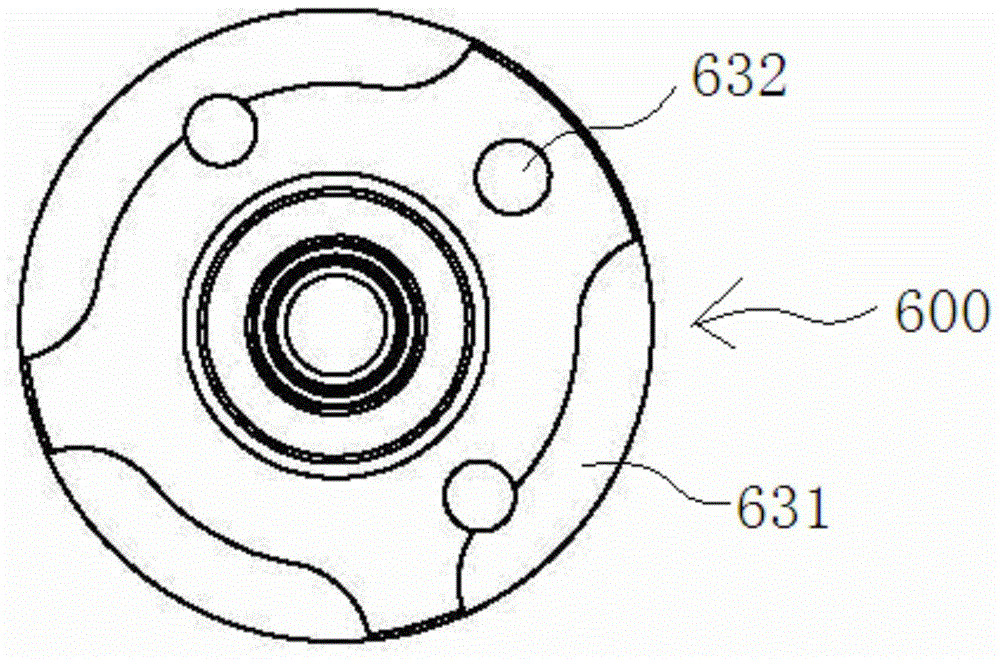

A fuel injector that can control the timing and quantitative injection of fuel for the engine

ActiveCN103644057BOpen quicklyMitigation of poor vibration capabilityFuel injection apparatusMachines/enginesCombustionEngineering

Owner:NANYUE FUEL INJECTION SYST CO LTD

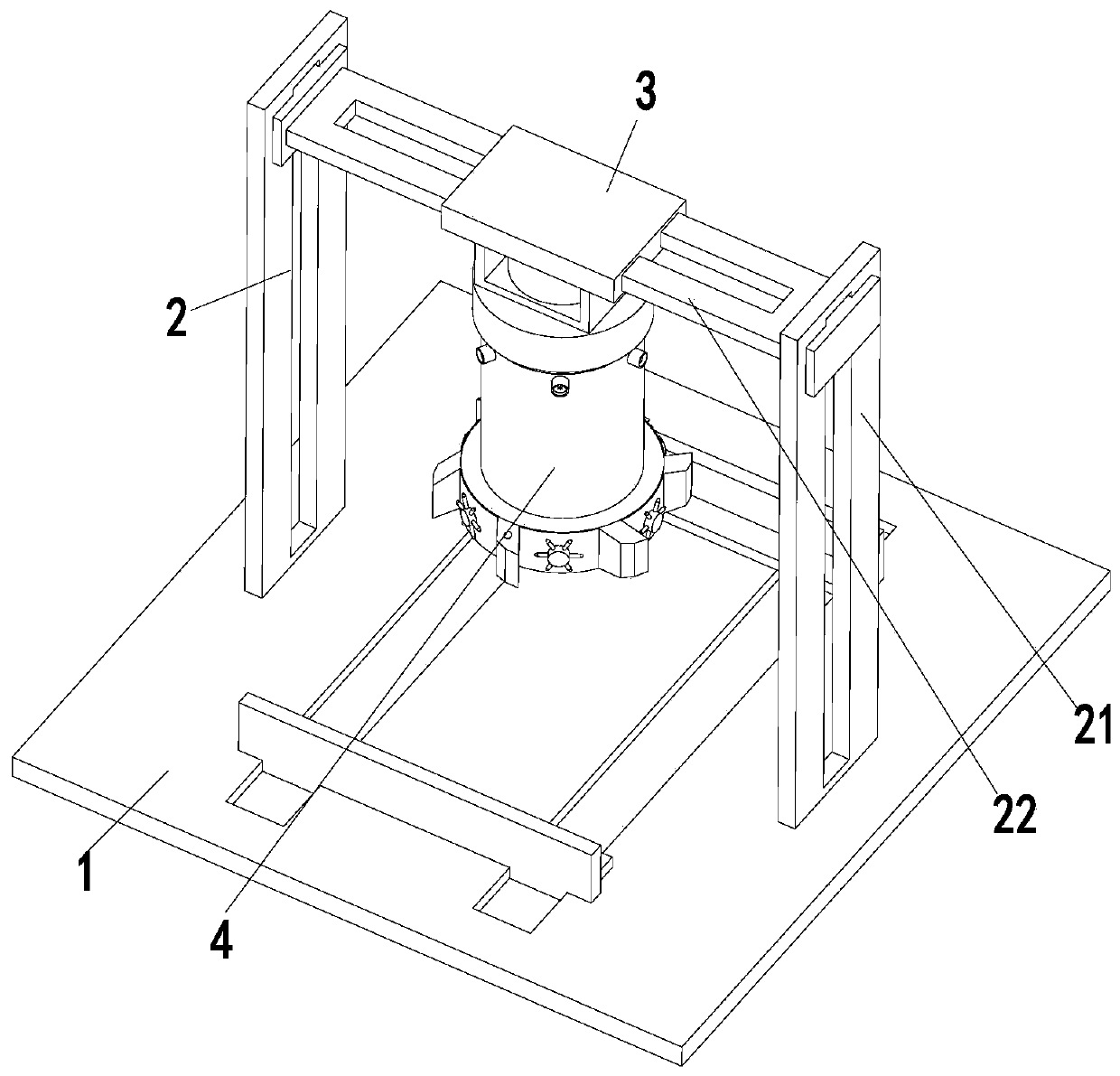

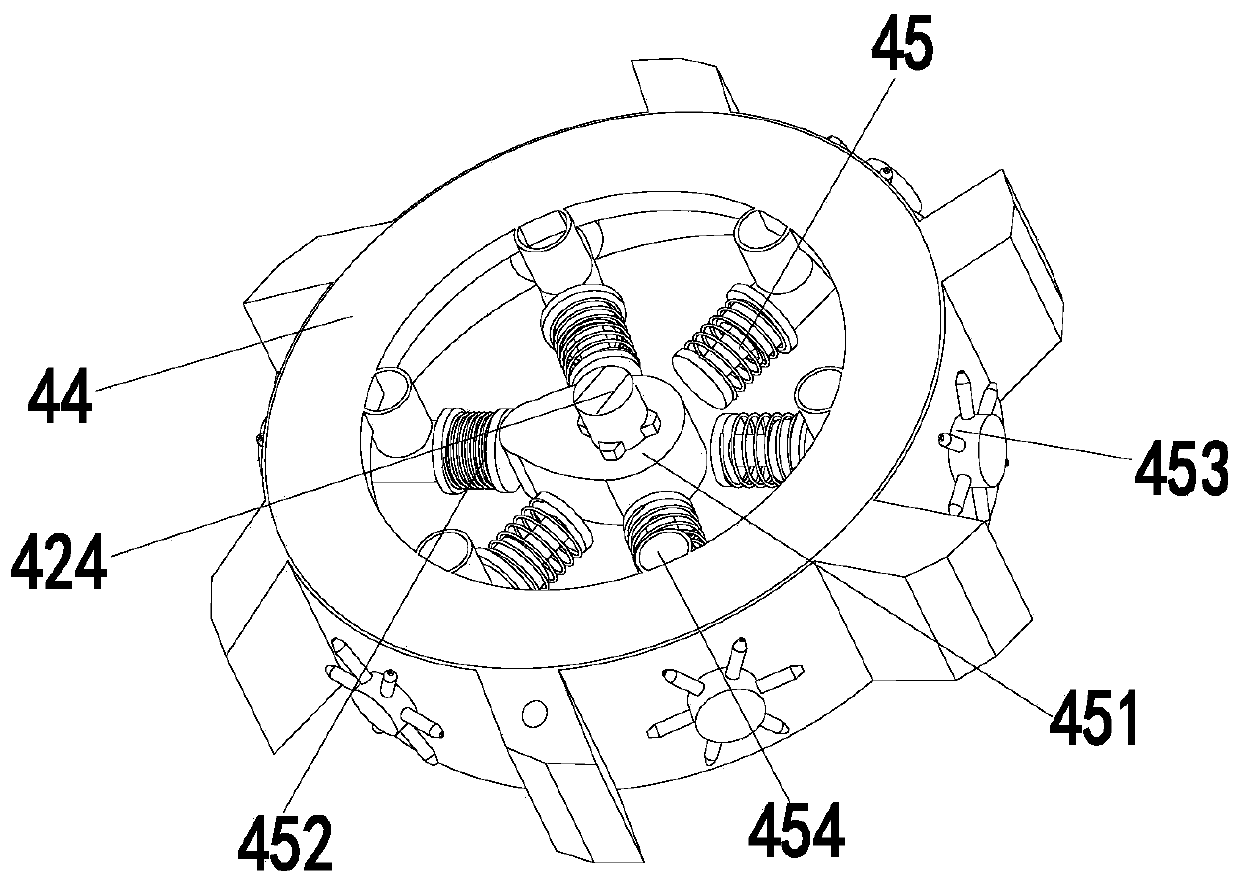

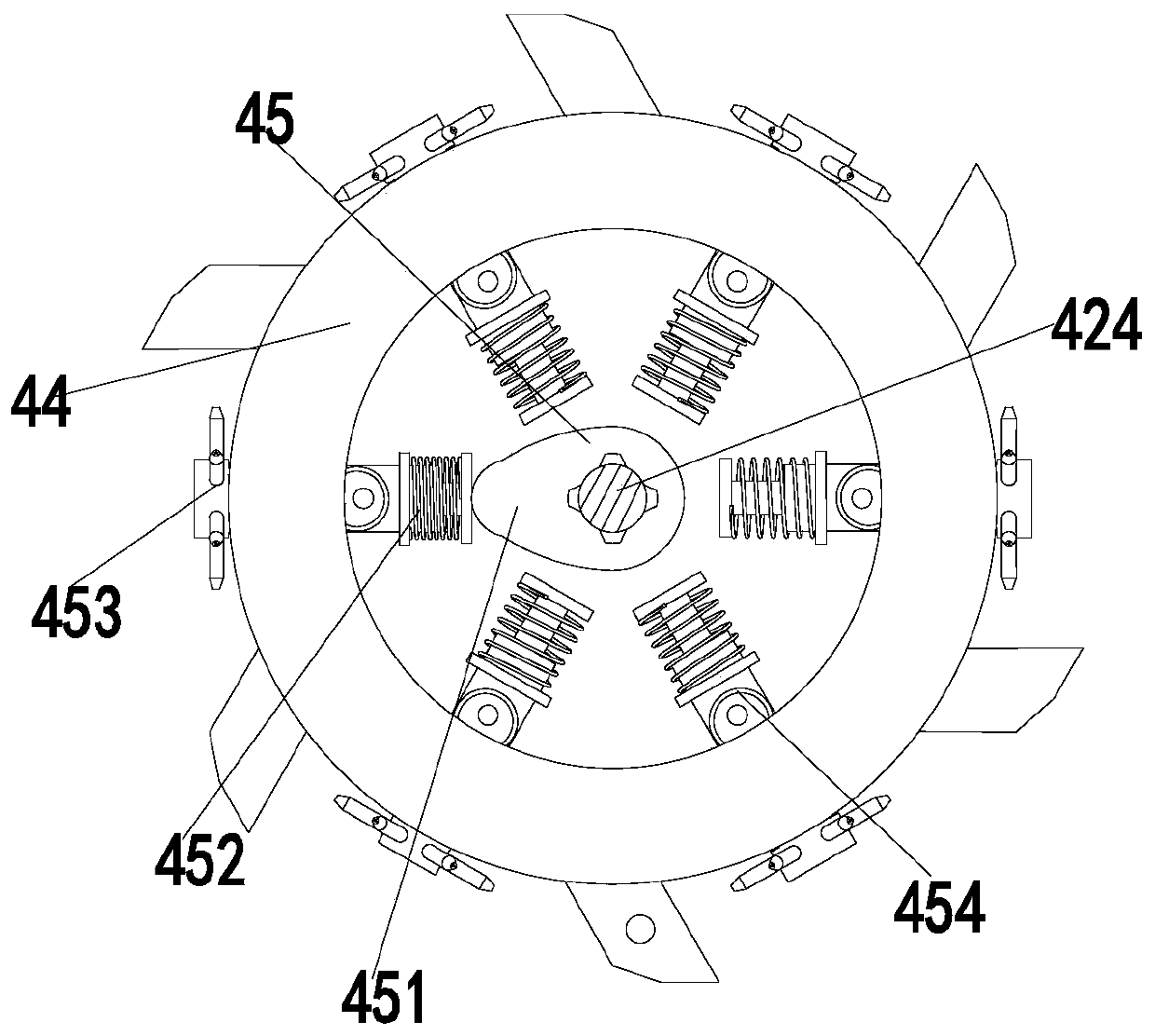

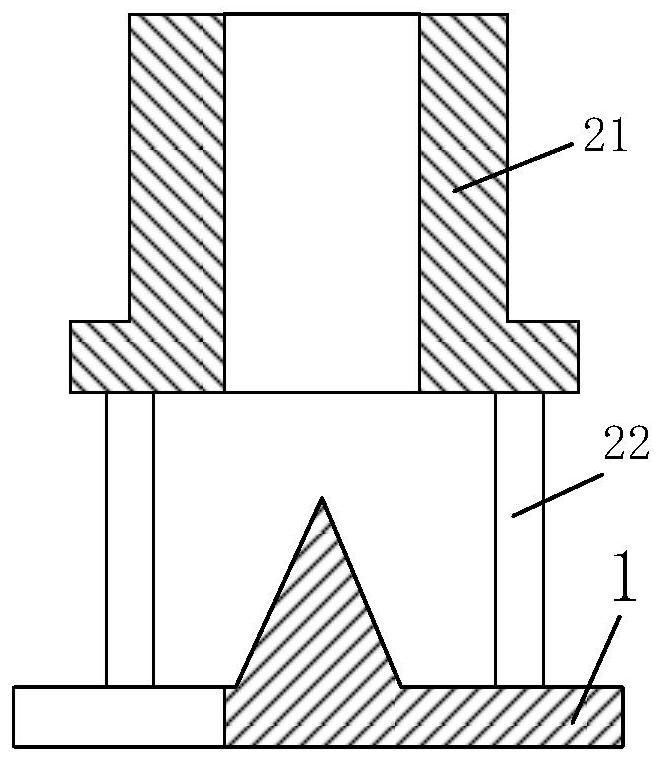

A NC Milling Tooling That Can Reduce Workpiece Deformation

ActiveCN110153475BReduce the temperatureReduce thermal deformationMilling cuttersMilling machinesNumerical controlMilling cutter

The invention relates to a numerical control milling tool capable of reducing deformation of a workpiece. The tool comprises a platen, a moving rack, an electric slide block and a milling mechanism. The moving rack is mounted at the upper end of the platen, the electric slide block is mounted at the lower end of the moving rack, the milling mechanism is mounted at the lower end of the electric slide block and comprises a driving moor, a driving connecting part, a knife handle, a milling cutter and a cooling branch chain, the driving connecting part comprises a connecting cap, a compacting rack, an auxiliary motor and an auxiliary rod, the cooling branch chain comprises a rotating block, a liquid spraying barrel, a liquid outlet and a liquid storage device, the liquid storage barrel comprises a barrel body, a piston rod, a reset spring and a shielding sheet. Most parts of the milling mechanism are connected detachably, so that the parts are detached and maintained conveniently. In the milling process, the cooling branch chain can reduce the temperature of the milling cutter, can reduce the thermal deformation degree of the workpiece as a result of too high temperature, and improvesthe processing quality.

Owner:靖江市永固汽配制造有限公司

An electrolytic aluminum prebaked anode anti-oxidation insulating coating and preparation method thereof

ActiveCN110964352BHigh strengthHigh purityFireproof paintsAnti-corrosive paintsMetallurgyAluminium oxides

The invention provides an electrolytic aluminum prebaked anode anti-oxidation insulating coating. The electrolytic aluminum prebaked anode anti-oxidation insulating coating comprises the following components in percentage by mass: 60%-75% of a main component, 0.01%-5% of a secondary component, 24%-34% of a nano solvent binding phase and 0.01%-5% of a coating stabilizing phase, wherein the main component comprises amorphous aluminum oxide, nano-scale rho-Al2O3, nano-scale gamma-Al2O3 and nano-scale alpha-Al2O3. The insulating coating prepared by the invention can be cured at normal temperaturefor 6-8 hours after being sprayed to an anode by a spraying machine, the anode coating can form a compact net-shaped structure at the working temperature of 500-800 DEG C, the long-term tolerable temperature is over 900 DEG C, and the physical and chemical properties are stable.

Owner:CENT SOUTH UNIV +1

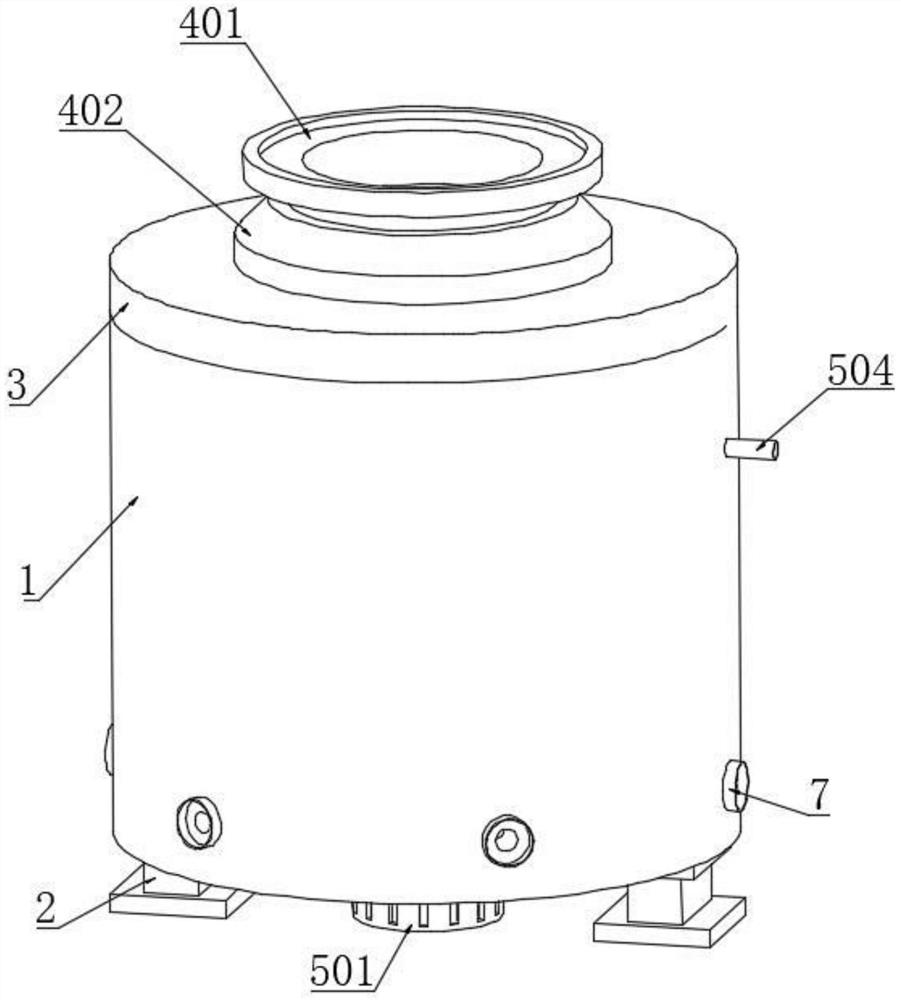

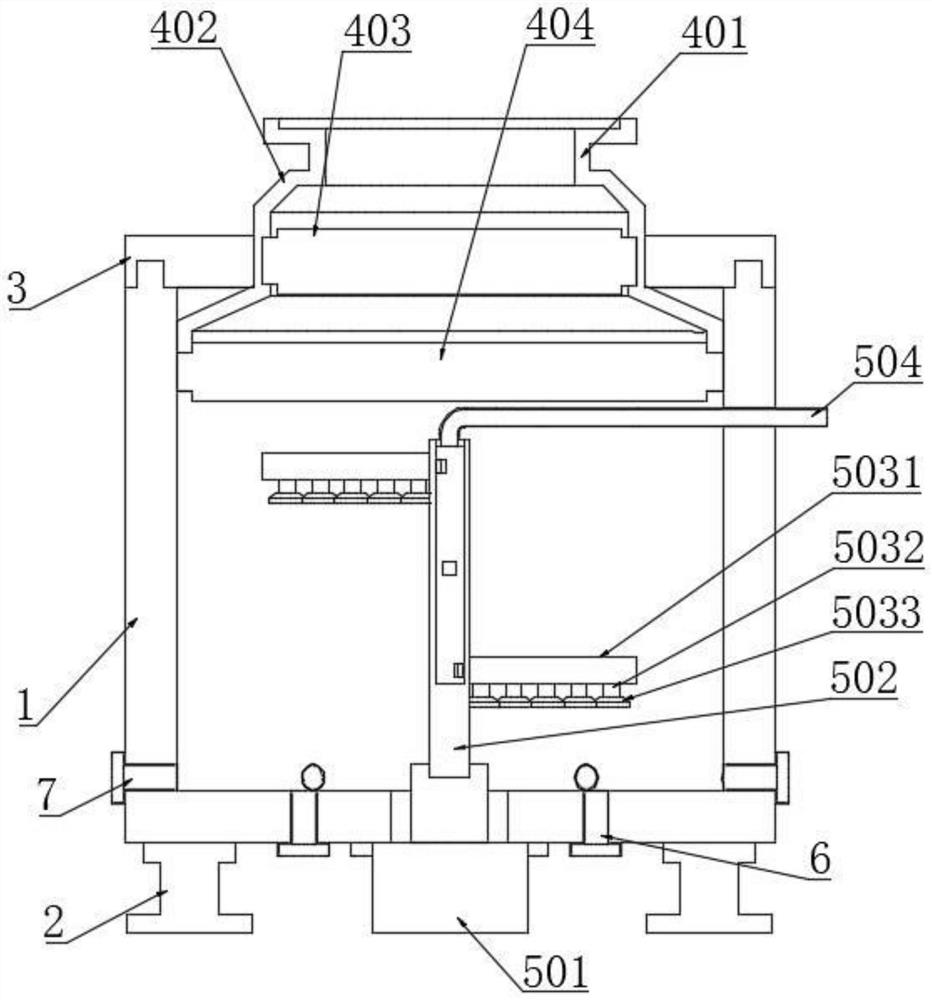

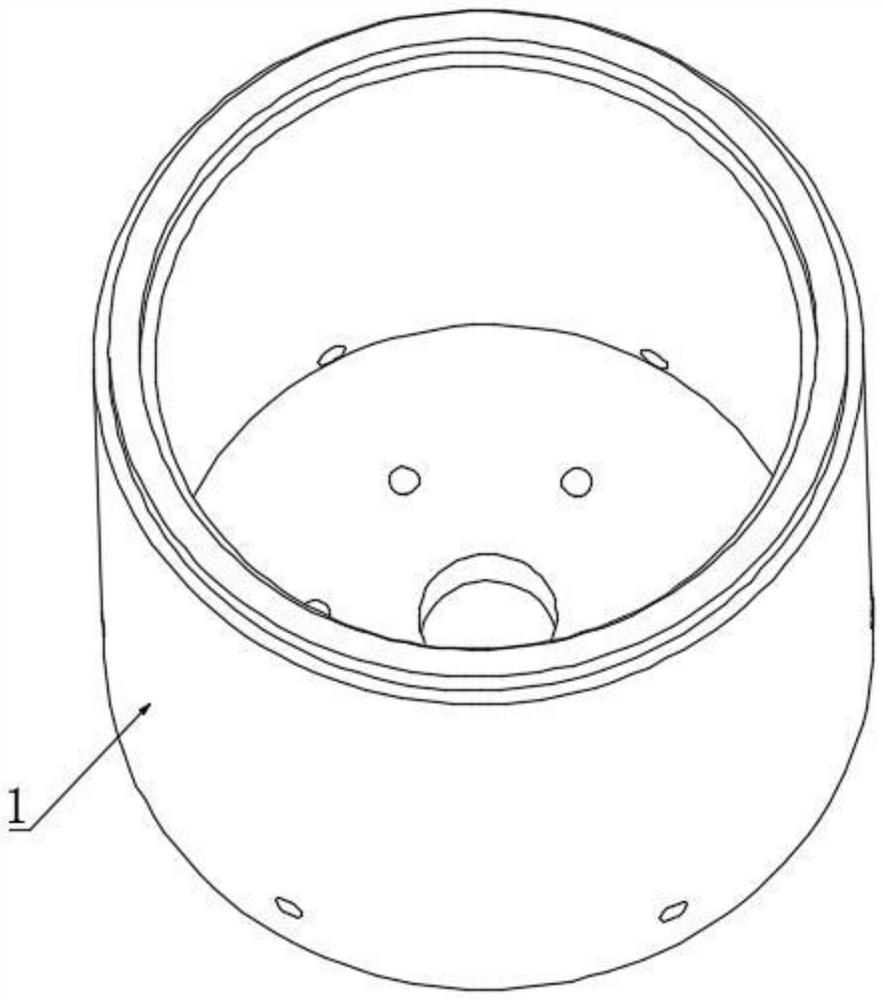

Boiler flue gas desulfurization and denitrification device

PendingCN114682016AImprove uniformityGuaranteed use effectCombination devicesGas treatmentFlue-gas desulfurizationMechanical engineering

The invention discloses a boiler flue gas desulfurization and denitrification device, which belongs to the technical field of flue gas desulfurization and denitrification equipment, and comprises a cylinder body, a top cover, a gas inlet pipe, a gas outlet pipe, a gas inlet pipe and a gas outlet pipe, the filtering mechanism is mounted in the top cover, and the lower end of the filtering mechanism extends into the barrel; the spraying mechanism is used for spraying gas in the cylinder body; the spraying uniformity can be effectively improved through the spraying mechanism, so that the actual using effect and the using quality can be guaranteed; the filtering mechanism is arranged to purify and filter the sprayed gas, the aperture of the second filter screen is larger than that of the first filter screen, and the first filter screen and the second filter screen are arranged to achieve the purpose of twice purification and filtration, so that the cleanliness of the sprayed gas during output can be ensured; and the use effect is good.

Owner:中农实创(北京)环境工程技术有限公司 +1

An in-pipe spraying device suitable for bent pipes

ActiveCN112756156BIncrease spacingGuaranteed alignmentSpraying apparatusStraight tubeClassical mechanics

Owner:河北方泉管道装备有限公司

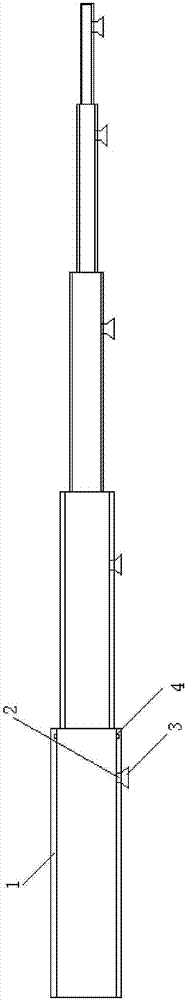

Extension spraying rod for medicine spraying box

PendingCN107127062AImprove spraying efficiencyTo achieve the purpose of sprayingSpray nozzlesEngineeringNozzle

The invention discloses an extension spraying rod for a medicine spraying box. The extension spraying rod comprises multiple spraying rod monomers slidingly sleeved with each other; the rod diameters of the spraying rod monomers are gradually reduced in the spraying rod directions; spraying ports are formed in the side walls of the spraying rod monomers; and nozzles are mounted in the spraying ports. The extension function of the spraying rod is used for driving extension or shrinkage of the nozzles to achieve the spraying purpose of crops in fields with different areas, so that the spraying efficiency is improved.

Owner:宿州市埇桥区时村镇农业技术推广站

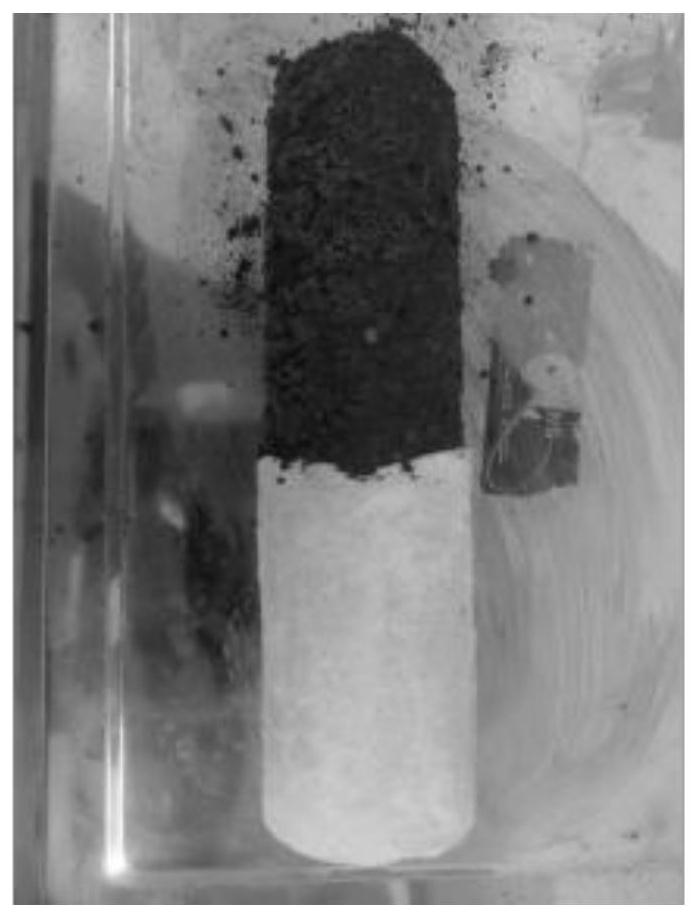

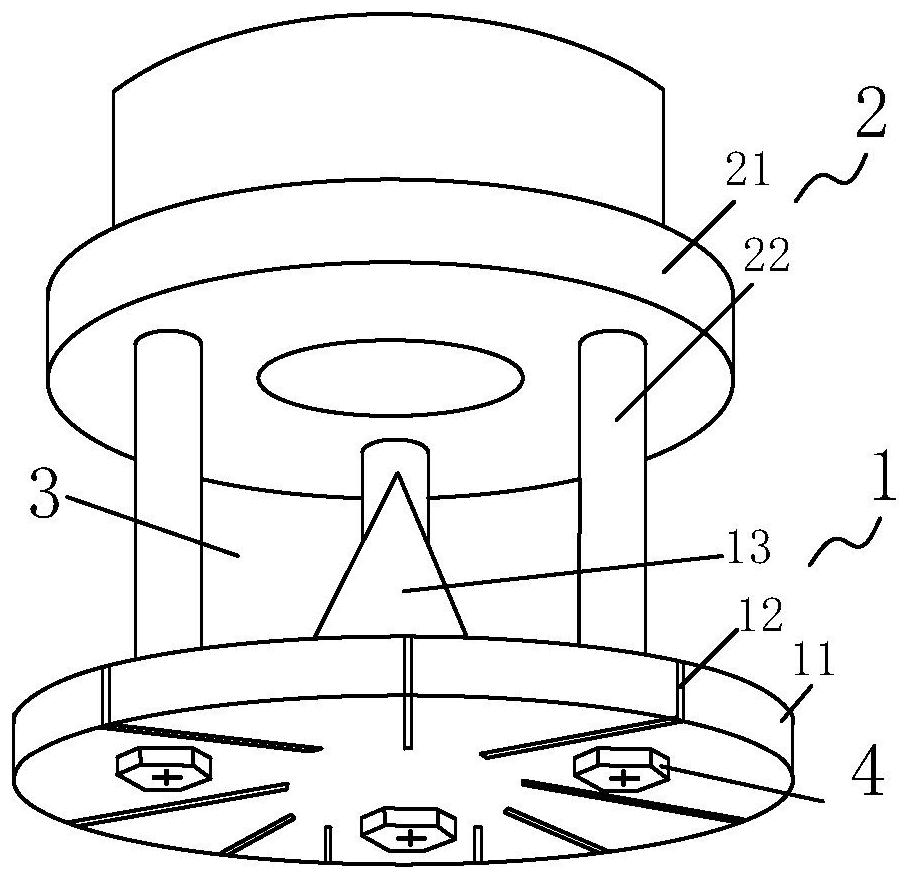

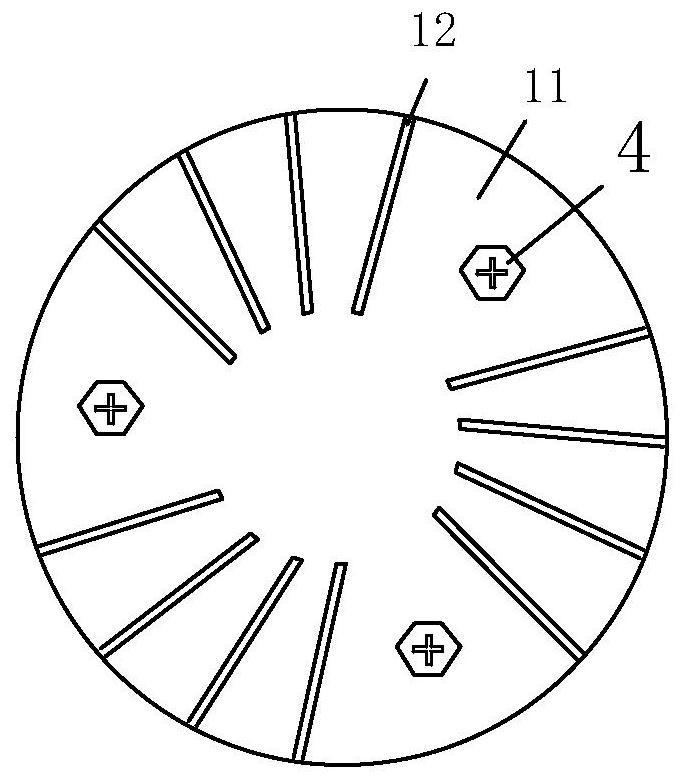

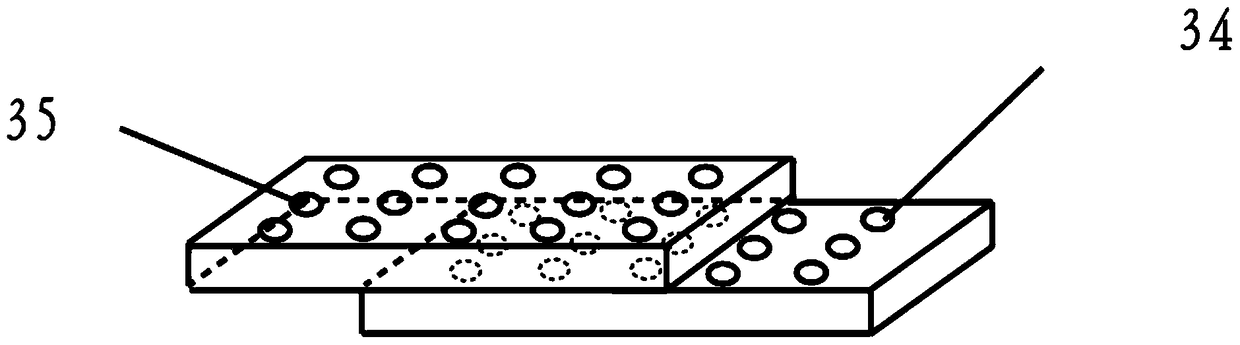

Spraying component and leachate reflux system for dry anaerobic fermentation formed by spraying component

PendingCN113122435AAvoid cloggingActive connectionBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyReflux

The invention discloses a spraying component and a leachate reflux system for dry anaerobic fermentation formed by the spraying component. The spraying component comprises a spraying disc, and a connecting piece; the spraying disc is composed of a disc body, and a dispersing water channel penetrating through the disc body; the connecting piece is used for connecting the disc body to a water outlet; and the connecting piece is provided with a large particle discharge port positioned between the disc body and the water outlet. The spraying component can overcome the defect of liable spray header blockage when leachate is returned to a spray system for spraying without deep filtration in existing dry anaerobic fermentation; and thus, the spraying component has the advantage that the spray header is not blocked when the leachate is subjected to reflux spraying.

Owner:CHINA HUADIAN ENG +1

An agricultural sprinkler

ActiveCN105594676BTo achieve the purpose of sprayingTo achieve the purpose of terminating sprayingWatering devicesCultivating equipmentsAgricultural engineeringNozzle

The invention discloses an agricultural spraying device, which comprises a spray head, several material storage devices, several first support rods and second support rods. The bottom of the spray head is provided with a spray hole, and the top of the spray head is open. Each material storage device is equipped with a horizontal plate, the bottom of each material storage device is provided with a number of seepage holes, and slide rails are respectively provided on the two inner side walls opposite to each material storage device, and the slide rails run through the corresponding inner wall of the Both ends of the horizontal plate are respectively inserted into the corresponding slide rails and are slidably connected with the slide rails. The bottom of the horizontal plate is provided with several through holes, and the bottom of the horizontal plate and the bottom of the material storage device keep seamless contact, and the thickness of the horizontal plate is equal to the height of the slide rail. Several material storage devices are arranged in a vertical direction, and adjacent material storage devices are connected by first support rods. One end of the second support rod is connected with the lowermost material storage device, and the other end of the second support rod is connected with the spray head. The invention has the advantages of improving efficiency, reducing cost and having various functions.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

A construction waterproof coating applicator

ActiveCN112252665BSpray evenlyTo achieve the purpose of sprayingRoof toolsMechanical engineeringMaterials science

The invention discloses a waterproof coating application device for building construction, which belongs to the technical field of waterproof coating construction. A building construction waterproof coating application device, comprising a bottom bracket, the top of the bottom bracket is fixed with a mounting plate, the top of the mounting plate is fixed with a paint box, and the outer wall of the paint box is provided with a power pump. The bottom of the paint tank is provided with a discharge hose, the end of the discharge hose away from the paint tank is provided with a uniform pipe, the bottom of the installation plate is fixed with a symmetrical cross bar, and the rear end is fixed on the cross bar There is a screw moving mechanism; when it is necessary to spray waterproof paint at the corner of the boundary, the present invention can extend the uniform pipe from the main body of the device through the screw moving mechanism to achieve the purpose of spraying; in addition, when the uniform pipe protrudes During the process, the smearing movable brush can rotate along the smearing fixed brush, so that when the uniform distribution pipe is stretched out, the place where the waterproof paint has been sprayed can be brushed, so that the paint can be evenly coated on the surface of the building.

Owner:武汉和谐永林建筑工程有限公司

A Coal Mine Support Variable Angle Shotcrete Structure

ActiveCN109162734BReduce reboundReduce wasteUnderground chambersTunnel liningShotcreteMechanical engineering

The invention relates to a coal mine supporting variable-angle spray structure that uses a sliding ring to change angles of a plurality of arc tubes so as to change the spray angle so that that the spray efficiency of coal mine surrounding rock can be improved effectively. A fixed frame is a concave arc plate; a through hole is formed in a middle portion of the fixed frame; and a plurality of clamping rings are respectively arranged at the outer side of the fixed frame. The clamping rings are arranged obliquely and are connected with the fixed frame at lowest heights; and the clamping rings are made of rigid materials. A plurality of supporting wheels are respectively arranged at the fixed frame and are arranged in the plurality of clamping rings in a one-to-one correspondence manner; andlimiting blocks are arranged at the inner rings of the clamping rings and are opposite to the supporting wheels. One end of a hollow tube is arranged in the through hole of the fixed frame and is connected with the fixed frame and has an enclosed structure. A sliding ring is arranged at the other end of the hollow tube; and a guiding plate is arranged at the sliding ring right above the fixed frame.

Owner:TAIAN TAISHUO STRATUM CONTROL SCI & TECH CO LTD

A paint automatic mixing and spraying device

ActiveCN109746139BPrevent solidificationImprove spraying effectLiquid spraying apparatusControl engineeringElectric machinery

The invention discloses an automatic stirring spraying device for oil paint. A first support is arranged on a fixed base, and a second support is connected to the first support; the end portion of thesecond support is connected with a first control module; the first control module is provided with a sliding lifting shaft; the lifting shaft penetrates through a sealing cover and then slides in anoil paint barrel; the lifting shaft is provided with a swinging stirring support; the other end of the lifting shaft is provided with a third control module sliding on the first control module; the lifting shaft rotates on the third control module; a first motor driving the lifting shaft to rotate is arranged in the third control module; due to sliding of the lifting shaft, the lifting shaft can further slide into the oil paint barrel; and meanwhile, due to swinging of the stirring support, the oil paint can be further stirred, and therefore solidification of the oil paint is avoided, and thespraying effect of the oil paint is further improved.

Owner:贵州永峰涂装科技有限公司

A method of making a selective emitter battery

ActiveCN103367124BConducive to industrial automation productionTo achieve the purpose of sprayingFinal product manufactureSemiconductor/solid-state device manufacturingChain typeSolar cell

The invention discloses a manufacturing method of a selective emitter cell, and the method comprises the steps: 1) removing the damage layer of a silicon chip and manufacturing a pile face on the surface of the silicon chip; 2) spraying phosphorus source and doping by utilizing laser on the silicon chip after the first step; 3) carrying out high-temperature chain-type diffusion for the sprayed and doped silicon chip to obtain p-n junctions of a zone outside the right positive electrode zone; 4) removing PSG on the surface of and p-n junctions around the silicon chip after the high-temperature chain-type diffusion; 5) depositing a layer of silicon nitride film which plays effects of reflection reduction and passivation on the surface of the silicon chip after the fifth step; 6) printing and sintering a back electrode, a back electric field, and a right electrode on the silicon chip with the silicon nitride film to metallize the electrodes and obtain the selective emitter cell; 7) testing each parameter of the selective emitter cell and grading the selective emitter cell according to the technology standard. The method can effectively improve the conversion efficiency of a solar cell and be used in production conveniently.

Owner:YINGLI ENERGY CHINA

A surface spraying device for automobile production parts that can be used for special-shaped parts

InactiveCN110756347BEasy to spraySolve the problem of inconvenient sprayingLiquid spraying apparatusEngineeringMotronic

Owner:HENAN MECHANICAL & ELECTRICAL VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com