Coal mine supporting variable-angle spray structure

A variable-angle spraying technology, which is applied to the rock wall spraying structure, spraying structure, and coal mine support variable-angle spraying structure, can solve the problems affecting concrete condensation, large recoil force, and large rebound loss. Achieve the effect of simple structure, improve spraying efficiency and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

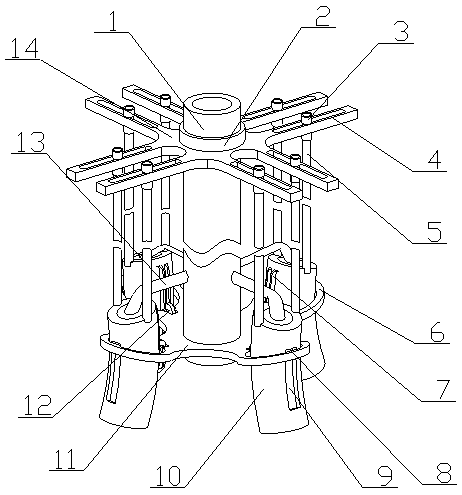

[0027] A variable-angle shotcrete structure for coal mine support in the present invention is realized in the following way: a variable-angle shotcrete structure for coal mine support in the present invention consists of a hollow pipe (1), a sliding ring (2), a limit sleeve (3), Guide bar (4), drive rod (5), clamping ring (6), arc guide rail (7), limit block (8), inner groove (9), arc tube (10), fixing frame (11 ), a support wheel (12), a connecting pipe (13) and a guide plate (14). The clamping rings (6) are respectively placed on the outside of the fixing frame (11), the clamping rings (6) are placed obliquely, and the height of the position connected to the fixing frame (11) is the lowest, and the clamping rings (6) are composed of Made of rigid material, a plurality of supporting wheels (12) are respectively placed on the fixed frame (11), and are located in a plurality of clamping rings (6) one by one, and the inner ring of the clamping ring (6) is limited Position block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com